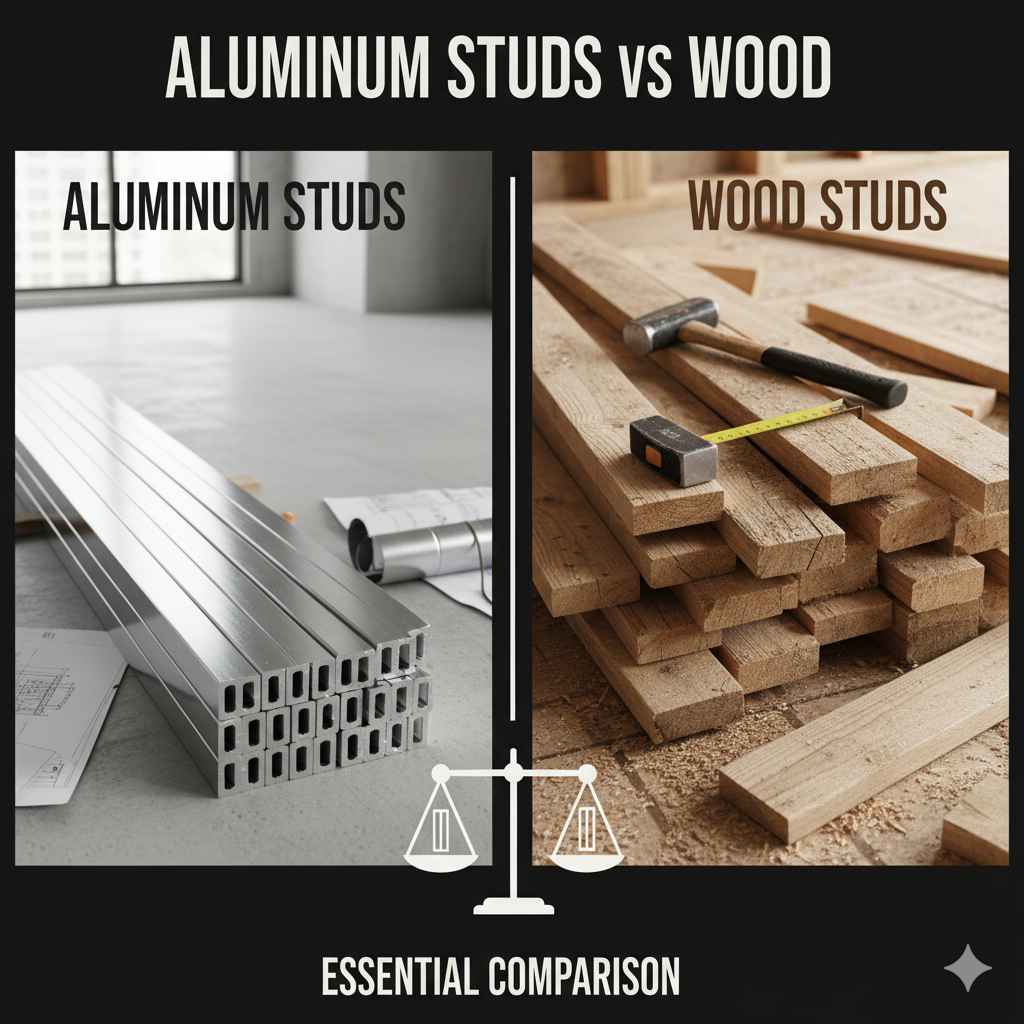

Aluminum Studs Vs Wood: Essential Comparison

Choosing between aluminum studs and wood studs is crucial for your project. Aluminum offers superior fire resistance, termite immunity, and lighter weight, while wood is generally more affordable, easier to work with for beginners, and offers better insulation. This guide breaks down their differences to help you decide.

Hey there, fellow DIYers and home improvers! Md Meraj here. Ever stand in the lumber aisle, or stare at a pile of metal framing, wondering which one is the right choice for your next build? It’s a common question, and frankly, getting it wrong can lead to headaches later on. Don’t sweat it! We’re going to break down the “aluminum studs vs wood” debate with simple, clear steps. We’ll look at what makes each material tick, so you feel super confident about your decision. Let’s get building!

