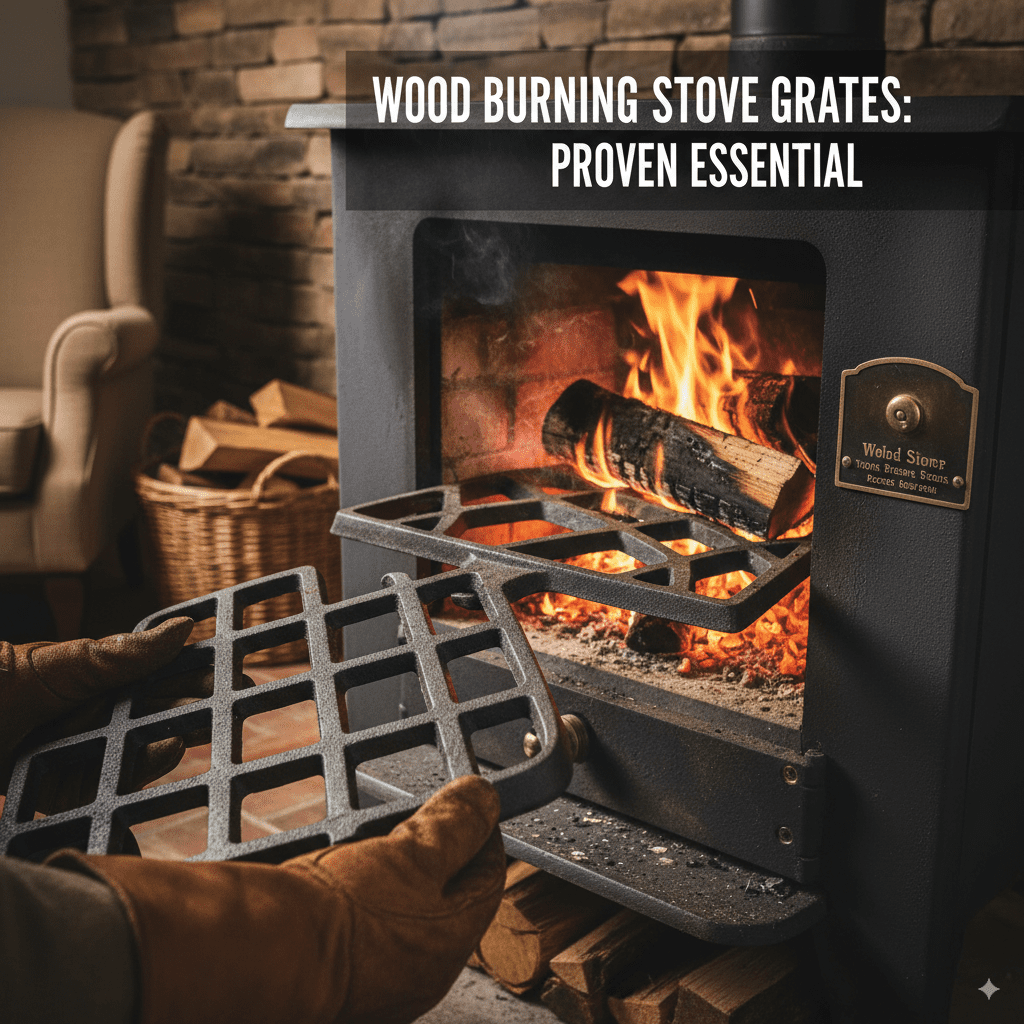

Wood Burning Stove Grates: Proven Essential

Wood burning stove grates are essential for efficient and safe operation, ensuring proper airflow for combustion and supporting your fuel for even burning. Replacing or maintaining them guarantees better heat, longer burn times, and protects your stove’s firebox.

