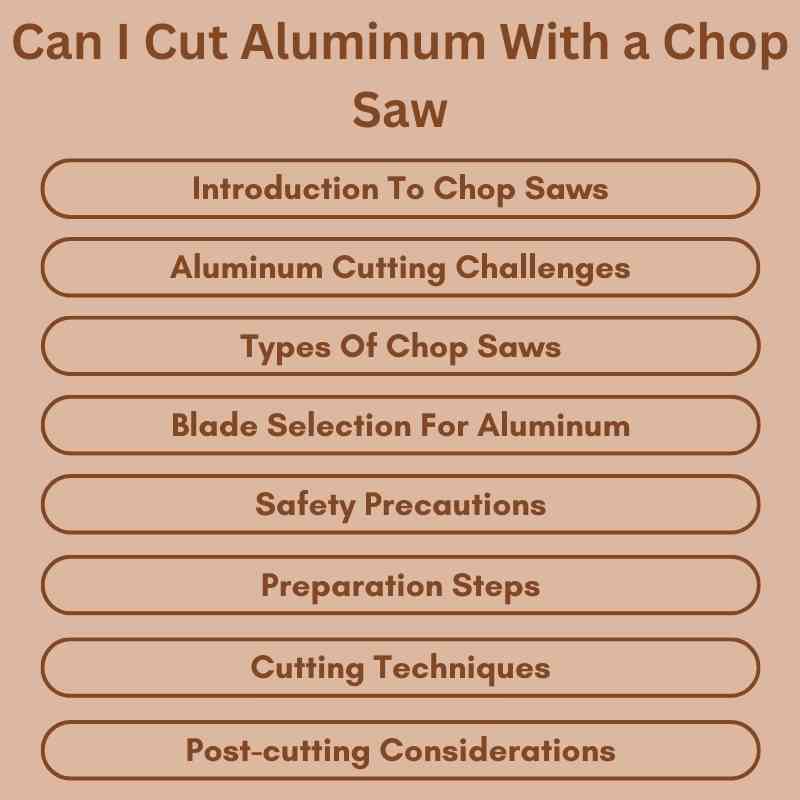

Can I Cut Aluminum With a Chop Saw?: Expert Tips

Yes, you can cut aluminum with a chop saw. Make sure to use the right blade designed for non-ferrous metals.

Cutting aluminum with a chop saw can be efficient and effective. This method allows for precise cuts and quick processing, making it popular among DIY enthusiasts and professionals alike. Aluminum is lightweight yet strong, making it a versatile material for various projects.

Using a chop saw equipped with the proper blade ensures clean cuts and reduces the risk of damaging the material. It’s essential to take safety precautions, including wearing protective eyewear and securing the aluminum properly. Understanding the right techniques and tools can make your aluminum cutting experience smooth and successful. Whether you’re working on construction or crafting, mastering this skill can significantly enhance your project outcomes.

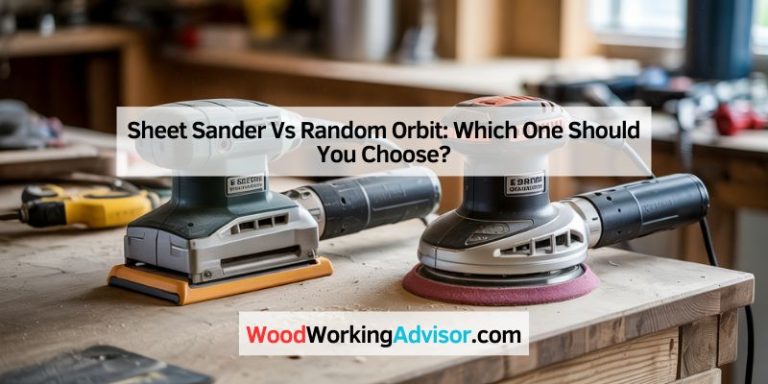

Introduction To Chop Saws

A chop saw is a powerful tool for cutting various materials. It is often used for metalworking and woodworking. The saw has a rotating blade that makes quick cuts. This tool is easy to handle and operate.

