Can You Drill Out a Barrel Lock? Proven Method!

Yes, you can drill out a barrel lock. While it’s a method of last resort for accessing a locked compartment when no key is available, it requires caution and the right tools to avoid damaging the surrounding material. This guide provides a proven, step-by-step approach for safely drilling out a barrel lock, ensuring you understand the process and necessary precautions.

Hey there, DIY friends! Md Meraj here. Ever faced a stubborn barrel lock – maybe on a toolbox, a cabinet, or even a storage unit – and realized your key has vanished into thin air? It’s a frustrating moment, I know! We’ve all been there, standing there, totally stuck. But don’t worry, there’s a common solution that often works when all else fails: drilling out the lock. It might sound a bit intimidating, but with a little guidance and the right approach, it’s a task you can handle. We’ll go through it together, step by step, making sure you feel confident and safe as we tackle this common lock-and-key problem. Get ready to regain access!

What Exactly is a Barrel Lock?

Before we dive into drilling, let’s quickly understand what a barrel lock is. You’ve likely seen them. They’re commonly found on things like display cabinets, bicycles, scooters, and even some older drawers. The term “barrel lock” often refers to the pin tumbler lock mechanism housed within a cylindrical (barrel-shaped) body. The key typically has a distinctive shape, often with a series of notches or teeth designed to align internal pins, allowing the cylinder to turn. Their compact design makes them popular for situations where a low-profile lock is needed, but their security can vary greatly.

While they offer a decent level of security for lighter applications, they are not typically considered high-security locks due to their common construction and susceptibility to certain bypass methods. However, when you lose the key, drilling them out becomes a viable, albeit destructive, solution.

