Can You Use Pressure Treated Wood for Floor Joists: Expert Guide

Are you considering using pressure treated wood for your floor joists? You might be wondering if it’s the right choice for your building project.

This question is more common than you think, and the answer isn’t as straightforward as it seems. The idea of using pressure treated wood often comes with a mix of curiosity and caution. After all, choosing the right material for your floor joists is crucial for the safety and longevity of your structure.

But don’t worry—you’re not alone in this decision-making process. We’ll explore the benefits and potential pitfalls of using pressure treated wood for floor joists, helping you make an informed choice for your next project. Stay tuned to discover if this type of wood is the perfect fit for your needs and how it could impact your construction plans.

Pressure Treated Wood Basics

Pressure treated wood lasts longer. It resists bugs and rot. This wood has special chemicals. These chemicals protect it. Not all wood gets this treatment.

Some wood is just for outdoors. It can get wet. Floor joists need strong wood. They must hold a lot of weight. Using the right wood is important.

Treated wood can be heavy. It might cost more. But it offers safety. Always check the label. Make sure it’s right for your project.

Credit: www.statelinebuilders.com

Benefits Of Pressure Treated Wood

Pressure treated wood is very strong. It lasts a long time. Builders often use it for floor joists. The wood gets a special treatment. This makes it strongerthan regular wood. It can hold up heavy floors. It is a safechoice.

This wood does not roteasily. Bugs do not like it. The special treatment helps the wood stay in good shape. It is great for wetplaces. It does not get damaged quickly. Many people trust it for floor joists.

Considerations For Floor Joists

Pressure treated woodis strong. It supports heavy loads. Builders often choose it for floor joists. Strength is important for safety. Floor joists must hold weight. Furniture, people, and more. Always check the wood rating. Ensure it meets the needs. Safety first.

Pressure treated wood resists water. This is crucial. Moisture causes wood rot. Rot weakens the structure. Floor joists must stay dry. Wood treatment helps prevent damage. Protects against mold. Keeps the home safe. Dry wood lasts longer. It’s reliable.

