Best Parts for a Ryobi Table Saw: Complete Guide

Finding the right parts for your Ryobi table saw can sometimes feel a little tricky, especially if you’re just starting out. Lots of different models exist, and knowing which blade fits or what accessory will work best can get confusing. But don’t worry!

This guide is here to make it super simple. We’ll walk through everything step-by-step so you can easily find the Best Parts for a Ryobi Table Saw: Complete Guide. Let’s get your saw ready for action.

Choosing the Best Parts for Your Ryobi Table Saw

Selecting the right parts for your Ryobi table saw is important for safety, performance, and getting the most out of your tool. Whether you need a new blade, a miter gauge, or safety accessories, the correct components ensure your saw operates efficiently and accurately. This section focuses on identifying the essential parts and understanding their role in your woodworking projects.

We will cover how to identify compatible parts and what to look for in terms of quality and function.

Ryobi Table Saw Blades

The blade is the heart of your table saw. Choosing the right one can dramatically affect the quality of your cuts. Ryobi table saws typically use standard 10-inch blades.

However, the number of teeth, the tooth material, and the blade’s design all play a role in how it performs. A blade with more teeth will give you a smoother cut, ideal for fine woodworking. A blade with fewer teeth can cut through material faster, which is good for rougher jobs.

Always check your saw’s manual to confirm the exact blade specifications it accepts.

- Carbide-Tipped Blades

A carbide-tipped blade offers superior durability and sharpness compared to standard steel blades. The carbide tips are brazed onto the steel blade. This means they stay sharp for much longer, reducing the frequency of blade changes and ensuring cleaner cuts over time. They are excellent for cutting a wide range of woods, from softwoods to hardwoods. The hardness of carbide also makes it more resistant to heat buildup, which can cause blade warping. - Number of Teeth (TPI)

The teeth per inch, or TPI, on a table saw blade is a key indicator of its cutting performance. Blades with a higher TPI, like 60 or 80 teeth, produce very smooth cuts. These are perfect for situations where the finish is critical, such as making trim or cabinet parts. Blades with lower TPI, often around 24 to 40 teeth, are designed for faster material removal. They are better suited for ripping large lumber where speed is more important than a perfectly smooth surface. - Blade Types

Different blades are designed for specific tasks. Rip blades have fewer, larger teeth for cutting with the grain of the wood. Crosscut blades have more teeth that are angled differently for cutting across the grain. Combination blades offer a balance, allowing for both ripping and crosscutting, making them a versatile choice for general woodworking. For Ryobi table saws, finding a good quality combination blade is often the most practical option for a variety of projects. - For example, a woodworker needing to make precise cabinet doors might opt for an 80-tooth thin kerf blade for a clean, splinter-free cut. On the other hand, someone building a workbench might choose a 40-tooth rip blade to quickly cut through 2x4s. The choice directly impacts the time spent sanding and the overall quality of the finished piece.

Dado Blades and Setup

Dado blades are specialized cutting heads that create grooves or channels in wood. They are essential for tasks like cutting dados for shelves, rabbets for joining boards, or tenons for furniture making. A dado blade set typically includes multiple blades and chippers.

These pieces can be arranged to create different widths of grooves. For Ryobi table saws, it is crucial to check the saw’s specifications to ensure it can accommodate a dado blade set and the depth of cut required. Some smaller saws may have limitations on dado blade width.

- Dado Set Components

A standard dado set includes two outside blades, several chippers, and shims. The outside blades make the initial cuts, while the chippers are placed between them. Each chipper removes a specific width of wood. Shims are thin pieces of metal used to fine-tune the width of the dado for a perfect fit. Arranging these components allows for precise groove widths, from a narrow 1/4 inch up to 1 inch or more, depending on the set. - Safety Considerations for Dado Blades

Working with dado blades requires extra attention to safety. The wider cutting surface creates more dust. Always use a dust collection system. Ensure the blade guard can be reattached or removed safely according to the manufacturer’s instructions for dado use. Using a push stick and ensuring the workpiece is held firmly against the fence and the table are also critical to prevent kickback. - Ryobi Saw Compatibility

Not all Ryobi table saws are designed to accept dado blades. Check your saw’s manual or the manufacturer’s website for compatibility information. If your saw is compatible, it will usually require a specific type of arbor or motor that can handle the load of a dado blade. Even if compatible, there might be a maximum width that the saw can safely cut with a dado set.

