Caster Wheels for Table Saw: Boost Mobility & Efficiency

Are you tired of wrestling with your table saw every time you need to rearrange your workspace? Imagine how much easier your woodworking projects would become if you could effortlessly glide your table saw into the perfect position.

That’s the magic of caster wheels for table saws. These simple yet game-changing tools can transform your workshop, offering flexibility and efficiency at your fingertips. By the end of this article, you’ll discover how caster wheels not only save time but also maximize your productivity, making your woodworking experience smoother and more enjoyable.

Ready to unlock the secret to a more dynamic workspace? Let’s dive in and explore how the right set of wheels can revolutionize your workshop experience.

Types Of Caster Wheels

Swivel casters can turn in any direction. This makes them easy to move. You can push your table saw anywhere. Turning corners is simple with these casters. They work well on smooth floors. Less effort is needed to move heavy items.

Rigid casters only move in one direction. They are very strong and stable. You cannot turn them easily. They work best in straight lines. Great choice for narrow spaces. They keep the table saw in control.

Locking casters have brakes. You can stop the wheels from moving. This keeps your table saw steady. Safety is important. These casters help prevent accidents. Lock them when cutting wood. Unlock them to move again.

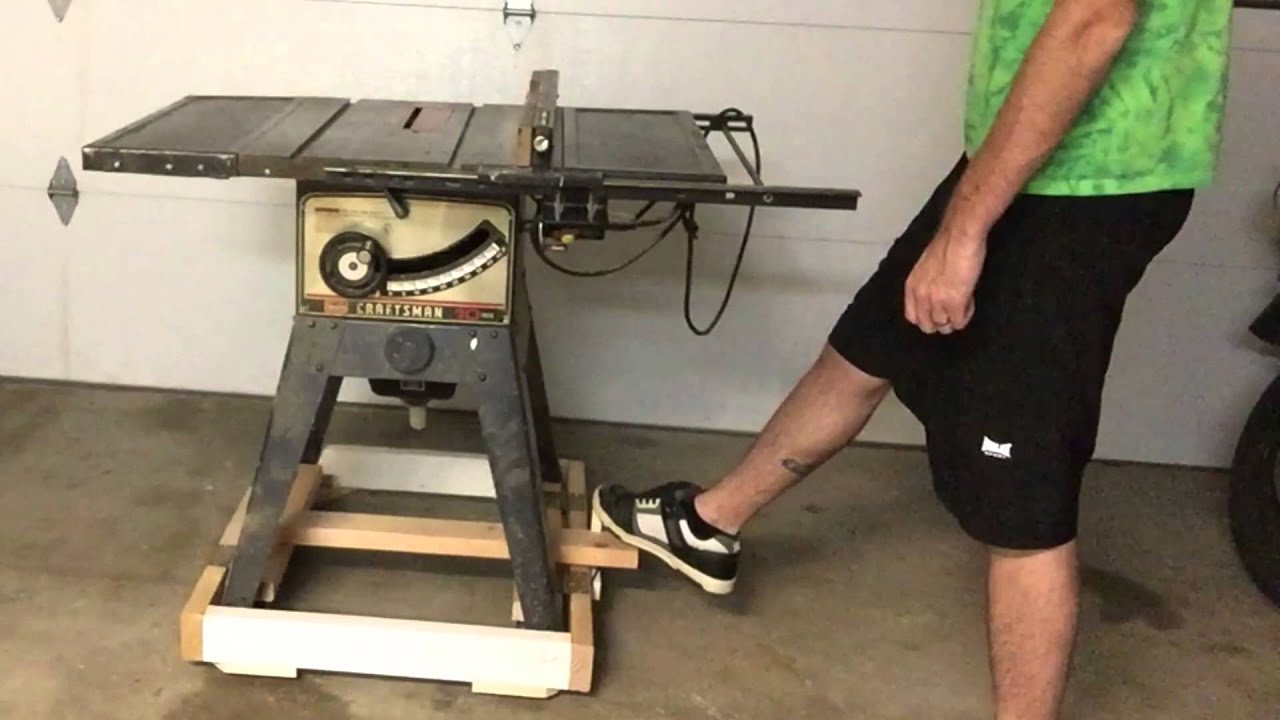

Credit: www.youtube.com

Benefits Of Using Caster Wheels

Caster wheels make table saws easy to move. You can push them with little effort. This helps in cleaning and rearranging your workspace. The wheels roll smoothly on different surfaces. This saves time and energy. It also reduces the risk of hurting yourself.

Moving your saw quickly boosts work speed. Workers can adjust the saw’s position easily. This leads to better cuts and less downtime. The flexibility enhances work quality. It makes the work environment more efficient and user-friendly.

Small workshops need smart space use. Caster wheels help in moving tools around. You can clear out space easily. This makes room for other activities. Your workshop looks neat and organized. It also prevents clutter and chaos.

Materials Used In Caster Wheels

Steel caster wheels are very strong. They can carry heavy loads. These wheels are perfect for hard surfaces. They last long and do not wear easily. Steel wheels can be noisy on hard floors. Using them on carpets is not ideal. They might leave marks on wooden floors.

