Engineered Hardwood Floors vs Hardwood: Key Differences

Figuring out the best flooring can feel a bit tricky when you hear terms like “engineered hardwood” and “solid hardwood” tossed around. It’s a common question for folks starting a home renovation or just trying to pick out new floors for their house. Many people get confused about what makes them different and which one is the right choice for their home and budget.

But don’t worry, this guide will break down the Engineered Hardwood Floors vs Hardwood: Key Differences in a way that’s super easy to get. We’ll walk through everything step by step so you can feel confident in your decision. Let’s get started and clear things up!

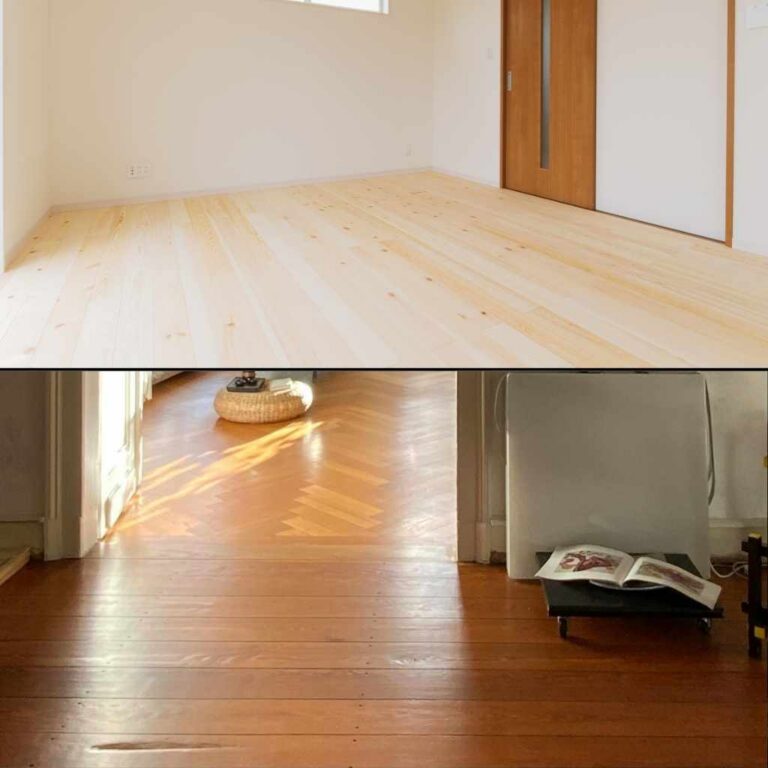

Solid Hardwood Floors Explained

Solid hardwood flooring is exactly what it sounds like: planks made from a single piece of wood. This means each board is cut directly from a tree, usually hardwoods like oak, maple, or cherry. The beauty of solid hardwood lies in its natural character.

You can see the grain patterns, knots, and variations that make each plank unique, giving your home a classic and timeless look. When people think of traditional wooden floors, they often picture solid hardwood.

The Core of Solid Hardwood

The construction of solid hardwood is straightforward. Each plank is typically 3/4 of an inch thick, and the entire board is made of the same wood species. This uniformity is a key characteristic.

Because it’s solid wood all the way through, it can be sanded and refinished multiple times over its lifespan. This means you can restore it if it gets scratched or worn, making it a flooring option that can last for generations.

Construction and Material

Solid hardwood planks are milled from a single piece of timber. This piece is then cut into planks of standard widths and lengths, usually ranging from 2 to 8 inches wide. The milling process ensures a consistent profile for installation, typically using tongue-and-groove edges so the planks lock together tightly.

The quality of solid hardwood is often judged by the type of wood used, its grade (which refers to the natural appearance and presence of knots), and the milling precision.

Durability and Longevity

Solid hardwood floors are known for their exceptional durability and longevity. When properly maintained, they can last for 50 years or even longer. The ability to refinish them means that minor damage, scratches, or even a change in style preference can be addressed by sanding down the old finish and applying a new one.

This makes solid hardwood a sustainable choice in the long run, as it doesn’t need to be replaced as frequently as some other flooring types.

Installation Considerations

Installing solid hardwood requires careful attention to the subfloor and environmental conditions. Because solid wood expands and contracts with changes in humidity and temperature, it’s usually best installed by nailing or stapling it down to a wooden subfloor. This method provides a secure attachment and allows the wood to move naturally.

It’s not recommended for installation in areas with high moisture, such as basements or bathrooms, as excessive moisture can cause warping or cupping.