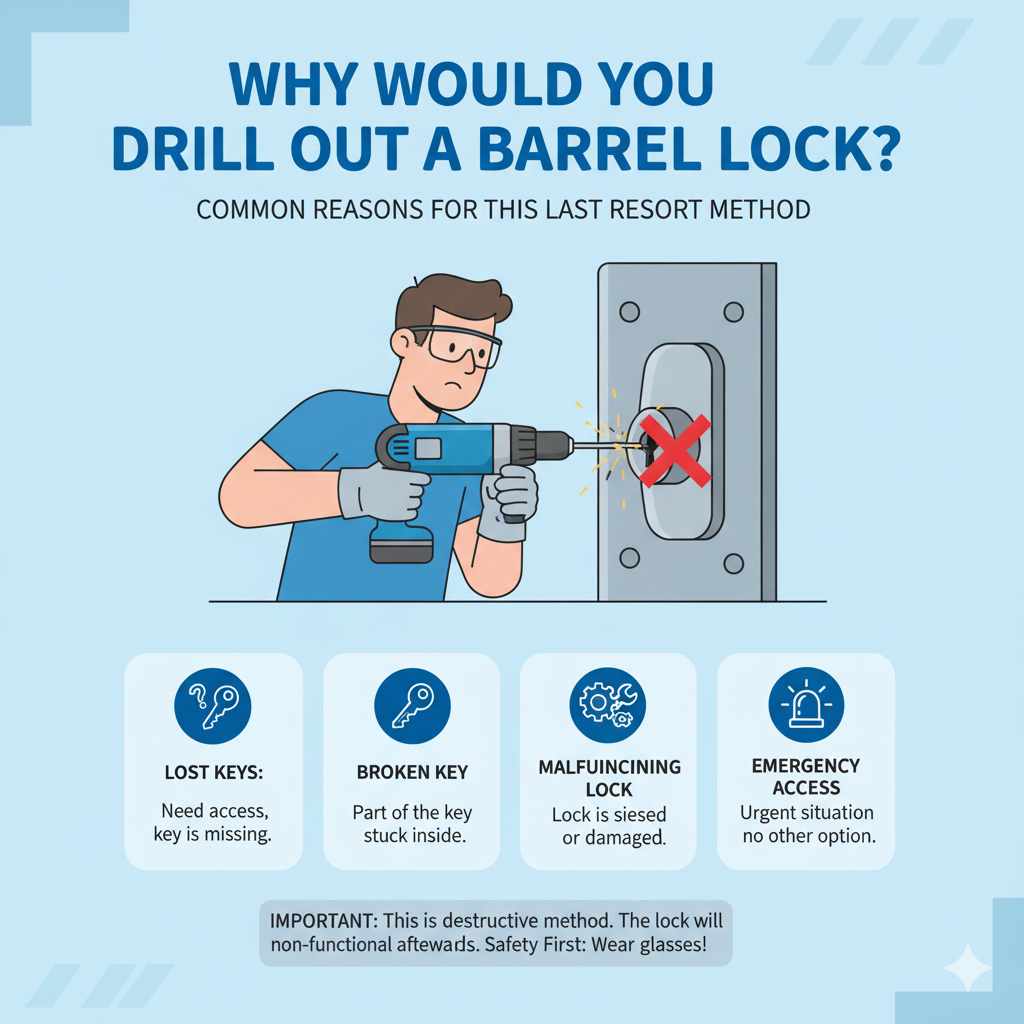

Why Would You Drill Out a Barrel Lock?

There are a few primary reasons why someone might consider drilling out a barrel lock:

- Lost Keys: This is the most common reason. The key is missing, and you need to access the item the lock secures.

- Broken Key: Sometimes a key can break off inside the lock, making it impossible to operate.

- Malfunctioning Lock: An old or damaged barrel lock might seize up, refusing to open even with the correct key.

- Emergency Access: In urgent situations where immediate access is required and no other method is feasible.

It’s important to remember that drilling a lock is a destructive method. It means the lock will no longer be functional after the process. This is why it’s generally considered a last resort once other options, like trying to pick the lock or finding a locksmith, have been exhausted or are not viable.

Important: Safety First!

Before we even touch a drill, let’s talk safety. This is super important, especially when working with tools. Safety glasses are a must! Drilling creates metal shavings and debris that can fly into your eyes. Also, consider wearing gloves to protect your hands from sharp edges. Work in a well-lit area so you can see exactly what you’re doing. If you’re unsure about any step, it’s always better to pause and ask someone more experienced or even consult a professional. Remember, the goal is to solve a problem, not create new ones!

Tools You’ll Need

To successfully drill out a barrel lock, you’ll want to gather a few essential tools. Having the right equipment makes the job much easier and safer. Here’s a list of what you’ll likely need:

- Safety Glasses: Absolutely non-negotiable for eye protection.

- Work Gloves: To protect your hands.

- Power Drill: A variable-speed drill is ideal.

- Drill Bits: Various sizes. You’ll primarily need bits made for metal, starting small and increasing in size. A center punch is also very helpful.

