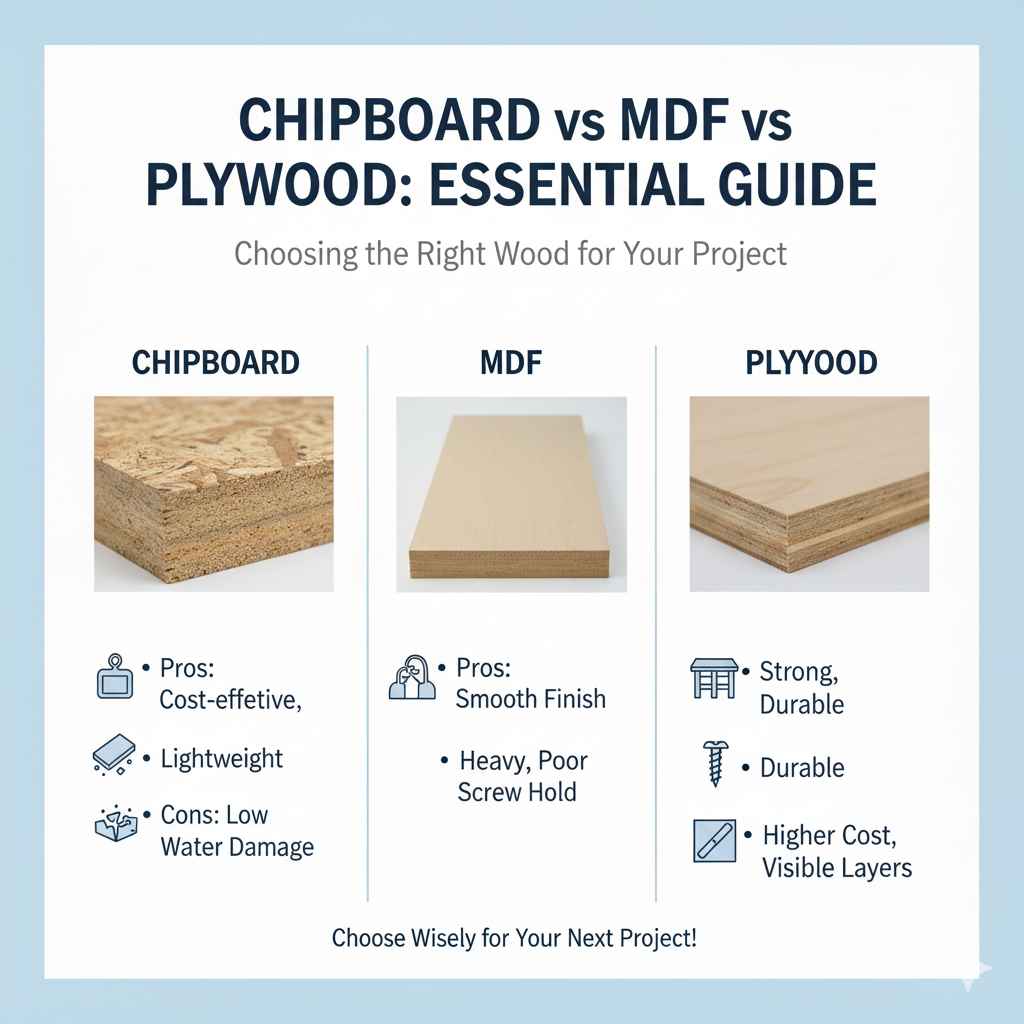

Chipboard vs MDF vs Plywood: Essential Guide

Choosing between chipboard, MDF, and plywood can be confusing! For strength and durability, plywood is often best. MDF is great for smooth finishes like painted cabinets. Chipboard is the most budget-friendly option. This guide breaks down each material, helping you pick the perfect one for your next DIY project with confidence.

Hey there, fellow DIYers and aspiring woodworkers! Md Meraj here, ready to demystify a common puzzle you’ll encounter when starting any woodworking project: understanding the different types of engineered wood. Walk into any hardware store, and you’ll see stacks of chipboard, MDF, and plywood. They might look similar, but they are quite different in how they’re made, how they perform, and, most importantly, which one is best for your specific needs. It’s easy to feel a little overwhelmed when you’re just starting out, but don’t worry!