Maintenance and Care

Caring for solid hardwood floors involves regular sweeping or vacuuming to remove dust and debris that can scratch the surface. Spills should be wiped up immediately with a slightly damp cloth. Avoid using excessive water or harsh cleaning chemicals, as these can damage the wood’s finish and the wood itself.

Periodic re-coating of the finish can help maintain its protective layer and appearance without needing a full sanding.

A Real-Life Example of Solid Hardwood’s Appeal

Consider a historic home in New England. Many of these homes, built over a century ago, still feature their original solid oak floors. These floors have been walked on by generations, seen countless gatherings, and survived the changing fashions.

When renovations are undertaken, owners often choose to restore these original floors rather than replace them. A gentle sanding and a fresh coat of protective sealant can bring back their rich luster, proving the enduring value and beauty of solid hardwood. This ability to be renewed is a significant advantage.

Pros and Cons of Solid Hardwood

- Pros:

- Can be sanded and refinished multiple times, extending its lifespan significantly.

- Offers a classic, authentic wood aesthetic that many homeowners desire.

- Adds significant value to a home due to its perceived quality and durability.

- Available in a wide variety of wood species, colors, and finishes to match any decor.

- Cons:

- More susceptible to damage from moisture and humidity, making it unsuitable for certain areas.

- Can be more expensive upfront compared to some other flooring options.

- Installation can be more labor-intensive and requires specific subfloor conditions.

- Prone to scratching and denting, especially in high-traffic areas or with pets.

Engineered Hardwood Floors Explained

Engineered hardwood flooring offers a different approach to achieving the look of real wood. It’s constructed from multiple layers of wood product that are bonded together under heat and pressure. The top layer, or “wear layer,” is a thin veneer of real hardwood.

Beneath this is a core of high-density fiberboard (HDF) or plywood. This construction makes engineered hardwood more stable and less prone to expansion and contraction than solid hardwood, especially with changes in humidity.

The Layered Construction

The key to engineered hardwood’s stability lies in its layered design. The top hardwood veneer can range in thickness from about 0.5mm to 4mm, with thicker veneers allowing for more refinishing opportunities. The core layers are typically made from cross-banded plywood or HDF, oriented in different directions.

This cross-grain construction counteracts the natural tendency of wood to expand and contract with moisture, resulting in a floor that stays flatter and is less likely to warp.

How It’s Made

The manufacturing process involves several steps. First, the real wood veneer is cut from a log. This veneer is then laminated onto the core material.

The core itself is composed of multiple plies of wood or HDF, with the grain of each layer running perpendicular to the layer below. This cross-ply construction is what provides dimensional stability. Finally, the top veneer is finished and coated with protective wear layers, making it ready for installation.

Wear Layer Thickness Matters

The wear layer, also known as the veneer, is the most visible and important part of engineered hardwood. Its thickness determines how many times the floor can be sanded and refinished. A thinner wear layer (around 0.5mm to 1mm) might only allow for one or two light sandings, while a thicker wear layer (2mm or more) can be refinished several times, similar to solid hardwood.

It’s essential to know the wear layer thickness when purchasing engineered wood.

Installation Flexibility

One of the biggest advantages of engineered hardwood is its installation flexibility. Thanks to its stable construction, it can often be installed in various ways. It can be nailed or stapled down to a wooden subfloor, glued down to concrete or wood, or even floated over an underlayment.

This makes it suitable for installation in areas where solid hardwood might not be ideal, such as basements, kitchens, and even bathrooms (with proper care).

Performance in Different Environments

Engineered hardwood performs remarkably well in environments with fluctuating humidity levels. This is because its layered construction significantly reduces its susceptibility to moisture-induced expansion and contraction. This stability means fewer gaps between planks and a lower risk of warping or buckling.

This makes it a popular choice for homes in climates with distinct wet and dry seasons or for areas of the home that experience more moisture.

A Scenario Showing Engineered Hardwood’s Advantage

Imagine a family living in Florida, where humidity can be high. They want the look of wood floors in their kitchen, which is prone to spills and moisture. Solid hardwood might warp or cup over time in such conditions.

However, engineered hardwood, with its stable layered construction, is a much better choice. It can withstand the humidity better and can be installed directly over the concrete slab. If a spill occurs, it can be cleaned up quickly, and the floor is less likely to suffer damage, offering peace of mind.

Pros and Cons of Engineered Hardwood

- Pros:

- Highly stable and less prone to expansion and contraction with humidity changes.

- Can be installed in a wider range of locations, including basements and kitchens.

- Offers a real hardwood surface that looks and feels like solid hardwood.

