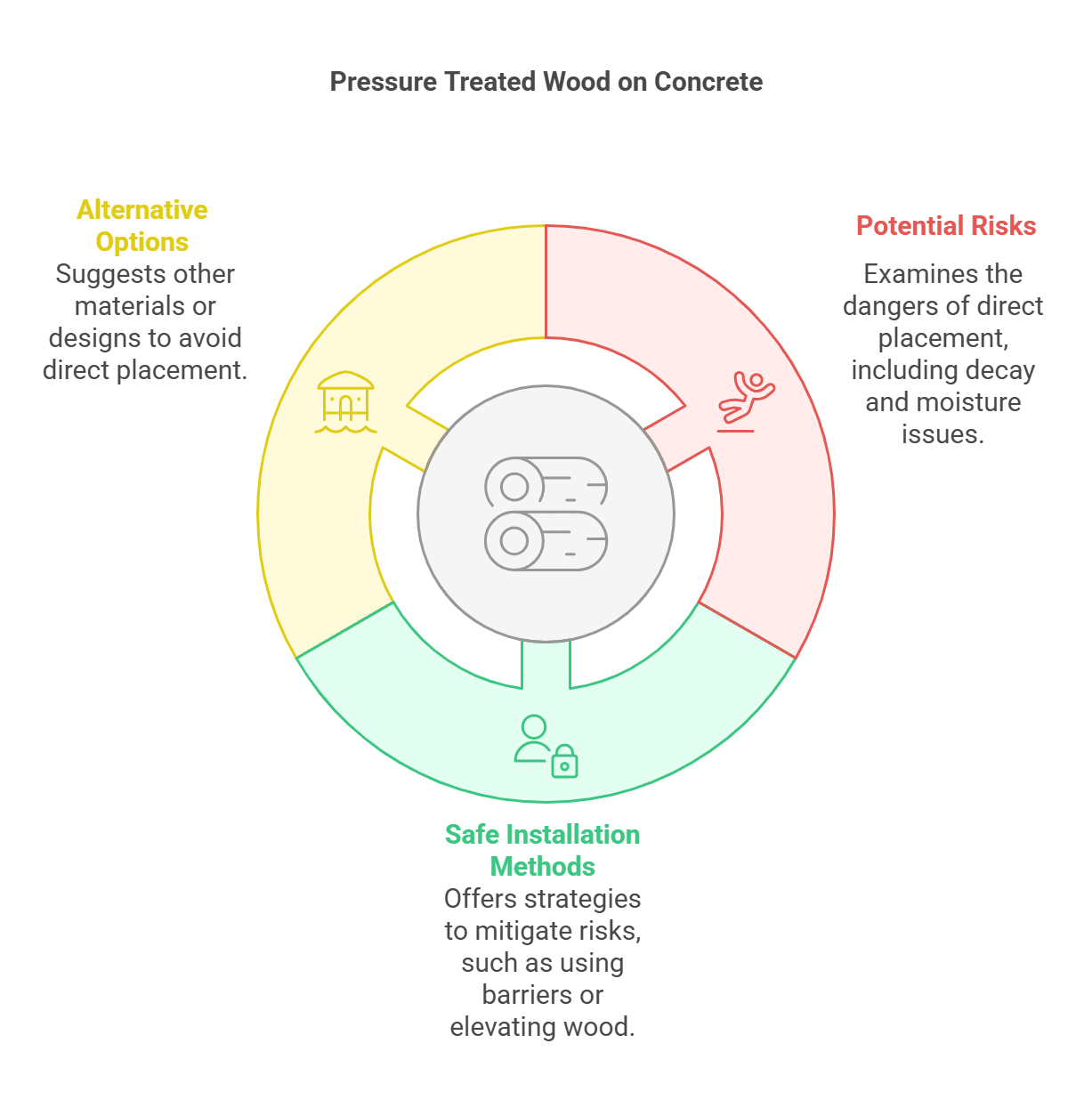

Can You Put Pressure Treated Wood Directly On Concrete? Amazing Insights Revealed

No, pressure treated wood should not be placed directly on concrete due to moisture retention and potential rotting problems. When pressure-treated wood comes into contact with concrete, the moisture from the concrete can be absorbed by the wood, leading to decay and weakening over time.

To prevent this, it is advisable to have a barrier between the wood and the concrete, such as a plastic moisture barrier or blocks to create a gap for air circulation. This will help maintain the longevity and structural integrity of the pressure treated wood.

Pressure treated wood is a popular choice for outdoor projects due to its resistance to decay and insect infestation. However, when it comes to placing pressure treated wood directly on concrete, it is essential to consider the potential issues that may arise. We will explore the reasons why pressure treated wood should not be in direct contact with concrete and discuss the importance of using a barrier to prevent moisture absorption and rotting. By understanding these considerations, you can ensure the long-lasting durability of your pressure treated wood projects.