I’m here to guide you through the ins and outs of chipboard, MDF, and plywood. We’ll explore what each one is, its pros and cons, and how to pick the right material to make your projects sturdy, beautiful, and successful. Get ready to build with confidence!

Chipboard vs MDF vs Plywood: The Essential Guide

As a woodworking mentor, I’ve seen many beginners scratch their heads trying to decide which of these common sheet goods to use. Each material has its place, and knowing their differences means you can avoid costly mistakes and achieve the best results for your projects. Let’s break them down one by one.

What is Chipboard?

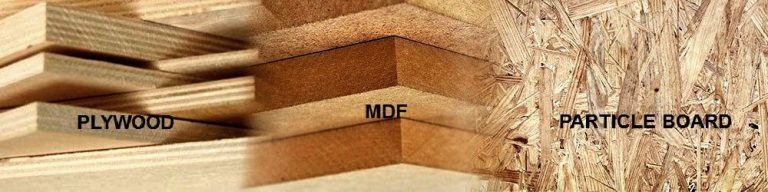

Chipboard, also often called particleboard, is made from wood chips, shavings, sawdust, and other wood waste products. These particles are bonded together with a synthetic resin or glue under high pressure and heat. Think of it like a very coarse pressed wood. Because it uses recycled wood waste, it’s generally the most affordable option among the three.

Pros of Chipboard:

- Affordability: It’s usually significantly cheaper than MDF or plywood.

- Lightweight: Easier to handle and maneuver, especially for large sheets.

- Consistent Texture: No knots or grain patterns, which can be a benefit for some finishes.

- Good for Laminates: It’s often used as a core for laminate flooring or melamine-coated furniture.

Cons of Chipboard:

- Low Strength and Durability: It’s prone to chipping, cracking, and breaking, especially around edges and corners.

- Poor Screw Holding: Screws don’t grip well and can easily strip or pull out.

- Susceptible to Moisture: It swells and disintegrates when exposed to water or high humidity.

- Dusty when Cut: Cutting chipboard produces a lot of fine dust.

- Not Ideal for Structural Use: It’s not strong enough for shelves that need to hold significant weight or for exterior projects.

What is MDF (Medium-Density Fiberboard)?

MDF is made by breaking down hardwood and softwood into wood fibers, then combining them with wax and resin binder. These fibers are formed into panels by applying high temperature and pressure. The result is a very dense, smooth, and stable panel. It’s denser than chipboard and much more uniform. MDF is a favorite for projects where a smooth, paintable surface is desired.

Pros of MDF:

- Smooth, Paintable Surface: Its fine, uniform texture provides an excellent base for painting or lacquering, giving a professional, seamless look.

- Consistent Density: It’s strong and stable, meaning it won’t warp or cup easily.

- Good Machining Properties: It can be easily cut, routed, and shaped with sharp tools, creating clean edges and detailed profiles.

- Doesn’t Split or Warp: Unlike solid wood or even plywood, MDF is very stable and less prone to movement due to humidity changes.

- Excellent Screw Holding (in the face): While edges can be tricky, the face of MDF holds screws reasonably well.

Cons of MDF:

- Heavy: It’s denser and heavier than plywood and chipboard, making it harder to handle.

- Susceptible to Moisture: Like chipboard, standard MDF will swell and fall apart when exposed to water. Moisture-resistant versions are available but are more expensive.

- Dust Production: Cutting and sanding MDF produces very fine dust that can be harmful if inhaled. Proper respiratory protection is essential. You can learn more about woodworking dust safety from the Occupational Safety and Health Administration (OSHA).

- Edge Screw Holding: Screwing into the edges of MDF is not very strong; screws can strip easily.

- Cannot Be Used Outdoors: It’s an interior-only material.

What is Plywood?

Plywood is made from thin sheets of wood veneer (plies) that are glued together with adjacent layers having their wood grain rotate 90 degrees to one another. This cross-graining provides exceptional strength, stability, and resistance to warping. Plywood is known for its structural integrity and can be used in a wide variety of applications. The more plies, the stronger and more stable the sheet.

