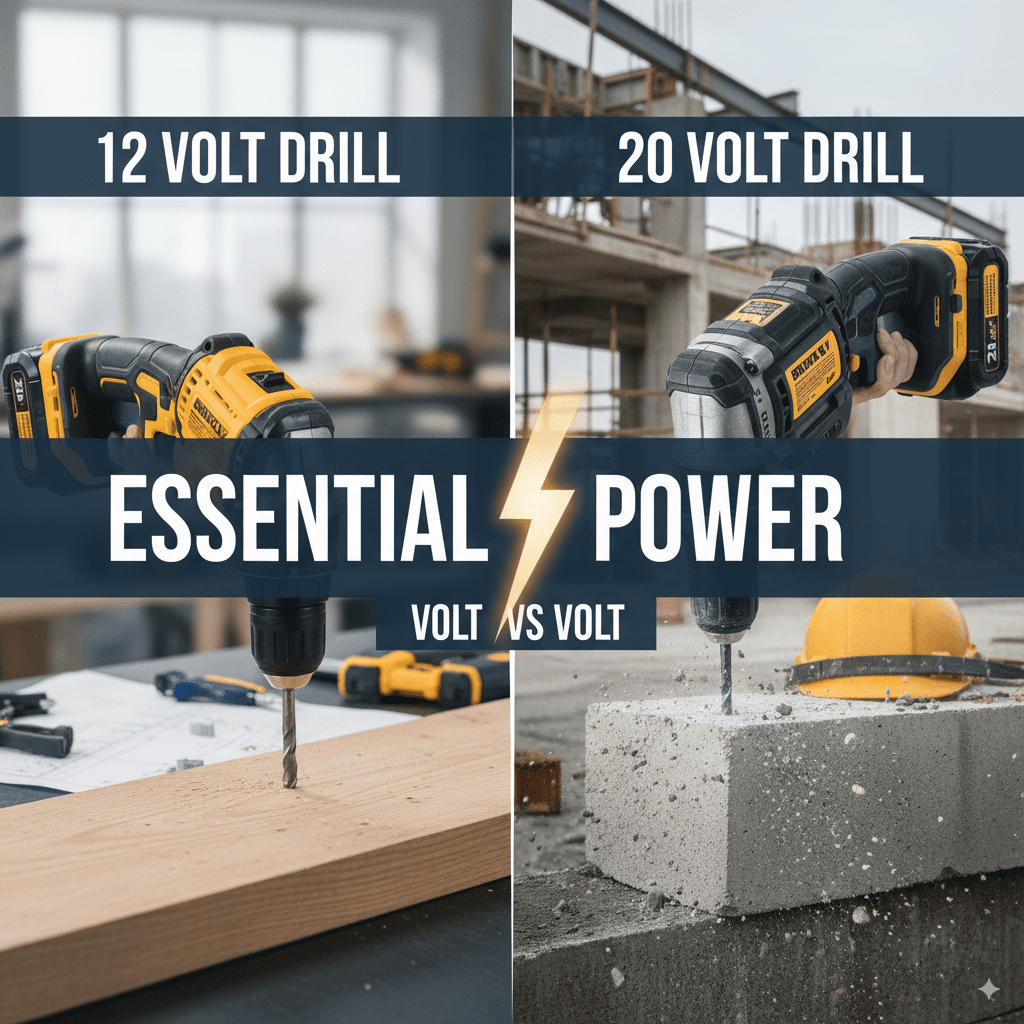

12 Volt Vs 20 Volt Drill: Essential Power

For a 12V drill versus a 20V drill, choose 12V for lightweight, occasional tasks and tight spaces. Opt for 20V when you need more power for tough materials, continuous use, and larger projects. The voltage indicates power, but consider battery capacity and motor type for your specific DIY needs.