Welcome to the warmth of your wood-burning stove! That satisfying crackle and cozy heat are wonderful, aren’t they? But have you ever looked at the metal structure at the bottom of your stove and wondered, “What’s its deal?” That, my friend, is the wood burning stove grate, and it’s a tiny titan in the world of your heating setup. Often overlooked, a damaged or dirty grate can drastically reduce your stove’s performance, leading to less heat, more smoke, and even damage. Don’t worry if yours isn’t in tip-top shape; we’re going to explore why these grates are so vital and how to keep them working perfectly. We’ll make sure your stove is a happy, efficient heater!

Why Wood Burning Stove Grates Are Your Heating Hero

At first glance, a wood burning stove grate might seem like just another piece of metal. However, its role is far more significant than you might imagine. It’s the unsung hero of your wood-burning stove, quietly working to keep your fire burning bright and your home warm. Think of it as the lungs of your stove, ensuring it can breathe properly.

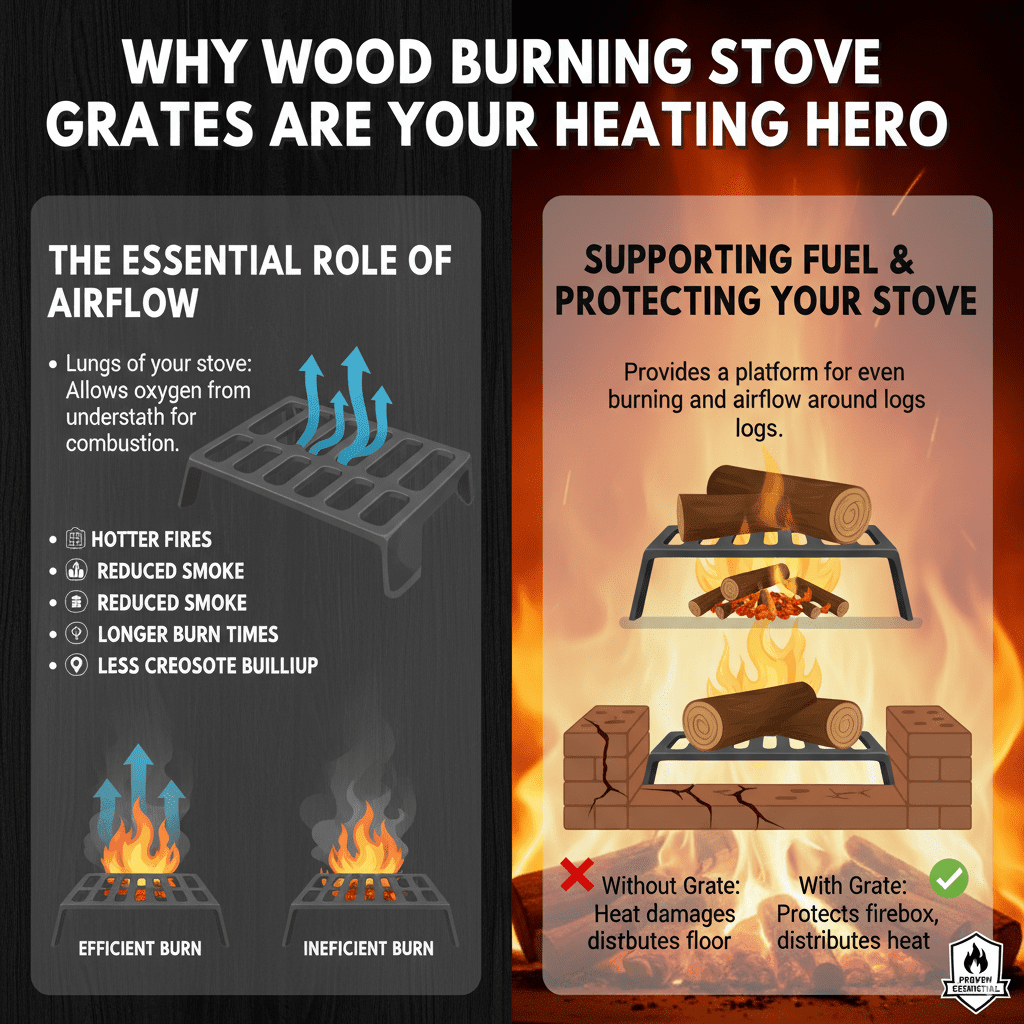

The Essential Role of Airflow

Combustion, the process that creates heat from burning wood, needs air. Specifically, it needs oxygen. The grate sits at the bottom of your stove’s firebox and is designed with openings or holes. These openings are crucial because they allow air to come up from underneath the fuel. This under-air supply is often referred to as primary combustion air. Without this consistent flow of air reaching the base of your wood, the fire simply cannot burn efficiently. It’s like trying to breathe through a stuffed nose – the fire struggles to get the oxygen it needs to produce robust heat.

This bottom-up airflow is particularly important for allowing the wood to burn from all sides. When air can circulate freely, the wood ignites more completely, leading to:

- Hotter Fires: More oxygen means a more complete and intense burn.

- Reduced Smoke: Efficient combustion means less unburned fuel particles escape as smoke.

- Longer Burn Times: A well-aerated fire consumes fuel more steadily.

- Less Creosote Buildup: Incomplete combustion is a major cause of creosote, a flammable substance that can build up in your chimney and pose a fire hazard.

Supporting Your Fuel for Even Burning

Beyond airflow, the wood burning stove grate serves a very practical purpose: it physically supports the wood. It creates a stable platform within the firebox, allowing you to arrange logs in a way that promotes good burning. Without a grate, logs would sit directly on the firebox floor, potentially smothering the fire and making it difficult to add more fuel effectively. The grate ensures that there’s always space for air to get to the fuel, even as the wood burns down and collapses into ash.

Protecting Your Stove’s Firebox

