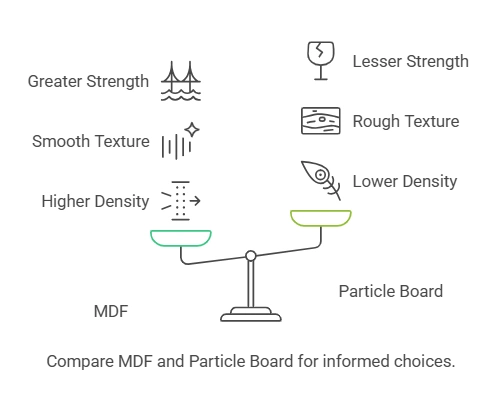

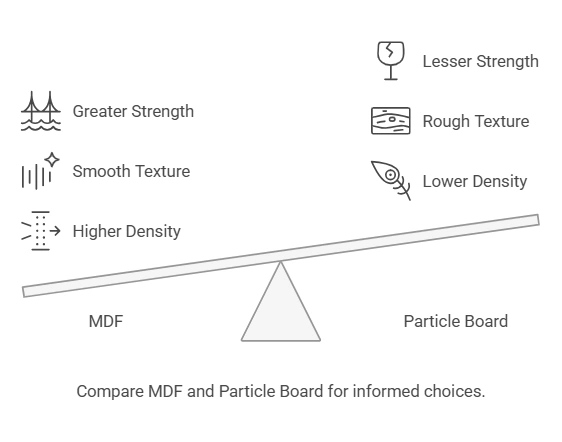

Are MDF and Particle Board the Same? Uncover the Differences

No, MDF and particle board are not the same. They are different materials with distinct properties and uses.

MDF, or Medium Density Fiberboard, is made from fine wood fibers and resin, which are compressed under high pressure. It is smooth, dense, and easy to paint, making it ideal for detailed work. Particle board, on the other hand, is made from wood chips and resin.

It is less dense and more prone to damage. Both materials are popular in furniture making and construction. Understanding their differences can help you choose the right material for your project. In this blog, we will explore the characteristics, benefits, and drawbacks of MDF and particle board. This will help you make an informed decision for your next DIY or professional project.

Introduction To MDF And Particle Board

When diving into the world of woodworking and furniture making, you may come across terms like MDF and Particle Board. If you’ve ever wondered what these materials are and how they differ, you’re not alone. Understanding these materials can help you make the right choices for your projects. Let’s break it down in simple terms.

What Is MDF?

MDF stands for Medium Density Fiberboard. It is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibers. These fibers are then combined with wax and a resin binder, and formed into panels by applying high temperature and pressure.

Here are some key features of MDF:

- Density: As the name suggests, MDF has medium density, making it relatively heavy but very smooth.

- Surface: It has a smooth surface that is easy to paint and finish.

- Strength: MDF is stronger and more durable than particle board.

- Uses: Commonly used in furniture, cabinetry, and decorative projects.

What Is Particle Board?

Particle Board, also known as chipboard, is another type of engineered wood product. It is made by combining wood chips, sawdust, and wood shavings with a synthetic resin or other suitable binder. These materials are then pressed and extruded to form sheets.

Let’s look at some characteristics of Particle Board:

- Density: Particle Board is less dense compared to MDF, making it lighter.

- Surface: It has a rougher surface and is not as smooth as MDF, often requiring a veneer or laminate finish.

- Strength: It is less strong and durable than MDF, making it more prone to damage.

- Uses: Often used in low-cost furniture, underlayment, and flooring.

In essence, while MDF and Particle Board might seem similar at first glance, they have distinct properties that make them suitable for different applications. Choosing between them depends on your specific needs and the demands of your project.

Material Composition

Understanding the material composition of MDF and Particle Board is vital. They are both used in furniture and construction, but they differ. Knowing the components helps in making better choices for your projects.

Components Of MDF

MDF stands for Medium-Density Fiberboard. It is made from wood fibers. These fibers are bonded with wax and resin. High pressure and heat help in this process. MDF has a fine texture. This texture makes it smooth and easy to paint. Hardwood and softwood are used in making MDF. The mix of these woods adds strength to MDF. Formaldehyde resin is often used as a binder. This resin helps in creating a strong bond between fibers.