Hey DIY friends! Picking the right drill can feel like a puzzle, especially when you’re just starting out. You see numbers like “12 Volt” and “20 Volt,” and wonder, “What’s the big deal? Does it really matter for my weekend projects?” It’s a common question, and honestly, it used to puzzle me too! Many beginners feel daunted by tool specifications, but you don’t need to be a pro to understand the basics. We’re here to demystify the difference between 12V and 20V drills so you can confidently choose the one that’s perfect for your workshop and your projects. Let’s break it down, keep it simple, and get you building with confidence!

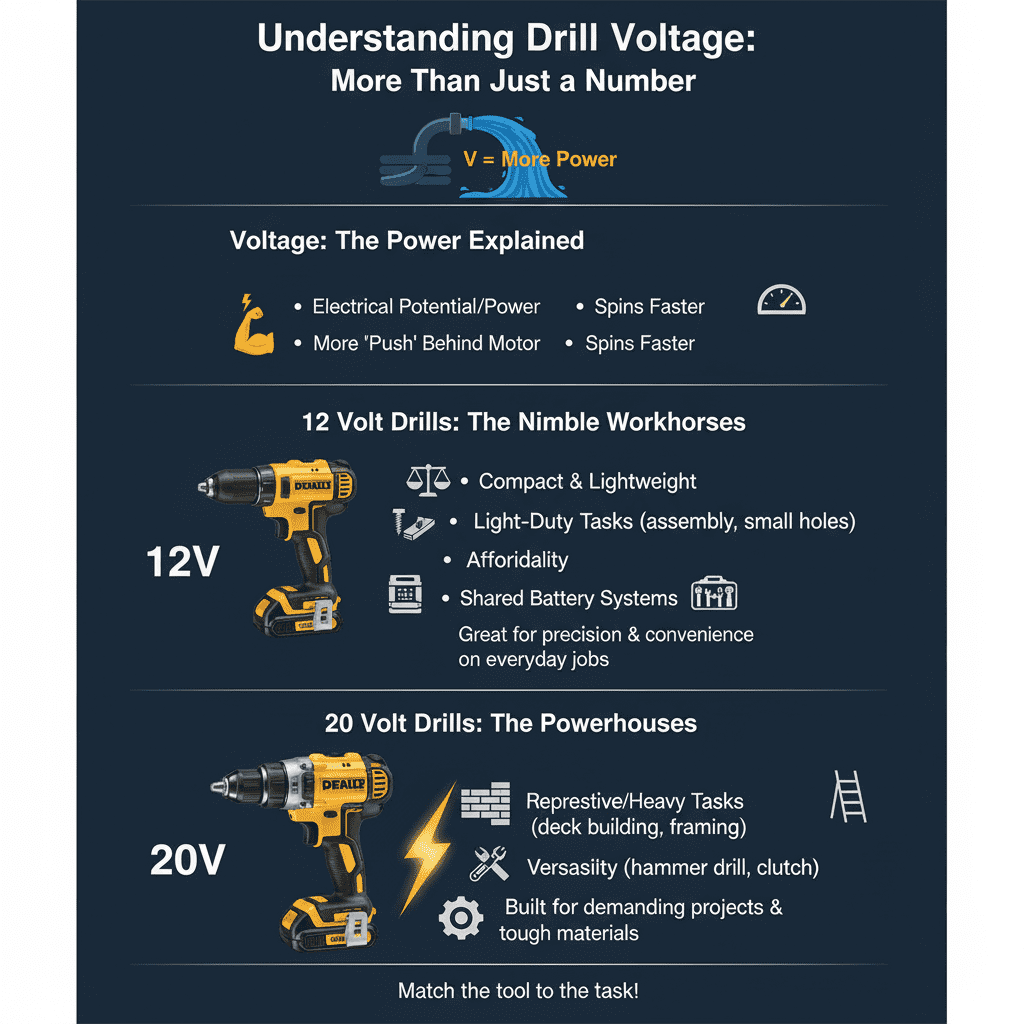

Understanding Drill Voltage: More Than Just a Number

Voltage, often abbreviated as ‘V,’ is essentially a measure of the electrical potential or power your drill’s motor can deliver. Think of it like the water pressure in a hose. A higher voltage means more “push” behind the motor, enabling it to handle tougher jobs and spin faster.

