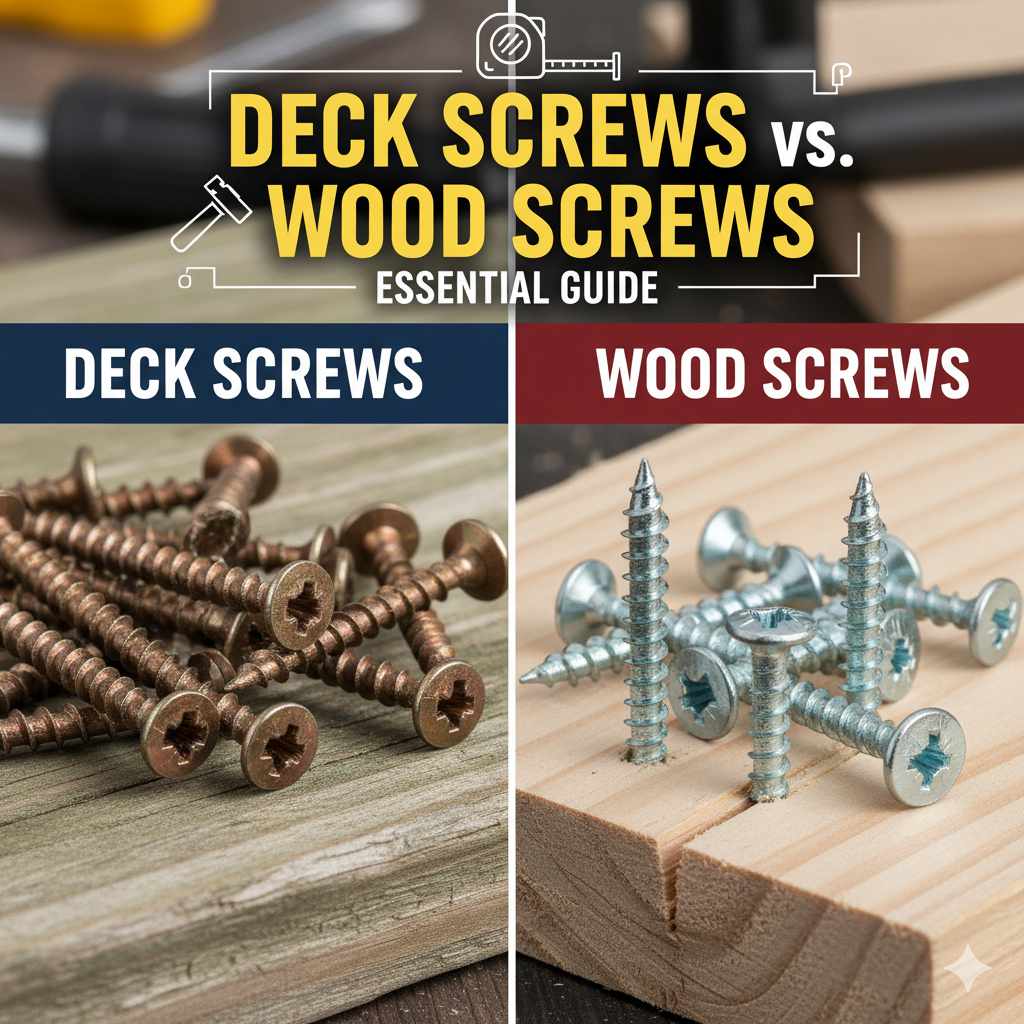

Deck Screws vs Wood Screws: Essential Guide

Deck screws and wood screws are both vital fasteners, but they have key differences in material, coating, and design that make them better suited for specific jobs to ensure strength and longevity. Deck screws are built tougher and coated for outdoor weather resistance, ideal for decks and exterior projects. Standard wood screws are suitable for general indoor carpentry where moisture isn’t a concern.

Hey there, DIY friends! It’s your woodworking buddy, Meraj, here to help you tackle a common question that pops up when you’re building or fixing something: “Which screw should I use?” Sometimes, you grab what looks right, only to find out later it wasn’t the best choice. This can lead to wobbly projects outdoors or even fasteners that rust away! Don’t worry, we’ll clear up the mystery of deck screws versus wood screws in this guide. By the end, you’ll know exactly which screw is your trusty sidekick for any project, big or small, inside or out.

