Bloodwood vs Padauk: Your Essential Guide

Bloodwood is denser, harder, and keeps its deep red color longer. Padauk is softer, easier to work with, and famous for its bright orange-red hue that darkens to a brown-red over time. Choose Bloodwood for high-durability projects like tool handles and flooring. Choose Padauk for decorative pieces, furniture, and musical instruments.

Have you ever walked into a lumberyard and seen two stacks of brilliant red wood? You might have wondered, “What’s the difference?” If you’ve ever felt stuck choosing between Bloodwood and Padauk, you are not alone. Both are beautiful, but they act very differently in the workshop.

Picking the wrong one can lead to frustration. One might be too hard on your tools, while the other might not be durable enough for your project. Don’t worry, I’m here to help clear things up. In this guide, I’ll walk you through everything you need to know about these two stunning woods. We will look at them side-by-side so you can feel confident picking the perfect red wood for your next project.

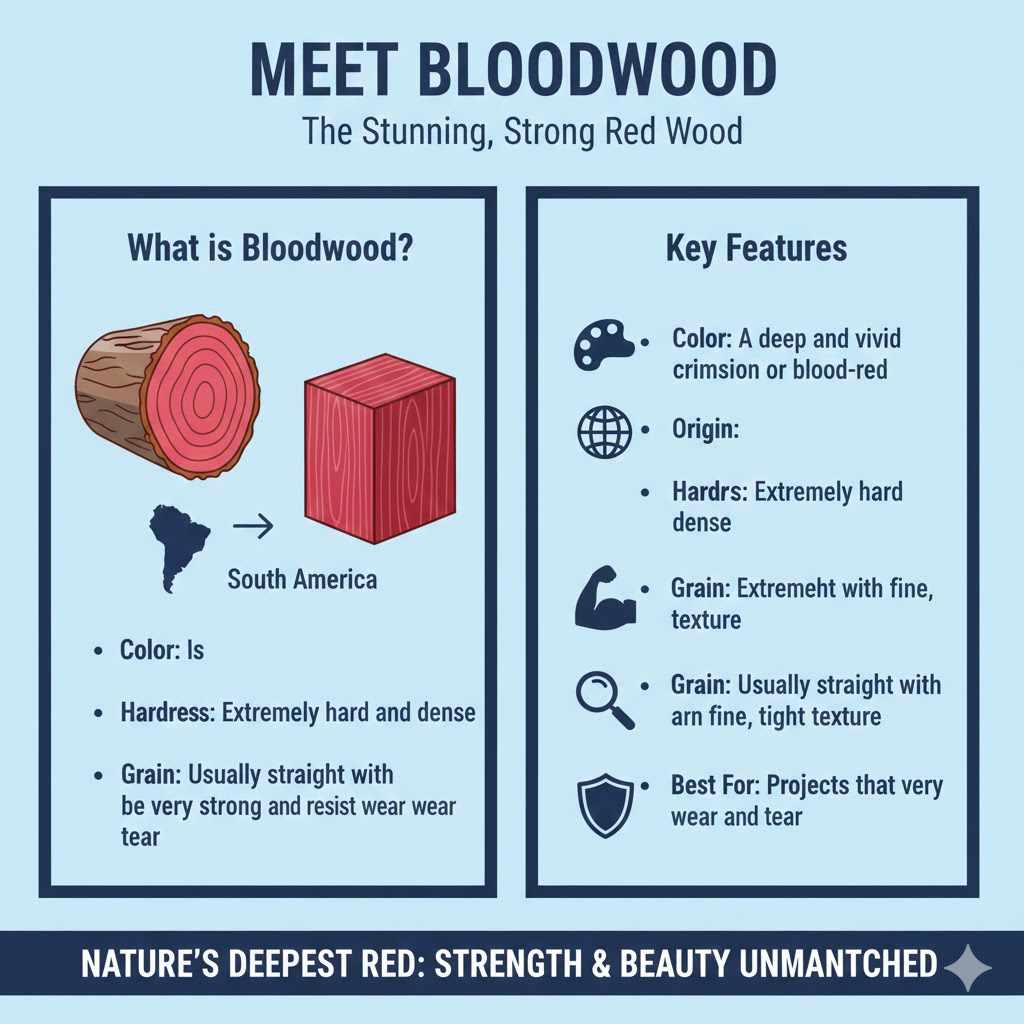

First, Let’s Meet Bloodwood

Bloodwood is a stunning wood that truly lives up to its name. When you first cut into it, you are greeted with a rich, vibrant crimson red color. It’s the kind of deep red that makes you stop and stare. This wood comes all the way from tropical South America, and it’s known for being incredibly tough.

