When Did MDF Come Out: Unveiling Its Origins

Have you ever wondered about the origins of MDF, the versatile material that’s revolutionized the way we design and build? If you’ve found yourself scratching your head about when MDF came out, you’re not alone.

Uncovering the history of this remarkable material can transform how you perceive the furniture and construction industries. Imagine unlocking the secrets of a product that has quietly become a staple in homes and businesses worldwide. Stay with us as we dive into the story of MDF’s invention and discover why it’s such a game-changer in today’s world.

You won’t want to miss out on understanding this pivotal moment that reshaped modern craftsmanship and design.

Birth Of MDF

MDF, or Medium Density Fiberboard, first appeared in the 1960s. It was made by breaking down wood into small fibers. These fibers were then mixed with resin and wax. After mixing, they were pressed into sheets. MDF became popular because it was cheap. It was also strong and smooth. People liked using it for furniture and cabinets.

MDF is easy to cut and shape. It does not have knots or grain, unlike natural wood. This makes it perfect for painting. Builders and carpenters often choose MDF for their projects. It is used in many homes today. MDF continues to be a favorite material for many. It is a part of everyday life.

Early Developments

MDF, or Medium Density Fiberboard, began its journey in the 1960s. It was first made in the United States. Engineers wanted a material that was strong and smooth. They mixed wood fibers with resin. Then, they pressed it at high pressure. This made MDF.

In the early days, MDF was used for furniture and cabinets. It was cheaper than solid wood. It also looked good when painted. MDF became popular quickly. People liked its smooth surface and easy-to-cut nature.

By the 1980s, MDF started to become more common worldwide. Manufacturers saw its benefits. It was versatile and affordable. MDF is now a key material in the wood industry. Its story began over 50 years ago.

Technological Innovations

MDF, or Medium Density Fiberboard, came out in the 1960s. It was a big change in furniture making. Manufacturers liked it because it is strong and smooth. MDF is made from wood fibers. These fibers are glued and pressed together. This makes a flat and dense board. Furniture makers use MDF for cabinets and shelves.

It is better than regular wood for some projects. MDF does not have knots or grain. This makes it easy to cut and paint. Technology in the 1960s helped make MDF possible. Machines could press the wood fibers tightly. This made MDF a popular choice for builders and designers.

Mdf In The Wood Industry

MDF, or Medium Density Fiberboard, is a popular material in furniture making. It first appeared in the 1960s. Builders love it for its smooth surface. It’s made from wood fibers glued together. This makes MDF strong and durable. It’s easy to cut and shape.

MDF is often used for cabinets and shelves. It can be painted or veneered. This makes it look like real wood. MDF is also less expensive than solid wood. This makes it a favorite for budget projects. But, MDF is heavier than plywood. It’s important to keep it dry. Moisture can damage it.

Global Expansion

MDF, or Medium Density Fiberboard, grew in popularity worldwide. This wood product is used in furniture and construction. It is strong and smooth, making it ideal for painting. Countries like the USA and China produce a lot of MDF. Factories make it from wood fibers and resin. Heat and pressure help form its shape. Many homes use MDF for shelves and cabinets. It is cheaper than solid wood. This makes it popular for budget projects. MDF is also easy to cut and shape. Craftsmen enjoy working with it. Large companies sell MDF in big sheets. These sheets are easy to transport. MDF plays a big role in the global market.

MDF Composition

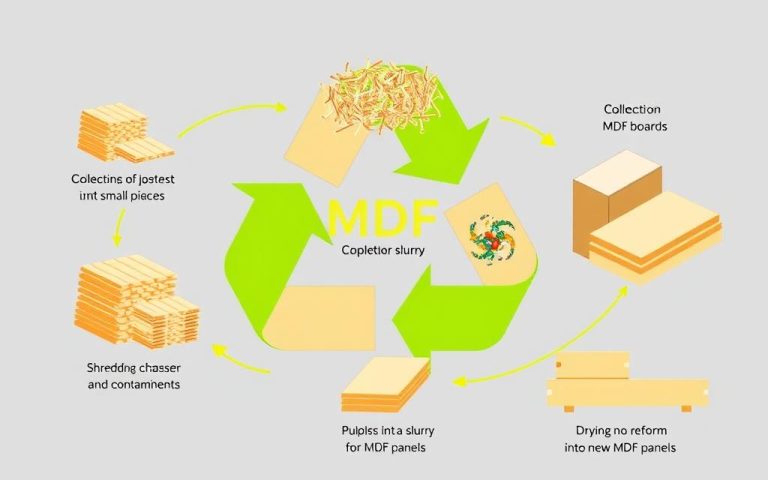

MDF stands for Medium Density Fiberboard. It is made from wood fibers. These fibers come from breaking down wood pieces. A special glue holds the fibers together. This glue is often a type of resin. It helps make the board strong.

After mixing, the material is pressed into sheets. These sheets are flat and smooth. They are then heated to harden. MDF is denser than plywood. It is also very smooth to touch. This makes MDF good for painting.

MDF does not have grain like wood. It is easy to cut and shape. People use MDF for furniture and cabinets. It is popular because it is cheaper than wood. But, MDF can be heavy to carry.

MDF Manufacturing Process

MDF stands for Medium Density Fibreboard. It is made from wood fibers. These fibers are combined with wax and resin. The mixture is heated and pressed. This forms strong boards. These boards are smooth and easy to cut.

