Do I Need a Table Saw? Essential Guide for Woodworkers

A table saw is essential for precision cuts in woodworking projects. It’s particularly useful for making straight and repeatable cuts.

Choosing the right tools can significantly impact your woodworking experience. A table saw stands out for its versatility and accuracy. This powerful tool helps you tackle various tasks, from ripping boards to making angled cuts. Whether you’re a hobbyist or a professional, a table saw can enhance your workflow.

It allows for safer cutting compared to handheld saws, minimizing the risk of accidents. Investing in a quality table saw can save you time and improve the quality of your work. Understanding your specific needs will guide you in deciding if this tool is necessary for your projects.

Introduction To Table Saws

A table saw is an essential tool in woodworking. It helps create precise cuts quickly. Many woodworkers prefer it for its accuracy and efficiency. This tool can handle large sheets of wood with ease.

Compared to other tools, a table saw offers more stability. Circular saws can be harder to control. Miter saws are great for angled cuts but lack versatility. A table saw can perform a variety of cuts, making it a versatile choice.

For beginners, using a table saw can boost confidence. It allows for consistent results on projects. Investing in a quality table saw pays off in the long run.

Types Of Table Saws

Choosing between portable and stationary models is essential. Portable table saws are lightweight and easy to move. They are perfect for small spaces and job sites. Stationary models are larger and more powerful. They work best for heavy-duty tasks in workshops.

Three main types of table saws exist: cabinet, contractor, and hybrid saws. Cabinet saws are very stable and offer great precision. They are ideal for professionals who need the best performance. Contractor saws are more affordable and portable. They are suitable for home projects and light work. Hybrid saws combine features of cabinet and contractor saws. They provide good quality at a reasonable price.

Evaluating Your Woodworking Needs

Evaluate your woodworking needs carefully. Think about the projects you want to complete. Small projects might not need a table saw. Simple cuts can be done with a hand saw or miter saw.

Consider how often you will use the tool. A table saw is great for frequent projects. If you plan to work on larger items, it is a good investment. Space is another factor to consider. A table saw requires a dedicated space for safe operation.

| Consideration | Details |

|---|---|

| Project Size | Large projects benefit from a table saw. |

| Frequency of Use | Frequent use justifies the purchase. |

| Space Availability | Ensure you have enough space for setup. |

Benefits Of Owning A Table Saw

Owning a table saw offers precision and efficiency in cuts. It allows for clean edges and straight lines with ease. This tool can handle various materials like wood, plywood, and MDF.

Versatility makes a table saw essential for many woodworking projects. Use it for ripping, crosscutting, and bevel cuts. It can also perform dado cuts for joinery work. This flexibility helps in achieving professional results.

Safety Considerations

Table saws come with important safety features. These include blade guards, riving knives, and anti-kickback pawls. Each feature helps prevent serious injuries while cutting.

Best practices ensure safe operation. Always wear safety glasses and ear protection. Keep hands away from the blade. Use push sticks for narrow cuts. Make sure the saw is on a stable surface.

| Safety Feature | Function |

|---|---|

| Blade Guard | Protects user from blade contact |

| Riving Knife | Prevents wood from pinching the blade |

| Anti-Kickback Pawls | Stops wood from being pushed back |

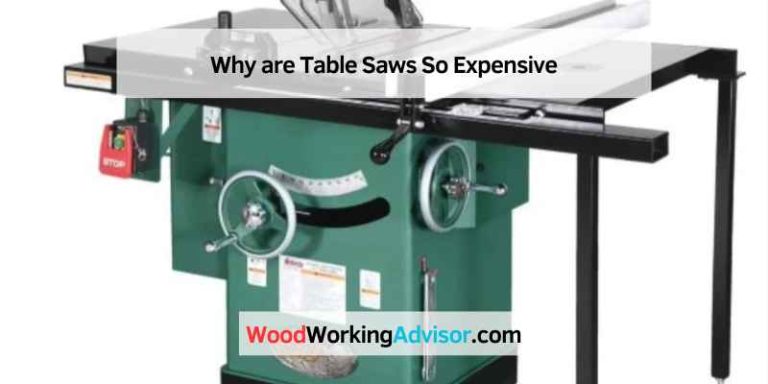

Cost Vs. Value Analysis

Choosing between quality and budget is essential for buying a table saw. A high-quality saw often lasts longer and performs better. Spending more upfront can save money on repairs later. Cheaper options may need replacements sooner. Think about how often you will use the saw.