The grain of Bloodwood is usually very straight and fine, which gives it a smooth, almost satiny look when it’s finished. Sometimes you’ll find pieces with a beautiful wavy or interlocking grain that seems to dance in the light. It has a wonderful natural shine, which woodworkers call luster. Think of Bloodwood as the strong, dependable member of the red wood family. It’s dense, heavy, and built to last.

Key Features of Bloodwood:

- Color: A deep and vivid crimson or blood-red.

- Origin: South America.

- Hardness: Extremely hard and dense.

- Grain: Usually straight with a fine, tight texture.

- Best For: Projects that need to be very strong and resist wear and tear.

Next, Let’s Get to Know Padauk

Padauk (usually African Padauk) is the other famous red wood, and it makes a completely different first impression. When you first cut Padauk, it’s not just red—it’s a brilliant, fiery orange-red. The color is so bright it almost looks like it’s glowing. It’s a fun, exciting wood to work with.

Padauk comes from Central and West Africa. Compared to Bloodwood, its grain is more open and coarse. It feels a little more textured. While still very durable, Padauk is not as dense or heavy as Bloodwood, which makes it a bit kinder to your tools and easier to work with. The most interesting thing about Padauk is how its color changes over time. That bright orange-red will slowly mellow into a rich, reddish-brown, sometimes with a hint of purple.

Key Features of Padauk:

- Color: Bright, vibrant orange-red when freshly cut.

- Origin: Africa.

- Hardness: Hard, but less dense than Bloodwood.

- Grain: More open and coarse than Bloodwood’s grain.

- Best For: Decorative projects, musical instruments, and when you want a pop of color.

Bloodwood vs Padauk: A Side-by-Side Comparison

Seeing the facts next to each other makes the choice much clearer. This table gives you a quick snapshot of the key differences between these two amazing woods. Use it as a quick reference when you’re planning your project.

| Feature | Bloodwood (Brosimum rubescens) | Padauk (Pterocarpus soyauxii) |

|---|---|---|

| Janka Hardness | ~2,900 lbf (Extremely Hard) | ~1,970 lbf (Very Hard) |

| Color (Fresh Cut) | Deep, rich crimson red | Bright, fiery orange-red |

| Color (Aged) | Darkens to a deep brownish-red | Darkens to a rich reddish-brown or purple-brown |

| Grain Texture | Fine and tight | Open and coarse |

| Workability | Difficult; very hard on tools | Moderate; easier to cut and sand |

| Rot Resistance | Very durable; highly resistant to insects | Very durable; excellent rot and insect resistance |

| Common Uses | Flooring, knife scales, tool handles, inlays | Furniture, musical instruments, jewelry boxes, turned objects |

| Average Cost | Moderate to High | Moderate |

Appearance and Color: How They Change Over Time

The biggest difference you’ll notice right away is the color. It’s also the factor that changes the most over time, and it’s something you need to plan for.

Bloodwood’s Rich and Lasting Red

Bloodwood starts as a deep, powerful red and largely stays that way. Over months and years, exposure to sunlight (UV light) will cause it to slowly darken. It doesn’t lose its red identity, though. It simply matures into a deeper, more muted brownish-red. Think of it like a fine wine—it gets richer with age. Because its color is more stable, it’s a great choice if you want to count on that deep red look for years to come.

Padauk’s Dramatic Transformation

Padauk is the color-changer of the two. Its initial blast of orange-red is breathtaking, but it won’t last forever without help. UV light will cause it to darken quite quickly, sometimes in just a few months. That vibrant orange will turn into a beautiful, warm reddish-brown. Some woodworkers love this aged look, seeing it as more sophisticated. If you love that initial orange pop, you’ll need to use a finish with strong UV blockers to slow down the change.