The process starts with the wood being broken down. It is turned into tiny fibers. Then, these fibers are mixed with glue. The mixture is then pressed with heat. This makes the fibers stick together. The boards are then cut into desired shapes.

MDF is popular for furniture. It is affordable. It is easy to paint. It does not warp. This makes it a favorite choice for many projects.

Credit: www.walmart.com

Environmental Impact

Medium Density Fiberboard, or MDF, has changed how we use wood. It is made from wood fibers and glue. Making MDF uses a lot of energy. This can harm the environment. Factories release gases that can be bad for the air. MDF needs trees to be cut down. This affects forests and animals. The glue in MDF can be toxic. It may be harmful if not handled right. Recycling MDF can be hard. It needs special care to recycle. Using MDF can be sustainable if done carefully. Choosing the right MDF helps the planet. Always check if MDF is eco-friendly before buying.

Current Applications

MDF, or Medium Density Fiberboard, is used in many ways today. Furniture is one of the main uses. It makes tables, chairs, and shelves. MDF is smooth and easy to paint. Cabinetry is another big use. Kitchen and bathroom cabinets often use MDF. It is cost-effective and looks nice.

Wall panels are made from MDF too. These panels are easy to install. MDF is also used in flooring. Some people choose it for its durability. Door skins are often MDF as well. They give a nice finish to doors. Lastly, craft projects use MDF. It is easy to cut and shape.

Credit: en.wikipedia.org

Future Prospects

Experts say MDF will be important in the future. It is known for its strength and versatility. More people use it for furniture and houses. MDF is cheaper than solid wood. This makes it popular for many builders. It is also easy to paint and finish.

Some people worry about its durability. Others think it might not last long. But many believe new technologies will make MDF better. They hope it will be more durable soon.

Some factories try to make MDF eco-friendly. They use recycled materials. This helps reduce waste. Using MDF can be a great choice. It helps save trees and the environment.

Frequently Asked Questions

When Did MDF Become Popular?

MDF gained popularity in the 1980s due to its versatility and affordability. It became a preferred material for furniture and cabinetry. Its smooth surface and ease of painting contributed to its widespread use in interior design. MDF remains popular today for its practicality and cost-effectiveness.

Why Is MDF Illegal In America?

MDF is not illegal in America. Concerns exist over formaldehyde emissions from MDF products. Regulations ensure safety and limit emissions. Always check local guidelines and use MDF responsibly.

When Did MDF Get So Expensive?

MDF prices surged due to increased demand and supply chain disruptions during the COVID-19 pandemic. Rising raw material costs also contributed to the price hike. The construction boom and home renovation trends further strained supply, leading to higher costs for consumers.

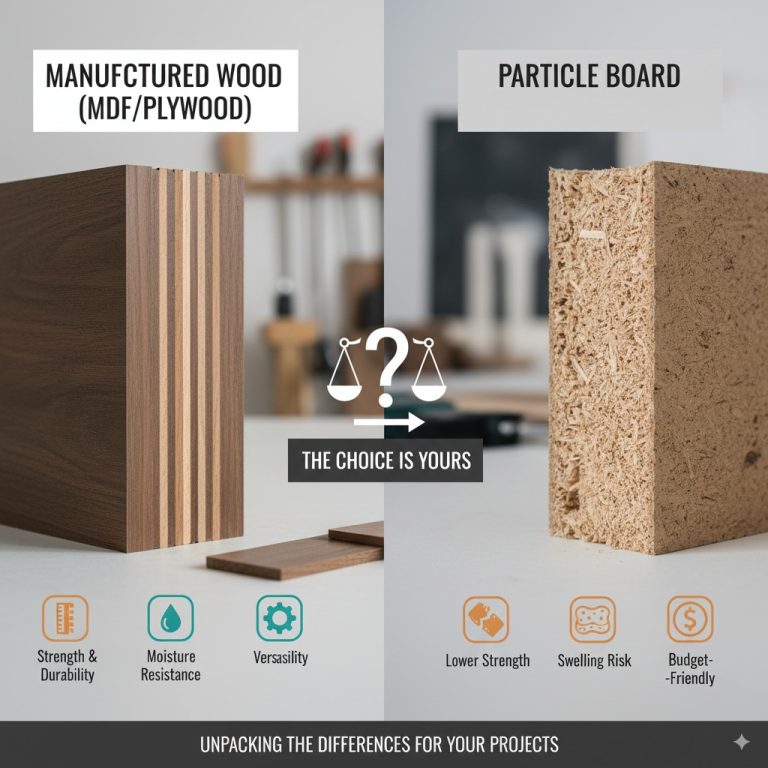

Is MDF Stronger Than Plywood?

Plywood is generally stronger than MDF. It has better resistance to warping and moisture. MDF is denser and smoother, making it ideal for painting and indoor use. Choose based on your specific project needs.

Conclusion

MDF first appeared in the 1960s. A versatile material. People use it in many projects. From furniture to flooring. Its popularity grew quickly. Why? Because of its affordability. And durability. MDF offers a smooth surface. Easy to paint or veneer.

Many find it a great alternative. Compared to solid wood, it’s cost-effective. Ideal for many DIY enthusiasts. And professionals too. MDF continues to be a favorite. Thanks to its practical benefits. It remains a staple in construction and design. A reliable choice for many needs.

MDF’s journey from the 60s is quite remarkable. A material that stands the test of time.