The intense heat of a wood fire can be damaging. The grate acts as a buffer, keeping the bulk of the raw, most intense heat away from the firebox floor. Firebox floors are often made of refractory panels (like vermiculite or fire bricks) or cast iron. If logs and embers sit directly on these surfaces without the protective layer and airspace provided by a grate, they can overheat and crack, leading to costly repairs. The grate distributes the weight and heat of the fuel, extending the life of your stove’s internal components.

Common Grate Problems and Their Solutions

Like any hard-working part of your wood burning stove, the grate can experience wear and tear. Understanding these common issues will help you spot them early and address them before they become bigger problems.

Warping and Cracking

The repeated cycles of extreme heat and cooling can cause metal grates to warp, bend, or even crack over time. A warped grate might not sit level in the firebox, leading to uneven airflow and potentially letting embers fall through the gaps. Cracks are more serious, as they can widen with heat and eventually lead to the grate breaking apart.

Solution: Visually inspect the grate regularly, especially after a long heating season. If you notice any significant warping or, worse, cracks, it’s time for a replacement. Minor warping might still allow for some function, but it’s a sign that replacement is likely needed soon.

Ash Buildup

As wood burns, it turns into ash. While some ash is good for insulating the fire, excessive ash buildup on the grate can clog the air holes. This dramatically restricts airflow, suffocating the fire and leading to the issues we discussed earlier (poor heat, smoke, creosote). Also, a thick layer of ash can hold moisture, which can accelerate corrosion of the grate.

Solution: Regularly clean your stove. This includes removing ash from the firebox. Most manufacturers recommend leaving a thin layer of ash (about an inch) on the firebox floor for insulation, but ensure this layer isn’t covering the grate openings. Use a metal ash shovel and bucket to safely remove excess ash. Always ensure the stove is completely cool before cleaning.

Rust and Corrosion

Metal, especially cast iron, is susceptible to rust, particularly if exposed to moisture or salt from damp wood. Rust can weaken the grate and clog its air passages. In severe cases, rust can eat away at the metal, leading to holes or breakage.

Solution: Keep the grate dry. Ensure your firewood is properly seasoned and stored. After cleaning, you can wipe down a cast iron grate with a light coating of vegetable oil or specialized stove polish before the off-season to prevent rust. If you notice significant rust, assess if it compromises the grate’s structural integrity. Light surface rust can sometimes be brushed away.