Durability and Hardness: Which is Tougher?

When we talk about how tough a wood is, we often use the Janka Hardness Scale. This is simply a test that measures how much force it takes to press a small steel ball into the wood. A higher number means a harder wood. According to the U.S. Forest Products Laboratory, understanding wood properties is key to choosing the right material.

Bloodwood is a champion of hardness. It has a Janka rating of around 2,900 pounds-force (lbf). To put that in perspective, Red Oak, a common hardwood for flooring, is only about 1,290 lbf. This makes Bloodwood incredibly resistant to dents, dings, and scratches. It’s an excellent choice for things that will see a lot of use and abuse, like flooring, tool handles, or a fancy workbench vise.

Padauk is no slouch either. It comes in with a Janka rating of around 1,970 lbf. That’s still much harder than many domestic hardwoods. It’s plenty tough for furniture, boxes, and decorative items. It will stand up to daily life beautifully, but it’s just not in the same heavyweight class as Bloodwood.

Both woods are also highly resistant to rot and insects, which makes them very durable choices.

Workability: How They Behave in the Shop

This is where your experience as a beginner really comes into play. A beautiful wood that is a nightmare to work with can take all the fun out of a project. Here’s what you can expect.

Working with Bloodwood: A Test of Patience

I’ll be honest with you: Bloodwood can be challenging. Its extreme density and hardness are tough on tools.

- Dulls Blades: Expect to sharpen your plane irons and saw blades more often. Use carbide-tipped blades if you have them.

- Can Burn: When routing or cutting, the wood can burn if you move too slowly or use a dull bit. Keep a steady pace.

- Prone to Splintering: The edges can be a bit brittle and prone to chipping or tear-out, especially on the jointer or planer. Take shallow passes.

- Drilling and Screwing: You must pre-drill holes for screws. Trying to drive a screw directly into Bloodwood will likely end with a snapped screw and a lot of frustration.

Bloodwood sands to a beautiful, glass-like finish, but its hardness means you’ll need to be patient. It also has natural oils that can sometimes make gluing a bit tricky. Wiping the surfaces with acetone just before gluing can help create a stronger bond.

Working with Padauk: A Messy Friend

Padauk is much more cooperative in the shop. It cuts, drills, and shapes more easily than Bloodwood. Your tools will stay sharp longer, and you’ll find it’s generally a pleasure to work with.

However, Padauk has one very big quirk: the dust.

- It’s Fine and Red: Padauk produces a huge amount of very fine, bright red dust.

- It Gets Everywhere: Seriously, everywhere. It will cover your tools, your floor, your clothes, and you. A good dust collection system is highly recommended.

- It Stains Other Woods: If you are using Padauk as an accent with a light-colored wood like Maple, be very careful. The red dust will get into the pores of the Maple and stain it pink. To avoid this, sand your Padauk parts separately and apply a sealing coat of finish before gluing them up with other woods.

Common Uses: Finding the Right Project

Knowing the strengths and weaknesses of each wood helps us choose the right one for the job.

Ideal Projects for Bloodwood:

Because of its incredible durability, Bloodwood shines in applications where toughness matters most.

- Tool Handles: A classic use, as it can withstand constant handling and impact.

- Flooring and Inlays: Its resistance to dents makes it perfect for high-traffic areas.

- Fine Boxes and Knife Scales: It provides a durable and beautiful finish for small, detailed items.

- Woodturning: It turns smoothly and polishes to a high shine, great for pens and decorative bowls.

- Archery Bows: Its strength and density are prized by bowyers.

Ideal Projects for Padauk:

Padauk’s stunning color and easier workability make it a favorite for projects where appearance is a top priority.

- Decorative Furniture: Used as accent panels, legs, or whole pieces where a splash of color is desired.

- Jewelry Boxes: The bright color makes for a striking and beautiful gift.

- Musical Instruments: It’s a popular choice for guitars and other stringed instruments due to its great look and good tonal qualities.

- Cutting Boards: It’s often used in striped patterns with other woods. Just be sure to use a food-safe finish.