Aluminum Studs Vs Wood: The Ultimate Showdown for Your Next Project

When you’re planning a renovation, a new wall, or even a small shed, the building material for your framing is a big deal. Think of studs as the skeleton of your project! For years, wood has been the go-to. But lately, aluminum studs have been popping up more and more. They both have their own strengths and weaknesses, and knowing them will make sure your project is sturdy, safe, and exactly what you dreamed of. We’re not just going to list facts; we’re going to help you understand which one is best for you.

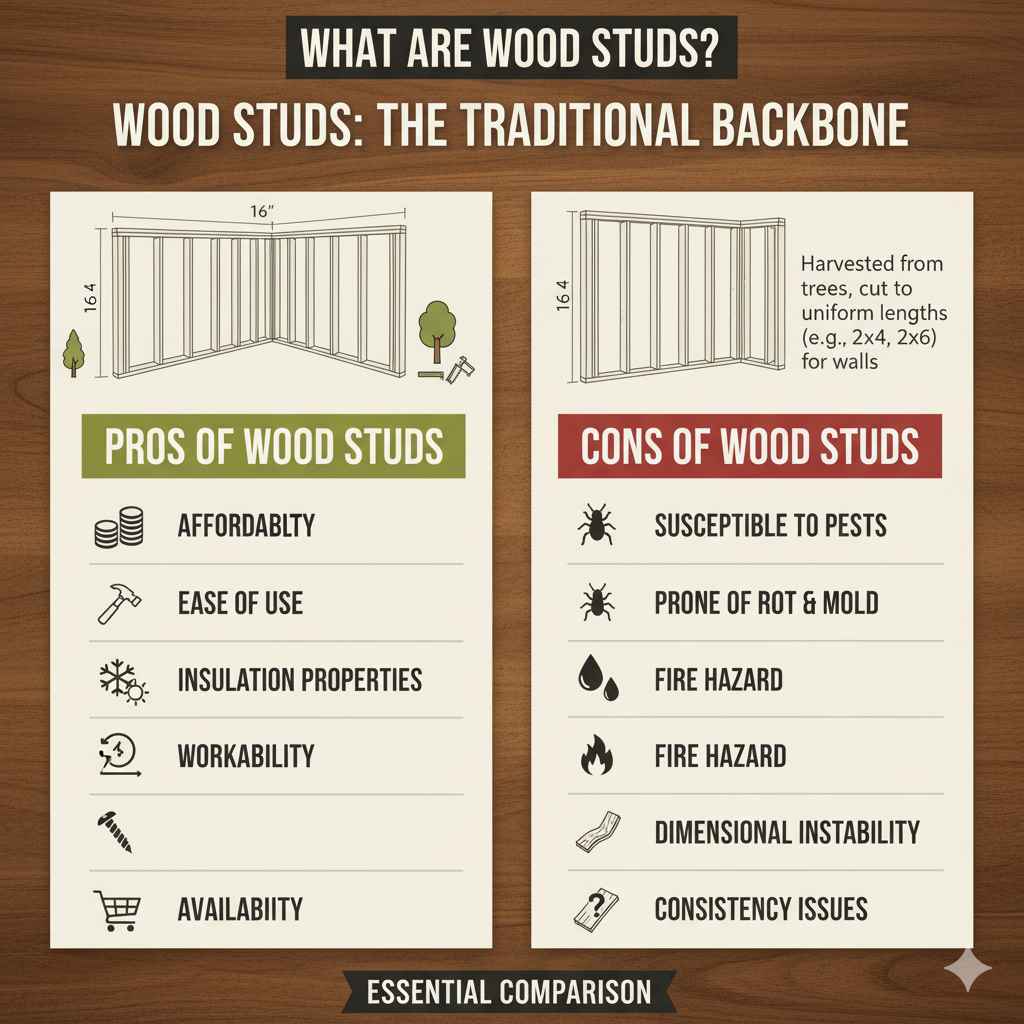

What Are Wood Studs?