A carpenter might use a dado blade set to create strong, traditional joinery for a bookshelf. By cutting a 1/2-inch dado, they can slide shelves directly into the side panels, creating a sturdy and attractive piece of furniture. This method eliminates the need for screws or glue in some areas, resulting in a cleaner look.

Table Saw Fences and Guides

The fence is a critical component of any table saw, acting as a guide for rip cuts. It ensures that your cuts are parallel to the blade, leading to consistent and accurate results. Ryobi table saws come with a basic fence, but upgrades can significantly improve precision and ease of use.

A good fence should be parallel to the blade, move smoothly, and lock securely in place.

- Types of Fences

Ryobi table saws often feature a T-square style fence. These are generally robust and easy to adjust. Some models may have a more basic Biesemeyer-style fence, known for its precision and stability. Aftermarket fences are also available that offer enhanced features like micro-adjustments, increased length, or better rigidity for heavy-duty use. - Alignment and Calibration

Proper alignment of the fence with the blade is crucial. A fence that is not parallel can cause binding, leading to kickback or inaccurate cuts. Most Ryobi fences have adjustment screws that allow you to fine-tune their alignment. It is recommended to check and adjust the fence alignment periodically, especially after moving the saw or experiencing any unusual cutting behavior. A simple test is to measure the distance from the fence to the front of the blade, and then to the back of the blade. These measurements should be identical. - Miter Gauges and Crosscuts

While fences are for rip cuts, miter gauges are essential for crosscuts. A good miter gauge slides smoothly in the miter slots on the table saw and has adjustable heads to set precise angles. Some Ryobi saws come with basic miter gauges, but upgrading to a high-quality, precision-miter gauge can greatly improve the accuracy of your crosscuts and angled cuts. Look for one with clear angle markings and a solid construction. - Imagine cutting multiple identical pieces of trim for a home renovation. With a precisely aligned fence on your Ryobi table saw, you can make numerous rip cuts, knowing each piece will be the exact same width. This saves time and ensures a professional finish, as all the pieces will fit together seamlessly.

Safety Accessories for Ryobi Table Saws

Safety is paramount when operating any power tool, and a table saw is no exception. Investing in good safety accessories for your Ryobi table saw is a wise decision. These accessories help protect you from kickback, flying debris, and accidental contact with the blade.

They are designed to work with your saw to create a safer working environment.

- Blade Guards and Riving Knives

Most Ryobi table saws come with a blade guard that covers the top of the blade. This guard often includes a dust collection port and a splitter or riving knife. A riving knife is a metal plate that follows the blade and prevents the kerf from closing, which is a primary cause of kickback. It is crucial to ensure your riving knife is properly aligned with the blade and is the correct thickness for your blade. - Push Sticks and Push Blocks

These simple tools are vital for keeping your hands away from the blade. A push stick is used for guiding smaller pieces of wood past the blade. A push block provides downward pressure on the workpiece, helping to keep it flat on the table and against the fence. They are inexpensive but can prevent serious injuries. Always have several of both readily accessible when using your table saw. - Eye Protection and Hearing Protection

Always wear safety glasses or goggles when operating a table saw. Wood chips, dust, and small pieces of wood can fly at high speeds. Similarly, table saws are loud machines. Wearing earplugs or earmuffs will protect your hearing from permanent damage. These are fundamental safety measures that should never be skipped. - Dust Collection Systems

Table saws generate a significant amount of sawdust. Breathing in fine wood dust can be harmful to your lungs over time. Connecting your Ryobi table saw to a dust collection system, even a shop vacuum, can significantly reduce the amount of airborne dust. This not only protects your health but also helps keep your workspace cleaner.

Consider a scenario where you are ripping a long board. Without a push stick, your hands might get too close to the blade as you near the end. Using a push stick allows you to safely guide the remaining piece through the blade, preventing injury.

This simple act can make the difference between a safe operation and a trip to the emergency room.

Upgrades and Enhancements for Ryobi Table Saws

While Ryobi table saws are excellent for many DIY and hobbyist projects, there are always ways to enhance their performance. Upgrades can turn a good saw into a great one, offering increased precision, versatility, and efficiency. These enhancements can range from simple modifications to more significant component replacements.