In the long run, a reliable table saw can improve your projects. It makes cuts more accurate and efficient. This can lead to better finished products. Over time, the investment in a quality table saw pays off.

| Factor | Quality Table Saw | Budget Table Saw |

|---|---|---|

| Price | Higher initial cost | Lower initial cost |

| Durability | Long-lasting | May wear out quickly |

| Performance | Superior accuracy | Can be less precise |

| Maintenance | Lower long-term maintenance | Higher long-term maintenance |

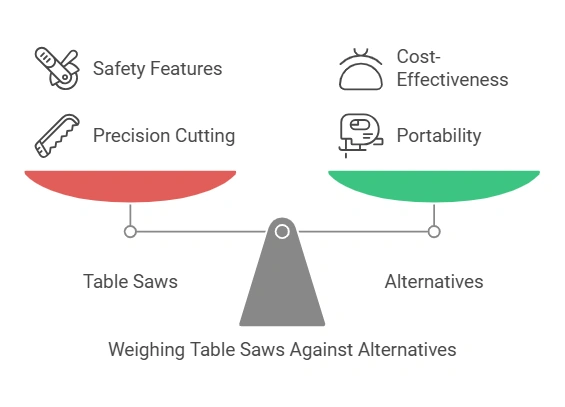

Alternatives To Table Saws

Hand saws are simple tools for cutting wood. They require physical strength and skill. Precision can be a challenge, especially for long cuts. Limited cutting speed can slow down projects. For small jobs, they work well.

Power saw alternatives offer speed and ease. Circular saws are popular for quick cuts. They can cut through thick materials easily. Jigsaws are great for curved cuts and intricate designs. Miter saws excel in making angled cuts.

Each tool has its strengths and weaknesses. Choosing the right one depends on the project. Understanding these options helps in making informed decisions.

Making The Decision

Deciding on a table saw is important for any workshop. This tool is essential for making precise cuts. Consider investing in a table saw if you frequently work with wood. It saves time and improves the quality of your projects.

Choosing the right model depends on your needs. Portable models are great for smaller spaces. They offer flexibility and easy storage. Stationary models provide more power and stability. They are ideal for larger projects.

| Model Type | Advantages | Best For |

|---|---|---|

| Portable | Lightweight, easy to store | Small workshops |

| Stationary | Powerful, stable | Large projects |

Setting Up Your Table Saw

Setting up a table saw requires careful initial setup and calibration. First, ensure the saw is on a stable surface. Check the blade alignment using a square. Adjust it until it is perfectly straight.

Next, calibrate the fence for accurate cuts. Measure the distance from the blade to the fence. Make sure it is correct for your desired cut width.

Regular maintenance keeps your table saw in great shape. Always keep the blade clean and sharp. Check for any loose parts or connections.

Store your saw in a dry area to prevent rust. Lubricate moving parts every few months. This helps ensure a long lifespan for your tool.

Advanced Techniques And Tips

Mastering complex cuts requires practice and the right tools. Techniques like bevel cuts and compound miter cuts can improve your skills.

Using jigs can enhance your cutting precision. Consider a crosscut sled for straight cuts. A dado stack allows for wider grooves in wood. Featherboards help keep the wood steady.

| Accessory | Benefit |

|---|---|

| Crosscut Sled | Improves straight cuts |

| Dado Stack | Creates wider grooves |

| Featherboard | Stabilizes wood during cuts |

Frequently Asked Questions

Do I Need A Table Saw For Woodworking?

A table saw is not mandatory for woodworking, but it is highly beneficial. It offers precision and efficiency for straight cuts. If you frequently work with large sheets of material, a table saw can significantly enhance your workflow. Consider your project needs before deciding.

What Can I Use Instead Of A Table Saw?

Alternatives to a table saw include circular saws, miter saws, and handsaws. Each tool has its strengths depending on the type of cuts needed. A circular saw is versatile for straight cuts, while a miter saw excels at angles. Choose based on your project requirements.

Is A Table Saw Worth The Investment?

Investing in a table saw can be worthwhile for serious woodworkers. It improves accuracy and saves time on repetitive cuts. Additionally, it enhances safety with better control over the material. Evaluate your woodworking frequency and project types to determine if it’s a good investment.

How Much Space Do I Need For A Table Saw?

A table saw typically requires a dedicated workspace of at least 6 feet by 6 feet. This space allows for safe maneuvering and material handling. Adequate clearance around the saw ensures better safety and efficiency. Plan your workshop layout to accommodate this essential tool.

Conclusion

Deciding whether you need a table saw depends on your woodworking needs. Consider the projects you want to tackle and the level of precision required. A table saw offers speed and accuracy for larger cuts. Evaluate your space, budget, and skill level to make the best choice for your workshop.