Why Choose Pressure Treated Wood

Pressure treated wood is a reliable choice for outdoor projects as it is resistant to rot and decay. However, it is not recommended to put pressure treated wood directly on concrete, as the moisture can cause the wood to warp or rot over time.

It is best to use a barrier such as gravel or plastic sheeting between the wood and the concrete to prevent direct contact.

Increased Durability

Pressure treated wood offers superior durability compared to untreated wood, making it an excellent choice for various construction projects. The process of pressure treating involves forcing a preservative solution deep into the wood, which helps protect it from environmental elements and extend its lifespan.

By subjecting the wood to high-pressure treatment, the preservative penetrates the core, providing increased resistance to moisture, rot, and decay. This increased durability makes pressure treated wood an ideal option for outdoor structures, such as decks, fences, and pergolas, where exposure to the elements is inevitable.

Protection Against Insects And Rot

One of the primary reasons to choose pressure treated wood is its exceptional ability to withstand insect damage and rot. The preservatives used in this type of wood treatment effectively discourage termites, carpenter ants, and other wood-damaging insects from infesting and causing structural damage.

Additionally, pressure treated wood exhibits excellent resistance to fungal decay, preventing the growth of harmful organisms and protecting the integrity of the wood for an extended period. This makes it a reliable choice for areas with high humidity, moisture, or where the wood will come into direct contact with the ground, such as in garden beds or posts buried in concrete.

By opting for pressure treated wood, you can rest assured that your project will have a longer lifespan and require less maintenance, reducing the need for frequent replacements and repairs.

The Relationship Between Pressure Treated Wood And Concrete

When considering placing pressure treated wood directly on concrete, it’s important to understand the chemistry between the two materials. Pressure treated wood, as the name suggests, undergoes a process where chemicals are forced into the wood to preserve it against rot, decay, and insects. One of the common chemicals used in this process is copper-based compounds, which provide excellent protection.

The chemicals used in pressure treated wood can react with the alkaline nature of concrete, creating a potential problem if the two materials come into direct contact. The reaction can lead to a process called corrosion, where the chemicals in the wood degrade the concrete over time. This can weaken the structural integrity of the concrete, leading to potential issues.

To prevent this reaction, it’s essential to create a barrier between the pressure treated wood and the concrete, such as using a plastic sheet or rubber membrane. This barrier will prevent moisture from seeping into the wood and allow for proper airflow, reducing the chances of corrosion occurring. By understanding the chemistry between pressure treated wood and concrete, you can make informed decisions about the placement of these materials.

Moisture is another crucial aspect to consider when deciding whether to put pressure treated wood directly on concrete. Both wood and concrete are susceptible to moisture-related issues that can compromise their structural integrity.

Wood, if exposed to moisture for extended periods, can absorb it, leading to swelling, warping, and eventually decay. This can be a significant concern when pressure treated wood comes into contact with concrete, as the moisture from the concrete can be transferred to the wood, accelerating its deterioration.

Concrete, on the other hand, is porous and can absorb moisture from the surrounding environment. If moisture is trapped between the concrete and the pressure treated wood, it can lead to mold and mildew growth, further compromising the materials.

To avoid these effects, it is recommended to elevate the pressure treated wood above the concrete using sleepers or other suitable supports. This will create an air gap, allow for proper drainage, and prevent direct contact between the two materials.

In summary, understanding the chemistry between pressure treated wood and concrete is crucial when considering their placement. By creating a barrier and preventing moisture accumulation, you can ensure the longevity and structural integrity of both materials.

Potential Risks Of Placing Pressure Treated Wood Directly On Concrete

Placing pressure treated wood directly on concrete can lead to potential risks such as moisture trapping, wood decay, and the growth of mold or mildew. It is advisable to use a moisture barrier or elevate the wood with a spacer to minimize these risks.

Wood Decay And Rot

Putting pressure treated wood directly on concrete can lead to potential risks such as wood decay and rot. Moisture from the concrete can seep into the wood, creating a damp environment that is ideal for fungal growth. This can eventually lead to decay and rot, compromising the structural integrity of the wood. To prevent this, it is important to create a barrier between the wood and concrete.

Air Circulation And Drying Out

When pressure treated wood is in direct contact with concrete, it can hinder air circulation and prevent the wood from drying out properly. Without proper airflow, moisture can become trapped, increasing the risk of wood decay. By providing a gap or using a moisture-resistant material between the wood and concrete, air circulation is promoted, allowing the wood to dry out efficiently.

Increased Moisture Content

By placing pressure treated wood directly on concrete, there is a higher chance of the wood absorbing moisture from the concrete. This increased moisture content can lead to a range of issues, including warping, swelling, and shrinking. Over time, these issues can cause the wood to become unstable and compromised. To minimize the risk of increased moisture content, it is advisable to use a moisture barrier or elevate the wood slightly above the concrete surface.

In summary, when placing pressure treated wood directly on concrete, potential risks like wood decay, hindered air circulation and drying, as well as increased moisture content can arise. By taking precautions such as using a barrier or elevating the wood, these risks can be minimized, helping to ensure the longevity and durability of the wood structure.