- Available in a wide variety of species, colors, and finishes.

- Often more cost-effective than solid hardwood.

- Cons:

- The number of times it can be refinished depends on the wear layer thickness.

- Very thin wear layers may limit refinishing options significantly.

- Some lower-quality engineered woods might not offer the same premium feel as solid hardwood.

- Can be damaged by standing water or prolonged exposure to extreme moisture.

Engineered Hardwood Floors vs Hardwood Key Differences Detailed

When comparing Engineered Hardwood Floors vs Hardwood: Key Differences, the most significant distinctions lie in their construction, stability, installation options, and how they handle moisture. Understanding these core differences helps you make an informed choice for your home based on your specific needs, environment, and aesthetic preferences. Both offer the beauty of real wood, but their underlying structure leads to varied performance characteristics.

Construction: The Fundamental Difference

The primary difference is how the planks are built. Solid hardwood is a single piece of wood, 100% hardwood all the way through. This gives it a certain density and feel.

Engineered hardwood, on the other hand, is a composite product. It has a top layer of real wood veneer, which is the part you see and walk on, glued to a core made of multiple layers of plywood or HDF. This multi-layer core is engineered for stability.

Layer Breakdown Comparison

Let’s visualize the layers:

| Feature | Solid Hardwood | Engineered Hardwood |

|---|---|---|

| Top Layer | 100% Hardwood | Real Wood Veneer (0.5mm – 4mm+) |

| Core Layers | N/A (Solid wood throughout) | Plywood or HDF (multiple cross-banded layers) |

| Total Thickness | Typically 3/4 inch | Typically 1/2 inch to 3/4 inch |

The stacked layers in engineered wood create a sort of “cross-grain” effect. This opposing grain direction in the core layers helps to minimize expansion and contraction caused by changes in temperature and humidity, making it more dimensionally stable than solid wood.

Stability and Moisture Resistance

This is where the engineered construction truly shines. Solid hardwood is susceptible to moisture. When humidity rises, it expands, and when it drops, it contracts.

This movement can lead to gaps between planks, cupping (edges curving up), or crowning (center curving up). Engineered hardwood, with its cross-layered core, is far more stable. It expands and contracts much less, making it a better choice for rooms with fluctuating humidity like kitchens, bathrooms, or basements.

Humidity’s Impact Explained

Imagine a solid wood table left outdoors in damp weather. It would likely swell and warp. Solid hardwood flooring behaves similarly, albeit more gradually and subtly.

The natural fibers of the wood expand when they absorb moisture and shrink when they dry out. Engineered wood’s core layers act as a buffer. While the top veneer will still respond to some extent, the core’s resistance to movement is much greater, preserving the floor’s flatness and integrity over time.

This is a critical advantage in many home environments.

Resistance Levels

While engineered hardwood is more moisture-resistant than solid hardwood, it’s not waterproof. Prolonged exposure to standing water can still cause damage to both the veneer and the core. However, for everyday spills, splashes, or general humidity fluctuations, engineered wood offers superior performance.

It’s important to note that even with engineered wood, prompt cleanup of spills is always recommended.

Installation Methods

The differing stability of solid and engineered hardwood also dictates their installation methods. Solid hardwood typically requires a wooden subfloor and is usually nailed or stapled down. This provides a very secure and durable installation.

Engineered hardwood offers more options. It can be nailed or stapled, glued down to concrete or wood subfloors, or even installed as a “floating floor” where planks are locked together and laid over an underlayment.

Floating Floor Advantage

The floating floor installation method is a significant benefit for engineered hardwood. It involves laying down an underlayment, then interlocking the planks on top. The floor is not attached to the subfloor itself.

This method is often quicker and less labor-intensive, making it a popular DIY option. It also works well over existing hard-surface flooring like tile, provided the surface is level and smooth.

Subfloor Suitability

Solid hardwood generally needs a robust wooden subfloor that it can be fastened to. This is because it needs that secure attachment to handle its natural movement. Engineered hardwood, due to its stability, can be installed over a wider variety of subfloors, including concrete slabs, which are common in many homes and often not suitable for direct solid hardwood installation without specialized underlayments and acclimatization.

Refinishing Capabilities

Both types of flooring can be refinished, but the number of times and the ease with which it can be done varies. Solid hardwood, being uniformly wood throughout, can be sanded down multiple times to remove scratches and wear and then resealed. This means a solid hardwood floor can potentially be restored and last for generations.

Engineered hardwood’s refinishing potential depends entirely on the thickness of its top hardwood veneer.

