How Do You Seal Glitter on Wood? Proven Fixes

To seal glitter on wood, you must use a strong, clear sealant like spray lacquer, clear acrylic spray, or a durable topcoat like polyurethane. Proper application—using thin, even coats over fully dried glitter glue—ensures the sparkle stays put, prevents shedding, and protects your beautiful woodworking project.

Hello there! I’m Md Meraj, and if you’ve just finished decking out a beautiful wood sign or craft project with dazzling glitter, you know the excitement—and then the little bit of panic when that glitter starts moving! A sparkling project can quickly turn into a dusty mess if you don’t seal it correctly. We’ve all been there. Glitter tends to shed, leaving specks everywhere but your craft piece. Don’t worry! Sealing glitter on wood is much easier than it looks. We are going to walk through the most reliable methods, step-by-step, so your shimmer stays exactly where you put it for years to come. Ready to lock in that shine? Let’s get started!

Why Sealing Glitter on Wood is Non-Negotiable

Glitter, while gorgeous, is notorious for being stubborn—it wants to travel! When you apply glitter onto a wooden surface, it’s usually stuck down with a wet adhesive like craft glue or Mod Podge. If you don’t seal this layer, you run into three main problems:

1. Shedding: Every time the piece is touched, bumped, or dusted, loose particles fly off.

2. Dulling: Exposure to dust, moisture, or UV light can degrade the adhesive, making the glitter look tired or uneven.

3. Damage: If the item is meant for outdoor use or high-contact areas, the glitter can easily chip away.

A good sealant acts like a protective, clear shell, locking every tiny piece in place while preserving the brilliance underneath. Craftsmanship is about making things last, and sealing is the final, most crucial step for glitter projects.

Understanding Your Materials: What Works Best for Wood

Before we grab a can, let’s quickly look at the top materials recommended for this job. Since you are working with wood, you need a sealant that adheres well to wood grain while offering good coverage over a textured, bumpy surface like glitter.

Top 3 Sealants for Locking Down Glitter

| Sealant Type | Best For | Pros | Cons |

|---|---|---|---|

| Clear Acrylic Spray Sealer | Indoor crafts, décor | Fast drying, easy application, generally non-yellowing | Less durable for high-traffic areas or outdoors |

| Spray Polyurethane (Water-Based) | Medium-use items (signs, small furniture) | Very durable, excellent clarity, good protection | Longer curing time; needs good ventilation |

| Epoxy Resin (2-Part) | Ultra-durable items, tabletops | Highest protection, glass-like shine, fully sealed | Most expensive; careful mixing and long cure time |

For most beginner woodworking and DIY home projects, a high-quality spray acrylic or water-based polyurethane is your best friend. They offer fantastic results without the complexity of mixing resin.

The Step-by-Step Guide: How Do You Seal Glitter on Wood?

Sealing glitter successfully isn’t just about what product you use; it’s about preparation and application technique. Here is the proven, three-phase method I use in my own workshop.

Phase 1: Preparation is Key (Don’t Skip This!)

The success of your seal relies heavily on the condition of your base. Think of it like getting a surface ready for paint—it needs to be clean and completely dry.

Step 1: Ensure the Glitter is Fully Dry

If you applied your glitter using standard craft glue, Mod Podge, or watered-down white glue, you must wait until it is completely cured. This is crucial! If the glue underneath is still tacky, the solvent in your sealant can reactivate the glue, causing the glitter to shift or clump under the coat.

Rule of Thumb: Wait at least 24 hours, even if the top layer of glue looks dry. Heat (like a low setting on a hairdryer) can speed this up, but avoid touching it.

Step 2: Dust Off Loose Glitter

Before sealing, you need to remove every piece of loose glitter that didn’t fully adhere. If you seal dust, you’ll just be sealing the mess!

Use a very soft, clean paintbrush or a lint-free cloth to gently brush away all loose particles.

If needed, use a low-power vacuum with a soft brush attachment to suck up stubborn specks.