Components Of Particle Board

Particle Board is made from wood chips and shavings. Sawdust is also a key component. These materials are mixed with resin. Then, they are pressed into flat sheets under heat. Particle Board is less dense than MDF. This makes it lighter. It has a rough texture. The texture does not take paint well. Softwood is mostly used in Particle Board. This makes it less strong than MDF. Urea-formaldehyde resin is commonly used as a binder. This resin is less durable than the one used in MDF.

Manufacturing Process

Ever wondered how MDF and particle board are made? Understanding the manufacturing process of these materials can help you decide which one is best for your next project. Let’s break it down simply and clearly.

How MDF Is Made

MDF, or Medium Density Fiberboard, is made from wood fibers. These fibers are obtained from hardwood and softwood trees. The process starts by breaking down the wood into small pieces. These pieces are then combined with wax and resin. This mixture is subjected to high temperature and pressure, forming it into dense sheets. Here’s a step-by-step look:

- Wood Preparation: Hardwood and softwood are broken down into small wood fibers.

- Mixing: The wood fibers are mixed with wax and resin.

- Forming: The mixture is formed into a sheet using high temperature and pressure.

- Finishing: The sheet is cooled, sanded, and cut to size.

This process results in a smooth, dense, and strong material that is ideal for furniture, cabinetry, and more.

How Particle Board Is Made

Particle board, on the other hand, is made from wood chips, sawdust, and wood shavings. The process is somewhat similar to MDF, but with a few key differences:

- Wood Preparation: Wood chips, sawdust, and shavings are collected.

- Mixing: These particles are mixed with a resin binder.

- Forming: The mixture is spread out into a sheet and pressed under high heat.

- Finishing: The sheet is sanded and cut to size.

While particle board is less dense than MDF, it is more affordable and lightweight. It is commonly used in furniture and flooring where cost-effectiveness is important.

So, are MDF and particle board the same? Not quite! Their manufacturing processes differ, leading to different properties and uses. Understanding these differences can help you make better choices for your DIY projects or home improvements.

Physical Properties

When it comes to woodworking and furniture building, understanding the physical properties of materials is crucial. MDF (Medium Density Fiberboard) and Particle Board are two popular choices. While they may seem similar at first glance, their physical properties can be quite different. Let’s dive into these aspects to help you make an informed decision for your next project.

Density And Weight

The density and weight of a material can greatly influence its use and application. MDF tends to be denser than Particle Board. This is because MDF is made by breaking down hardwood or softwood residuals into wood fibers, and then mixing it with wax and a resin binder. This process results in a heavier and denser board.

On the other hand, Particle Board is made by pressing wood chips, sawmill shavings, or even sawdust together with a synthetic resin. As a result, it’s lighter and less dense. If you need something easy to handle and move around, Particle Board might be the way to go. But, remember, the lighter weight comes with less strength and durability.

Texture And Appearance

When it comes to texture and appearance, MDF and Particle Board also have distinct characteristics. MDF has a smooth and consistent texture. This is because it’s made from very fine wood fibers. It’s almost like the difference between a fine sandpaper and a rough one. The smooth surface of MDF makes it excellent for painting and finishing.

Particle Board, however, has a rougher texture due to the larger wood particles used in its composition. This can make it less ideal for a polished finish. If you’re planning to cover it with a veneer or laminate, this rough texture is less of an issue. But if the final appearance is important, MDF might be the better choice.

In essence, while both MDF and Particle Board have their own sets of advantages and drawbacks, understanding their physical properties can help you choose the right material for your project. Whether it’s the weight, density, or surface texture, each of these factors plays a crucial role in the final outcome of your work.

Strength And Durability

When it comes to choosing materials for your furniture or home projects, understanding the strength and durability of each option is crucial. MDF (Medium-Density Fiberboard) and Particle Board are popular choices, but they have distinct differences in these areas. Let’s dive into the specifics to help you make an informed decision.

Mdf Strength

MDF is known for its superior strength compared to Particle Board. It is made from wood fibers glued together under high pressure and temperature, resulting in a dense and robust material. This process gives MDF its uniformity, making it less likely to crack or split.

- Density: MDF is denser than Particle Board, making it stronger and more durable.

- Smooth Surface: The smooth surface of MDF is perfect for painting and finishing, giving your projects a polished look.

- Load-Bearing Capacity: MDF can handle more weight, making it ideal for shelves, cabinets, and other furniture pieces that need to support heavy items.

However, MDF is not without its downsides. It is susceptible to moisture, which can cause it to swell and deteriorate over time. So, while it’s strong, it’s best used in dry environments.