Wear Layer Thickness

If the wear layer of an engineered hardwood floor is very thin (e.g., less than 1mm), it may only be possible to refinish it once, or not at all, without damaging the core. Thicker wear layers (2mm or more) allow for multiple refinishing sessions, bringing them closer to the longevity of solid hardwood in this regard. It’s crucial to ask about the wear layer thickness when purchasing engineered hardwood if refinishing is a key concern.

The Refinishing Process

The process of refinishing involves sanding off the old finish and any minor imperfections, then applying a new stain or sealant. For solid hardwood, this is a straightforward process that can be repeated as needed. For engineered hardwood, it’s important to be aware that sanding too deeply can expose the core layers, which would ruin the floor’s appearance and protective qualities.

Professional advice is often recommended for engineered wood refinishing.

Cost Considerations

Generally, solid hardwood flooring tends to be more expensive than engineered hardwood, both in terms of material cost and installation. The raw material cost for solid wood is higher, and its installation can be more demanding. Engineered hardwood, while still a premium flooring option, often offers a more accessible price point.

This makes it an attractive choice for homeowners looking to achieve the look of hardwood within a specific budget.

Material and Installation Costs

The price of hardwood flooring varies greatly depending on the wood species, grade, and finish. However, as a general rule, solid oak might be $5-$10 per square foot for materials, while similarly sized engineered oak could be $4-$8 per square foot. Installation costs also differ.

Solid hardwood installation can be $3-$7 per square foot, while engineered can be $2-$6 per square foot, depending on the installation method and complexity.

Value Over Time

While solid hardwood may have a higher upfront cost, its ability to be refinished multiple times can make it a better long-term investment for some. If a floor can be beautifully restored every 10-15 years for decades, its cost per year of use can be very low. Engineered hardwood, especially with a thick wear layer, also offers good longevity, but its refinishing potential is more limited.

The choice often comes down to balancing initial budget with long-term expectations.

A Comparison Table

Here’s a quick look at the main points:

| Feature | Solid Hardwood | Engineered Hardwood |

|---|---|---|

| Construction | Single piece of solid wood | Real wood veneer over plywood/HDF core |

| Moisture Resistance | Low | Moderate (better than solid) |

| Stability | Lower (expands/contracts more) | Higher (less expansion/contraction) |

| Installation | Nail/staple down (wood subfloor) | Nail, staple, glue, or float (various subfloors) |

| Refinishing | Multiple times | Limited by veneer thickness |

| Cost | Higher | Generally lower |

| Ideal Locations | Dry, climate-controlled rooms | Most rooms, including kitchens, basements |

Choosing the Right Flooring For You

Deciding between engineered hardwood and solid hardwood comes down to understanding your specific needs and priorities. Consider the rooms where the flooring will be installed, your budget, the desired aesthetic, and how much maintenance you’re willing to do. There’s no single “best” option; the ideal choice depends on your unique circumstances.

Both offer the warmth and beauty of real wood.

Assessing Your Home Environment

The climate in your region and the specific rooms you’re flooring are crucial factors. If you live in an area with significant humidity fluctuations or are flooring a kitchen, bathroom, or basement, engineered hardwood’s stability and moisture resistance make it a more practical and forgiving choice. For bedrooms, living rooms, or dining rooms in climate-controlled environments where moisture is less of a concern, solid hardwood is a beautiful and enduring option.

Moisture Levels and Climate

Think about typical indoor humidity. If your home’s humidity levels swing dramatically throughout the year, solid wood will react more noticeably. Engineered wood is built to handle these changes better.

Even in a dry climate, rapid temperature changes can cause some movement in solid wood. The layered core of engineered wood acts as a dampener for these environmental shifts.

Room-Specific Needs

Kitchens and bathrooms are high-traffic areas that also experience higher moisture levels from cooking, cleaning, and steam. While no real wood floor is entirely waterproof, engineered hardwood is much better suited for these areas than solid hardwood. Basements are also prone to dampness and temperature changes, making engineered wood a safer bet.

Budget and Long-Term Value

Your budget will play a significant role in your decision. Engineered hardwood is typically more affordable upfront, making it accessible for more homeowners. However, consider the long-term value.

A solid hardwood floor that can be refinished multiple times might offer a lower cost per year of use over its very long lifespan. If you plan to stay in your home for many years and want a floor that can be renewed, the higher initial investment in solid hardwood could pay off.

Initial Investment vs. Lifespan

When comparing costs, don’t just look at the price per square foot. Factor in the expected lifespan and the potential for restoration. A well-maintained solid hardwood floor could last 50+ years with periodic refinishing.