Step 3: Protect Your Work Area

Because most sealants are sprays, overspray is inevitable. Always work in a well-ventilated area. A garage, outdoors on a calm day, or a well-vented booth is ideal.

Lay down drop cloths or large pieces of cardboard to protect your floor and surrounding items.

Wear a proper respirator mask, especially when using strong aerosol cans like polyurethane or lacquer. Your long-term health is worth this simple precaution (see safety guidance from OSHA regarding spray fumes).

Phase 2: Applying the First “Tack Coat”

This first coat is the most important one for “capturing” the glitter without disturbing its placement. We call this the tack coat because its main job is to lightly grab everything without drowning it.

Step 1: Select Your Product (Recommended Starter Choice: Acrylic Spray)

For beginners, a simple, non-yellowing clear acrylic sealer spray (like a satin or matte finish) is usually the safest bet for the first coat.

Step 2: Test Your Spray

Always test your spray pattern on a piece of scrap cardboard or wood first. You want a fine, consistent mist, not a heavy stream.

Step 3: Spray the Tack Coat

This needs to be light—almost like fogging the surface.

Hold the can about 10 to 12 inches away from the wood.

Use slow, sweeping, side-to-side motions. Keep the can moving constantly! Do not linger over any single spot.

Apply a very thin, light coat, just enough to see the surface is slightly hazy or damp. This light touch locks the highest pieces down.

Once the surface looks slightly wet, STOP. Do not attempt to fully cover the glitter on this first pass.

Step 4: Let it Dry Completely

Because this coat is so thin, it usually dries quickly—often within 30 minutes. Do not touch it until you are sure it is dry to the touch. If the glitter feels loose after this coat, that means your initial adhesive needed more time to cure, and you’ll need to add another very light mist.

Phase 3: Building Protection and Shine

Once the tack coat is dry, the remaining glitter is anchored. Now you can start applying the coats that will build true depth, durability, and shine.

Step 1: Apply the Second Coat (Full Coverage)

This coat can be slightly heavier than the first, but consistency is still key.

Maintain the 10- to 12-inch distance.

Overlap your passes by about 50% to ensure there are no gaps between sprays.

Apply this coat until the entire surface appears uniformly covered and you can no longer see dry patches between the glitter pieces.

Step 2: Build Subsequent Coats

Most projects require at least three full coats for real durability.

Allow the second coat to dry completely (check the can instructions, usually 1–2 hours).

Apply a third, light-to-medium coat, following the same technique.

For heavy-duty pieces, repeat this process up to five times. More thin coats are always better than one thick coat, which can run or bubble.

Step 3: Optional: Using a Brush-On Topcoat Over Spray

If you used an acrylic spray sealer for the initial coats but want a glass-like, tough finish (like one provided by polyurethane or epoxy), you can transition to a brush-on coat after the sprays have cured (usually 24 hours).

Apply your final protective coat of water-based polyurethane. This requires care! Brush lightly in long, even strokes, following the grain of the wood. Brush strokes can smear glitter if you scrub, so use a light touch.

Advanced Sealing Techniques for Specific Finishes

The technique slightly changes based on the look you are aiming for—high gloss versus subtle protection.

Technique A: Achieving a Smooth, High-Gloss Finish

To eliminate the gritty texture often left by thick layers of glitter, you need to physically bury the glitter under several layers of sealant.

1. Use Thick Sealant: Polyurethane or clear sanding sealer works well here because it builds depth faster than thin acrylic sprays.

2. Layer and Level: Apply three or four medium coats, allowing full drying time between each. The surface will start to feel smoother.

3. Wet Sanding (For the Brave Beginner): If you want truly glass-like smoothness, after the final coat has cured for 48–72 hours, you can very lightly wet sand using very high-grit sandpaper (600 grit or higher). This takes away minor bumps. Always reapply a final thin clear coat after sanding to restore shine.

