What Size Wood for Face Frame: Perfect Picks for Durability

For a standard face frame, use 1×2 or 1×3 wood to ensure proper support and stability. Choosing the right size wood for your face frame is crucial for the overall strength and appearance of your project.

The size of wood you use will depend on the specific dimensions and design requirements of your face frame. By understanding the different options available and their respective benefits, you can make an informed decision that will contribute to the success of your woodworking project.

We will explore the factors to consider when selecting the size of wood for your face frame, as well as the various options available to help you achieve the desired results.

Choosing The Right Wood For Face Frames

Choosing the right wood for face frames is crucial, and determining the appropriate size is equally important. Carefully selecting the size of wood for your face frame ensures a sturdy and aesthetically pleasing result.

Importance Of Material Selection

Choosing the right wood for face frames is crucial as it affects the overall durability and appearance of your cabinet. The face frame serves as a foundation for the cabinet box and needs to withstand the weight of the cabinet doors and drawers. Using low-quality wood can lead to warping or cracking over time, causing the cabinet to fall apart. Therefore, it’s essential to choose the right wood for your face frame to ensure the longevity and stability of your cabinetry.

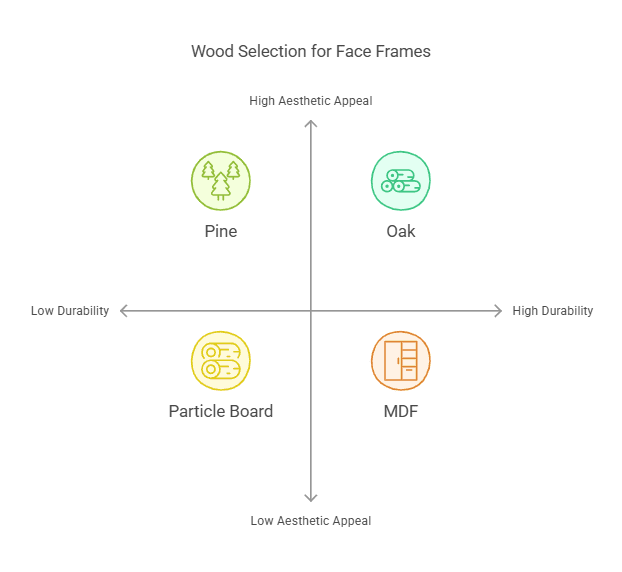

Types Of Wood Suitable For Face Frames

There are many types of wood available for face frames, and each has its own unique characteristics. Here are some of the most common types of wood suitable for face frames:

| Wood Type | Pros | Cons |

|---|---|---|

| Hard Maple | Durable, smooth, and uniform texture | Expensive and difficult to work with |

| Cherry | Beautiful, smooth, and stable | Expensive and may darken over time |

| Alder | Stable, easy to work with, and affordable | Softwood and prone to dents and scratches |

| Oak | Durable and affordable | Coarse texture and may warp over time |

Other suitable types of wood for face frames include pine, birch, and walnut. It’s essential to consider the wood’s color, grain, and texture as they can affect the overall appearance of your cabinetry. For instance, oak has a prominent grain pattern, while maple has a uniform texture.

In conclusion, choosing the right wood for your face frame is crucial to ensure the longevity and stability of your cabinetry. Consider the pros and cons of each wood type and choose the one that best suits your needs and preferences. Remember to select high-quality wood to prevent warping and cracking over time.

Standard Dimensions For Face Frame Components

The standard dimensions for face frame components dictate the size of wood used for constructing them. These dimensions ensure structural integrity and uniformity in cabinetry. By adhering to these standards, builders can create face frames that fit seamlessly and provide a solid foundation for the overall cabinet structure.

When building cabinets, the face frame is an essential component that adds both structural strength and aesthetic appeal. The face frame consists of stiles, rails, and other elements, which are typically made of wood. One of the most critical factors to consider when building a face frame is the size of the wood used. In this section, we’ll discuss the standard dimensions for face frame components.

Stile And Rail Specifications

The stiles and rails are the vertical and horizontal components that make up the face frame. The standard dimensions for stiles and rails are as follows:

- Stiles: 1 1/2″ wide by 3/4″ thick

- Rails: 2 1/4″ wide by 3/4″ thick

These dimensions are based on industry standards and are suitable for most cabinet sizes. However, it’s important to note that the size of the wood used can vary depending on the size of the cabinet.

Influence Of Cabinet Size On Frame Dimensions

The size of the cabinet can affect the dimensions of the face frame components. For example, if the cabinet is larger than average, the stiles and rails may need to be thicker to provide adequate support. Conversely, if the cabinet is smaller than average, thinner wood can be used to minimize the overall weight of the cabinet.