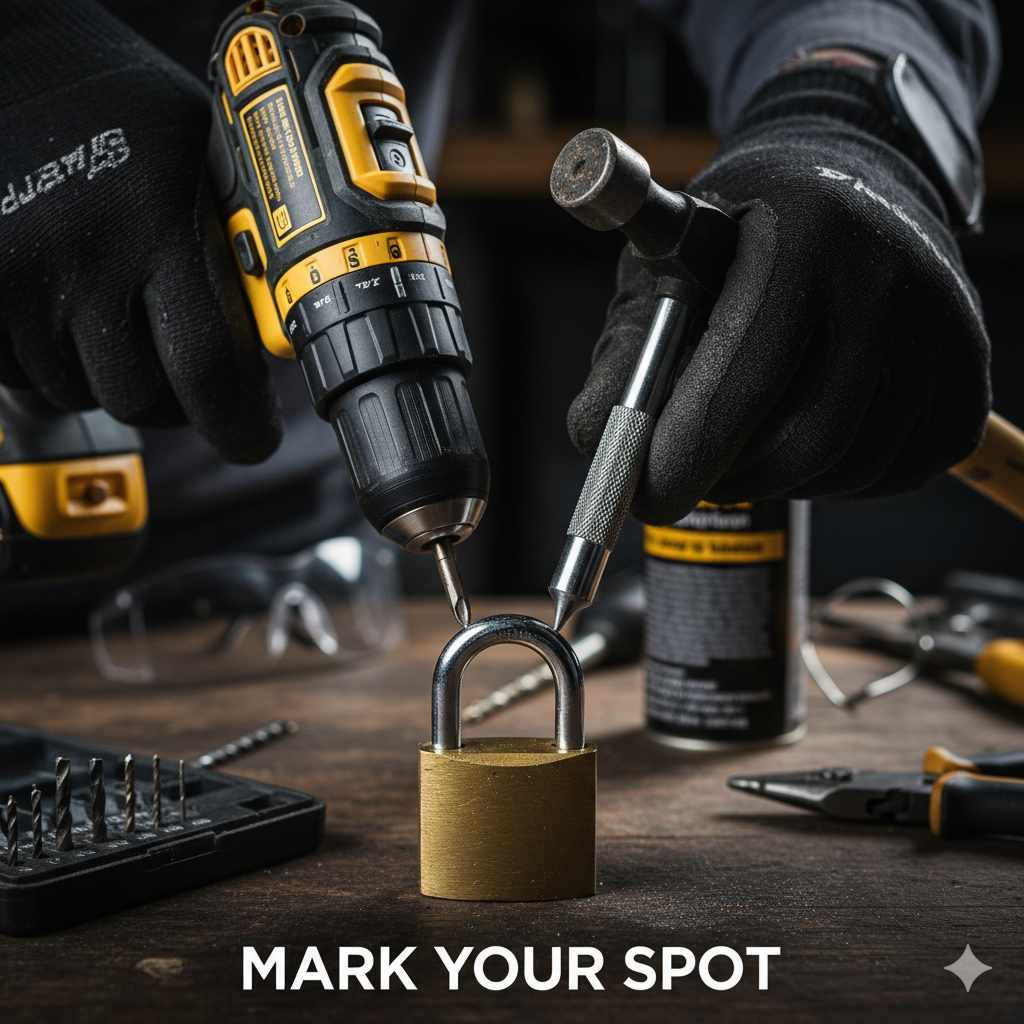

- Center Punch: To create a starting point for the drill bit, preventing it from wandering.

- Hammer: To strike the center punch.

- Pliers or Vice Grips: To hold the lock cylinder once it’s loosened.

- Screwdriver (Flathead): May be needed to help manipulate parts after drilling.

- Penetrating Oil (like WD-40): To help loosen seized parts.

Having a good quality drill and sharp metal drill bits will make a significant difference in how smooth the process goes. Dull bits can make the metal harder to penetrate and can overheat.

The Proven Method: Step-by-Step Guide

Alright, let’s get to it! This method focuses on drilling through the core of the lock cylinder to destroy the pins, allowing you to bypass the locking mechanism. We’ll be working from the keyway, which is the most direct path to the internal pins.

Step 1: Prepare the Lock and Work Area

First, ensure the item the lock is attached to is stable. If it’s a portable item like a toolbox, place it on a sturdy workbench. Make sure you have ample light. If the lock seems stiff or dirty, give it a spray of penetrating oil and let it sit for a few minutes. This can help loosen things up and make drilling smoother. Put on your safety glasses and gloves now.

Step 2: Locate the Pin Shear Line

The keyhole in a pin tumbler lock contains a series of pins. These pins are spring-loaded and are divided into two parts: the key pin and the driver pin. When the correct key is inserted, it lifts the pins so that the gap between the key pin and the driver pin aligns perfectly with the edge of the cylinder’s plug. This imaginary line is called the “shear line.” Our goal is to drill along this shear line to destroy these pins.

For most barrel locks, the shear line is located directly above the keyway, within the cylinder itself. You’ll be drilling into the cylinder, aiming to cut through all the pins within their housings.

Step 3: Mark the Drill Spot

Using your center punch and hammer, make a small indentation directly above the keyway. This indentation will serve as a guide for your drill bit, preventing it from slipping off the smooth metal surface. Aim for a spot that seems centered over where the internal pins would be located.

Step 4: Start Drilling with a Small Bit

Select a small metal drill bit. A good starting point is typically around 1/8 inch (about 3mm). Align the tip of the drill bit with the indentation you made with the center punch. Begin drilling at a slow, steady speed. Apply firm but not excessive pressure. Allow the drill bit to do the work.

