Brushless Motor vs Brushed Drill: Proven Power

Brushless drills offer superior power, efficiency, and lifespan compared to brushed drills due to their advanced motor technology, making them a worthwhile investment for most DIYers and professionals seeking proven performance.

Are you standing in the tool aisle, scratching your head, wondering what the big deal is between a “brushed” and a “brushless” drill? You’re not alone! This is a common question for anyone starting out in DIY or woodworking. It can feel a bit confusing with all the technical terms. But don’t worry, I’m here to make it super simple. We’ll break down exactly what these terms mean, how they affect your drill’s performance, and help you make the best choice for your projects.

Think of your drill as your trusty sidekick for countless projects, from hanging shelves to building furniture. The heart of that drill is its motor. The type of motor—brushed or brushless—makes a surprising difference in how your tool works, how long it lasts, and how much power it delivers. Let’s dive in and shed some light on “brushless motor vs brushed drill” so you can feel confident and empowered in your next tool purchase.

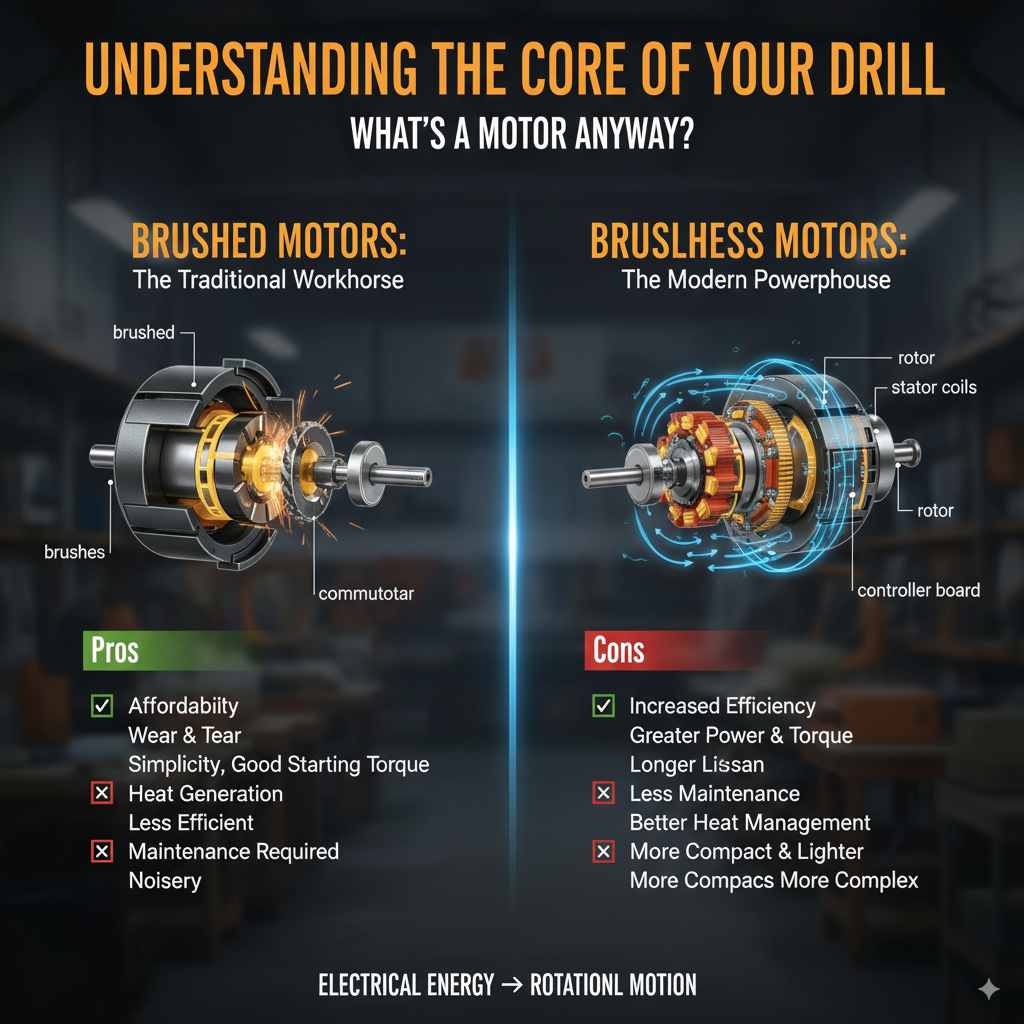

Understanding the Core of Your Drill: What’s a Motor Anyway?