Particle Board Strength

Particle Board, on the other hand, is made from wood chips and sawdust bonded together with resin. This makes it less dense and less strong than MDF. But don’t write it off just yet!

- Cost-Effective: Particle Board is cheaper than MDF, making it a budget-friendly option.

- Lightweight: It is lighter than MDF, which can be advantageous for certain projects where weight is a concern.

- Ease of Use: Due to its lighter weight, Particle Board is easier to handle and transport.

While Particle Board is not as strong as MDF, it can still be a good choice for low-stress applications like interior furniture or flat-packed units. It’s important to avoid exposing it to moisture, as it can absorb water and weaken.

In conclusion, both MDF and Particle Board have their unique strengths and weaknesses. Your choice should depend on the specific needs of your project. Need something strong and smooth? Go for MDF. On a budget and looking for something lightweight? Particle Board might be your answer. Happy building!

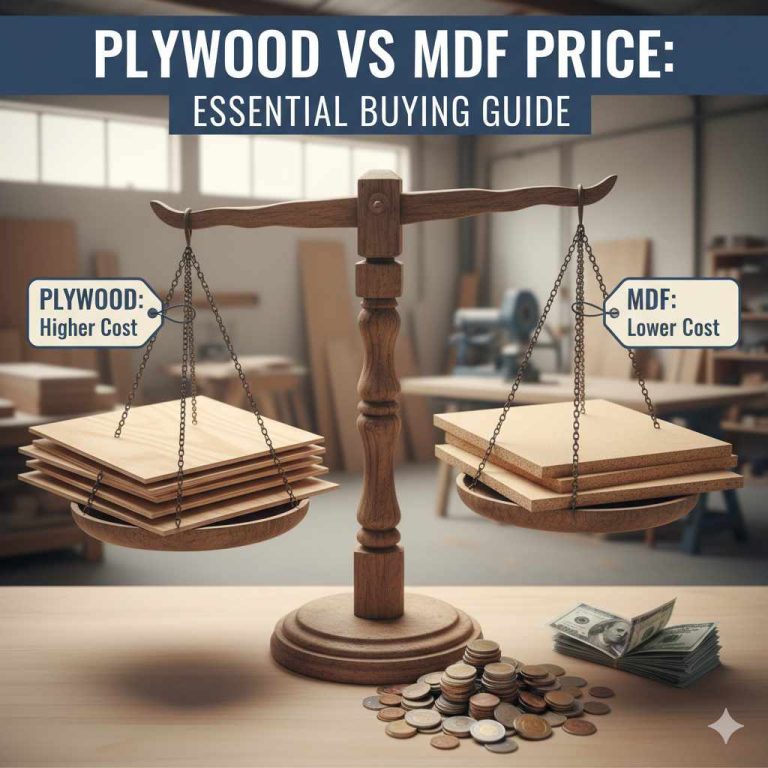

Cost Comparison

When it comes to choosing between MDF (Medium-Density Fiberboard) and particle board, one of the most significant factors to consider is the cost. Both materials are popular choices for furniture and cabinetry, but how do they stack up in terms of price? Let’s delve into a detailed cost comparison to help you make an informed decision.

Price Of MDF

MDF is a popular choice for many projects due to its smooth surface and versatility. But what about its price tag? Generally, MDF is more expensive than particle board. The cost of MDF can vary depending on the thickness and quality, but you can expect to pay anywhere from $30 to $60 per sheet. Here’s a quick breakdown:

- 1/4-inch thick MDF: Approximately $30 per sheet

- 1/2-inch thick MDF: Around $40 per sheet

- 3/4-inch thick MDF: About $50 to $60 per sheet

In essence, if you’re working on a budget, MDF might not be the most cost-effective option. However, its durability and smooth finish often justify the higher price.

Price Of Particle Board

On the other hand, particle board is typically more budget-friendly. It’s made from wood chips, sawdust, and resin, which makes it less expensive to produce. The price of particle board usually ranges from $10 to $30 per sheet. Let’s break it down:

- 1/4-inch thick particle board: Around $10 per sheet

- 1/2-inch thick particle board: Approximately $20 per sheet

- 3/4-inch thick particle board: About $25 to $30 per sheet

So, if you’re looking to save some money, particle board could be the way to go. It’s a great option for projects where cost is a critical factor, but remember, you might be compromising on quality and durability.

In conclusion, while MDF tends to be pricier, its quality and finish might make it worth the extra bucks. Particle board, being more affordable, is ideal for budget-conscious projects. Weigh your options carefully, keeping in mind both your budget and the demands of your project.