Pros of Plywood:

- High Strength and Durability: Its layered construction makes it very strong, stable, and resistant to cracking, shrinking, and twisting. It’s excellent for shelves, cabinets, and structural components.

- Good Screw Holding: Screws penetrate into multiple layers of wood, providing excellent holding power.

- Versatile: Available in many grades, thicknesses, and wood types (like birch, pine, oak) to suit different needs and budgets.

- Moisture Resistance (relative): While not waterproof, some types of plywood (especially marine-grade) handle moisture better than MDF or chipboard. Exterior grades are also available.

- Aesthetically Pleasing: Many grades of plywood have attractive wood grain faces that can be stained or clear-coated for a beautiful finish.

Cons of Plywood:

- Cost: Generally more expensive than chipboard and often more expensive than MDF for comparable quality.

- Edge Appearance: The layered edge can sometimes look unfinished and may require edge banding or other treatments for a clean look.

- Potential for Splitting: While resistant, edges can sometimes splinter if not cut carefully.

- Glue Lines: Visible glue lines can appear on the edges.

Chipboard vs MDF vs Plywood: A Side-by-Side Comparison

To help you visualize the differences, here’s a table summarizing key characteristics. This is a great reference point when you’re standing in the aisles, trying to make that crucial decision!

| Feature | Chipboard (Particleboard) | MDF (Medium-Density Fiberboard) | Plywood |

|---|---|---|---|

| Construction | Wood chips, shavings, sawdust bonded with resin | Wood fibers bonded with wax and resin | Thin wood veneers glued in alternating grain directions |

| Cost | Lowest | Medium | Higher (varies by grade) |

| Strength | Low | Medium to High | High to Very High |

| Surface Smoothness | Rough (unless laminated) | Very Smooth | Varies (can have visible grain) |

| Moisture Resistance | Very Poor | Poor (unless specially treated) | Moderate (depends on grade) |

| Screw Holding (Edges) | Poor | Poor | Good |

| Ease of Machining | Can crumble | Easy with sharp tools | Good, can splinter |

| Best For | Laminates, budget furniture cores | Painted cabinets, decorative mouldings, smooth surfaces | Shelving, cabinets, structural components, furniture carcasses, jigs |

When to Use Each Material

Knowing the stats is one thing, but when do you actually choose one over the other for your DIY projects? Let’s look at some common scenarios:

Using Chipboard: Best for Budget-Friendly Projects

Chipboard is your go-to when cost is the primary concern and the project won’t face much stress or moisture. It’s most commonly found as the core material in lower-cost furniture that is then covered with a laminate or veneer. For a DIYer, it’s often best to buy chipboard pre-laminated (like with melamine).

- Quick Shelving: If you need some very temporary, light-duty shelving and you’re on a tight budget, chipboard can work. However, be very careful about weight limits.

- Acoustic Panels: Its density makes it useful in some acoustic panel applications.

- Base for Laminates: If you plan to cover your project entirely with laminate or vinyl, chipboard can be a base, provided it’s not for a high-moisture area.

Pro Tip: Always use screws or fasteners designed for particleboard, or pre-drill pilot holes. Better yet, when working with chipboard, consider joining pieces with dowels and glue and reinforcing with pocket hole screws if your joinery requires it, as screw threads may strip easily.