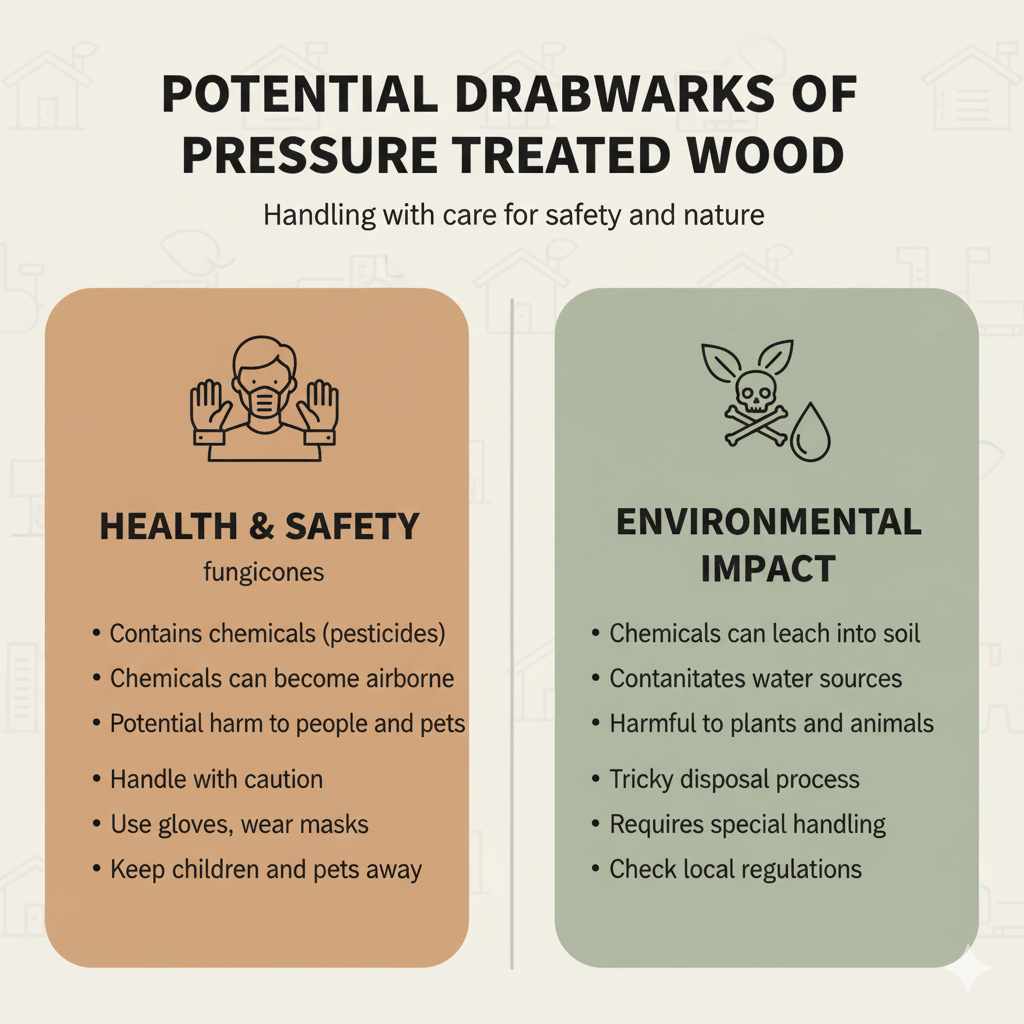

Potential Drawbacks

Pressure treated wood has chemicals. These chemicals keep bugs away. They also stop rot. But they may not be safe. Chemicals can get into the air. They might harm people. Or pets. It is important to handle this wood with care. Use gloves. Wear masks. Keep kids away from it.

The chemicals in the wood might hurt nature. They can wash into the soil. Water can carry them far. This can hurt plants. And animals too. Disposing of treated wood is tricky. You can’t just throw it away. It needs special handling. Some places have rules for this. So, always check local laws.

Installation Tips

Handling pressure treated wood with care is important. Use gloves to protect your hands. Always wear safety goggles to keep your eyes safe. The wood can be heavy. Get help if you need to move it. Wash your hands after touching the wood. This removes any chemicals from the skin. Keep the wood dry. This stops it from bending. Store it in a cool, dry place.

Use galvanized nails for pressure treated wood. These nails do not rust easily. Screws are also a good choice. They hold the wood tightly. Space the fasteners evenly. This helps the wood stay strong. Pre-drill holes if the wood is thick. This stops the wood from splitting. Tighten the fasteners carefully. Do not tighten too much. The wood may crack.