Rubber wheels are quiet and smooth. They work well on most floors. These wheels do not leave marks. They can carry light to medium loads. Rubber wheels are soft and can wear out over time. They provide good grip on floors. Not ideal for very heavy loads.

Polyurethane wheels mix strength and softness. They can hold heavier loads than rubber. These wheels last longer and are durable. They are quiet on most floors. Polyurethane wheels do not mark floors. They are great for many surfaces. Easy to move and control.

Credit: www.instructables.com

Choosing The Right Caster Wheels

The weight capacity of caster wheels is crucial. You must know the table saw weight. A heavy table needs wheels that can hold it. Check the weight limit on the wheel. Choose wheels that support more than your table saw’s weight.

Not all wheels work on every surface. Surface compatibility matters. Some wheels roll well on carpet. Others are best for concrete or wood floors. Think about where your table saw will be used. Pick wheels that roll smoothly on that surface.

Diameter and width affect how wheels move. Wheel diameter impacts stability. Bigger wheels roll easier over bumps. Wheel width affects grip. Wider wheels offer more grip. Select the right size for your workspace.

Installation Guide

You need some basic tools. First, get a screwdriver. A wrench is also needed. You might need a drill for some tables. Pliers can be helpful too. Gather all tools before you start.

Start by turning off the table saw. This keeps you safe. Next, flip the table on its side. Find the holes on the legs. These are for the wheels. Align the wheels with the holes. Use a screwdriver to attach them. Tighten the screws well. Make sure the wheels can spin freely. Finally, put the table back upright.

Wear gloves to protect your hands. Check the wheels regularly. Keep the area clean. This prevents accidents. Ensure the wheels are locked when not in use. Never leave tools lying around. This keeps everyone safe.

Maintenance Tips

Check your caster wheelsevery month. Look for cracks and dirt. Clean them with a damp cloth. This keeps them rolling smoothly. Tighten any loose screws. This will stop wobbling.

Apply oil to the wheel axles. This keeps them moving easily. Use a small amount. Too much oil attracts dust. Wipe off any extra oil. Use lubricant spray for hard-to-reach places.

Worn-out wheels make noise. They can scratch your floor. Replace them with new ones. Choose the right size and type. Use a wrench to remove old wheels. Install new wheels carefully.

Common Issues And Solutions

Caster wheels can get jammed easily. Dirt and debris often cause this. Keep the wheels clean to avoid jamming. Use a damp cloth to clean them regularly. Check for any small stones stuck in the wheels. Remove them gently with a tool or your hands. Regular cleaning can help the wheels move smoothly.

Uneven rolling is a common problem. It can make your table saw shake. Check if the wheels are worn out. Replace them if needed. Ensure all wheels are the same size. This helps in smoother movement. Tighten loose screws on the wheels. A firm fit reduces uneven rolling.

Noise from caster wheels is bothersome. It often comes from loose parts. Tighten all screws and bolts. Lubricate the wheels with oil. This reduces friction and noise. Avoid using too much oil. Excess oil attracts dust and dirt. Regular maintenance keeps noise away.

Credit: www.youtube.com

Cost Considerations

Buying caster wheels can be cheap. Some wheels cost less than a toy. Plastic wheels are often the cheapest. They work well on smooth floors. Rubber wheels are also cheap. They are good for quiet moves. Always check the weight they can hold. Some cheap ones might break easily. Sales and discounts help save money too. Look for them in stores and online.

Metal wheels last a long time. They are strong and durable. Polyurethane wheels are another choice. They are good on rough floors. Spending more now can save money later. Strong wheels need less fixing. They help the table saw move smoothly. Investing in good wheels makes work easier. It saves time and effort.

Frequently Asked Questions

What Are Caster Wheels For Table Saws?

Caster wheels are detachable wheels that allow your table saw to be easily moved. They provide flexibility in your workspace, making it easier to adjust the table saw’s position. This is especially useful in smaller workshops where space is limited.

How Do Caster Wheels Benefit Table Saws?

Caster wheels provide mobility, allowing you to reposition your table saw with ease. This improves workspace efficiency and safety by enabling quick adjustments. They help in optimizing space and can be locked to keep the saw stable during operation.

Are Caster Wheels Easy To Install On Table Saws?

Yes, caster wheels are generally easy to install on table saws. Most caster wheel kits come with straightforward instructions. You typically need basic tools for installation. Ensure you choose the right size and type for your specific table saw model.

Do Caster Wheels Affect Table Saw Stability?

Caster wheels can affect stability if not properly locked. However, most quality caster wheels come with locks to secure the saw in place. It’s important to check the weight capacity and locking mechanism to ensure stability during use.

Conclusion

Caster wheels for table saws offer great convenience. They make moving tools easy. No more heavy lifting or straining. Just roll your table saw smoothly. This improves your workspace flexibility. You can rearrange your setup anytime. Caster wheels also enhance safety.

They prevent accidents during transportation. Choose the right wheels for your needs. Consider weight capacity and material. Install them carefully. Enjoy a more efficient workshop. Investing in caster wheels saves time and effort. It’s a practical choice for any woodworker.

Make your tasks easier today with caster wheels.