- Aftermarket Table Inserts

The insert plate that surrounds the blade on your table saw can be upgraded. Aftermarket inserts made from materials like phenolic or aluminum can offer better flatness and durability. Some are designed to be zero-clearance, meaning they have a very tight fit around the blade. This helps prevent small wood pieces from falling into the saw’s internals and can improve dust collection efficiency and prevent tear-out. - Mobile Base Systems

Many Ryobi table saws, especially benchtop models, can be heavy and cumbersome to move. A mobile base system, often a wheeled platform that attaches to the saw’s legs, allows you to easily relocate the saw around your workshop. This is incredibly useful for smaller spaces or for organizing your shop layout. Look for a sturdy base that can support the weight of your saw and remain stable during operation. - Upgraded Fences and Miter Gauges

As mentioned earlier, upgrading your fence and miter gauge can dramatically improve accuracy. While the stock components are functional, higher-quality aftermarket versions offer better precision, easier adjustments, and greater stability. A precision-ground fence can ensure your rip cuts are dead-on every time, and a robust miter gauge will make your crosscuts far more accurate and repeatable. - Router Table Insert Plates

Some table saw models can be adapted to include a router table insert. This effectively turns your table saw into a dual-purpose tool, adding the functionality of a router table to your workshop without needing a separate machine. These inserts typically have openings to accept various router mounting plates.

A hobbyist looking to tackle more complex furniture projects might invest in a zero-clearance insert and a better fence for their Ryobi table saw. This combination can improve cut quality, reduce tear-out on delicate hardwoods, and make repeatable cuts for joinery much more accurate. The result is a higher level of craftsmanship from their existing tool.

| Part Category | Standard Ryobi Part | Potential Upgrade | Benefit of Upgrade |

|---|---|---|---|

| Blade | Basic 10-inch blade | Carbide-tipped 60-80 tooth combination blade | Smoother cuts, longer life, less tear-out |

| Fence | Standard T-square fence | Biesemeyer-style or aftermarket precision fence | Improved accuracy, stability, and ease of adjustment |

| Miter Gauge | Basic plastic miter gauge | Precision aluminum miter gauge with positive stops | More accurate and repeatable angled crosscuts |

| Mobility | Stationary or basic stand | Wheeled mobile base system | Easy repositioning of the saw in the workshop |

| Dust Collection | Basic dust port | Integrated dust collection system or shop vac hookup | Cleaner air, healthier working environment |

Understanding Ryobi Table Saw Model Differences

Ryobi offers various table saw models, each with its own set of features and specifications. Understanding these differences is key to selecting the correct replacement parts and accessories. From portable jobsite saws to larger workshop models, the design and capabilities can vary significantly.

This section will help you identify your specific Ryobi table saw model and understand what parts are likely to fit.

Identifying Your Ryobi Table Saw Model Number

The first step to finding the right parts is to know your exact Ryobi table saw model number. This number is usually found on a label or plate located on the saw itself. Common locations include the base of the saw, the side panel, or near the motor housing.

The model number often starts with “R” followed by a series of numbers and letters, for example, R2740 or BTS100.

- Location of the Model Number

Always check the body of the saw for a manufacturer’s sticker. This sticker contains essential information like the model number, serial number, and voltage requirements. Sometimes, this information might be stamped directly into the metal casing. If you’ve lost the manual, this label is your best reference for ordering parts. - Reading the Model Number

Model numbers can sometimes be confusing. Take your time to write it down accurately. Ensure you note any letters or hyphens, as these are important for identifying the correct version of the saw. Comparing this number to online part diagrams or retailer listings will help ensure compatibility. - Online Resources for Model Identification

If you are still having trouble identifying your model, Ryobi’s official website often has a support section where you can search for your saw based on its appearance or general description. They also typically have downloadable manuals for most of their products. Many online retailers also provide tools to help you find parts based on your model number.

For instance, if you own a Ryobi R2740, knowing this specific number is vital. A part designed for a Ryobi BTS100 might not fit the R2740 due to differences in the saw’s dimensions, mounting points, or internal mechanisms. Accurate identification prevents the frustration and cost of purchasing incompatible parts.

Common Ryobi Table Saw Models and Their Parts

Ryobi has produced several popular table saw models over the years, each catering to different user needs. Some common models include the R2740, the BTS100, and various JobPlus base systems that include a table saw attachment. Each model might share some common parts, but critical components like the motor, trunnions (which support the blade assembly), and fence systems can be unique.