Table: Recommended Wood Sizes for Face Frame Components

| Cabinet Height | Stile Width | Rail Width | Stile Thickness | Rail Thickness |

|---|---|---|---|---|

| Less than 30″ | 1 1/2″ | 2 1/4″ | 3/4″ | 3/4″ |

| 30″ – 48″ | 1 1/2″ – 2″ | 2 1/4″ – 3″ | 3/4″ – 1″ | 3/4″ – 1″ |

| 48″ – 60″ | 2″ – 2 1/2″ | 3″ – 3 1/2″ | 1″ – 1 1/4″ | 1″ – 1 1/4″ |

| More than 60″ | 2 1/2″ or more | 3 1/2″ or more | 1 1/4″ or more | 1 1/4″ or more |

The table above shows the recommended wood sizes for face frame components based on the height of the cabinet. These dimensions are not set in stone and can be adjusted depending on the specific needs of the project.

In conclusion, the size of the wood used for face frame components can vary depending on the size of the cabinet. However, by following industry standards and recommended guidelines, you can ensure that your face frame provides the necessary support and looks great.

Thickness Matters: Striking The Balance

When it comes to building a face frame for your woodworking project, choosing the right size wood is crucial. The thickness of the wood plays a significant role in both the functionality and aesthetics of the face frame. Striking the right balance between thickness and practicality is essential for achieving a successful outcome.

Benefits Of Thicker Wood

Thicker wood for your face frame offers several advantages that make it a popular choice among woodworkers:

- Durability: Thicker wood provides increased strength and durability to the face frame, ensuring its longevity.

- Stability: The added thickness helps in maintaining the stability of the face frame, preventing warping or twisting over time.

- Enhanced Appearance: Thicker wood can give a more substantial and visually appealing look to the face frame, especially in larger projects.

- Easy Joinery: Working with thicker wood allows for easier joinery methods, such as pocket screws or mortise and tenon joints, providing a solid and secure frame.

Drawbacks Of Excessive Thickness

While thicker wood has its benefits, excessive thickness may also present some challenges:

- Weight: Heavier face frames can be more challenging to handle and install, especially in larger projects.

- Material Cost: Thicker wood generally comes at a higher price point, which can impact the overall cost of the project.

- Space Constraints: In cases where space is limited, excessive thickness may not be suitable, as it can reduce the available storage or display area.

- Compatibility: If you plan to combine the face frame with pre-made cabinet components, excessive thickness might not align well with the existing dimensions.

Striking the right balance between the benefits of thicker wood and avoiding the drawbacks of excessive thickness is crucial when selecting the appropriate wood size for your face frame. Consider the specific requirements of your project, including its size, weight, and budget, to ensure you achieve the desired results.

Width Considerations For Structural Integrity

Choosing the right size of wood for a face frame is crucial for structural integrity. The width of the wood should be proportional to the size of the cabinet and the weight it will hold. Proper width considerations will ensure a sturdy and durable face frame.

Optimal Width For Different Cabinet Sizes

When it comes to choosing the right size wood for face frames, considering the width is crucial for ensuring structural integrity. The width of the wood determines the overall strength and stability of the cabinet, making it essential to select the optimal size for different cabinet sizes.

For smaller cabinets, such as those used in bathrooms or utility rooms, a standard width of 1.5 inches is often sufficient. This width provides enough support for the cabinet while keeping it lightweight and easy to handle.

When it comes to medium-sized cabinets, such as those found in kitchens or bedrooms, a width of 2 inches is recommended. This slightly wider width offers increased strength and stability, ensuring that the cabinet can withstand the weight of its contents without sagging or warping over time.

For larger cabinets, such as those used for storage or heavy-duty purposes, a width of 2.5 inches or more is advisable. The added width provides extra support and rigidity, making it suitable for cabinets that will be subject to heavier loads or frequent use.

When To Deviate From Standard Widths

While standard widths are generally recommended for face frames, there are instances where deviating from these sizes may be necessary. Factors such as design preferences, specific cabinet requirements, or unique installation circumstances can influence the decision to choose a non-standard width.

For example, if you are working on a custom cabinet with intricate details or a unique design, you may opt for a narrower or wider width to enhance the aesthetic appeal. Additionally, certain cabinet installations may require specific widths to accommodate appliances or fixtures, making it necessary to deviate from standard sizes.

It is important to note that when deviating from standard widths, careful consideration must be given to the overall structural integrity of the cabinet. The chosen width should still provide sufficient strength and support to ensure the longevity and functionality of the cabinet.

In conclusion, when selecting the size of wood for face frames, considering the width is essential for maintaining structural integrity. Optimal widths vary depending on the cabinet size, with smaller cabinets typically requiring narrower widths and larger cabinets benefiting from wider widths. However, there are instances where deviating from standard widths may be necessary to meet design or installation requirements, as long as the overall strength and stability of the cabinet are not compromised.

Grain Orientation And Its Impact On Durability

Vertical Vs. Horizontal Grain

Vertical grain refers to the orientation of wood fibers running parallel to the longer dimension of the face frame, while horizontal grain indicates fibers running along the shorter dimension.

How Grain Affects The Strength Of Face Frames

The orientation of wood grain significantly influences the strength and durability of face frames. Vertical grain wood tends to be more stable and less prone to warping, making it an ideal choice for face frames.

