Best Pressure Treated Wood Stain Long Lasting Color

Picking the right stain for your pressure treated wood can feel tricky, especially when you want the color to last a long time. So many options are out there, and it’s hard to know where to start. Don’t worry!

We’ll make it super simple. This guide will walk you through everything, step-by-step, so you can get that beautiful, lasting color for your wood.

Choosing the Best Pressure Treated Wood Stain for Long-Lasting Color

When it comes to protecting and beautifying your pressure treated wood, selecting the right stain is key for longevity and appearance. Pressure treated wood is designed to resist rot and insects, but it still needs a good protective finish to withstand the elements. The wrong stain can fade quickly, peel, or fail to provide adequate protection, leading to a less-than-ideal look and reduced lifespan for your wood.

This section will explore the factors that make a stain suitable for pressure treated wood and what to look for to ensure that the color stays vibrant and the wood remains protected for years to come.

Understanding Pressure Treated Wood

Pressure treated wood is wood that has been chemically preserved to resist decay, fungi, and insect attacks. This process involves forcing chemicals deep into the wood under high pressure. These chemicals, often copper-based, make the wood suitable for outdoor use, including decks, fences, and garden furniture.

However, this treatment process can also affect how well a stain penetrates and adheres to the wood.

New pressure treated wood often contains a high moisture content from the treatment process. This moisture needs to evaporate before you can effectively apply any stain. If you stain wood that is still too wet, the stain may not soak in properly, leading to a blotchy finish and reduced durability.

It can also trap moisture within the wood, potentially causing problems down the line.

Wood that has been properly treated and dried is more receptive to stains. The chemicals within the wood, while protective, can also create a surface that is less porous than untreated wood. This means that the stain needs to be formulated to adhere well to this specific type of surface.

Understanding these characteristics is the first step in making an informed decision about stain selection.

Moisture Content Testing

Before applying any stain, it’s crucial to test the moisture content of your pressure treated wood. A simple way to do this is the sprinkle test. Sprinkle a small amount of water on the wood.

If the water beads up and sits on the surface, the wood is likely still too wet and needs more time to dry. If the water soaks into the wood, it’s generally ready for staining.

For a more precise measurement, you can use a wood moisture meter. These devices insert probes into the wood to give a digital reading of the moisture percentage. For most stains, a moisture content below 15-18% is ideal.

This ensures better adhesion and a longer-lasting finish.

Allowing adequate drying time is essential. Depending on weather conditions like sun, wind, and humidity, new pressure treated wood can take anywhere from a few weeks to several months to dry out sufficiently. Rushing this step is one of the most common mistakes people make, and it directly impacts how well the stain performs and how long its color lasts.

Types of Wood Stains

There are several types of wood stains available, each with its own pros and cons. For pressure treated wood, you’ll want to consider stains that offer good protection against UV rays and moisture, as well as those that can penetrate the wood effectively. The type of stain you choose will significantly impact how long the color lasts and how well it protects the wood from wear and tear.

Oil-Based Stains

Oil-based stains are known for their ability to penetrate deeply into the wood. This deep penetration helps to protect the wood from the inside out and can result in a rich, long-lasting color. They often contain oils like linseed or tung oil, which condition the wood and provide a natural look.

Oil-based stains are generally more durable and resistant to fading than water-based options.

These stains often require mineral spirits or other petroleum-based solvents for cleanup, which can be a consideration for some users. They typically dry slower than water-based stains, allowing more time for them to soak into the wood. The finish from oil-based stains can sometimes have a slight sheen, enhancing the natural beauty of the wood grain.

A key advantage of oil-based stains for pressure treated wood is their flexibility. As wood expands and contracts with changes in temperature and humidity, an oil-based stain can move with it without cracking or peeling as easily as some other types. This makes them a popular choice for exterior applications where wood movement is common.

Water-Based Stains

Water-based stains, also known as latex or acrylic stains, have improved significantly over the years. They are generally easier to clean up, usually requiring just soap and water. They also tend to dry faster than oil-based stains, which can be a benefit if you have a limited time to complete your project.

Modern water-based stains often contain advanced resins that offer excellent UV protection and water repellency. They can be formulated to mimic the look of oil-based stains, providing vibrant colors and good durability. Many are designed to be low in VOCs (Volatile Organic Compounds), making them a more environmentally friendly option.