At its simplest, a drill’s motor is what gives it the spinny power to drill holes or drive screws. It takes electrical energy from the battery and turns it into rotational motion. The “brushed” and “brushless” in drill names refer to the specific type of electric motor used. It’s like the difference between an old-school car engine and a modern, fuel-efficient one – both get you there, but in very different ways.

The key difference lies in how electricity is delivered to the moving parts of the motor. This might sound a bit technical, but I’ll break it down so it’s easy to understand.

Brushed Motors: The Traditional Workhorse

Brushed motors are the older, more traditional type of motor found in many power tools. They’ve been around for a long time and are known for being reliable and affordable. If you’ve ever used a drill that felt a bit clunky or just ‘older,’ it likely had a brushed motor.

Here’s how they work in simple terms:

- Inside a brushed motor, there are components called brushes. These are typically made of carbon.

- These brushes physically rub against a spinning part called the commutator.

- This physical contact is what transfers electrical power to the rotor, making it spin.

- Think of it like flipping on a light switch every time the rotor needs a little push. The brushes do the flipping.

Pros of Brushed Motors:

- Affordability: They are generally less expensive to manufacture, making drills equipped with them more budget-friendly.

- Simplicity: The design is less complex, which can sometimes mean easier (though less frequent) repairs for simple issues.

- Good Starting Torque: They often provide a good initial “kick” of power when you start a job.

Cons of Brushed Motors:

- Wear and Tear: The physical contact between brushes and the commutator causes friction and wear. Brushes eventually wear down and need to be replaced. This is a common maintenance point.

- Heat Generation: The friction creates heat, which can reduce the motor’s efficiency and lifespan. The motor housing can get quite warm during extended use.

- Less Efficient: Due to energy loss from friction and heat, brushed motors are less efficient at converting battery power into work. This means shorter runtimes per battery charge.

- Maintenance Required: As mentioned, brushes wear out and need replacement over time.

- Can be Noisier: The physical contact can sometimes lead to a bit more noise.

Brushless Motors: The Modern Powerhouse

Brushless motors are the newer, more advanced technology you’ll find in many high-end and newer model power tools. They are designed to overcome the limitations of brushed motors, offering better performance and durability. When you see “brushless” on a drill, it’s a sign of enhanced capability.

The “brushless” name tells you that the physical brushes have been removed. So, how does it get its power? It uses electronics:

- Instead of physical brushes, brushless motors use magnets and an electronic controller.

- The electronic controller precisely manages the flow of electricity to different parts of the motor (the stator coils).

- This electronic switching is much more efficient and generates less heat.

- Think of it like a smart conductor orchestrating the motor’s performance without any physical contact, just precise timing.

This electronic control is the key to many of their advantages. It allows for more precise power delivery, which translates to better control and more efficient use of battery power. According to manufacturers like Bosch, brushless technology allows for up to 20% more power and 30% longer runtime. You can learn more about the advancements in electric motor technology you may find on resources from institutions like the U.S. Department of Energy’s Advanced Electric Motor Technologies page.

Pros of Brushless Motors:

- Increased Efficiency: Much less energy is wasted as heat and friction, leading to significantly longer runtimes per battery charge. You can get more work done before needing to swap batteries or recharge.

- Greater Power and Torque: Brushless motors can deliver more power and torque, meaning they can handle tougher jobs, drill through denser materials, and drive larger fasteners with ease.

- Longer Lifespan: With no brushes to wear out and less heat buildup, brushless motors last much longer than brushed motors. This means fewer replacements and less hassle.