Loose or Broken Grate Supports

Some stoves have grates that rest on specific supports or brackets within the firebox. Over time, these supports can become loose, break, or wear down. If a grate isn’t sitting securely, it can shift, affecting airflow and potentially putting stress on other parts of the stove.

Solution: Check that the grate sits firmly and levelly on its supports. If the supports seem damaged or worn, consult your stove’s manual or a professional. Replacing or repairing these supports might be necessary.

Types of Wood Burning Stove Grates

Wood burning stove grates aren’t one-size-fits-all. They come in various materials and designs, each with its pros and cons. Understanding these differences can help you make an informed decision when it’s time for a replacement.

Cast Iron Grates

Cast iron is the most common material for wood burning stove grates. It’s known for its durability and ability to withstand high temperatures. Cast iron grates are typically heavy and robust, providing excellent support for fuel.

- Pros: Very durable, excellent heat tolerance, readily available, relatively inexpensive.

- Cons: Can be brittle and crack if subjected to sudden temperature changes (thermal shock) or significant impact, susceptible to rust if not maintained.

Steel Grates

Some manufacturers opt for steel for their grates. Steel grates can also be strong and durable, and they might be less prone to cracking from thermal shock than cast iron. They can be fabricated in various designs.

- Pros: Strong, often less prone to cracking than cast iron from temperature fluctuations.

- Cons: Can be more expensive depending on the manufacturing process, may still rust if not coated or maintained.

Shaker Grates vs. Fixed Grates

This refers to the design and how the grate operates:

- Fixed Grates: These are the most basic and common. They are permanently installed in the firebox and do not move. You clean ash from them by raking or brushing.

- Shaker Grates: These grates have a mechanism (often a lever on the outside of the stove) that allows you to shake them. Shaking breaks up ash and lets it fall through the openings into the ash pan below without opening the stove door. This is convenient for ash removal while the stove is operating.

Table: Grate Types and Considerations

| Grate Type | Material | Mechanism | Pros | Cons |

|---|---|---|---|---|

| Standard | Cast Iron, Steel | Fixed | Durable, cost-effective, simple design | Requires manual ash removal, can clog easily |

| Shaker | Cast Iron, Steel | Mechanical Shaker | Easy ash removal, improved airflow management during operation | More complex mechanism can fail, potentially higher cost |

Choosing and Replacing a Wood Burning Stove Grate

When it’s time to replace your wood burning stove grate, selecting the right one is crucial for optimal performance and safety. Don’t just grab the first one you see!

Step 1: Identify Your Stove Model

The most important step is to know the exact make and model of your wood burning stove. This information is usually found on a metal plate or sticker located on the back, side, or underside of the stove. If you can’t find it, look for any manufacturer’s name or serial number.

Step 2: Consult Your Owner’s Manual

Your stove’s owner’s manual is your best friend for finding the correct replacement part. It will often have a parts list with diagrams that identify the specific grate part number. If you no longer have the manual, you can usually find a digital copy on the manufacturer’s website by searching for your stove model.

Step 3: Measure the Old Grate (If Necessary)

If you can’t find a manual or part number, you may need to measure your existing grate. Measure its length, width, and the thickness of the material. Note the number and size of any air gaps or openings. However, be aware that even slight variations can cause a grate not to fit correctly. It’s always best to rely on the manufacturer’s specified part if possible.

Step 4: Source the Correct Part

Once you have the part number or specifications, you can start looking. Your best bet is usually:

- The Stove Manufacturer or Dealer: They are the most reliable source for genuine replacement parts.

- Specialty Stove Parts Websites: Many online retailers specialize in wood stove parts and carry a wide range of grates for various brands.

- Local Stove Shops: A local hearth or stove shop can be an excellent resource. They can help you identify the correct part and may even stock common replacements.

When searching online or in a store, use keywords like “wood burning stove grate replacement [Your Stove Brand] [Your Stove Model]”.