Drill straight into the lock cylinder. You should feel the bit cutting through the metal. The depth you need to drill is typically until you’ve gone past the shear line, effectively destroying all the pins within the lock cylinder.

Step 5: Increase Drill Bit Size

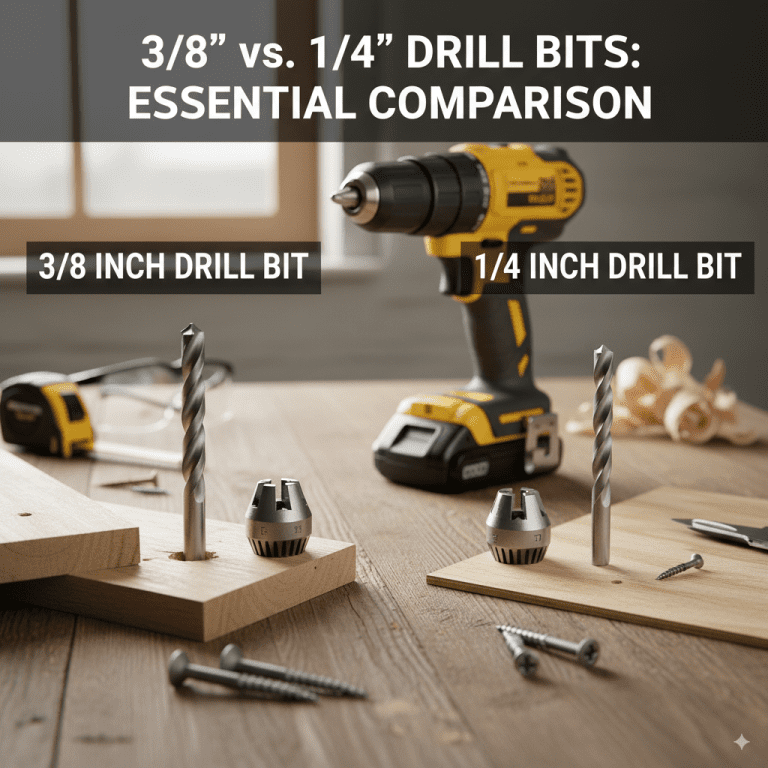

Once you’ve drilled to a sufficient depth with the small bit, and assuming you’ve encountered resistance from the pins, you’ll need to enlarge the hole. This is done to break apart the pins completely. Switch to a slightly larger drill bit, perhaps 3/16 inch (about 5mm) or even 1/4 inch (about 6mm), depending on the size of the lock cylinder and how aggressive you need to be.

Continue drilling straight, once again ensuring you’re going deep enough to destroy all the pins. You might feel the drill bit break through resistance as it cuts through the pin stacks. Keep drilling until you can feel less resistance, indicating you’ve likely cleared the pin chambers.

Step 6: Final Drilling or Manipulation

In some cases, you might need to use an even larger drill bit, sometimes up to 5/16 inch (about 8mm) or 3/8 inch (about 10mm), to completely remove the remaining parts of the pins and the central core of the lock cylinder. The goal is to create a hole large enough to clear out the pin tumblers and springs.

After drilling, the lock cylinder might still be somewhat in place. You may need to use a flathead screwdriver to gently pry apart the components or use pliers/vice grips on any protruding parts of the cylinder to turn and pull it out. If the lock opens, you’ve succeeded! You can then easily remove the barrel and its remains.

Drill Bit Sizes and Purpose

Here’s a quick reference table for the drill bits you might use:

| Drill Bit Size (Approximate)PurposeNotes | ||

|---|---|---|

| 1/8 inch (3mm) | Initial penetration and breaking first set of pins. | Start with this to create a clear entry point. |

| 3/16 inch (5mm) – 1/4 inch (6mm) | Enlarging the hole, destroying more pins and springs. | Increases the chance of breaking up the entire pin stack. |

| 5/16 inch (8mm) – 3/8 inch (10mm) | Final clearing of the cylinder core. | May be necessary for larger locks or stubborn pins. |

Alternative: Drilling the Sidebar (Not for Typical Barrel Locks)

It’s worth noting that some locks, particularly disc detainer locks (often used on storage units or bicycles), have a different mechanism. For these, drilling the sidebar that engages the locking mechanism, rather than the keyway, is a common destructive entry method. However, the “barrel lock” typically refers to pin tumbler mechanisms, and the method described above is the standard approach for those.