- Less Maintenance: No brushes to replace means less ongoing maintenance.

- Quieter Operation: Generally, they operate more quietly than brushed motors.

- Better Heat Management: They run cooler, which is better for the tool’s components and the user.

- More Compact and Lighter: Often, brushless motors can be made smaller and lighter, leading to more ergonomic and maneuverable tools.

Cons of Brushless Motors:

- Higher Initial Cost: The advanced technology and more complex electronics mean that drills with brushless motors are typically more expensive upfront.

- Electronics are More Complex: While they require less maintenance, if the electronic controller fails, repairs can be more complex and costly.

Brushless vs. Brushed Drill: The Head-to-Head Comparison

When we put a brushless motor vs. a brushed drill side-by-side, the differences become very clear, especially for demanding tasks. It’s not just about power; it’s about how that power is delivered and sustained.

Let’s break down the key performance areas:

Power and Torque

Brushless drills generally offer superior power and torque. This means they can spin faster and with more force. For driving long screws into hardwood or drilling large holes, a brushless drill will often outperform a brushed one, feeling less strained and more capable. You’re less likely to bog down the motor when you put it under heavy load.

Battery Life and Runtime

This is a major win for brushless. Because they are more efficient, they use battery power more wisely. You can expect to get significantly more runtime out of a single battery charge with a brushless drill compared to a brushed model of similar battery capacity. This is a huge advantage if you’re working on a large project or away from a power source.

Durability and Lifespan

Brushless motors are built to last. The absence of physical brushes means there are fewer parts that can wear out from friction and heat. While both types of drills can be durable, a brushless drill will, on average, have a longer operational lifespan and require less periodic maintenance related to the motor itself.

Speed and Control

Brushless motors can often be controlled more precisely by their electronic systems. This can translate to smoother acceleration and better speed control, which is beneficial for delicate tasks where you need to start screws slowly or maintain a consistent speed for drilling.

Heat Management

Brushed motors generate more heat due to friction. This heat can affect the tool’s performance over time and reduce the lifespan of other components. Brushless motors run significantly cooler, which is better for the longevity of the drill and more comfortable for the user during extended use.

Cost

The most significant difference here is the upfront price. Drills with brushless motors are typically more expensive. However, it’s important to consider the total cost of ownership. The increased efficiency, longer lifespan, and reduced maintenance of a brushless drill can make it a more cost-effective choice in the long run. The initial investment buys you better performance and longevity.

Here’s a quick way to see the main differences:

| Feature | Brushed Drill | Brushless Drill |

|---|---|---|

| Motor Type | Traditional with physical brushes | Advanced electronic control, no brushes |

| Efficiency | Lower (more energy lost to heat/friction) | Higher (less energy wasted) |

| Power/Torque | Good, but can bog down under heavy load | Superior, handles heavy loads better |

| Runtime per Charge | Shorter | Significantly Longer |

| Lifespan | Shorter (brushes wear out) | Significantly Longer (no brushes to wear out) |

| Maintenance | Brushes need eventual replacement | Virtually no motor-specific maintenance |

| Heat Buildup | Higher | Lower |

| Noise Level | Can be noisier | Generally quieter |

| Initial Cost | Lower | Higher |

When to Choose a Brushed Drill

So, is there ever a reason to pick a brushed drill? Absolutely! For the budget-conscious beginner or for very light-duty tasks, a brushed drill can be a perfectly good choice. If your projects are few and far between, mainly involve drilling into drywall, or driving small screws, a brushed drill will likely serve you well.

Consider a brushed drill if:

- Your budget is very tight: Brushed drills are almost always cheaper upfront.

- You only do occasional DIY tasks: For light, infrequent use, the durability and power benefits of brushless might be overkill.

- You’re comfortable with basic maintenance: Knowing that brushes might need replacing down the line is not a deterrent.

- You already have batteries for a specific brand: Sometimes, you can find great deals on brushed tools as older models are phased out, making them attractive if they fit your existing battery ecosystem.