Deck Screws vs Wood Screws: A Quick Look

Choosing the right screw is more than just picking a sharp point. It’s about ensuring your project stands the test of time, especially if it’s going to face the elements. Let’s break down what makes deck screws and wood screws different, so you can feel confident with every turn of your drill.

| Feature | Deck Screws | Wood Screws |

|---|---|---|

| Primary Use | Outdoor projects (decks, fences, pergolas) | Indoor projects (furniture, cabinetry, general carpentry) |

| Material | Hardened steel, often stainless steel or specially coated alloys | Steel, brass, or other metals; can be uncoated or coated |

| Coating | Corrosion-resistant (e.g., ceramic, polymer, hot-dip galvanized) designed for outdoor exposure | Varies; uncoated, zinc-plated, or other finishes suitable for indoor use |

| Thread Design | Often have sharper, deeper threads and a cutting tip to bite into dense wood and resist pull-out. Sometimes a partial thread to pull pieces together. | Tapered threads designed for a good grip in wood without splitting. |

| Head Type | Usually flat head with nibs to recess into wood, or trim head for a less visible finish. | Commonly flat head, round head, pan head. |

| Strength | Generally stronger and designed to withstand bending and shear forces outdoors. | Sufficient for most indoor applications. |

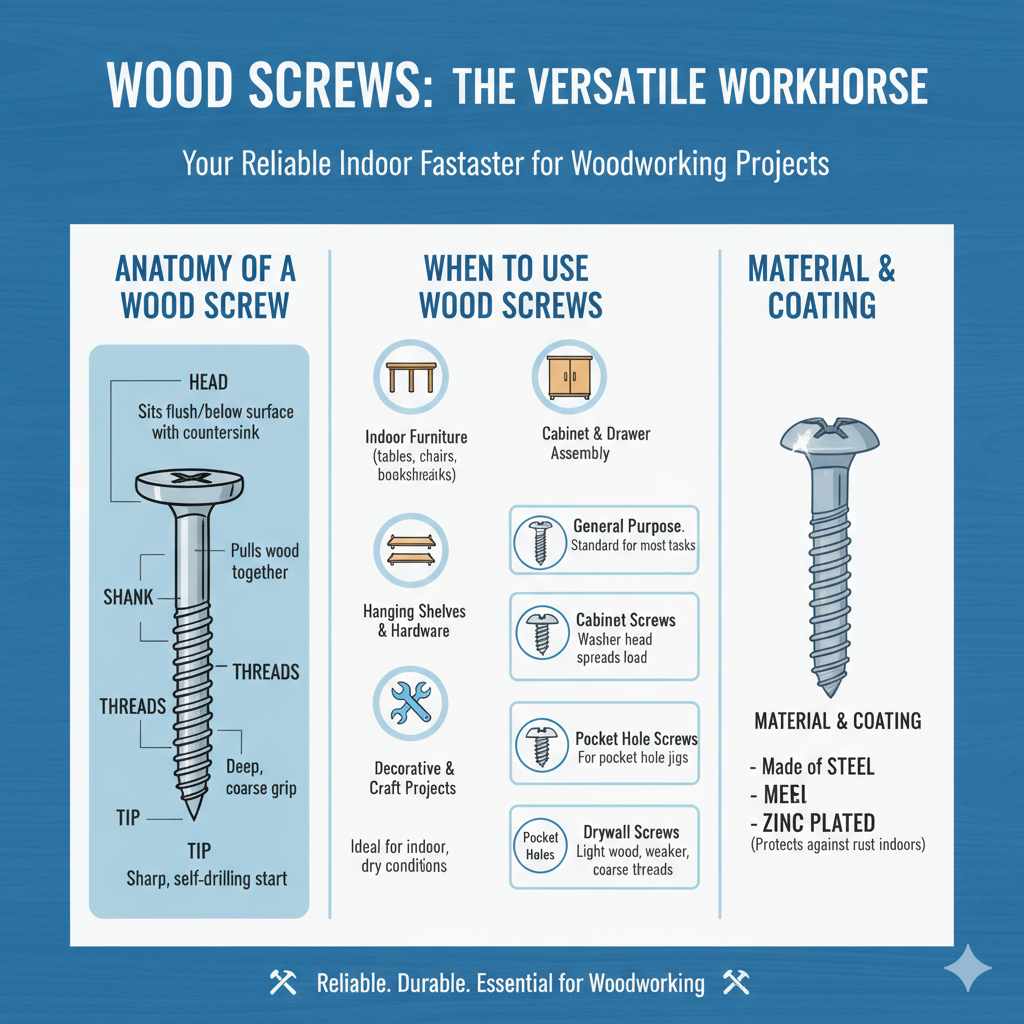

Understanding Wood Screws: The Versatile Workhorse

Wood screws have been around for ages and are the go-to fastener for most indoor woodworking projects. Think of them as your reliable friend for building furniture, assembling cabinets, or just fixing that loose shelf in your living room. Their design is pretty straightforward, focusing on securely joining pieces of wood together indoors.