Common Uses

Understanding the common uses of MDF (Medium Density Fiberboard) and particle board can help you choose the right material for your project. While both are engineered wood products, they serve different purposes based on their properties. Let’s explore where each material shines.

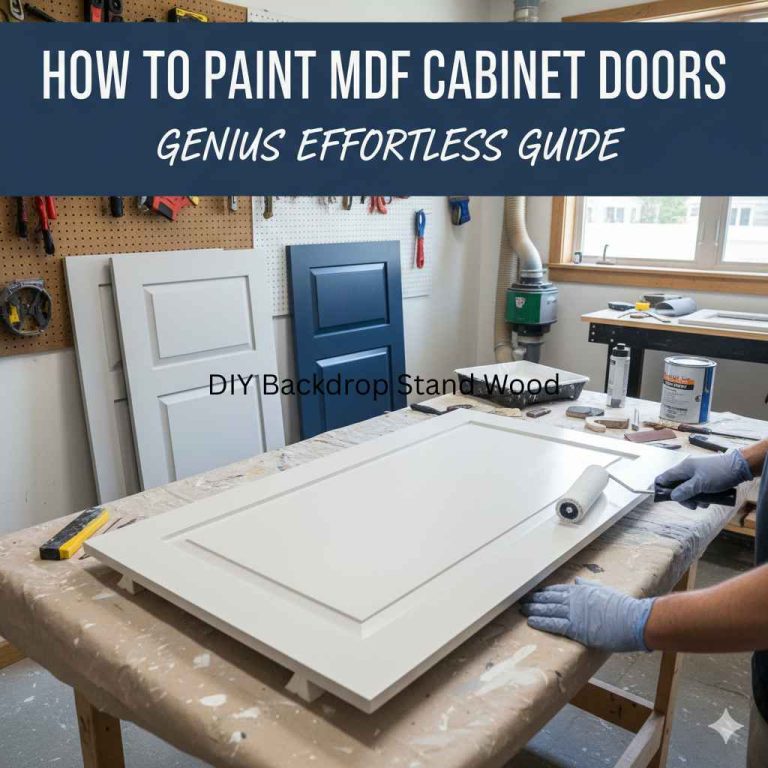

Applications For MDF

MDF is a versatile material used in various applications. It is commonly used for making furniture. Its smooth surface allows for easy painting and finishing. MDF is also used for creating cabinets and shelves. It is strong and can hold weight well. Many people use MDF for decorative projects like molding and trim. It can be easily cut and shaped.

Another common use of MDF is in speaker boxes. Its dense structure helps produce better sound quality. MDF is also a popular choice for making doors. It provides a smooth surface that can be painted or veneered. Overall, MDF is a good choice for projects that need a smooth and strong material.

Applications For Particle Board

Particle board is often used in budget-friendly furniture. It is lighter and cheaper than MDF. Many ready-to-assemble furniture pieces use particle board. It is also used for countertops. A laminate coating is added for durability. Particle board is good for temporary or low-cost projects.

Another use for particle board is in flooring underlayment. It provides a smooth base for carpets and other flooring materials. Some people use particle board for shelving. It works well for light to medium loads. Particle board is also used in packaging and shipping crates. Its lower cost makes it a practical choice for disposable items.

In summary, particle board is best for low-cost, lightweight projects. Choose MDF for a smoother finish and stronger structure.

Pros And Cons

Choosing the right material for your project can be challenging. MDF (Medium Density Fiberboard) and Particle Board are popular choices in furniture and construction. But are they the same? Let’s explore the pros and cons of each material to help you make an informed decision.