For example, if you’re just looking for a drill to hang picture frames, assemble flat-pack furniture, or do minor repairs around the house, a brushed drill often does the trick without breaking the bank. Think of it as a reliable tool that gets the basic job done.

When to Invest in a Brushless Drill

For most DIYers and homeowners who plan on tackling a variety of projects or want a tool that will last and perform consistently, a brushless drill is the way to go. The ‘proven power’ aspect is undeniable.

Invest in a brushless drill if:

- You tackle frequent or demanding projects: Woodworking, renovations, building decks, or any task that requires sustained power and torque.

- You value efficiency and battery life: Getting more done on a single charge makes a huge difference.

- You want a tool that lasts: The longer lifespan and reduced wear mean fewer tool replacements over time.

- You want the best performance: For consistent power, speed, and control, especially under load.

- You can stretch your budget a bit: The increased performance and longevity often justify the higher initial cost.

- You’re looking for a more ergonomic tool: The lighter weight and better heat management can make a tool more comfortable to use for longer periods.

Imagine building a workbench or a garden shed. A brushless drill will maintain its power through thick lumber and drive screws without complaint, making the process smoother and faster. It’s about having the confidence that your tool won’t let you down when the work gets tough. For more on tool selection, you can check out guides from reputable DIY resources like Family Handyman, which often review and compare tool technologies.

Beyond the Motor: Other Features to Consider

While the motor type is a big factor in “brushless motor vs brushed drill,” it’s not the only thing to look for in a drill. Don’t forget these other important features when you’re shopping:

- Chuck Size: This is the part that holds the drill bit or screwdriver bit. Common sizes are 3/8-inch and 1/2-inch. A 1/2-inch chuck is generally more robust and universally compatible with larger bits.

- Voltage: Higher voltage (e.g., 18V, 20V MAX) usually means more power and torque. Lower voltage (e.g., 12V) tools are often lighter and more compact, great for tight spaces.

- Gears and Speed Settings: Most drills have at least two speed settings (e.g., 1 for high torque/low speed, 2 for high speed/low torque) and a clutch to prevent over-driving screws. More settings offer finer control.

- Ergonomics and Grip: How the drill feels in your hand is crucial, especially for long work sessions. Look for comfortable rubber grips and a balanced design.

- LED Work Light: A built-in light that illuminates your work area is incredibly useful, especially in dim conditions.

- Battery System: If you plan on buying other tools from the same brand, make sure their battery systems are compatible. This can save you money in the long run.