For cordless drills, voltage is an important indicator of its capability. It’s not the only factor, but it’s a major one when comparing different models and brands. Understanding voltage helps you match the tool to the task, ensuring you have enough power without overspending or buying more than you need.

12 Volt Drills: The Nimble Workhorses

12-volt drills are often the first cordless drills many home renovators and hobbyists pick up. They’re designed with ease of use and portability in mind. Imagine needing to screw in a few drywall anchors, assemble a flat-pack shelf, or tackle a small woodworking project in a cramped corner. That’s where a 12V drill shines.

- Compact and Lightweight: Their smaller battery packs mean these drills are noticeably lighter and smaller. This makes them less fatiguing to use for extended periods and much easier to maneuver in tight spaces, like under a sink or inside a cabinet.

- Excellent for Light-Duty Tasks: Driving screws into soft woods, thin metal, or plastics, drilling small holes, and general assembly work are all well within the capabilities of a 12V drill.

- Affordability: Generally, 12V drill kits tend to be more budget-friendly than their 20V counterparts, making them an attractive entry point for DIYers.

- Battery Compatibility: Often, 12V systems from the same brand share batteries across different tools (like jigsaws, impact drivers, or multi-tools), which can save you money if you plan to build out a cordless tool collection.

While they’re fantastic for many common home tasks, 12-volt drills have their limits. They might struggle with really dense hardwoods, large screws in multiple passes, or continuous heavy-duty drilling. Think of them as your go-to for precision and convenience on everyday jobs.

20 Volt Drills: The Powerhouses

Stepping up to a 20-volt drill means you’re looking for more muscle. These drills are built to handle more demanding tasks that a 12V might find challenging. If you’re planning on tackling larger renovation projects, working with thicker or harder materials, or need a drill that can keep up with more frequent use, a 20V is likely what you’ll want.

- Increased Power and Torque: The higher voltage translates to more torque (rotational force), allowing the drill to power through tougher materials like hardwoods, masonry (with the right setting), or drive larger fasteners with ease.

- Better for Repetitive or Heavy Tasks: Whether you’re building a deck, framing a wall, or frequently drilling multiple holes, a 20V drill offers the sustained power needed without bogging down.

- Versatility (With the Right Attachments): Many 20V drills offer a clutch setting that allows for precise torque control, preventing over-driving screws. Some also have hammer drill functionality, making them effective for drilling into concrete or brick.

- Future-Proofing: As you tackle more ambitious DIY projects, a 20V drill provides a solid foundation for more advanced work.

The trade-off for this extra power is usually size, weight, and cost. 20V drills and their batteries are typically larger and heavier. However, modern battery technology has made them surprisingly comfortable to handle for most users.

Key Differences: A Side-by-Side Look

To make things even clearer, let’s put the core differences side-by-side. This table highlights what you can generally expect when comparing a 12V drill to a 20V drill:

| Feature12 Volt Drill20 Volt Drill | ||

|---|---|---|

| Primary Use Case | Light-duty tasks, quick fixes, assembly, tight spaces | Medium to heavy-duty tasks, construction, frequent use, tough materials |

| Power (Torque) | Lower; suitable for screws and small holes | Higher; capable of driving larger fasteners and drilling hardwoods |

| Size & Weight | Compact and lightweight; easy maneuverability | Larger and heavier; requires more effort in tight spaces |

| Battery Life / Capacity | Generally smaller capacity, suitable for shorter tasks | Generally larger capacity, suitable for longer tasks (though this varies by Ah rating) |

| Cost | More affordable | More expensive |

| Versatility | Best for driving screws and light drilling | Can often handle drilling, driving, and sometimes masonry (with hammer function) |

Beyond Voltage: Other Important Factors to Consider

While voltage is a primary differentiator, it’s not the only thing that makes a drill powerful or suitable for your needs. Here are other factors that play a significant role:

- Amp-Hours (Ah): This rating tells you how long the battery can deliver power. A higher Ah rating means longer run time on a single charge. For example, a 2.0Ah battery will last about twice as long as a 1.0Ah battery under the same load. This is crucial for both 12V and 20V systems.