- Ryobi R2740

This is a common benchtop table saw model. Parts like - Ryobi BTS100

Another popular benchtop or portable model. Similar to the R2740, standard accessories like blades and push sticks will fit. However, its table insert, blade guard assembly, and potentially the motor might differ, requiring model-specific parts. Always cross-reference part numbers to be certain. - Ryobi JobPlus Base with Table Saw Attachment

This is a modular system. The table saw attachment uses a specific blade and often has a unique mounting mechanism for its fence and other accessories. Parts for this attachment are usually sold separately from the base unit. You’ll need to identify the table saw attachment part of the JobPlus system specifically.

When searching for a replacement belt for your Ryobi BTS100, you need to ensure the belt’s length, width, and tooth profile match the original. Using a belt of the wrong size can lead to slippage, inefficient power transfer, or even damage to the motor or arbor. This level of detail is why knowing the precise model number is essential for ordering.

Where to Buy Ryobi Table Saw Parts

Finding reliable sources for Ryobi table saw parts is crucial. You want to ensure you are getting genuine or high-quality aftermarket parts that will fit correctly and perform as expected. Several options are available, ranging from the manufacturer’s direct channels to specialized online retailers.

- Ryobi Official Website and Service Centers

The most straightforward way to get genuine Ryobi parts is through their official website or authorized service centers. This guarantees that the parts are designed specifically for your model. You can often find part diagrams and order directly, which is the safest bet for critical components like motors or trunnions. - Online Retailers Specializing in Power Tool Parts

Many online stores focus specifically on selling replacement parts for power tools from various brands, including Ryobi. These sites often have extensive catalogs and search functions that make finding parts by model number easy. Examples include ereplacementparts.com or Toolparts.com. They may offer both OEM (Original Equipment Manufacturer) parts and compatible aftermarket options. - General Online Marketplaces

Platforms like Amazon or eBay can also be good sources for parts. However, be cautious. Ensure the seller is reputable and clearly states compatibility with your specific Ryobi table saw model. Always read reviews and check the seller’s return policy. Generic accessories like blades or push sticks are widely available, but specialized internal parts might be harder to verify. - Local Authorized Dealers

Some hardware stores or tool repair shops are authorized Ryobi dealers. They can often order parts for you or may stock common wear-and-tear items. Visiting a local dealer can be helpful if you need advice or want to see a part before purchasing.

For a critical part like a trunnion for a Ryobi R2740, ordering directly from the Ryobi website or a reputable parts specialist is advisable. These are complex components that are integral to the saw’s alignment and stability. Purchasing from an unknown seller on a general marketplace might result in receiving a poorly made replica that could compromise your saw’s performance and safety.

Maintenance and Replacement of Key Parts

Regular maintenance and timely replacement of worn-out parts are essential for keeping your Ryobi table saw running smoothly and safely. This section will guide you through the common maintenance tasks and help you recognize when a part needs to be replaced. Proper care extends the life of your saw and ensures consistent, accurate results.

Blade Changing and Cleaning

Changing the blade on your Ryobi table saw is a fundamental maintenance task. This should be done whenever a blade becomes dull, damaged, or when you need to switch to a blade for a different type of cut. Always unplug the saw before changing the blade.

- Unplugging the Saw

This is the most critical safety step. Ensure the power cord is completely disconnected from the electrical outlet before you attempt to touch the blade or any part of the blade assembly. This prevents accidental startup. - Accessing the Blade Arbor

Most Ryobi table saws have a mechanism to access the blade arbor, usually by removing the table insert or a portion of the table itself. You may need to loosen set screws or lift a shroud. Consult your owner’s manual for the specific procedure for your model. - Removing the Old Blade

The blade is typically held in place by an arbor nut and washer. You will need a wrench to hold the arbor still (often by inserting a pin or using a specific wrench) while you loosen the nut. The nut is usually threaded clockwise to loosen, but always double-check your manual. Remove the nut, washer, and then the blade. - Cleaning the Arbor and New Blade

Before installing a new blade, clean any sawdust or debris from the arbor shaft and the inside of the blade collar. Inspect the new blade for any defects. Ensure it is installed with the teeth pointing in the correct direction of rotation (usually indicated by an arrow on the blade and the saw’s housing). - Installing the New Blade and Tightening the Nut

Place the new blade on the arbor, followed by the washer and the arbor nut. Tighten the nut securely, again holding the arbor stationary. Do not overtighten, but ensure it is snug. Reinstall any removed parts like the table insert.