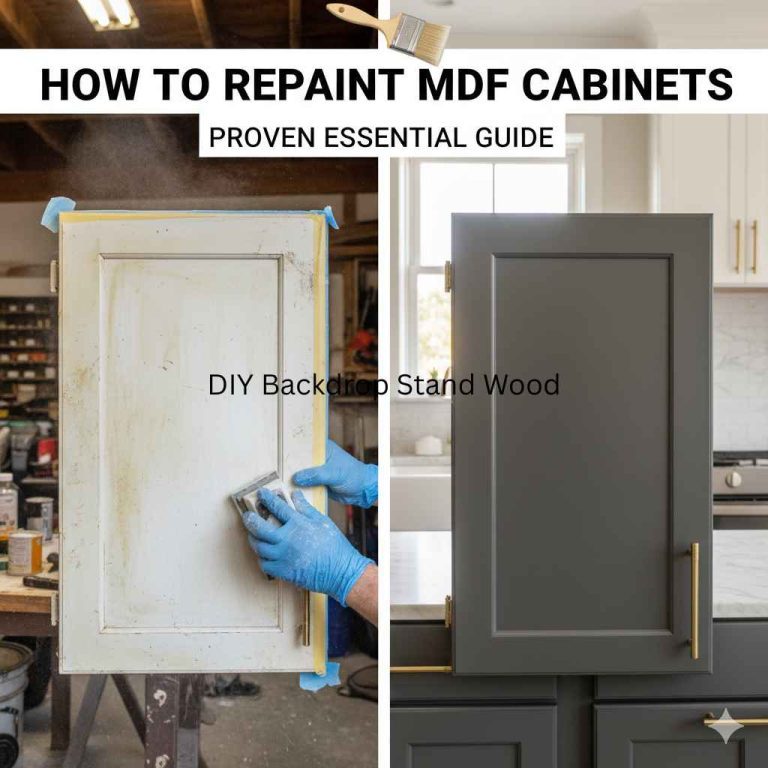

Using MDF: Perfect for Smooth, Paintable Surfaces

MDF shines when you want a flawless finish, especially for painted projects. Its smooth surface and consistent density mean you get professional-looking results that are hard to achieve with other engineered woods.

- Cabinet Doors and Drawer Fronts: This is a classic use for MDF. It takes paint beautifully and can be easily routed for decorative profiles.

- Decorative Mouldings and Trim: For interior trim that you plan to paint, MDF offers a smooth, stable option.

- Wall Paneling: Think wainscoting or Shaker-style wall panels.

- Speaker Boxes: Its density helps deaden vibrations, making it ideal for enclosures.

- DIY Project Bases: For projects like tabletop gaming terrain or dioramas, MDF provides a stable, smooth base.

Cutting Tip: When cutting MDF, use a sharp, fine-tooth blade to get the cleanest cuts. And remember that MDF dust is notoriously fine and can irritate your lungs. Always wear a good dust mask or respirator and eye protection. Setting up dust collection is also highly recommended. You can find great information on dust collection systems for home workshops on the Association for Manufacturing Technology website.

Using Plywood: The All-Rounder for Strength and Stability

Plywood is like the workhorse of the wood panel world. Its strength and stability make it suitable for a vast range of projects, from simple to complex. When you need something to hold weight, resist warping, and last, plywood is often your best bet.

- Cabinet Carcasses: The main boxes of cabinets are frequently made from plywood for its strength and screw-holding ability.

- Shelving: Particularly for shelves that need to support significant weight (books, tools, etc.), plywood is the superior choice.

- Jigs and Fixtures: Makers and woodworkers often use plywood to build sturdy jigs for their saws or routers because it’s stable and easy to work with.

- Furniture Frames and Structures: Plywood is excellent for building the underlying structure of most furniture pieces.

- Subflooring and Structural Sheathing: In construction, higher grades of plywood are used for these essential structural elements.

Grades of Plywood: Plywood comes in different grades based on the quality of the face and back veneers. Common grades include:

- A-A / A-B: High-quality faces, suitable for staining and clear finishes.

- B-B / B-C: Good for painting or when the backside isn’t visible.

- C-D: Utility grades, used where appearance isn’t a factor, often for subflooring or utility purposes.

For most DIY furniture and cabinet projects, a good sanded pine or birch plywood (often labeled as sanded plywood) is a great starting point.

Working with Engineered Woods: Safety First!

Before we wrap up, a word on safety, which is always my top priority when we’re in the workshop. Engineered woods like MDF and chipboard can release formaldehyde as part of their binding agents. While most modern products have low formaldehyde emissions, it’s wise to:

- Work in a well-ventilated area.

- Always wear a dust mask or respirator rated for fine particles.

- Use safety glasses to protect your eyes.

- Consider using low-VOC or formaldehyde-free versions if available for your project.

Plywood can also produce fine dust, so the same precautions apply.

Frequently Asked Questions (FAQ)

What is the strongest material: Chipboard, MDF, or Plywood?

Plywood is generally the strongest and most durable material due to its layered construction with alternating grain directions. It offers excellent resistance to bending and breaking.