Important Considerations and Tips

Here are some extra tips to help you through the process:

- Drill Speed: Use a slower speed for getting started and a medium speed once you’re through the initial metal. Too high a speed can overheat the drill bit and the lock.

- Coolant: For tougher locks, especially with hardened steel components, using a metal drilling lubricant or cutting oil can help prevent overheating and make drilling smoother.

- Don’t Force It: If you’re encountering extreme resistance, stop. You might be drilling at an angle, hit a particularly hard part of the lock, or the lock might be more robust than anticipated. Forcing it can break your drill bit.

- Lock Type Matters: The success and ease of drilling depend on the quality and material of the lock. Cheaper, softer metal locks are easier to drill than those made with hardened steel. A quick search online for your specific lock model might give you an idea of its construction. For example, many bike locks use hardened steel that is much more difficult to drill through. Resources like https://www.locksmiths.co.uk/locksmith-guides/lock-types/ offer insights into different lock categories.

- When to Call a Pro: If you’re dealing with a high-security lock, a very large or complex lock, or if you’re simply not comfortable with the process, it’s always best to contact a professional locksmith. They have specialized tools and knowledge to open locks with minimal damage, sometimes even without destruction. You can often find local locksmiths easily through a quick search query like “locksmith near me.”

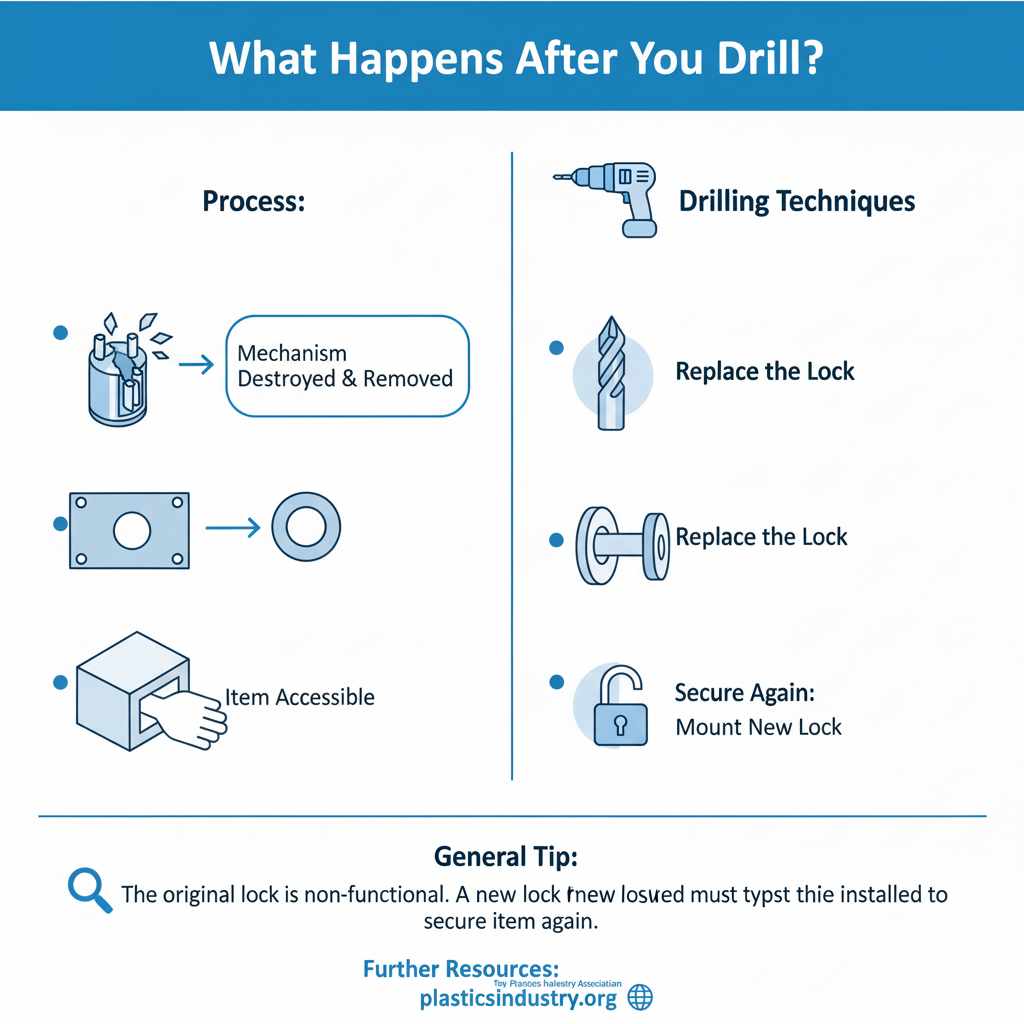

What Happens After You Drill?

Once you’ve successfully drilled out the barrel lock, the mechanism inside will be destroyed. You should be able to remove the remnants of the lock cylinder. The item it was securing will now be accessible. You will, of course, need to replace the lock entirely if you want to secure it again. Any new lock will need to be mounted in its place.

FAQ: Drilling Barrel Locks for Beginners

Q1: Is drilling a barrel lock difficult for a beginner?

A: It can be challenging for a complete beginner, especially if they’re not familiar with using a power drill or metal drill bits. However, by following these steps carefully and using the right tools, it becomes much more manageable. Patience and a steady hand are key.

Q2: Will drilling damage the item the lock is on?

A: There’s always a risk of collateral damage, but if you focus your drilling solely on the lock cylinder and are careful, you can often minimize damage to the surrounding material. Measure carefully and drill precisely. For delicate items, professional help might be wiser.