A dull blade on a Ryobi BTS100 can lead to slow cuts, excessive heat buildup, and splintering. Replacing it with a sharp combination blade might take five minutes but can save you an hour of sanding and frustration on your project.

Motor and Belt Maintenance

The motor is the powerhouse of your Ryobi table saw, and the belt transfers its power to the blade. Keeping these components in good condition ensures optimal performance.

- Inspecting the Drive Belt

Periodically inspect the drive belt for signs of wear, such as cracking, fraying, or glazing (a smooth, shiny surface). A worn belt can slip, reducing power to the blade and causing inefficient cuts. Most Ryobi benchtop saws have an accessible belt guard. - Replacing the Drive Belt

If the belt shows signs of wear, it should be replaced. This usually involves removing the belt guard, loosening the tension (if applicable on your model), sliding off the old belt, and installing the new one. Ensure the new belt is the correct size and type for your Ryobi saw model. - Motor Brushes (if applicable)

Some Ryobi table saw motors use carbon brushes. These brushes wear down over time and will eventually need replacement. If your saw starts to lose power or the motor sounds unusual, worn brushes might be the cause. Replacing motor brushes is often a repair that can be done by the user, but always consult your manual and ensure the saw is unplugged. - Keeping the Motor Vents Clear

Ensure that the vents on the motor housing are kept clear of dust and debris. Blocked vents can lead to the motor overheating, which can shorten its lifespan. Use compressed air or a brush to clean them regularly.

A common issue with some older Ryobi benchtop models is a stretched or worn drive belt. This leads to the blade slowing down significantly when it encounters resistance during a cut. Replacing this belt with a new, correctly sized one will restore the saw’s cutting power.

Lubrication and Cleaning

Proper lubrication and regular cleaning are vital for the longevity and smooth operation of your Ryobi table saw. This applies to moving parts like the trunnions, fence rails, and height adjustment mechanisms.

- Lubricating Moving Parts

Use a light machine oil or a spray lubricant designed for tools to lubricate parts like the arbor shaft (where the blade mounts), the mechanisms for raising and lowering the blade, and the fence rails. Apply sparingly and wipe away any excess. Over-lubrication can attract dust and create a mess. - Cleaning the Table Surface

Keep the table surface clean and free of sawdust, glue, or other residue. A clean surface allows wood to slide smoothly and helps maintain accuracy. You can use a damp cloth or a mild cleaning agent. Avoid abrasive cleaners that could damage the finish. - Cleaning Under the Table

Don’t forget to clean the area underneath the table where dust and debris tend to accumulate. This includes the blade housing and the trunnions. Keeping this area clean improves dust collection and allows the height adjustment mechanism to move freely. - Checking Alignment Points

Periodically check the alignment of the blade to the miter slots and the fence to the blade. If you notice any issues, adjustments can often be made using screws accessible on the saw’s frame or trunnions. Refer to your manual for specific alignment procedures.

A Ryobi table saw with stiff height adjustment or a fence that doesn’t glide smoothly is often suffering from a lack of lubrication and accumulated dust. A thorough cleaning and a light application of oil can make a world of difference, returning the saw to its intended smooth operation.