Joinery Techniques For Enhanced Durability

To ensure enhanced durability in joinery techniques, it’s important to use the right size wood for face frames. Choosing the appropriate width and thickness based on the project’s needs can prevent warping and cracking over time.

Popular Methods For Assembling Face Frames

Face frames play a critical role in the structural integrity of cabinets and furniture pieces. Joinery techniques are essential for ensuring the longevity and durability of face frames.

Choosing The Right Joinery For Your Wood Type

Different types of wood require specific joinery techniques to achieve optimal strength and stability. Selecting the appropriate joinery method is crucial for ensuring the longevity of face frames.

In the table below, you can find a comparison of popular joinery techniques used for assembling face frames:

| Joinery Technique | Wood Types | Strength |

|---|---|---|

| Pocket-Hole Joinery | Softwoods, Plywood | Good |

| Dado Joints | Hardwoods, MDF | Excellent |

| Mortise and Tenon Joints | Hardwoods | Superior |

– Pocket-Hole Joinery: Suitable for softwoods and plywood, offering good strength.

– Dado Joints: Ideal for hardwoods and MDF, providing excellent durability.

– Mortise and Tenon Joints: Best for hardwoods, ensuring superior strength.

Consider the wood type and project requirements when selecting the joinery technique for your face frame assembly.

Finishing Touches: Sealants And Treatments

Choose the right size wood for face frame to ensure a sturdy and aesthetically pleasing finish. Opt for 1×2 or 1×3 lumber for narrow face frames, and 1×4 or 1×6 for wider ones. This selection will provide the structural support needed for the finishing touches, such as sealants and treatments.

Protecting Wood From Moisture And Wear

Applying a protective sealant on the face frame wood is crucial to prevent moisture damage.

Water-based sealants are effective in shielding wood from humidity and spills.

Selecting The Best Finish For Your Face Frame

Consider the durability and aesthetic appeal when choosing a finish for your face frame.

Polyurethane finishes offer excellent protection and a beautiful sheen.

Custom Sizing For Unique Cabinet Designs

Discover the ideal wood size for face frame construction in custom cabinet designs. Achieve unique dimensions tailored to your project’s specific requirements for a personalized touch.

Tailoring Face Frame Dimensions For Custom Projects

When working on unique cabinet designs, custom sizing of face frame wood is essential.

Adapting face frame dimensions to fit individual projects ensures a perfect fit.

Balancing Aesthetics And Functionality In Custom Sizes

Custom sizes must harmonize aesthetics with practical functionality in cabinet design.

Choosing the right wood size is crucial for achieving a balanced look.

Troubleshooting Common Face Frame Issues

Face frame cabinets can encounter various issues during construction, leading to imperfections. Understanding how to troubleshoot these common face frame issues is crucial for achieving a seamless and professional finish.

Dealing With Wood Warping

Wood warping is a common problem faced when constructing face frames. To prevent warping, ensure you use kiln-dried wood and store it in a dry environment. If warping occurs, you can try steaming the wood or using clamps to straighten it.

Solutions For Misaligned Components

Misaligned components can create gaps and uneven edges in face frame cabinets. To solve this, double-check measurements and ensure precise cutting. Adjust the alignment by using shims or sanding down excess material.

Future Trends In Face Frame Construction

Innovations In Woodworking

The woodworking industry is witnessing exciting innovations in the production of wood for face frame construction. Manufacturers are developing advanced techniques to produce high-quality, durable wood that meets the specific requirements of face frame construction.

Sustainable Wood Options For Eco-conscious Design

As sustainability becomes a significant concern in the woodworking industry, there is a growing emphasis on using sustainable wood options for face frame construction. This includes the utilization of reclaimed wood, FSC-certified lumber, and bamboo as eco-conscious alternatives.

Frequently Asked Questions

What Is The Best Wood For Face Frame Construction?

The best wood for face frame construction is hardwood such as oak, maple, or cherry. These woods are durable and provide excellent strength and stability for the face frame, ensuring longevity and a high-quality finish for your cabinetry.

How Thick Should The Wood Be For A Face Frame?

The recommended thickness for wood in a face frame is typically 3/4 inch. This thickness provides the necessary strength and stability to support the cabinet structure and withstand daily use, ensuring the face frame’s durability and longevity.

Can I Use Softwood For Building A Face Frame?

While softwood can be used for a face frame, it is not as durable as hardwood. Softwood such as pine or cedar may be more prone to dents and dings over time, so it’s important to consider the level of wear and tear the cabinetry will endure before choosing the wood for the face frame.

What Are The Benefits Of Using Hardwood For A Face Frame?

Hardwood offers superior strength, durability, and a beautiful finish for the face frame. It provides excellent stability and resistance to wear and tear, ensuring that the cabinetry maintains its structural integrity and aesthetic appeal for years to come.

Conclusion

Choosing the right wood size for your face frame is crucial for a sturdy and well-constructed project. Consider the wood’s durability and thickness to ensure a long-lasting finish. By following these guidelines, you can achieve a professional look and enhance the overall quality of your woodworking creations.