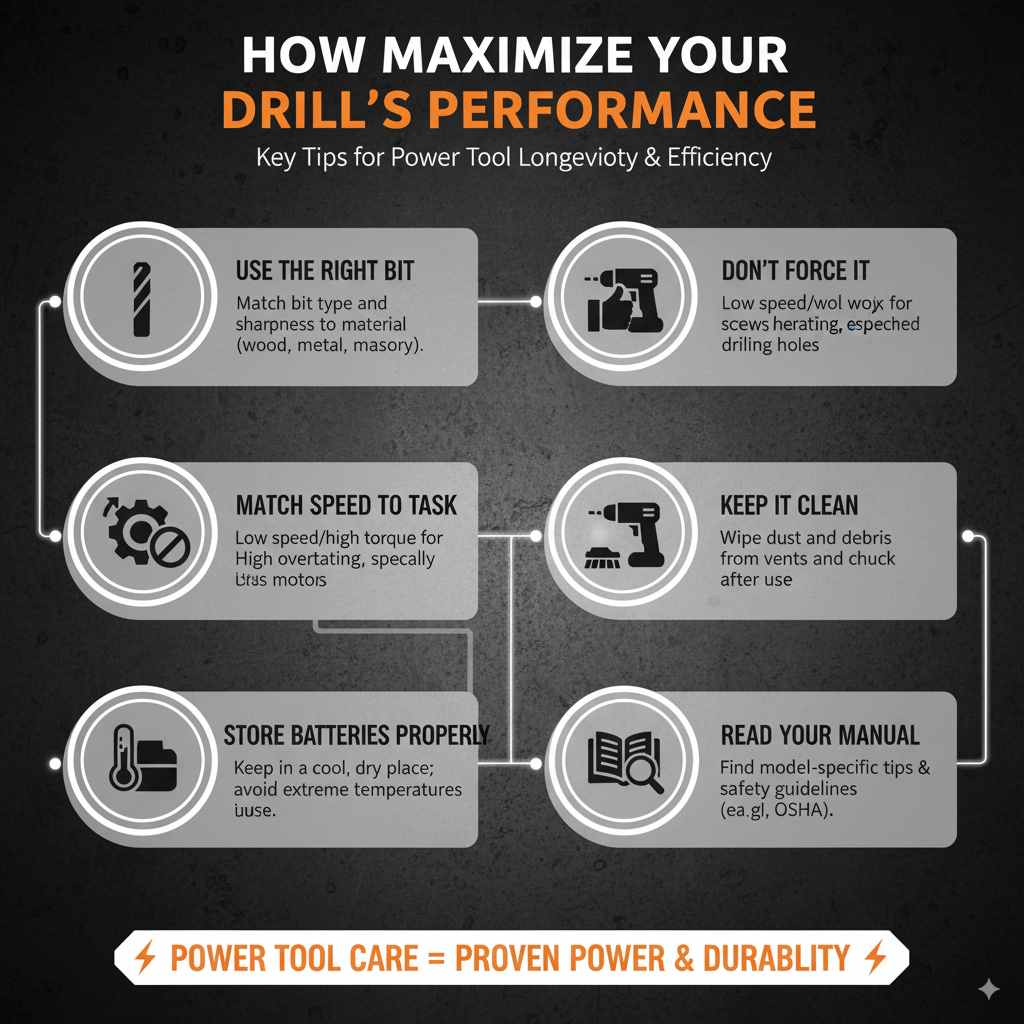

How to Maximize Your Drill’s Performance

Once you have your drill, whether it’s brushed or brushless, here are a few tips to keep it running smoothly and safely:

- Use the Right Bit: Always use a bit that is sharp and appropriate for the material you are drilling into or the type of screw you are driving. A dull bit makes the motor work harder.

- Match Speed to Task: Use a lower speed setting with higher torque for driving screws, especially into softer materials or when you don’t want to strip the screw head. Use higher speeds for drilling holes in wood or metal.

- Don’t Force It: Let the drill do the work. Forcing a drill, especially a brushed one under load, can overheat the motor and potentially damage it over time.

- Keep it Clean: After use, wipe down your drill to remove dust and debris, especially around vents and the chuck.

- Store Batteries Properly: Store batteries in a cool, dry place, and avoid leaving them in extreme temperatures.

- Read Your Manual: Seriously! Manufacturer manuals often contain specific care and maintenance tips for your particular model. For example, the Occupational Safety and Health Administration (OSHA) provides excellent general safety guidelines for power tool usage, which you can explore on their OSHA Power Tools Safety page.

Frequently Asked Questions (FAQ)

What is the main difference between a brushed and brushless drill?

The main difference is the motor technology. Brushed drills use physical carbon brushes that create friction and wear to transfer power. Brushless drills use electronic controls and magnets, eliminating physical brushes for greater efficiency, power, and a longer lifespan.

Which type of drill is more powerful, brushed or brushless?

Brushless drills are generally more powerful. They can deliver higher torque and sustain their power under heavy loads better than brushed drills.

Will a brushless drill last longer?

Yes, brushless drills typically have a longer lifespan. Without brushes to wear out and with better heat management, the motor components experience less wear and tear.

Is a brushless drill worth the extra cost?

For most users who tackle regular or demanding DIY projects, yes, a brushless drill is often worth the higher initial cost. The increased efficiency, power, durability, and reduced maintenance provide better value over time.

Can I use the same batteries for brushed and brushless drills from the same brand?

Usually, yes. Most tool manufacturers design their battery platforms to be compatible with both brushed and brushless versions of their tools within the same voltage class (e.g., 18V). Always check compatibility for your specific brand.