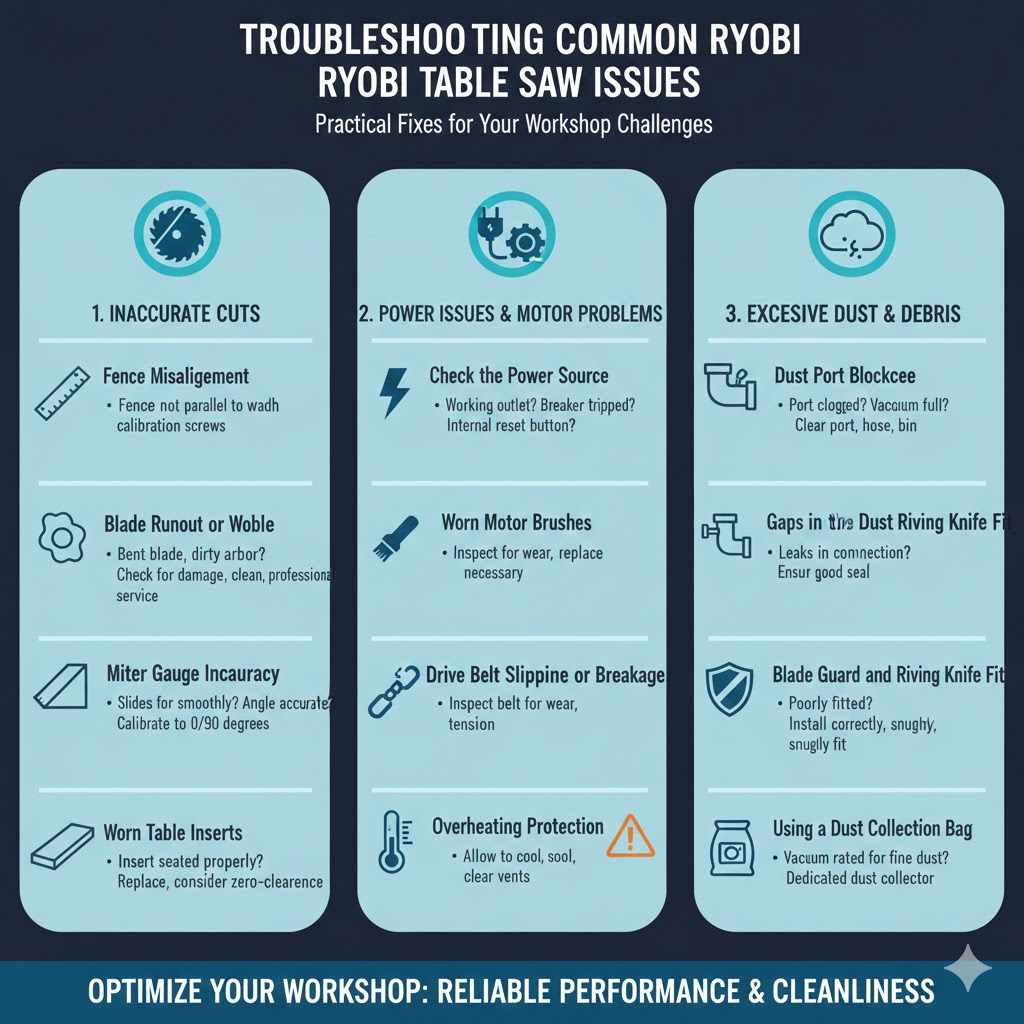

Troubleshooting Common Ryobi Table Saw Issues

Even with regular maintenance, you might encounter issues with your Ryobi table saw. Understanding common problems and their solutions can save you time and prevent minor issues from becoming major ones. This section addresses frequent challenges users face with their Ryobi table saws and provides practical fixes.

Inaccurate Cuts

Inaccurate cuts are one of the most frustrating problems. This can manifest as cuts that are not square, parallel, or at the desired angle. The causes are usually related to alignment issues or worn components.

- Fence Misalignment

The most common culprit for inaccurate rip cuts is a fence that is not parallel to the blade. Measure the distance from the fence to the blade at the front and back of the saw. If they differ, adjust the fence using the calibration screws on your Ryobi saw. - Blade Runout or Wobble

If the blade itself is not spinning true, your cuts will be off. This can be due to a bent blade, a dirty arbor, or loose arbor bearings. Inspect the blade for damage and ensure the arbor is clean. If the arbor bearings are suspected, this may require professional service. - Miter Gauge Inaccuracy

For inaccurate crosscuts, check your miter gauge. Ensure it slides smoothly in the miter slot and that its angle setting is accurate. Many miter gauges have a calibration screw that can be adjusted to set the gauge precisely to 0 or 90 degrees. - Worn Table Inserts

A poorly fitting or worn table insert can cause the wood to shift during a cut, leading to inaccuracies. Ensure your insert is seated properly and is not damaged. Consider a zero-clearance insert for better support.

A user might notice their rip cuts are consistently slightly angled, making it hard to assemble square boxes. After checking, they find the fence is not perfectly parallel to the blade. A few turns of the adjustment screws on the fence bracket quickly resolve this, resulting in perfectly square cuts.

Power Issues and Motor Problems

If your Ryobi table saw is not starting, or if the motor is struggling, there are several potential causes. These issues often relate to power supply, the motor itself, or the drive system.