While water-based stains might not penetrate quite as deeply as oil-based ones, they form a strong bond on the surface. This surface bond can be very effective in protecting the wood from the elements. For pressure treated wood, choosing a high-quality, exterior-grade water-based stain with good UV blockers is important for achieving long-lasting color.

Gel Stains

Gel stains are a thicker, more concentrated form of stain. They are ideal for situations where you need more control over application, such as on vertical surfaces or when you want to avoid drips and runs. Gel stains sit more on the surface of the wood rather than penetrating deeply.

Because they are more surface-oriented, gel stains can provide a very rich and opaque color. This can be beneficial for covering imperfections or for achieving a dramatic color change. When applied correctly to properly prepared pressure treated wood, gel stains can offer good durability.

However, their adherence to the wood’s surface is critical for long-term performance.

Cleanup for gel stains is often similar to other water-based or oil-based products, depending on the specific formulation. They are a good option if you are looking for a bold, consistent color that hides some of the wood’s natural variations. However, for the most natural wood look, a penetrating stain might be preferred.

Factors for Long-Lasting Color on Pressure Treated Wood

Achieving a vibrant and enduring color on pressure treated wood depends on several key factors. It’s not just about the stain itself, but also how it’s applied and the environment it’s exposed to. Understanding these elements will help you select the best stain and ensure it performs as expected.

UV Protection

Sunlight is one of the biggest culprits in fading wood stains. UV rays break down the pigments in the stain, causing colors to become dull and washed out over time. The best stains for long-lasting color contain high levels of UV inhibitors.

These are special additives that act like sunscreen for your wood, blocking or reflecting the harmful UV radiation.

When choosing a stain, look for labels that specifically mention UV protection or sunblock. Even a stain with excellent color saturation will fade quickly if it lacks adequate UV resistance. This is particularly important for decks and fences that are constantly exposed to direct sunlight.

The intensity of the color also plays a role. Darker, more pigmented stains generally have better UV resistance than lighter or semi-transparent ones. This is because they contain more pigment particles to absorb or reflect the UV rays.

However, this doesn’t mean lighter stains can’t last; they just need to be formulated with superior UV blocking technology.

Water Repellency

Water is another major enemy of wood finishes. Constant exposure to rain, snow, and humidity can cause wood to swell and contract, stressing the stain. It can also lead to mildew and mold growth, which can degrade the stain and the wood itself.

A good stain for pressure treated wood should repel water effectively.

Look for stains that contain water-repellent additives. These additives create a barrier on the wood surface that prevents water from soaking in. This helps to maintain the structural integrity of the wood and prevents the stain from becoming waterlogged, which can lead to peeling and premature failure.

The type of oil or resin in the stain also contributes to its water repellency. Some oils are naturally water-repellent, while others can be formulated with polymers to enhance this property. A stain that provides excellent water repellency will protect your wood and keep the color looking fresh for longer.

Penetration and Adhesion

For pressure treated wood, the ability of a stain to penetrate the wood fibers is crucial for its longevity. A stain that soaks into the wood forms a bond within the wood itself, rather than just sitting on the surface. This deep bond is much more resistant to wear, tear, and weathering.

Oil-based stains are generally better at penetrating wood than water-based stains. However, modern high-quality water-based stains are formulated with advanced technologies to improve their penetration capabilities. Gel stains, as mentioned, tend to be more surface-level.

Proper preparation of the wood is vital for both penetration and adhesion. The wood must be clean, dry, and free from any old coatings, dirt, or mill glaze. If the wood surface is too smooth or has been treated with a sealant that prevents stain absorption, the stain will not be able to bond effectively, regardless of its quality.