Technique B: Sealing Ultra-Fine Glitter

Very fine, powdery glitter (often called “holographic dust” or “super fine”) adheres easily but can lift instantly with heavy spray.

Recommendation: Avoid sprays initially. Use a fine foam brush to carefully dab or roll thin coats of Mod Podge directly onto the glitter first. The viscosity helps hold the powder in place better than the atomized mist of a spray can.

Once the Mod Podge is cured, proceed with the spray sealant steps above (Tack Coat, then Full Coats).

A Note on Sealing Painted Wood with Glitter Accents

If your wood item is painted, and you are only applying glitter accents (like lettering or borders), the sealant should be compatible with the underlying paint. Most standard clear acrylic or water-based polyurethanes are safe for cured latex or acrylic paints. Always check compatibility if you are working with oil-based paints.

Troubleshooting Common Sealing Issues

Even with careful steps, things can go slightly sideways. Here’s how we fix the common issues I see:

| Problem | Cause | Fix / Prevention |

|---|---|---|

| Glitter moves or clumps during sealing | Glue layer underneath was still wet | Stop and let dry 24 more hours; if continuing, dab Mod Podge instead of spraying |

| Sealant looks foggy or milky | Coats too thick; solvent trapped; high humidity | Sand foggy layer with 400-grit and reapply 3–4 very thin coats with good ventilation |

| Sealant pools or drips | Spraying too close or holding trigger too long | Gently wipe runs while slightly wet and allow to dry; always use light coats |

| Glitter coverage looks uneven after 3 coats | Missing spots during the tack coat or heavy texturing. | After everything has cured, you can carefully use a toothpick to apply clear glue exactly where the glitter is missing, add a tiny speck of glitter, let dry, and then apply one final light topcoat over the area. |

For more information on proper application techniques for clear coats on crafts, resources like those from major finishing material manufacturers often provide excellent technical data sheets on coverage rates and curing environments.

Selecting the Right Topcoat Finish: Shine vs. Protection

The final choice dictates the look and feel of your project. Which finish speaks to your style?

Satin Finish

A satin finish offers a slight sheen, diffusing the light just enough to give the glitter depth without overwhelming the room with reflection.

Why Choose Satin? It hides minor imperfections (like slightly uneven glitter placement) better than high gloss. It’s very popular for wooden signs and home décor items where you want sophistication rather than flashy bling.

Gloss Finish

The high-gloss finish makes the colors of the glitter “pop” and gives the entire surface a wet, liquid look.

Why Choose Gloss? If you want maximum impact and a smooth, almost plastic-like feel, go glossy. This is best achieved with multiple, even coats of high-gloss spray polyurethane or brushed-on clear varnish. Be warned: gloss shows every bump!

Matte Finish

A matte finish seals the glitter but removes almost all shine, leaving a velvety or frosted appearance.

Why Choose Matte? This is an artistic choice for achieving a subdued sparkle, perfect when the glitter needs to be felt but not harshly seen. Matte sealants tend to require a slightly thicker build-up to fully lock down sharp glitter edges.