- Check the Power Source

Ensure the saw is plugged into a working outlet and that the circuit breaker has not tripped. For some Ryobi models, especially those with soft-start features, there might be an internal power switch or reset button that needs to be engaged. - Worn Motor Brushes

As mentioned in the maintenance section, worn motor brushes can cause the motor to run weakly or not at all. If your saw has brushes, inspect them for wear and replace them if necessary. - Drive Belt Slippage or Breakage

A loose or broken drive belt will prevent power from reaching the blade. Inspect the belt for wear and proper tension. If it’s broken, - Overheating Protection

Many Ryobi saws have thermal overload protection. If the motor overheats due to heavy use or blocked vents, it will shut off. Allow the saw to cool down completely before attempting to restart it. Ensure the vents are clear. - A common scenario is a Ryobi table saw that suddenly stops during a demanding cut. This is often the thermal overload protector engaging. After a few minutes of cooling and clearing the dust collection port (which might have been contributing to the overload), the saw can be restarted for lighter duty.

Excessive Dust and Debris

Table saws are notorious for producing a lot of dust. While some dust is unavoidable, excessive amounts can be a sign of poor dust collection setup or leaks in the system.

- Dust Port Blockage

The dust port on your Ryobi saw can become clogged with sawdust. Ensure it is clear, and if you are using a shop vacuum, check that its hose and collection bin are also not full or blocked. - Gaps in the Dust Collection System

Check for any gaps or leaks in the connection between the saw, any dust chute, and your vacuum or dust collector. A good seal is crucial for effective dust removal. - Blade Guard and Riving Knife Fit

A poorly fitted blade guard or riving knife can allow dust to escape into the air rather than being directed towards the dust port. Ensure these components are correctly installed and snugly fit. - Using a Dust Collection Bag

For smaller Ryobi saws, connecting to a shop vacuum is common. Ensure the vacuum is rated for fine dust and has a good filter. For larger saws or a more dedicated setup, consider a dedicated dust collector with a bag or canister.

If your workshop becomes covered in a thick layer of sawdust after only a few minutes of operation, it’s a clear sign that your dust collection system isn’t working efficiently. Checking and clearing the dust port on the saw and the hose connected to your shop vac is a good first step to improving this.

The Importance of the Best Parts for a Ryobi Table Saw: Complete Guide

Understanding all the nuances of the Best Parts for a Ryobi Table Saw: Complete Guide can seem overwhelming at first. Many beginners find it challenging to know which components are essential, what specifications to look for, and how to ensure they are compatible with their specific Ryobi model. This comprehensive resource aims to simplify that process.

By breaking down each component and offering clear advice, we empower you to make informed decisions about the parts you need for your table saw. From blades and fences to safety features and upgrade options, this guide covers it all.

Frequently Asked Questions

Question: What is the most common type of blade replacement for a Ryobi table saw

Answer: The most common blade

Question: How often should I replace the drive belt on my Ryobi table saw

Answer: You should inspect the drive belt periodically, perhaps every few months, or if you notice any signs of wear like cracking, fraying, or glazing. If the belt appears worn or damaged, it should be replaced immediately to prevent power loss or potential damage to other parts.

Question: Can I use a dado blade set on any Ryobi table saw

Answer: No, not all Ryobi table saws are designed to accept dado blades. You must check your specific model’s manual or the Ryobi website for compatibility. Some smaller or portable models may not have the motor power or blade arbor capacity for dado sets.

Question: Where can I find specific part numbers for my Ryobi table saw

Answer: The best place to find specific part numbers for your Ryobi table saw is on the manufacturer’s official website, often in their support or parts section. You can also usually find this information on the label or plate attached to your saw itself, which will list the model number.

Question: What should I do if my Ryobi table saw is making a lot of noise

Answer: Excessive noise can indicate several issues, including worn motor brushes, a loose or damaged drive belt, or worn bearings in the arbor or motor. It’s also possible for debris to be caught in the blade assembly. Always unplug the saw and inspect these components carefully, cleaning any debris and checking for wear.

Conclusion

Finding the best parts for your Ryobi table saw is achievable with the right information. This guide covers blades, fences, safety gear, and model-specific considerations. By understanding your saw’s needs and knowing where to find reliable parts, you ensure optimal performance and safety.

Keep your Ryobi saw in top condition for all your projects.