A good quality engineered hardwood with a thick wear layer might last 20-30 years, with fewer refinishing possibilities. This comparison helps determine which offers better value for your specific plans.

Return on Investment

Both solid and engineered hardwood flooring are considered upgrades that can increase a home’s resale value. Buyers often perceive real wood floors as a sign of quality and durability. The natural beauty of wood is universally appealing.

The decision then becomes about which type of wood flooring best suits the overall style and condition of the home, and which is more likely to appeal to future buyers in your market.

Aesthetic Preferences

Both engineered and solid hardwood offer the genuine beauty of real wood. The visual difference between them is often minimal, especially with high-quality engineered products. The choice might come down to subtle preferences in grain patterns, the availability of specific wood species, or the exact finish and color you desire.

Many manufacturers offer both types in similar styles.

Wood Species and Finishes

You can find a wide array of wood species, from classic oak and maple to more exotic choices like walnut and hickory, in both solid and engineered forms. Similarly, the range of stains, finishes, and textures available is vast for both types. Whether you prefer a light, natural look, a dark, dramatic tone, or a rustic hand-scraped texture, you’ll find options in both categories.

Matching Existing Floors

If you’re adding to existing hardwood floors, matching the species, width, and finish can be a challenge. In such cases, it’s often easier to match engineered hardwood due to the wider availability of pre-finished options that can closely mimic the look of older solid floors. However, careful selection and possibly custom staining might be needed for a seamless blend.

Installation and DIY Considerations

If you’re planning a DIY installation, engineered hardwood often has an advantage due to its flexibility. The floating floor installation method is particularly appealing for DIYers as it requires fewer specialized tools and can be less physically demanding than nailing down solid planks. However, always ensure you follow manufacturer instructions precisely for either type.

Ease of Installation Comparison

Nailing solid hardwood requires specific tools like a flooring nailer and a good, flat subfloor. Gluing is also an option but can be messy for DIYers. Engineered hardwood, especially click-lock systems for floating floors, simplifies the process.

The planks simply lock together, often over a layer of underlayment. This reduces the skill and equipment needed.

Professional Installation

For the best results, especially with solid hardwood or complex engineered installations, professional installation is often recommended. Experienced installers ensure the subfloor is properly prepared, the wood is acclimated correctly, and the flooring is laid with precision for optimal appearance and longevity. This can add to the overall cost but is often worth it for a high-quality finish.

Frequently Asked Questions

Question: Can I install engineered hardwood in a bathroom?

Answer: Yes, engineered hardwood can be installed in bathrooms, but it’s not waterproof. Promptly clean up any standing water or spills. Its greater stability makes it more suitable than solid hardwood for high-humidity areas, but caution is still advised.

Question: How many times can I refinish engineered hardwood floors?

Answer: This depends on the thickness of the top hardwood veneer (wear layer). Floors with a thin wear layer may not be refinishable, while those with a thicker wear layer (2mm or more) can be refinished a few times, similar to solid hardwood.

Question: Is solid hardwood better for resale value?

Answer: Both solid and engineered hardwood add value. Solid hardwood might be perceived as more premium by some buyers due to its traditional appeal and longevity, but well-installed engineered hardwood is also a highly desirable feature.

Question: What’s the main difference between solid and engineered hardwood?

Answer: Solid hardwood is made from a single piece of wood throughout. Engineered hardwood has a top layer of real wood veneer bonded to a stable core of plywood or HDF. This makes engineered wood more stable and moisture-resistant.

Question: Can I install hardwood flooring in my basement?

Answer: Engineered hardwood is generally recommended for basements due to its stability and better performance in potentially damp environments. Solid hardwood is usually not recommended for basement installations because of moisture concerns.

Final Thoughts

Choosing between engineered and solid hardwood floors involves weighing construction, stability, installation flexibility, refinishing potential, and cost. Solid hardwood offers that classic, all-wood charm and the ability to be renewed repeatedly, making it a timeless choice for many homes, especially in drier, climate-controlled areas. Engineered hardwood, with its layered design, provides greater stability and resilience against moisture and humidity fluctuations.

This makes it a versatile option, suitable for a wider range of rooms and environments, often at a more accessible price point. Consider the specific conditions of your home, such as humidity levels and the intended use of each room, alongside your budget and aesthetic preferences. Both options bring the natural beauty and warmth of real wood into your living space.

By understanding these key differences, you can confidently select the flooring that best suits your lifestyle and home, ensuring a beautiful and functional result for years to come. Take your time to examine samples, consider the long-term benefits, and select the wood that will truly enhance your home.