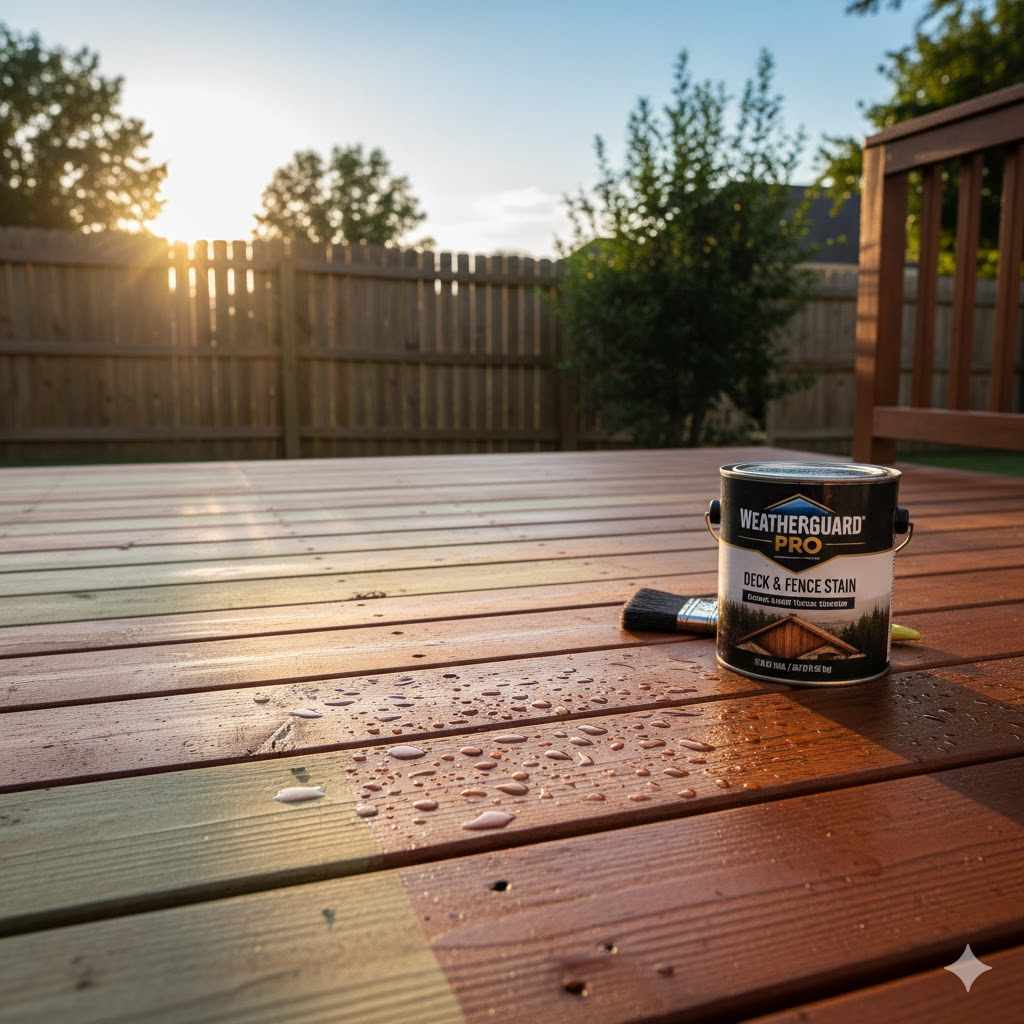

Top Stain Brands and Products for Pressure Treated Wood

When you’re looking for the Best Pressure Treated Wood Stain for Long-Lasting Color, certain brands and product lines consistently perform well. These companies have invested in research and development to create stains that can withstand harsh outdoor conditions and maintain their color for extended periods.

Sherwin-Williams SuperDeck

Sherwin-Williams SuperDeck is a highly regarded stain for decks and other exterior wood surfaces. It is a high-solids acrylic coating that offers excellent durability and resistance to wear and tear. SuperDeck provides superb UV protection, helping to prevent fading and prolong the life of the color.

This stain forms a protective film that is highly resistant to water, mildew, and cracking. It is known for its ability to adhere well to various wood types, including pressure treated lumber. SuperDeck comes in a wide range of colors, allowing for customization while ensuring long-lasting vibrancy.

Application is straightforward, but proper surface preparation is essential for optimal performance. Many professionals and DIYers choose SuperDeck for its proven track record in demanding environments. It’s a premium product that delivers premium results in terms of color retention and wood protection.

Behr Premium Semi-Transparent Stain and Sealant in One

Behr is a popular choice for homeowners, and their Premium Semi-Transparent Stain and Sealant in One offers a good balance of protection and natural wood beauty. This product combines stain and sealant in a single step, simplifying the application process. It is designed to penetrate the wood, offering protection from within.