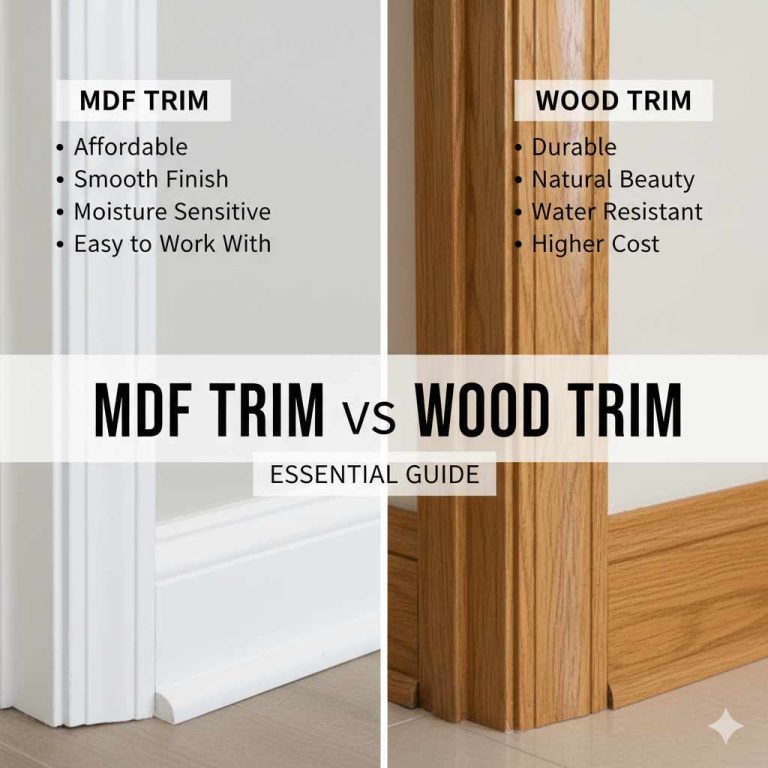

Advantages Of MDF

MDF has several benefits that make it a favorite among builders and DIY enthusiasts:

- Consistency: MDF has a smooth and even surface, perfect for painting and finishing.

- Strength: It is stronger than particle board and less likely to crack.

- Versatility: MDF can be easily cut, drilled, and shaped without splintering.

Disadvantages Of MDF

Despite its advantages, MDF has some drawbacks:

- Heavy: MDF is denser and heavier than particle board, making it harder to handle.

- Water Damage: It is highly susceptible to water damage and swelling.

- Cost: MDF is generally more expensive than particle board.

Advantages Of Particle Board

Particle board has its own set of strengths:

- Cost-Effective: It’s cheaper than MDF, making it ideal for budget projects.

- Lightweight: Particle board is lighter, which makes it easier to transport and work with.

- Eco-Friendly: Made from recycled wood waste, it’s an environmentally friendly option.

Disadvantages Of Particle Board

On the flip side, particle board has some limitations:

- Durability: It is less durable and more prone to damage compared to MDF.

- Appearance: The surface is rougher and less attractive, often requiring a veneer or laminate.

- Moisture Sensitivity: Like MDF, it doesn’t handle moisture well and can swell or disintegrate.

Environmental Impact

Understanding the environmental impact of MDF and particle board is crucial. Both materials are popular in furniture and construction. But how do they affect the environment? Let’s explore their sustainability aspects.

Sustainability Of MDF

MDF, or Medium Density Fiberboard, is made from wood fibers. It often uses wood waste, which reduces the need for new trees. This helps in conserving forests. MDF manufacturing involves adhesives that can release formaldehyde. Newer processes use low-emission adhesives, making MDF more eco-friendly. Recycling MDF is challenging due to the glue. But, newer methods are improving recyclability.

Sustainability Of Particle Board

Particle board uses wood chips and sawdust. This repurposes waste, saving more trees. Its production uses less energy compared to solid wood. Particle board also uses formaldehyde-based adhesives. Manufacturers are shifting to safer, low-emission options. Particle board is easier to recycle than MDF. Its components can be reused in various products.

Frequently Asked Questions

Which Is Better MDF Or Particle Board?

MDF is denser and smoother than particle board, making it better for painting and detailed work. Particle board is cheaper and lighter, suitable for budget-friendly furniture. Choose based on your project’s needs and budget.

When Should You Not Use MDF?

Avoid using MDF in high-moisture areas like bathrooms or kitchens. It’s unsuitable for outdoor use due to moisture sensitivity. High-load bearing applications are not ideal for MDF. It can easily get damaged or chipped, making it unsuitable for high-impact environments.

Avoid using MDF where strong joints are required.

What Is A Particle Board Called Now?

Particle board is now commonly called chipboard or low-density fiberboard (LDF). It is widely used in furniture.

What Is The Biggest Drawback Of Using MDF?

The biggest drawback of using MDF is its susceptibility to moisture. It can swell and warp when exposed to water.

Conclusion

MDF and particle board are not the same. MDF is denser and smoother. Particle board is cheaper but less durable. Choose MDF for furniture and cabinets. Use particle board for temporary or low-cost projects. Both materials have their unique benefits.

Consider your project needs before deciding. Knowing the differences helps make better choices.