To cut aluminum with a chop saw, you need the right blade. A carbide-tipped blade works best for aluminum. Make sure the blade is sharp to ensure smooth cuts. Always use safety gear like goggles and gloves.

| Common Uses for Chop Saws |

|---|

| Cutting wood for framing |

| Trimming metal pipes |

| Making furniture parts |

| Creating decorative metal pieces |

Aluminum Cutting Challenges

Aluminum has unique characteristics that affect cutting. It is soft and lightweight, making it easy to handle. However, this can lead to difficulties during cutting.

Aluminum can gall or stick to blades. This causes friction and can create poor cuts. Using the wrong blade can also lead to issues. A blade made for metal is essential for good results.

Another challenge is heat generation. Cutting aluminum produces heat, which can damage the material and the tool. Proper cooling techniques are necessary for effective cutting.

Types Of Chop Saws

Two main types of chop saws are available: abrasive and cold cut saws. Each serves different purposes.

Abrasive saws use a grinding wheel to cut materials. They produce a lot of heat and sparks. This can be a safety risk.

Cold cut saws use a toothed blade. They cut metal cleanly and produce less heat. This makes them safer for cutting aluminum.

Choosing the right saw is crucial. For thin aluminum, a cold cut saw works best. For thicker pieces, consider an abrasive saw.

Both saws can cut aluminum, but cold cut saws are more efficient. Always wear safety gear when cutting.

Blade Selection For Aluminum

Choosing the right blade is key for cutting aluminum. Blade materials can greatly affect performance. Carbide-tipped blades are excellent for this task. They stay sharp longer and cut smoothly.

Teeth count matters too. A blade with 60 to 80 teeth is ideal. This helps create clean cuts without burrs. Finer teeth give better results on thinner aluminum. For thicker pieces, a blade with fewer teeth works well.

Consider the kerf width as well. A thinner kerf means less waste. Ensure the blade fits your chop saw. Quality blades may cost more but last longer.

| Blade Material | Teeth Count | Best For |

|---|---|---|

| Carbide-Tipped | 60-80 | Clean Cuts |

| High-Speed Steel | 40-60 | Thicker Aluminum |

Safety Precautions

Wearing the right Personal Protective Equipment (PPE) is essential. Always use safety goggles to protect your eyes. A dust mask helps keep you safe from particles. Ear protection reduces noise exposure.

Always keep your work area clean and organized. Ensure the chop saw is in good condition. Use the right blade for aluminum cutting. Secure the aluminum piece firmly before cutting. Always follow the manufacturer’s guidelines.

Stay alert and avoid distractions while operating the saw. Never wear loose clothing or jewelry. Make sure others are at a safe distance.

Preparation Steps

Secure the aluminum piece firmly to avoid movement. Use clamps to hold it in place. This ensures a clean cut.

Setting the correct angles is crucial for accuracy. Measure the angle needed for your cut. Adjust the chop saw to match this angle.

Check the alignment before starting the saw. This will help achieve precise cuts every time. A steady hand and focus lead to better results.

Cutting Techniques

Cutting aluminum with a chop saw requires the right speeds and feeds. Use a low RPM setting to prevent overheating. A high-quality blade designed for aluminum is essential for clean cuts.

Support the aluminum properly during cutting. Use clamps to secure the material. This prevents movement and ensures a straight cut.

Always wear safety gear like goggles and gloves. Safety should be a top priority. Check the saw and blade before use to ensure they are in good condition.

Post-cutting Considerations

After cutting aluminum, deburring is important. This removes sharp edges. Use a file or deburring tool for this process. Smooth edges help prevent injuries.

Finishing edges can improve appearance. A good finish also helps resist corrosion. Sanding or using a polishing compound can achieve this.