Wood studs are the traditional backbone of most residential construction. They’re like the tried-and-true friend in the building world. Harvested from trees and cut into uniform lengths, they’re what most of us are familiar with. They come in various types and sizes, but standard lumber like 2x4s and 2x6s are the most common for walls.

Pros of Wood Studs

- Affordability: Generally, wood is more budget-friendly upfront compared to steel or aluminum framing.

- Ease of Use: Most DIYers are comfortable cutting and fastening wood. Basic tools like a hammer or a cordless drill work great.

- Insulation Properties: Wood is a natural insulator, meaning it doesn’t conduct heat or cold as readily as metal. This can contribute to a more comfortable indoor temperature and potentially lower energy bills.

- Workability: It’s easier to drive nails, screws, and hang fixtures on wood. You can also easily cut, shape, and modify wood if your plans change mid-project.

- Availability: Wood is readily available at almost any hardware store or lumber yard.

Cons of Wood Studs

- Susceptible to Pests: Termites, carpenter ants, and other wood-boring insects can damage wood structures over time. Regular inspection and treatment might be necessary.

- Prone to Rot and Mold: If wood is exposed to moisture, it can rot or develop mold, leading to structural weakness and potential health issues. Proper sealing and ventilation are key.

- Fire Hazard: Wood is combustible. While building codes have standards for fire resistance, wood frames are inherently more flammable than metal.

- Dimensional Instability: Wood can warp, shrink, or swell depending on humidity and temperature changes. This can lead to popped nails, cracked drywall, and squeaky floors over time.

- Consistency Issues: Wood is a natural material, so there can be variations in strength, knots, and straightness from piece to piece.

What Are Aluminum Studs?

Aluminum studs are framing members made from extruded aluminum. Instead of harvested timber, these are manufactured products designed for specific building applications. They are often used in commercial construction but are becoming more popular in residential projects for their durability and specific advantages. They typically come in standard stud and track sizes, similar to their wood counterparts, but are made from lightweight metal.

Pros of Aluminum Studs

- Durability and Strength: Aluminum is a strong metal that doesn’t warp, twist, or shrink like wood. This means a straighter, more stable structure over the long term.

- Pest and Rot Resistance: Unlike wood, aluminum is impervious to termites, carpenter ants, and other wood-boring insects. It also won’t rot or succumb to mold, even in damp environments.

- Fire Resistance: Aluminum is non-combustible. This significantly reduces the risk of fire spreading and can be a major safety advantage. It can also help lower insurance premiums.

- Lightweight: Aluminum is much lighter than wood, making it easier to transport, handle, and install, especially for large jobs or when working at heights. This can reduce labor costs and the need for heavy equipment.

- Consistency: As a manufactured product, aluminum studs offer great consistency in dimensions and strength, making design and construction more predictable.

- Sustainability: Aluminum is infinitely recyclable without losing its quality. Using recycled aluminum significantly reduces the energy needed for production. You can learn more about the benefits of recycled aluminum from the Aluminum Association.

Cons of Aluminum Studs

- Higher Upfront Cost: Aluminum studs can be more expensive to purchase than traditional wood studs.

- Lower Insulation Value (Thermal Bridging): Metal is a good conductor of heat. This means aluminum studs can allow heat to transfer more easily from inside to outside (or vice versa), leading to potential energy loss. This is known as thermal bridging and often requires extra insulation strategies. You can find more details on thermal bridging from resources like Energy.gov.

- Specialized Fasteners and Tools: While not overly complex, working with metal studs often requires specific screws (like self-tapping screws) and sometimes different cutting tools than you’d use for wood.

- Workability and Modification: Cutting and modifying aluminum requires more effort and specialized tools than wood. Hanging heavy items might also require specific anchor systems designed for metal studs.

- Potential for Noise: Some builders note that metal-framed walls can transmit sound more easily than wood-framed walls, though this can often be mitigated with proper insulation and drywall installation techniques.