Step 5: Installation (DIY-Friendly)

Replacing a wood burning stove grate is typically a straightforward DIY job. Here’s a general guide:

- Ensure the Stove is Cool: This is paramount for safety. Make sure the stove has not been used for at least 24 hours and is completely cold to the touch.

- Remove Existing Grate: If your stove has a shaker grate, you might need to disengage the mechanism first. Then, carefully lift out the old, potentially heavy, grate. You may need gloves for better grip and to protect your hands from sharp edges.

- Clean the Firebox: While the grate is out, this is the perfect opportunity to thoroughly clean the firebox. Remove any loose ash, debris, or creosote.

- Install the New Grate: Carefully place the new grate into the firebox, ensuring it sits correctly on its supports. If it’s a shaker grate, re-engage the mechanism as per your stove’s instructions.

- Inspect Functionality: Gently test the grate to ensure it sits level and, if applicable, the shaker mechanism works smoothly.

Safety Note: Always wear sturdy gloves and eye protection when handling stove parts, as they can have sharp edges. If you are unsure about any step, consult your owner’s manual or seek professional help from a certified stove technician.

For more information on stove maintenance, the Chimney Safety Institute of America (CSIA) offers excellent resources on safe wood burning practices and appliance care, which indirectly benefit grate longevity: CSIA Wood Burning Tips.