Cleaning the chop saw is essential for its longevity. Remove debris after each use. Regularly check the blade for wear. A clean saw cuts better and lasts longer.

Lubricate the moving parts of the saw. This ensures smooth operation. Keeping the saw in good shape saves money over time.

Expert Tips And Tricks

To extend blade life, always keep your chop saw clean. Remove dust and debris regularly. Use a high-quality blade designed for aluminum. A sharp blade cuts better and lasts longer.

For improving cut quality, adjust the saw’s speed settings. A slower speed reduces heat buildup. This minimizes the chance of warping or melting the aluminum. Use a cutting lubricant to help with smooth cuts.

| Tip | Description |

|---|---|

| Clean Regularly | Remove dust and debris for better performance. |

| Use Quality Blades | Invest in blades designed specifically for aluminum cutting. |

| Adjust Speed | Lower speeds help prevent heat-related issues. |

| Apply Lubricant | Use cutting lubricant for smoother cuts. |

Alternatives To Chop Saws

Using band saws is a great alternative to chop saws for cutting aluminum. They provide a smoother cut and reduce the chance of burrs and sharp edges. Band saws are ideal for both straight cuts and curved cuts.

Consider using band saws if you need to cut thicker pieces of aluminum. They handle larger workpieces better than chop saws. With the right blade, band saws can make precise cuts.

| Advantages of Band Saws | Disadvantages of Band Saws |

|---|---|

| Smoother cuts | More expensive |

| Less waste | Requires more space |

| Versatile for shapes | Learning curve for setup |

CNC routing is another option worth considering. It offers high precision and can cut complex shapes. Ideal for large production runs, CNC routing saves time and reduces manual labor.

Faqs On Cutting Aluminum

Cutting aluminum with a chop saw can lead to some common issues. Burring occurs when the blade makes rough edges. This can be fixed by using a proper cutting blade. Dulling of the blade happens quickly with aluminum. Regularly check and replace blades to maintain efficiency.

Another issue is melting. This happens due to excessive heat while cutting. Use a slower feed rate to avoid this problem. Feed rate is how fast you push the material into the saw. A coolant or lubricant can help manage heat.

Always ensure the aluminum is securely clamped. This prevents movement and improves safety. Proper safety gear should be worn, including goggles and gloves. Always follow the manufacturer’s instructions for best results.

Frequently Asked Questions

Can A Chop Saw Cut Aluminum Effectively?

Yes, a chop saw can cut aluminum effectively. However, it is essential to use the right blade designed for cutting non-ferrous metals. A carbide-tipped blade works best for clean, precise cuts. Always ensure you secure the aluminum properly to avoid movement during cutting.

What Type Of Blade Is Best For Aluminum?

The best blade for cutting aluminum is a carbide-tipped blade. These blades are designed to handle non-ferrous materials, providing clean cuts. Ensure the blade has a fine tooth count for smoother finishes. Using the right blade reduces the risk of burrs and other imperfections.

Is It Safe To Cut Aluminum With A Chop Saw?

Yes, it is safe to cut aluminum with a chop saw if you follow safety precautions. Always wear safety goggles and gloves to protect against metal shards. Ensure the workspace is clear and well-lit. Properly securing the aluminum piece minimizes the risk of accidents during cutting.

How Do I Prepare Aluminum For Cutting?

To prepare aluminum for cutting, clean the surface to remove any debris or oils. Measure and mark your cutting line accurately. Secure the aluminum firmly in place using clamps or a vise. This preparation ensures precise cuts and enhances safety while using the chop saw.

Conclusion

Cutting aluminum with a chop saw is definitely possible. Using the right blade is crucial for achieving clean cuts. Always prioritize safety by wearing protective gear. This method offers efficiency and precision for your projects. With the right preparation, your aluminum cutting tasks can be straightforward and effective.

Happy cutting!