Q3: Can I use a hand drill instead of a power drill?

A: While technically possible, using a hand drill (brace and bit) is significantly more difficult and time-consuming for drilling metal. Power drills provide consistent speed and torque which are crucial for efficiently cutting through metal lock components. A power drill is highly recommended.

Q4: What if the drill bit breaks inside the lock?

A: If a drill bit breaks off, it can make the situation more complicated. You might need to try to extract the broken bit using pliers or a specialized screw extractor. Sometimes, if the bit is small enough and breaks off after you’ve made sufficient progress, you can drill around it or alongside it with a larger bit. However, if this happens, it might be time to consider calling a locksmith.

Q5: How deep do I need to drill?

A: You need to drill deep enough to pass the “shear line”—the point where the pins meet within the lock cylinder. This means drilling through all the pin chambers. For most standard barrel locks, drilling about 1/2 to 3/4 inch (12-19mm) into the cylinder is usually sufficient, but this can vary. The goal is to destroy the internal mechanism. You’ll know you’re there when the lock cylinder starts to loosen or turn.

Q6: Is drilling a barrel lock legal?

A: It is perfectly legal to drill out a lock that you own or have explicit permission to access. However, attempting to drill out a lock on property you do not own or have permission for can be considered vandalism or attempted burglary, which are illegal. Always ensure you have the right to disable the lock.

Q7: What kind of locks can typically be drilled out?

A: Most standard pin tumbler locks, including many common barrel locks, padlocks, and some deadbolts, can be drilled out. However, locks with specialized hardened steel cores, anti-drill pins, or complex internal mechanisms (like high-security locks) are significantly more difficult, and may require specialized tools or techniques, or are best left to professionals.

Conclusion: Regaining Access and Moving Forward

Facing a locked item with no key can feel daunting, but as we’ve explored, drilling out a barrel lock is a viable method when all other options are exhausted. It’s a process that requires careful preparation, the right tools, and a steady hand. By following the step-by-step guide, focusing on safety, and understanding the mechanics of the lock, you can successfully gain access to what’s behind it.

Remember, this is a destructive technique, meaning the lock will no longer function afterward. You’ll need to replace it to restore security.