The semi-transparent nature allows the wood grain to show through, providing a more natural look. Behr states that this product offers advanced UV protection to prevent fading and chalking, and it also provides excellent water repellency. It’s formulated to resist mildew and algae growth.

This stain is a good option if you’re looking for a product that is widely available, reasonably priced, and offers decent longevity. While perhaps not as robust as some heavy-duty professional coatings, it’s a solid choice for many residential projects requiring a long-lasting color.

Benjamin Moore Arborcoat Exterior Stain

Benjamin Moore’s Arborcoat line is another premium option for exterior wood protection. The Arborcoat Exterior Stain is available in various opacities, including solid, semi-solid, and semi-transparent. For long-lasting color, their solid and semi-solid formulations often provide the best protection against fading.

These stains are engineered to withstand harsh weather conditions, offering superior resistance to cracking, peeling, and mildew. They contain advanced pigments that provide rich, deep color that holds up well against UV exposure. The formula also includes water repellents to keep moisture out.

Arborcoat stains are known for their smooth application and excellent coverage. They can be a bit pricier than some other options, but the quality and longevity of the finish are often worth the investment, especially when preserving the appearance of your pressure treated wood.

Thompson’s WaterSeal Advanced Solid Color Waterproofing Stain

Thompson’s WaterSeal is a well-known name in wood protection, and their Advanced Solid Color Waterproofing Stain is designed for durability. This product offers solid color coverage, meaning it will completely hide the wood grain, similar to paint, but with the protective benefits of a stain. This solid color approach offers excellent UV blocking.

The waterproofing aspect is a primary feature, creating a barrier that repels water effectively. This helps prevent rot and extends the life of the wood. It’s formulated to resist mildew and algae growth, keeping the surface looking cleaner for longer.

This stain is a good choice if you want a bold, uniform color and maximum protection. It’s generally easy to apply and provides a thick coating that stands up well to foot traffic and weather. For those prioritizing a completely opaque and long-lasting color on their pressure treated wood, this is a strong contender.

Application Tips for Maximum Stain Longevity

Even the best stain won’t perform optimally without proper application. Following a few key steps can significantly extend the life of your stain and keep your pressure treated wood looking great for years. These tips focus on preparing the surface and applying the stain evenly and effectively.

Surface Preparation is Key

This cannot be stressed enough: proper preparation is vital. Start by cleaning the wood thoroughly. Use a dedicated wood cleaner and a stiff brush or a pressure washer on a low setting.

Remove all dirt, mildew, algae, and any loose or peeling old finish.

After cleaning, you may need to sand the wood. This is especially important if there is any mill glaze remaining on new lumber or if there are rough spots. Light sanding can also help open up the wood pores, allowing the stain to penetrate better.

Always sand in the direction of the wood grain.

Ensure the wood is completely dry before staining. As mentioned, this can take several days or even weeks after washing or rain. Using a moisture meter is the most reliable way to confirm the wood is ready.

Applying stain to damp wood will lead to poor adhesion and premature failure of the finish.

Choosing the Right Application Method

You have a few options for applying stain: brushing, rolling, or spraying. Each has its advantages.

- Brushing: This is often the preferred method for applying stains, especially on decks and fences. Brushing allows you to work the stain into the wood grain, ensuring good penetration and coverage. It also helps to force the stain into any cracks or crevices.

Using a good quality brush, typically 3-4 inches wide with synthetic bristles for water-based stains or natural bristles for oil-based stains, is recommended. Apply the stain evenly, working in sections.

- Rolling: A roller can speed up the application process, particularly on large, flat surfaces like decks. Use a roller with a nap that is appropriate for the stain’s viscosity.

A medium-nap roller is usually suitable for semi-transparent stains, while a thicker nap might be needed for solid stains. Be sure to follow behind with a brush to work the stain into the wood and ensure consistent coverage, especially around edges and joints.

- Spraying: Spraying is the fastest method and can provide a very smooth finish. However, it requires more skill and preparation to avoid overspray.

If you choose to spray, you’ll need to protect surrounding areas like plants, siding, and pavement. Always back-brush after spraying to ensure the stain is properly worked into the wood and to achieve an even appearance.

Applying Multiple Coats and Drying Times

Depending on the product and the desired look, you might need to apply more than one coat of stain. For semi-transparent stains, one coat is often sufficient to achieve the desired color and protection. For solid stains, one coat might provide coverage, but a second coat can add an extra layer of protection and ensure complete uniformity.