Anatomy of a Wood Screw

Let’s take a closer look at what makes a standard wood screw tick:

- Shank: This is the smooth part of the screw shaft just below the head. It helps pull the pieces of wood together tightly.

- Threads: These are the spiral ridges that grip the wood. Wood screws typically have deeper, coarser threads than machine screws.

- Tip: The sharp point that allows the screw to start drilling into the wood. Many modern wood screws have self-drilling tips, making starting easier.

- Head: This is the part that sits on the surface of the wood. The most common is the flat head, which is designed to sit flush or slightly below the surface when used with a countersunk hole.

When to Use Wood Screws

Wood screws are perfect for a wide range of indoor projects where moisture and harsh weather aren’t factors. Here are some prime examples:

- Building indoor furniture like tables, chairs, and bookshelves.

- Assembling cabinets and drawers in your kitchen or workshop.

- Hanging shelves and mounting hardware indoors.

- General repairs around the house where wood needs joining.

- Creating decorative wooden items or craft projects.

Types of Wood Screws and Their Uses

While the basic wood screw is versatile, you’ll find variations:

- General Purpose Wood Screws: These are your standard go-to screws for most indoor tasks. They come in various lengths and thread types.

- Cabinet Screws: Often have a washer-like head to spread the load and prevent damage to softer cabinet wood.

- Pocket Hole Screws: Designed specifically for use with pocket hole jigs, these often have a washer head and a self-drilling tip.

- Drywall Screws: While designed for drywall, they are sometimes used in light wood applications due to their sharp point and coarse threads, but they are generally weaker.

The Importance of Material and Coating

Most indoor wood screws are made of steel and often have a protective coating like zinc plating to prevent rust in normal indoor conditions. However, they are not designed to withstand prolonged exposure to moisture, salt, or extreme temperatures.

Exploring Deck Screws: The Outdoor Specialists

Now, let’s talk about deck screws. These guys are the superheroes for anything built outside. Whether you’re constructing a sturdy deck, a beautiful fence, or a charming pergola, deck screws are engineered to handle the elements and keep your project looking great for years.

What Makes Deck Screws Different?

The primary difference lies in their construction and coating, designed specifically for outdoor longevity:

- Corrosion Resistance: This is their superpower! Deck screws are made from materials or coatings that fiercely resist rust, corrosion, and staining caused by rain, humidity, UV rays, and even treated lumber chemicals.

- Strength and Durability: They are typically made from hardened steel or stainless steel, making them stronger and more resistant to bending or breaking than standard wood screws.

- Specialized Designs: Many deck screws have unique thread patterns and head designs that help them drive into tough outdoor lumber, like pressure-treated wood, and prevent pull-out. Some have a “clean shear” design which is important for structural integrity.

When to Use Deck Screws

If your project is going to live outdoors, deck screws are almost always the right choice. Here’s where they shine:

- Building or repairing decks and patios.

- Constructing fences and gates.

- Assembling garden structures like pergolas, arbors, and trellises.

- Attaching siding or trim to the exterior of a house.

- Any project involving pressure-treated lumber, which can be corrosive to standard fasteners.

- Outdoor furniture that will be exposed to the weather.

Types of Deck Screws and Their Coatings

Deck screws come with various finishes to combat the elements:

- Ceramic Coated Screws: Offer excellent corrosion resistance and are often a good, more affordable alternative to stainless steel for general decking.

- Polymer Coated Screws: These have a smooth coating that resists corrosion and can be easier to drive.

- Hot-Dip Galvanized Screws: A thick layer of zinc coating provides robust protection against rust, commonly used for heavy-duty outdoor projects.

- Stainless Steel Screws: The premium choice for the best corrosion resistance, especially in coastal areas or environments with high salt content. They are more expensive but offer unparalleled longevity. You can learn more about the importance of proper fasteners for outdoor structures from resources like the Building Science Corporation, which discusses screws for exterior decks.

Design Features for Outdoor Performance

Beyond the coating, deck screws often feature:

- Cutting Threads/Tips: Allow them to bite into dense outdoor woods more easily, reducing the chance of wood splitting.

- Washer or Trim Heads: Help to secure the decking boards without excessive damage to the surface. Some have “nibs” underneath the head that self-countersink.