Aluminum Studs Vs Wood: A Direct Comparison

Let’s put them head-to-head on the most important factors for any project. Understanding these differences will really help you make the best choice for your specific needs.

| Feature | Wood Studs | Aluminum Studs |

|---|---|---|

| Cost (Material) | Lower initial cost | Higher initial cost |

| Durability | Prone to warping, shrinking, swelling | Resistant to warping, shrinking, swelling; remains dimensionally stable |

| Resistance to Pests | Susceptible to termites, carpenter ants, etc. | Immune to pests |

| Resistance to Rot/Mold | Can rot or mold if exposed to moisture | Immune to rot and mold |

| Fire Resistance | Combustible | Non-combustible |

| Weight | Heavier | Significantly lighter |

| Ease of DIY Installation | Generally easier for beginners; familiar tools | Requires specific tools/fasteners; can be trickier for first-timers |

| Insulation (Thermal Bridging) | Natural insulator | Poor insulator; prone to thermal bridging |

| Sustainability/Recycling | Renewable if harvested responsibly, but recycling is energy-intensive | Highly recyclable, often made from recycled materials |

| Noise Transmission | Generally good at sound dampening | May transmit more sound without proper acoustic treatments |

| Hanging Heavy Items | Easy to nail/screw into; can hold a lot of weight | Requires specific anchors/techniques for heavy items |

When to Choose Wood Studs

Wood is a fantastic choice for many projects, especially for beginners or when budget is a primary concern. Here are some scenarios where wood studs really shine:

- Small Home Projects: For weekend projects like building shelves, a workbench, or a small garden shed, wood is probably your easiest and most cost-effective option.

- Beginner DIYers: If you’re new to framing and are using basic tools, wood is much more forgiving. You’re likely already familiar with how it cuts, nails, and screws.

- Standard Residential Construction: For most interior walls in a typical home where moisture and pests aren’t extreme concerns, wood is the standard and works perfectly well.

- Budget-Conscious Renovations: If you need to frame out several rooms and want to keep material costs down, wood is almost always the cheaper option.

- When Superior Insulation is a Priority: Wood’s natural insulating properties can be a plus, reducing the need for extra thermal breaks compared to metal.

When to Choose Aluminum Studs

Aluminum studs offer specific advantages that make them the superior choice in other situations. Consider aluminum if:

- Moisture or Pests Are a Concern: If you’re building in a damp basement, a humid bathroom, an area prone to termites, or an outdoor structure like a shed that will face the elements, aluminum’s resistance to rot, mold, and pests is invaluable.

- Fire Safety is Paramount: For any structure where fire resistance is a major concern (like attached garages, or if you want an extra layer of safety for your home), the non-combustible nature of aluminum is a significant benefit.

- You Need a Very Stable, Straight Structure: For projects where maintaining perfect straightness and dimension over decades is critical, aluminum’s stability is unmatched.

- Weight is a Factor: If you’re working on an upper floor, in a tight space, or if labor costs are high, the lighter weight of aluminum can make a big difference in ease of handling and installation speed.

- Commercial or Specialty Building: In environments where durability, hygiene, and resistance to harsh cleaning agents are important (like certain commercial kitchens or labs), aluminum is often the preferred material.

- Sustainability is a Key Goal: If you’re dedicated to using recycled materials and minimizing environmental impact, aluminum’s recyclability is a major plus.

Installation Tips: Wood vs. Aluminum

While both involve similar framing concepts, the installation process has some key differences:

Wood Stud Installation

- Measure and Mark: Measure the space and mark the locations for your studs.

- Cut Studs: Use a miter saw or handsaw to cut wood studs to length.

- Position and Fasten: Place studs in position and nail or screw them to the top and bottom plates.

- Secure to Walls/Floors: Ensure studs are plumb (vertically straight) and then fasten them securely.

- Add Bracing: As needed, add diagonal bracing for extra stability.

Aluminum Stud Installation

- Measure and Mark: Similar to wood, measure and mark your layout.

- Cut Studs: Use a metal-cutting saw (like a portable band saw, chop saw with a metal blade, or even a reciprocating saw) to cut aluminum studs. Always wear safety glasses and hearing protection when cutting metal.

- Position and Fasten: Aluminum studs typically use self-tapping metal screws (often called “tek screws”) to attach them to the metal tracks and to each other. A cordless drill with the correct driver bit is essential.