- Brushless vs. Brushed Motors: Modern drills often feature brushless motors. These are more efficient, run cooler, last longer, and provide more power and better control than traditional brushed motors. Brushless technology is increasingly common in both 12V and 20V lines, so look for it if you want the best performance. You can learn more about brushless motors and their benefits from resources like the U.S. Department of Energy on their efficiency standards.

- Chuck Type: Most modern drills have a keyless chuck, meaning you can tighten and loosen the drill bit by hand. Ensure the chuck size (e.g., 3/8-inch or 1/2-inch) is appropriate for the bits you plan to use. A 1/2-inch chuck is generally more robust and accepts larger bits.

- Gearing and Clutch Settings: The gearbox determines the drill’s speed and torque. Look for multiple speed settings (e.g., low for driving screws, high for drilling) and an adjustable clutch to prevent stripping screws or damaging your material.

- Ergonomics and Comfort: How the drill feels in your hand is important, especially for longer projects. Features like soft-grip handles and balanced weight distribution can make a big difference.

When to Choose a 12 Volt or 20 Volt Drill for Your Projects

Let’s get practical. Here’s how to match the right drill to some common DIY scenarios:

Scenario 1: Assembling Flat-Pack Furniture

Recommendation: 12 Volt Drill

For putting together shelves, tables, or cabinets delivered in boxes, a 12V drill is often perfect. It’s lightweight, easy to control, and has just enough power to drive screws without stripping them or burying them too deep. Plus, its compact size lets you work comfortably in confined spaces.

Scenario 2: Building a Small Bookshelf

Recommendation: 12 Volt Drill (possibly 20V if using hardwood)

If you’re using softer pines or plywood for a small shelf, a 12V drill can handle it. You’ll likely want a battery with a decent Ah rating for sustained work. If your plans include denser hardwoods or driving many long screws, a 20V drill might offer a smoother, more powerful experience and reduce the chance of bogging down.

Scenario 3: Mounting Kitchen Cabinets

Recommendation: 20 Volt Drill

Mounting cabinets involves driving long screws into studs, often at awkward angles. This requires significant torque and sustained power. A 20V drill with a hammer drill function (if you’re also drilling pilot holes into a wall or masonry) is highly recommended for this job to ensure a secure installation.