- Partial Threads: Many deck screws have a smooth shank near the head. This allows the screw to pull the decking board down tightly against the joist without the threads getting stuck in the top board.

Key Differences Summarized

To really nail down the distinction between these two essential fasteners, let’s boil it down to the core differences:

Material and Strength

Deck screws are built tougher. They use hardened steel or stainless steel to withstand the stresses of outdoor structures and the forces of nature. Standard wood screws are sufficient for indoor use where these extreme demands aren’t present.

Corrosion Resistance

This is arguably the biggest differentiator. Deck screws are coated or made from materials that fight off rust and corrosion, crucial for longevity in rain, sun, and humidity. Standard wood screws offer minimal protection, making them prone to degradation outdoors.

Thread Design and Grip

While both have threads to grip wood, deck screws often have specialized threads and tips to penetrate tougher outdoor lumber and resist pull-out better. Partial threads on deck screws are also common for achieving a tight fit between decking boards and joists.

Cost Consideration

Generally, deck screws are more expensive than standard wood screws due to their specialized materials and coatings. However, the extended lifespan and structural integrity they provide for outdoor projects make them a worthwhile investment.

Choosing the Right Screw for Your Project

So, how do you make the final call? It all comes down to where your project will live and what it needs to do.

For Indoor Projects:

If you’re building a coffee table, assembling kitchen cabinets, or hanging a picture frame indoors, a standard wood screw is your best bet. They are cost-effective and provide plenty of holding power for these applications. Look for zinc-plated steel screws for general use.

For Outdoor Projects:

When your project is exposed to the elements – decks, fences, outdoor furniture, pergolas – you absolutely need deck screws. Opt for ceramic-coated, polymer-coated, galvanized, or stainless steel depending on your budget and the severity of your local climate. Using standard wood screws outdoors is a recipe for rust, staining, and structural failure.

A good rule of thumb from construction professionals is to always specify fasteners that are rated for exterior use when the application demands it. Organizations like the International Code Council Evaluation Service (ICC-ES) provide reports that verify the performance of building materials, including fasteners, ensuring they meet building code requirements for safety and durability.

Treated Lumber and Fasteners

It’s important to note that modern pressure-treated lumber often contains chemicals that can be corrosive to certain metals. This is another reason why specialized deck screws with robust coatings are essential for projects using treated lumber. Always check the recommendations for fasteners when working with specialty woods or treated lumber to ensure compatibility.

Impact on Project Longevity

Using the correct screw directly impacts how long your project will last and how safe it will remain. A deck built with the wrong screws might develop unsightly rust stains or, worse, suffer from premature fastener failure, compromising its structural integrity. A beautifully crafted indoor cabinet might sag or fall apart if weak, non-wood-specific screws are used.