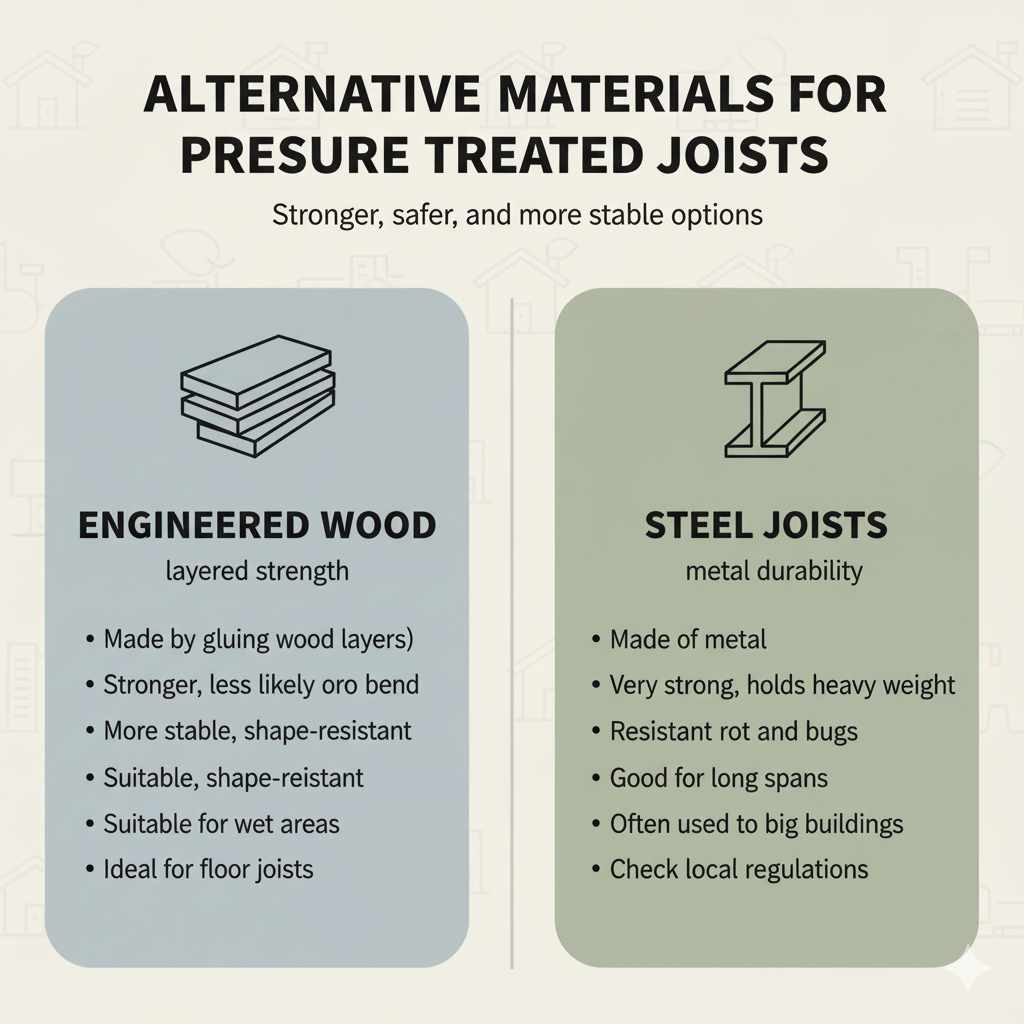

Alternative Materials

Engineered wood is a strong option. It is made by gluing wood layers together. This makes it stronger and less likely to bend. Engineered wood is also more stable than regular wood. It does not change shape easily. This is good for buildings. It can also be used in wet places. This makes it a good choice for floor joists.

Steel joists are another choice. They are made of metal. Steel is very strong. It can hold a lot of weight. Steel joists do not rot or get bugs. They are good for long spans. This means they can cover large areas. Steel joists are often used in big buildings. They are also fire-resistant, which is a big plus.

Expert Recommendations

Experts suggest pressure treated wood for floor joists in damp areas. It resists moisture and prevents decay. This choice extends the lifespan of your flooring structure.

When To Use

Pressure treated wood is strong. Builders use it often for floor joists. It lasts long in damp places. Wood has special chemicals. These chemicals stop bugs and rot. Pressure treated wood can be used in basements. It’s also good in areas with high humidity. Builders choose it for safety and durability. Always check local building codes. They may have rules about using treated wood. Some places allow it, others do not. Ask an expert before starting your project.

Safety Precautions

Safety is important with treated wood. The chemicals can be harmful. Wear gloves when handling it. It’s safe for floors but be careful. Do not burn treated wood. The smoke is dangerous. Cut wood outside or in a ventilated area. Use a mask to avoid breathing dust. Wash hands after touching the wood. Keep children away from sawdust. Follow all safety tips for a safe building experience.

Credit: shedsunlimited.net

Frequently Asked Questions

What Type Of Wood Should I Use For Floor Joists?

Use Douglas fir, Southern yellow pine, or hemlock for floor joists. These woods are strong, durable, and widely available. Ensure the wood is properly graded and treated to resist moisture and pests. Choosing quality lumber ensures structural integrity and longevity for your floor joists.

What Should Never Be Done With Pressure-treated Wood?

Avoid burning pressure-treated wood due to toxic chemicals. Do not use it for indoor or food-related projects. Refrain from sanding or sawing without protection. Avoid contact with skin; wear gloves. Never dispose of it improperly.

How Far Can You Span A 2×8 Pressure Treated Joist?

A 2×8 pressure-treated joist typically spans up to 12 feet for residential flooring. Factors such as load and spacing affect span distance. Always consult local building codes and a structural engineer for precise requirements. Proper installation ensures safety and longevity in construction projects.

Can You Use Pressure-treated Wood For Structural Support?

Pressure-treated wood is suitable for structural support, offering durability and resistance to decay and insects. It’s commonly used in outdoor projects like decks and fences. Ensure proper safety measures during handling and installation. Always check building codes for specific requirements.

Conclusion

Choosing pressure treated wood for floor joists? It’s a solid option. This type of wood resists rot and pests. It adds durability and strength to your structure. Remember to check local building codes. They ensure safety and suitability for your project.

Pressure treated wood can last longer. It’s great for areas with moisture exposure. Always use safety gear when handling. Proper care ensures the wood’s longevity. Make informed decisions for your building needs. Consider consulting with a professional for advice. They can guide you through any specific requirements.

Happy building!