Scenario 4: Deck Building or Large Framing Projects

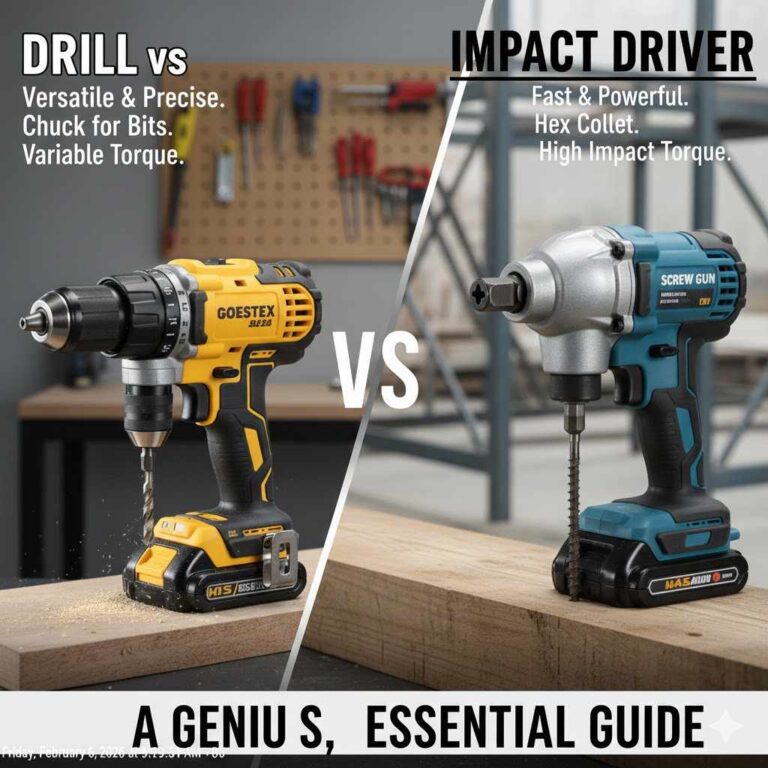

Recommendation: 20 Volt Drill (or even a Cordless Impact Driver)

For tasks like building a deck or framing walls, you’ll be driving large fasteners repeatedly into tough lumber. A robust 20V drill is essential. For even more specialized power and speed in these applications, a dedicated cordless impact driver is often the preferred tool, as it delivers rotational blows for maximum torque.

Scenario 5: Working in Very Tight Spaces (e.g., Under a Sink)

Recommendation: 12 Volt Drill

When you’re maneuvering in tight, awkward spots, the smaller size and lighter weight of a 12V drill are invaluable. You can get the job done without feeling like you’re wrestling with the tool.

Battery Systems: The Backbone of Your Cordless Tools

One of the biggest advantages of buying into a cordless tool system is the ability to share batteries. If you’re just starting, consider which battery platform you want to invest in:

- Sticking with One Brand: Most major tool manufacturers (like DeWalt, Milwaukee, Makita, Ryobi, etc.) offer both 12V and 20V lines. If you buy a 20V drill from Brand X, you can often use the same 20V batteries with their other 20V tools (like saws, sanders, or leaf blowers). The same applies to their 12V line.

- Cross-Platform Compatibility: Be aware that batteries from different brands are almost never interchangeable. You’re usually locked into a brand’s ecosystem.

- Battery Upgrades: As battery technology advances, you might find higher capacity (more Ah) or even higher voltage (like 20V/60V FLEXVOLT systems that can switch to 20V) batteries for increased run time and power.

Choosing a platform early can save you money in the long run, as you won’t need to buy new batteries and chargers for every new tool you acquire.