- Veneer and Marquetry: Thin slices are used to create intricate designs and patterns.

Safety First: Working with Exotic Woods

Whenever you work with a new wood, especially an exotic one, you need to think about safety. The fine dust from any wood is not good to breathe, but some woods can cause even more trouble.

Both Bloodwood and Padauk dust can act as a “sensitizer.” This means that even if you don’t have a reaction the first time, repeated exposure can lead to allergic reactions like skin rashes, eye irritation, or respiratory problems. As stated by safety organizations like the Occupational Safety and Health Administration (OSHA), protecting yourself from wood dust is essential.

Your Safety Checklist:

- Wear a Respirator: A simple paper mask isn’t enough. Use a properly fitted N95-rated dust mask or a respirator with cartridges to protect your lungs.

- Use Dust Collection: Connect your tools to a shop vac or dust collector to capture as much dust as possible at the source.

- Ensure Good Ventilation: Open a window or use an air filtration system to keep the air in your shop clean.

- Cover Your Skin: Consider wearing long sleeves when doing a lot of sanding to minimize skin contact.

- Wash Up: After you’re done working, wash your hands and face thoroughly to remove any lingering dust.

Staying safe ensures you can enjoy woodworking for years to come. Don’t take chances!

Conclusion: So, Which Wood Should You Choose?

As we’ve seen, Bloodwood and Padauk are both fantastic woods, but they are far from the same. The choice really comes down to your project and your comfort level in the workshop.

Choose Bloodwood if:

- You need extreme hardness and durability for your project.

- You want a deep, true red color that will remain stable for a long time.

- You are prepared for a bit of a challenge and have sharp tools ready to go.

Choose Padauk if:

- You want a brilliant, eye-catching orange-red that will mellow into a warm brown.

- Your project is more decorative and requires a wood that is easier to cut and shape.

- You have a good dust management system and are prepared to handle the messy red dust.

Ultimately, there is no single “better” wood. There is only the better wood for your project. I encourage you to try both when you get the chance. Working with beautiful exotic woods is one of the great joys of this craft. Start with a small project, respect the material, and enjoy the process of turning a remarkable piece of nature into something you can be proud of.

Happy building!

Frequently Asked Questions (FAQ)

Here are some quick answers to the most common questions beginners have about Bloodwood and Padauk.

1. Which wood is better for a cutting board?

Padauk is more commonly used for cutting boards. It is easier to work with and its pores can be sealed well with a food-safe finish like mineral oil and beeswax. While Bloodwood is harder, its very fine, tight grain can sometimes make it harder for oil to penetrate, and it’s tougher on your tools during the build process.

2. Will Padauk really stay bright orange if I use a UV-blocking finish?

A UV-blocking finish can significantly slow down the color change, but it won’t stop it forever. Think of it as sunscreen for your wood. It will help keep the bright color for much longer, but eventually, some darkening is inevitable, especially if the piece is in direct sunlight.

3. Is Bloodwood too difficult for a beginner to use?

It can be challenging. If it’s your first or second project, I might recommend starting with Padauk. However, if you are patient, use very sharp blades, take your time, and remember to pre-drill your holes, a beginner can successfully work with Bloodwood. Just don’t be in a hurry!

4. Do I need to buy special tools to work with these woods?

You don’t need special tools, but you do need your regular tools to be in excellent condition. Sharp saw blades (carbide-tipped are best), sharp planer and jointer knives, and sharp chisels are essential. Dull tools will burn, chip, and frustrate you when working with hard woods like these.

5. Is one wood more expensive than the other?

Prices can vary depending on your location and the supplier. Generally, Padauk is more widely available and often a little less expensive than Bloodwood. Both are considered premium hardwoods and will cost more than common domestic woods like pine or oak.

6. How can I stop Padauk dust from staining a lighter wood like Maple?

The best way is to work on and sand the pieces separately. Once your Padauk piece is sanded to its final grit, apply a thin coat of a clear sealer (like dewaxed shellac). This will lock in the red dust. After the sealer is dry, you can safely glue it to the Maple without the color bleeding into the Maple’s pores.