Always follow the manufacturer’s recommendations for drying times between coats. Applying a second coat too soon can prevent the first coat from curing properly, leading to adhesion issues. Typically, drying times can range from a few hours to 24 hours, depending on the stain type and environmental conditions.

It’s also important to consider the temperature and humidity during application. Staining in direct, hot sun can cause the stain to dry too quickly, leading to lap marks and an uneven finish. Avoid staining in temperatures below 50°F (10°C) or if rain is expected within 24-48 hours.

Maintenance for Long-Term Protection

Even the best stain needs ongoing maintenance to ensure your pressure treated wood remains protected and beautiful. Regular care will significantly extend the life of the stain and the wood itself, keeping your outdoor spaces looking their best.

Regular Cleaning

Keeping your stained wood clean is the simplest yet most effective maintenance step. Periodically sweep or rinse off dirt, leaves, and debris. This prevents organic matter from breaking down on the surface and causing stains or mildew.

For more stubborn dirt or mildew, use a mild soap and water solution or a specialized wood cleaner. Avoid harsh chemicals or overly aggressive scrubbing, which can damage the stain’s protective layer. Always rinse thoroughly after cleaning.

Regular cleaning also gives you an opportunity to inspect the wood for any signs of damage, wear, or potential problems, allowing you to address them early.

Annual Inspection

It’s a good practice to inspect your stained wood at least once a year, usually in the spring. Look for any areas where the stain may be wearing thin, peeling, or where there’s been damage from foot traffic, furniture, or weather.

Pay close attention to horizontal surfaces like decks, as they bear the most wear. Check for any signs of mold or mildew, particularly in shaded areas or places that don’t get much airflow. Any cracks, splits, or loose boards should also be noted and addressed.

This annual inspection allows you to catch minor issues before they become major problems. Addressing wear and tear proactively can save you from having to do a complete refinishing job sooner than necessary.

Reapplication and Touch-Ups

Eventually, even the most durable stain will need to be reapplied. The timeline for this varies greatly depending on the quality of the stain, the amount of sun and weather exposure, and the level of maintenance performed. A high-quality stain on a well-maintained deck might last 3-5 years or even longer.

Before reapplying, clean the surface thoroughly. If the old stain is still in good condition with only minor wear, you might be able to simply clean the wood and apply a new coat. If the old stain is peeling or has worn significantly in spots, you may need to lightly sand or even strip the old finish before applying a new one.

For minor touch-ups, such as on scratches or worn areas, you can often apply a small amount of the original stain. However, it’s important to feather the edges of the touch-up area to blend it seamlessly with the surrounding stained surface. Using the same product and color is crucial for a uniform appearance.

Frequently Asked Questions

Question: How do I know when my pressure treated wood is dry enough to stain?

Answer: The best way is to use a wood moisture meter and aim for a moisture content below 15-18%. Alternatively, you can do the sprinkle test: if water beads up, it’s too wet. If it soaks in, it’s likely ready.

Question: Can I use a deck stripper on pressure treated wood before staining?

Answer: Yes, if the wood has an old coating or is very dirty. Always follow the stripper’s instructions and ensure the wood is thoroughly rinsed and completely dry afterward.

Question: Will a solid stain last longer than a semi-transparent stain on my deck?

Answer: Generally, solid stains offer more UV protection and can hide imperfections better, potentially lasting longer in terms of color vibrancy. However, they also form a thicker film that can be more prone to peeling if not applied correctly.

Question: How often should I reapply stain to my pressure treated wood fence?

Answer: This depends on the stain quality and exposure, but typically every 2-5 years. Look for signs of wear or fading, and reapply when needed to maintain protection.

Question: What’s the difference between stain and sealant for pressure treated wood?

Answer: Stain adds color and some protection, while sealant primarily provides water repellency. Many products are now stain and sealant in one, offering both benefits for convenience and performance.

Conclusion

Finding the Best Pressure Treated Wood Stain for Long-Lasting Color involves careful selection and application. Prioritize stains with strong UV protection and water repellency. Proper surface preparation, including ensuring the wood is dry, is critical.

Choose a quality product from a reputable brand and follow application instructions closely. Regular cleaning and annual inspections will ensure your stained wood looks great for many years.