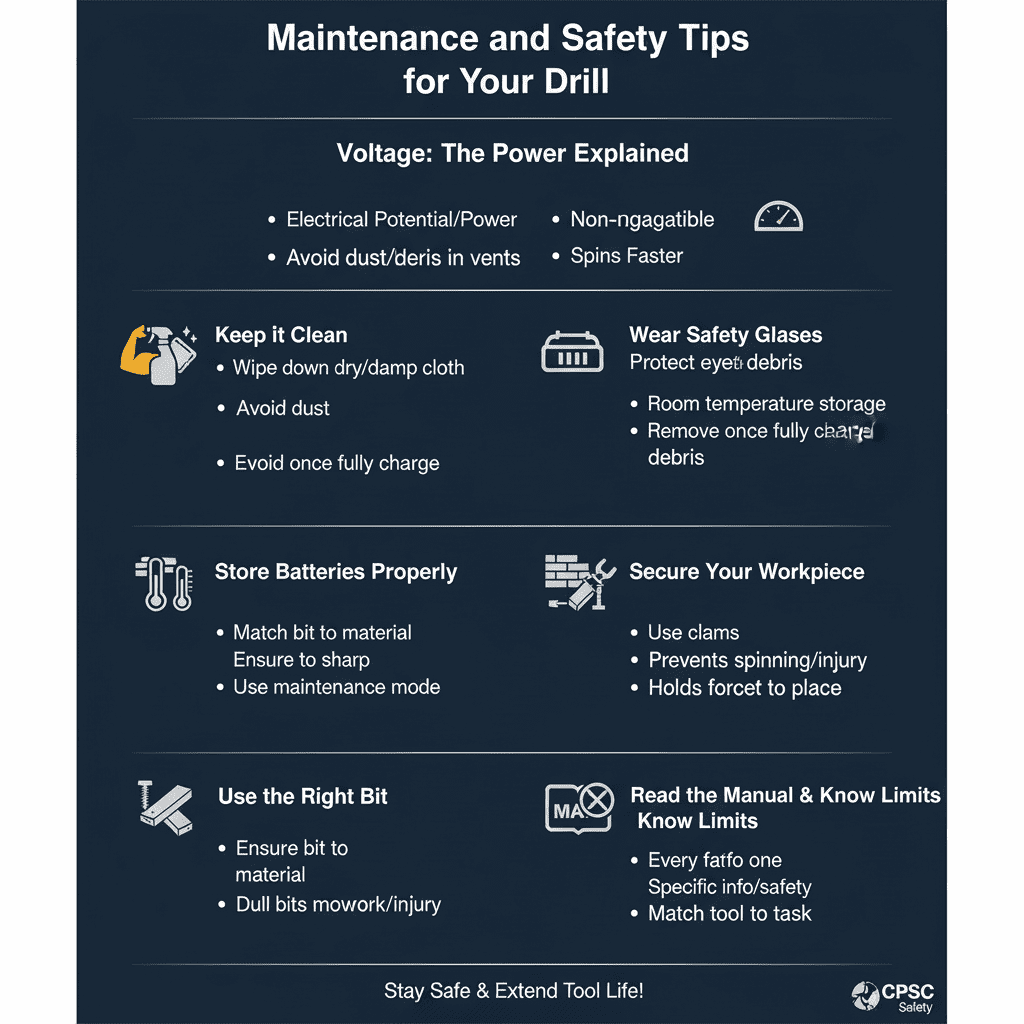

Maintenance and Safety Tips for Your Drill

Regardless of the voltage you choose, proper care and safety are paramount. This ensures your tools last and you stay safe:

- Keep it Clean: Dust and debris can get into the motor vents. After use, wipe down your drill with a dry or slightly damp cloth.

- Store Batteries Properly: Avoid extreme temperatures. Store batteries indoors at room temperature. Don’t leave them on the charger indefinitely; remove them once fully charged unless the charger has a maintenance mode.

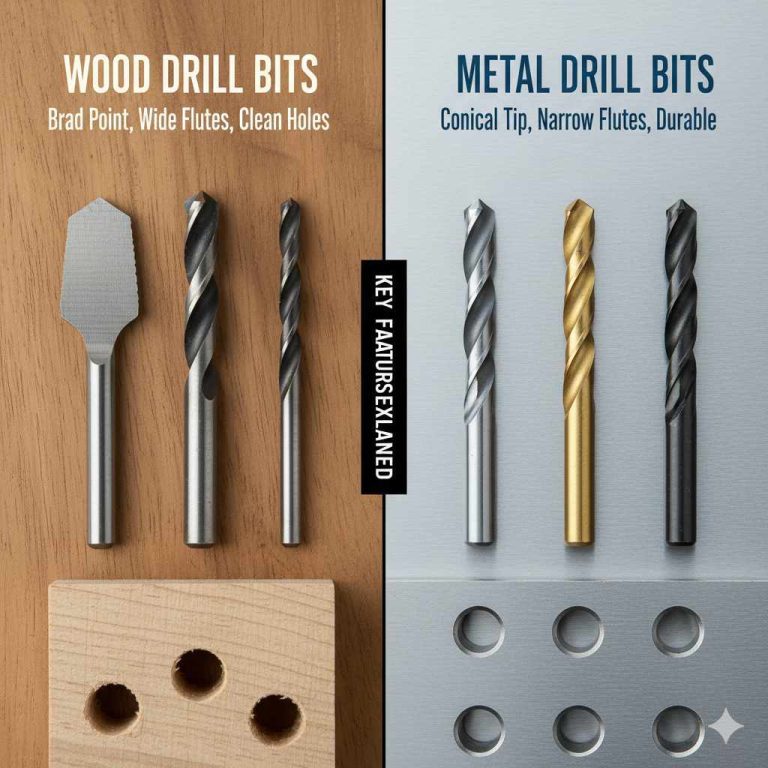

- Use the Right Bit: Always match the drill bit to the material you’re working with and ensure it’s sharp. A dull bit makes the drill work harder.