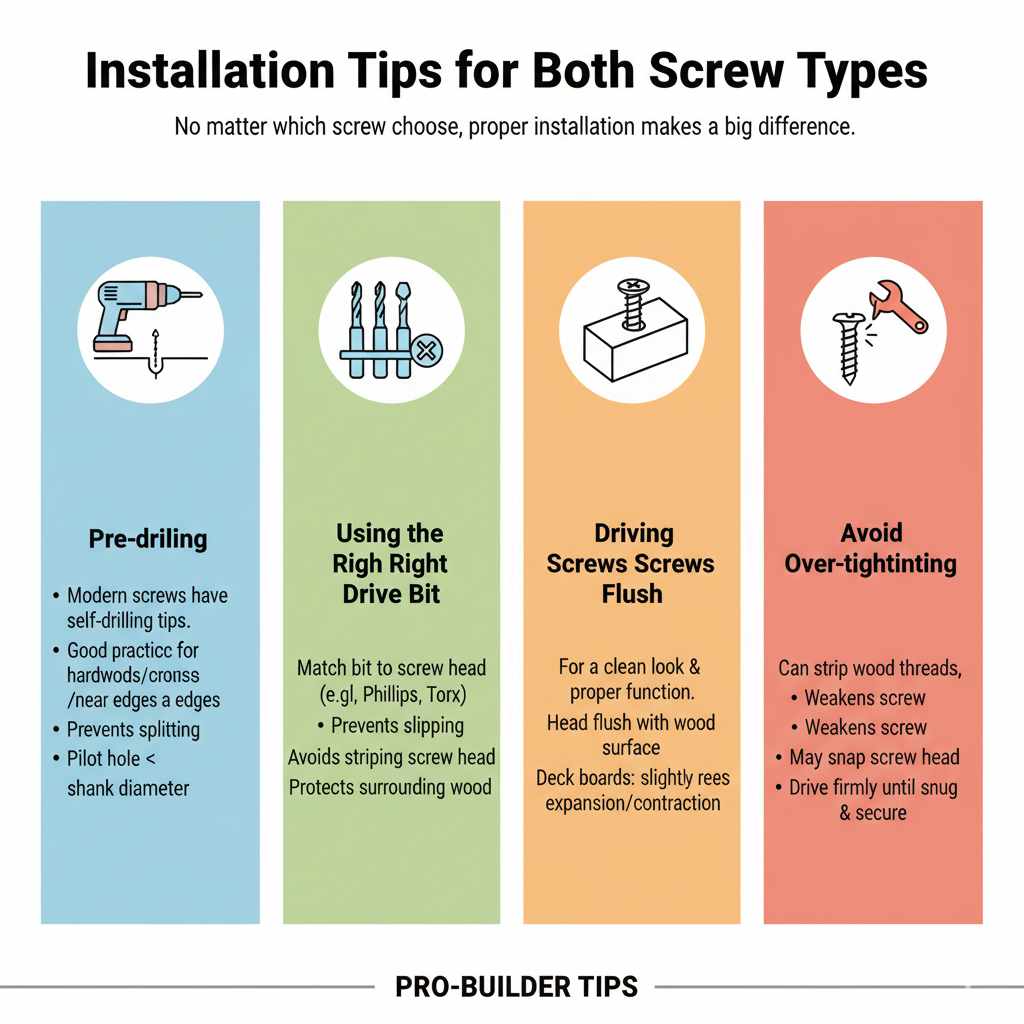

Installation Tips for Both Screw Types

No matter which screw you choose, proper installation makes a big difference:

Pre-drilling

While many modern screws have self-drilling tips, pre-drilling pilot holes is still a good practice, especially in hardwoods or near the edge of a board to prevent splitting. The pilot hole should be slightly smaller than the screw’s shank diameter.

Using the Right Drive Bit

Ensure your drill or driver has the correct bit for the screw head (e.g., Phillips, Torx/Star drive). A proper fit prevents the bit from slipping, stripping the screw head, and damaging the surrounding wood.

Driving Screws Flush

For a clean look and proper function, aim to drive the screw head flush with the surface of the wood. For deck boards, slightly recessing the head can allow for the wood to expand and contract without issues.

Avoid Over-tightening

Over-tightening can strip the threads in the wood, weaken the screw, or even snap the screw head off. Drive the screw firmly until it’s snug and secure.

FAQ: Your Top Questions Answered

Can I use deck screws indoors?

Yes, you absolutely can use deck screws indoors. Since they are designed for harsh outdoor conditions, they will perform more than adequately inside. They offer excellent holding power and corrosion resistance, though their advanced coatings might be overkill and more expensive than needed for most indoor applications.

Can I use wood screws outdoors?

It’s strongly advised not to use standard wood screws outdoors. They are not designed for weather resistance and will quickly rust, stain the surrounding wood, and lose their holding strength. This can lead to project failure and safety hazards, especially for structural elements like decks.

What is the difference between galvanized screws and deck screws?

Galvanized screws are coated with zinc to resist rust. Hot-dip galvanized screws are a type of deck screw that offers good corrosion resistance for outdoor use. However, “deck screws” is a broader category that includes various specialized coatings (ceramic, polymer) and materials (stainless steel) specifically engineered for outdoor durability, often exceeding the performance of basic galvanized screws in certain environments.

Are stainless steel screws better than deck screws?

Stainless steel screws are a type of deck screw, representing the highest tier of corrosion resistance. While they are excellent and often the best choice for extreme coastal or humid environments, they are also the most expensive. For general outdoor projects, high-quality ceramic-coated or polymer-coated deck screws often provide sufficient protection and a better balance of cost and performance.

What does a partial thread on a deck screw mean?

A partial thread on a deck screw means the screw has threads only on the lower portion of the shank, with a smooth section closer to the head. This design is especially useful for joining two pieces of wood, as it allows the smooth shank to pull the top piece tightly against the bottom piece without the threads creating resistance, resulting in a more secure and flush connection.

Why do deck screws cost more?

Deck screws cost more primarily due to the higher quality materials (hardened steel, stainless steel) and specialized coatings (ceramic, polymer, advanced galvanization) required to provide superior strength and corrosion resistance needed for outdoor applications. The manufacturing processes for these specialized screws are also more complex.