- Secure to Walls/Floors: Ensure studs are plumb and secure them. You might need specialized anchors for attaching metal studs to concrete or existing structures.

- Consider Thermal Breaks: When attaching to exterior walls or where thermal loss is a concern, use non-metallic shims or specialized thermal break materials between the aluminum and other conductive components.

For a deeper dive into the technical specs and installation guides for metal framing systems, manufacturers like ClarkDietrich Building Systems offer extensive resources, often covering both steel and aluminum products.

Common Beginner Mistakes to Avoid

Whether you choose wood or aluminum, a few common slip-ups can make your life harder. Let’s sidestep them!

With Wood Studs:

- Using Wet Lumber: If wood is still “green” or wet, it will shrink as it dries, potentially causing nails to pop and drywall to crack. Let it acclimate to your building’s environment.

- Not Checking for Plumb: Every single stud must be perfectly vertical (plumb). Use a level! A crooked stud leads to crooked walls, doors that don’t fit, and cabinets that can’t be hung straight.

- Over-Nailing/Screwing: While tempting to add extra fasteners, this can split wood, especially near the ends. Use the recommended number of fasteners.

- Ignoring Spacing Rules: Stick to the prescribed spacing (usually 16 or 24 inches on center) for proper structural support and for easily attaching drywall.

With Aluminum Studs:

- Using the Wrong Fasteners: Regular wood screws won’t work. You need self-tapping metal screws. Using the wrong ones can strip, break, or not hold securely.

- Cutting Without Protection: Metal shavings can be sharp, and the noise from cutting can be loud. Always wear safety glasses, gloves, and hearing protection.

- Forgetting Thermal Bridging: In cold climates, failing to address thermal bridging can lead to condensation and energy loss. Plan for insulation beyond just filling the cavity.

- Trying to Nail into Metal: Metal studs are rigid; you can’t just hammer a nail into them to hang a picture like you can with wood. You’ll need to drill pilot holes and use appropriate screws or anchors.

Frequently Asked Questions (FAQ)

Q1: Can I mix wood and aluminum studs in the same wall?

Generally, it’s not recommended to mix wood and aluminum studs within the same structural framing system in a single wall. Different materials have different expansion/contraction rates and structural behaviors. Sticking to one material per wall ensures consistency and avoids potential joint issues.

Q2: Which is better for soundproofing, wood or aluminum studs?

Wood studs tend to offer slightly better natural sound dampening than bare aluminum studs. However, soundproofing is largely dependent on the entire wall assembly, including insulation type and density (like mineral wool), the number of drywall layers, and the use of acoustic sealants or resilient channels. Both can be made to perform very well with the right details.

Q3: Is it harder to hang cabinets on aluminum studs than wood studs?

It can be, if you’re not prepared. You can’t simply nail or screw into an aluminum stud and expect it to hold heavy weight. You’ll need to locate the exact center of the stud (often by feel or by marking it first) and use specialized metal-to-metal screws or toggle bolts designed for metal studs. Planning the cabinet placement during framing is helpful.

Q4: Which material is more eco-friendly?

This is nuanced. Wood is a renewable resource if harvested sustainably. However, its processing and transport can be energy-intensive. Aluminum is highly energy-intensive to produce from raw ore, but it is also infinitely recyclable and often made from recycled content, which uses far less energy. For a project focused on recycled materials, aluminum wins. For using a renewable resource, well-managed wood is a good choice.

Q5: What kind of insulation works best with aluminum studs?

Standard batt insulation (fiberglass, mineral wool) works well in the cavities of aluminum studs, just like with wood. However, due to thermal bridging, you might consider adding a layer of rigid foam insulation on the exterior of the studs (if building a wall) or interior, or using spray foam to create a better thermal seal. The total R-value of the wall will be affected by the conductive metal.

Q6: Can I use aluminum studs for load-bearing walls?

Yes, absolutely. Aluminum studs are designed with structural integrity in mind and are widely used in commercial construction for load-bearing applications. The load capacity depends on the specific stud gauge, size, and manufacturer’s specifications. Always consult the manufacturer’s load tables or a structural engineer for critical load-bearing applications.