- Wear Safety Glasses: This is non-negotiable. Always wear safety glasses to protect your eyes from flying debris.

- Secure Your Workpiece: Use clamps to hold your material in place. This prevents it from spinning, which can cause injury or damage.

- Read the Manual: Every drill comes with an instruction manual. Take a few minutes to read it. It contains specific information about your model, including safety features and operating instructions. Resources like the Consumer Product Safety Commission (CPSC) also offer valuable general safety advice for power tools.

- Know Your Drill’s Limits: Don’t force your drill. If it’s struggling, you might be using the wrong tool, the wrong bit, or the material is too tough.

Frequently Asked Questions (FAQ)

Q1: Can a 12V drill cut through wood?

A1: Yes, a 12V drill can definitely cut through wood, but it depends on the type and thickness of the wood, and the size of the bit. It’s best suited for smaller pilot holes or driving screws into soft to medium-density woods. For larger holes or hardwoods, a 20V drill or a dedicated drill press might be more appropriate.

Q2: Will a 20V drill damage screws more easily than a 12V drill?

A2: Not necessarily. The risk of over-driving or stripping screws comes from not using the clutch setting correctly on any drill. Both 12V and 20V drills usually have adjustable clutches. You set the clutch to a low number for screws to stop the drill from turning once a certain torque is reached, preventing damage.

Q3: Is a 20V drill too heavy for a beginner?

A3: For most beginners, a 20V drill is perfectly manageable. While they are heavier than 12V models, manufacturers design them with comfortable grips and good balance to minimize fatigue. If you have limited strength or are performing tasks overhead, a 12V might be more comfortable, but for general use, 20V is usually fine.

Q4: What does the ‘Ah’ rating on a battery mean?

A4: ‘Ah’ stands for Amp-hours. It’s a measure of battery capacity, indicating how much current the battery can deliver over time. A higher Ah rating (e.g., 4.0Ah vs. 2.0Ah) means the battery can power your drill for a longer period on a single charge. It doesn’t directly affect the drill’s raw power (that’s the voltage), but rather its endurance.

Q5: Do I need both a 12V and a 20V drill?

A5: Most DIYers find that one voltage platform serves their needs well. If your projects are small and infrequent, a 12V is a cost-effective and convenient choice. If you tackle larger, more frequent projects requiring more power, invest in a 20V. Some professionals might carry both for different specialized tasks, but for beginners, pick the one that best matches your current and anticipated projects.

Q6: Can I use a 20V battery on a 12V drill?

A6: Absolutely not. Batteries are designed for specific voltage systems. Using a 20V battery on a 12V drill would supply too much power, likely damaging or destroying the drill and potentially creating a safety hazard. Always use the correct battery for the tool.

Q7: What is a “hammer drill” function?

A7: A hammer drill function adds a rapid, percussive hammering action to the rotation of the drill bit. This is extremely useful for drilling into hard materials like concrete, brick, or stone. When drilling wood or metal, you’d keep the hammer function turned OFF, using it only for masonry.

Conclusion: Power Up Your Projects Wisely

Choosing between a 12V and a 20V drill ultimately comes down to understanding your DIY habits and the tasks you want to accomplish. For the beginner embarking on light repairs, furniture assembly, or small crafting projects, the 12V drill offers a fantastic balance of portability, ease of use, and affordability. It lightens the load and makes those quick fixes a breeze.