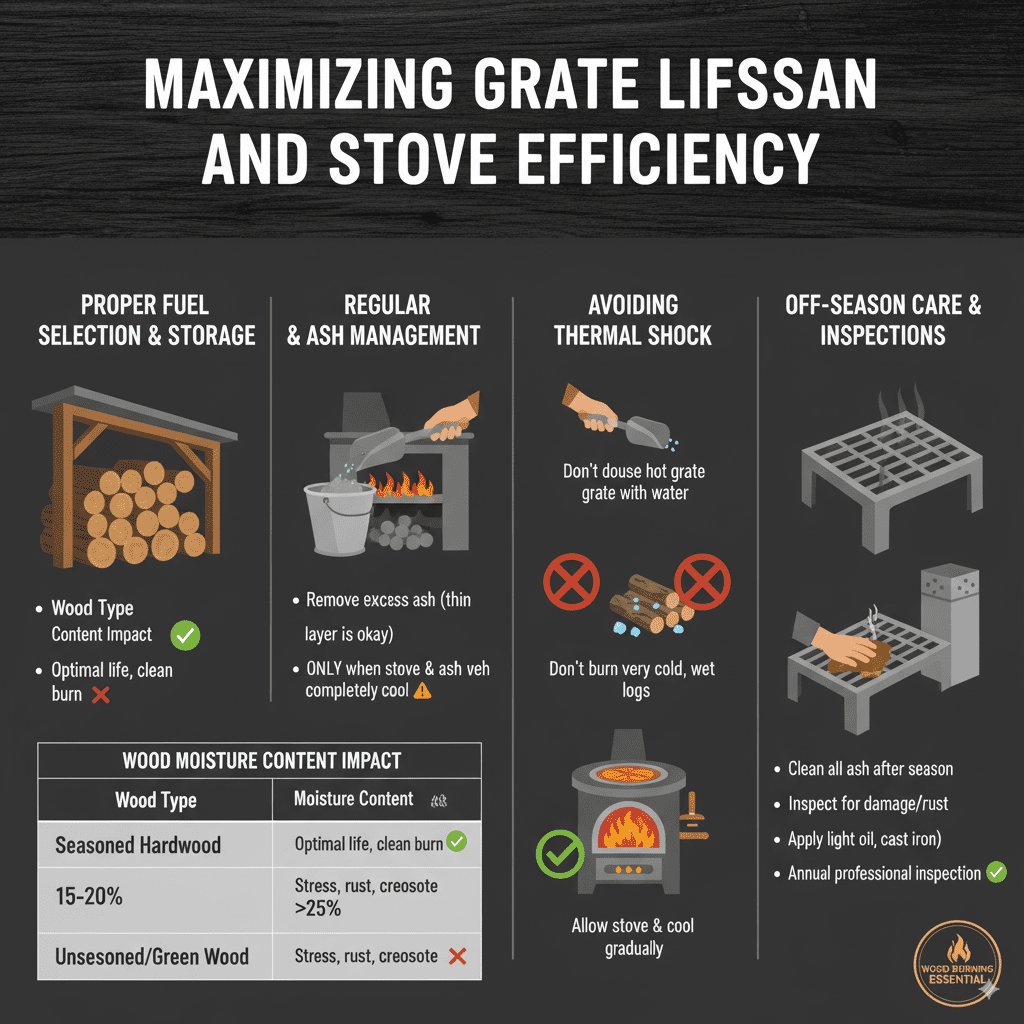

Maximizing Grate Lifespan and Stove Efficiency

Taking good care of your wood burning stove grate will not only make it last longer but also ensure your stove operates at its best. Think of it as a little TLC for your heating system.

Proper Fuel Selection and Storage

The type and condition of the wood you burn have a direct impact on your grate and stove. Always use seasoned hardwoods. Seasoned means the wood has been dried for at least six months to a year, reducing its moisture content significantly. Wet or green wood burns poorly, produces excessive smoke and creosote, and can create a more intense, prolonged heat that can stress metal components more.

Table: Wood Moisture Content Impact

| Wood Type | Moisture Content | Burning Characteristics | Grate/Stove Impact |

|---|---|---|---|

| Seasoned Hardwood | 15-20% | Efficient, hot, clean burn | Optimal for grate life and stove performance |

| Unseasoned/Green Wood | >25% | Smoldering, smoky, low heat, high creosote | Increased stress on grate, promotes rust, accelerates creosote buildup affecting airflow |

Store your firewood off the ground and covered at the top but open at the sides to allow air circulation, helping it stay dry.

Regular Cleaning and Ash Management

As mentioned, consistent ash removal is key. Don’t let ash build up to the point where it covers the grate and blocks airflow. A thin layer of ash can be beneficial for insulation, but excess is detrimental. Use appropriate tools like an ash shovel and a metal ash bucket. It’s crucial to remove ash only when the stove and ash are completely cool. Placing hot ashes in a plastic bin or near combustibles is a serious fire hazard.

Avoiding Thermal Shock

Metal grates can crack if they experience rapid temperature changes. This is known as thermal shock. Avoid these practices:

- Don’t douse a hot grate or stove with water to cool it down.

- Don’t try to start a fire with very cold, wet logs.

- Allow your stove to cool down gradually after use.

Off-Season Care

When your wood burning season ends, take a moment to give your stove and grate some attention. Clean out all ash. Inspect the grate for any signs of damage or excessive rust. If you have a cast iron grate, you might want to wipe it down with a light coating of vegetable oil or a specialized stove blacking product. This can help prevent rust during the months when the stove isn’t in use. For shaker grates, ensure the mechanism is clean and lubricated if the manual suggests it.

Professional Inspections

Consider having your wood burning stove and its components, including the grate, inspected annually by a certified chimney sweep or stove technician. They can spot wear and tear that you might miss, ensure everything is functioning safely, and offer advice on maintenance. Organizations like the National Fireplace Institute (NFI) certify professionals who can offer expert service for your heating appliances. Regular maintenance, including grate care, is a core recommendation for ensuring the safe and efficient operation of your wood-burning appliance, as promoted by fire safety officials nationwide.

Frequently Asked Questions About Wood Burning Stove Grates

What is the primary function of a wood burning stove grate?

The primary functions are to allow essential airflow from underneath the fuel for efficient combustion and to support the wood or fuel source, ensuring an even burn while protecting the stove’s firebox from excessive direct heat.

How often should I clean my wood burning stove grate?

You should clean excess ash away from your grate frequently, ideally every few uses or as ash buildup begins to obstruct airflow. This means removing ash from the firebox to ensure the grate openings remain clear. Annual deep cleaning and inspection are also recommended.