Ways To Safely Install Pressure Treated Wood On Concrete

When it comes to adding a touch of natural beauty to your outdoor space, pressure treated wood is a popular choice. However, if you want to install pressure treated wood directly on concrete, there are a few important considerations to keep in mind. This article will explore three options for safely installing pressure treated wood on concrete: using a moisture barrier, using pressure treated wood sleepers, and elevating the wood. Let’s delve into each option below.

Using A Moisture Barrier

One way to protect your pressure treated wood from moisture damage when installing it on concrete is by using a moisture barrier. A moisture barrier, such as a plastic sheet or vapor barrier, creates a barrier between the wood and the concrete, preventing moisture from seeping into the wood and causing it to rot or decay. To use a moisture barrier, follow these simple steps:

- Clean the concrete surface thoroughly to remove any dirt or debris.

- Lay down the moisture barrier over the concrete, ensuring that it covers the entire area where the pressure treated wood will be installed.

- Secure the moisture barrier to the concrete using adhesive or double-sided tape.

- Place pressure treated wood on top of the barrier, ensuring that it is level and securely positioned.

Using Pressure Treated Wood Sleepers

Another option for installing pressure treated wood on concrete is by using pressure treated wood sleepers. Sleepers are horizontal boards that create a framework between the concrete and the pressure treated wood, allowing for proper ventilation and drainage. Here’s how you can use pressure treated wood sleepers for this installation:

- Clean the concrete surface to ensure it is free from dirt, dust, and debris.

- Measure and mark the desired placement of the sleepers on the concrete.

- Secure the sleepers to the concrete using concrete anchors or adhesive.

- Place the pressure treated wood on top of the sleepers, ensuring they are evenly spaced and aligned.

Elevating The Wood

The third option for safely installing pressure treated wood on concrete is by elevating the wood. This method involves creating a raised platform using concrete blocks or pavers as a base for the pressure treated wood. By elevating the wood, you provide proper airflow and drainage, reducing the risk of moisture damage. Follow these steps to elevate the wood:

- Clear the area of any debris and make sure the concrete is clean.

- Place concrete blocks or pavers on the concrete, creating a stable foundation for the wood.

- Position the pressure treated wood on top of the elevated platform, ensuring it is level and securely positioned.

By following these three methods – using a moisture barrier, using pressure treated wood sleepers, or elevating the wood – you can safely install pressure treated wood on concrete while protecting it from moisture-related issues. Whichever method you choose, be sure to prioritize proper ventilation, drainage, and a level installation for lasting durability.

Alternative Options To Consider

Putting pressure-treated wood directly on concrete may seem like a convenient option, but it can lead to moisture-related problems and compromise the longevity of your deck. Fortunately, there are alternative options that you can explore to ensure a sturdy and durable deck.

Using Composite Decking

Composite decking offers an excellent alternative to pressure-treated wood for building a deck directly on concrete. Made from a mixture of wood fibers and recycled plastic, composite decking provides the look and feel of real wood while offering enhanced moisture resistance and durability. Unlike traditional wood, composite decking won’t rot or warp, making it a smart and long-lasting choice.

Composite decking can be installed directly on concrete using specific installation methods. One option is to use sleepers, which are pressure-treated wood beams placed horizontally on the concrete to provide a sturdy base for the composite decking boards. This method not only elevates the deck to prevent moisture accumulation but also enables better air circulation, reducing the risk of mold or decay.

Building A Freestanding Deck

If you prefer a deck that is not directly attached to your concrete surface, building a freestanding deck is another viable option. A freestanding deck is not only versatile but also gives you the flexibility to position it anywhere in your outdoor space. By using beams, posts, and joists, you can construct a durable and stable deck that is separate from your concrete surface.

This option eliminates the need for pressure-treated wood to come into contact with concrete, reducing the risk of moisture-related damage. It also allows for better ventilation and drainage underneath the deck, minimizing the chance of moisture accumulation and potential issues such as rot or mold growth.

When constructing a freestanding deck, it’s important to ensure proper support and structural integrity. Be sure to follow local building codes and guidelines to ensure your deck meets the necessary safety standards.

When it comes to building a deck, it’s crucial to consider alternative options to putting pressure-treated wood directly on concrete. Composite decking and building a freestanding deck are both excellent choices that offer durability, moisture resistance, and longevity. By exploring these alternatives, you can create a beautiful and long-lasting deck without compromising its structural integrity.

Conclusion

Pressure treated wood can be placed directly on concrete, but it is essential to take proper precautions to ensure its longevity. By using a moisture barrier, like plastic or roofing felt, and allowing for adequate ventilation, you can protect the wood from moisture buildup and potential damage.

It is crucial to follow manufacturer guidelines and consult with experts to ensure you are using the correct treatment and installation methods. With careful planning and attention to detail, you can enjoy the durability and beauty of pressure treated wood for years to come.