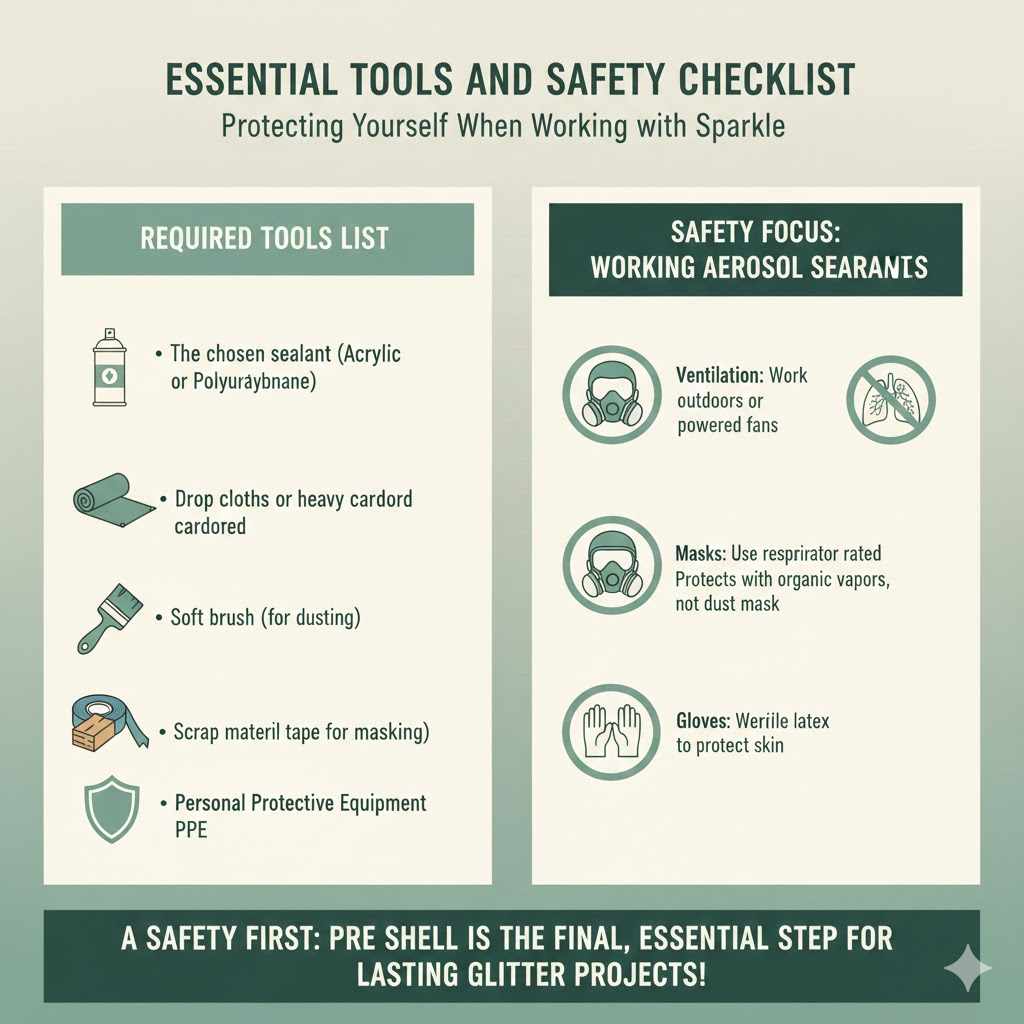

Essential Tools and Safety Checklist

As your mentor, Md Meraj, safety and having the right gear are non-negotiable. Working with aerosol sealants requires respect for the chemicals involved.

Required Tools List

The chosen sealant (Acrylic spray or Polyurethane).

Drop cloths or heavy cardboard for protection.

Soft brush (for dusting off loose particles).

Painter’s tape (if masking off surrounding areas).

Scrap material for testing spray patterns.

Personal Protective Equipment (PPE).

Safety Focus: Working with Aerosols

When dealing with solvents in sprays, ventilation and respiratory protection are key. According to the U.S. National Institute for Occupational Safety and Health (NIOSH), proper vapor management is essential for all painting and sealing tasks.

Ventilation: Work outdoors or in an area with cross-breezes. If using solvents indoors, use high-powered fans directed out a window.

Masks: Use a respirator rated for organic vapors, not just a simple dust mask. This protects your lungs from harmful solvents as the product cures.

Gloves: Wear nitrile or latex gloves to prevent sealants from drying on your skin.

FAQ: Simple Answers for Glitter Sealing Success

Here are some quick answers to the most common questions I hear when beginners tackle this process.

Q1: Can I seal glitter on wood using regular hairspray?

A: Hairspray might hold the very top layer of glitter temporarily, but it is not a durable, long-term solution. Hairspray is not waterproof, can become sticky over time, and will not provide the hard protective layer needed for cured wood crafts. Use dedicated clear sealants instead.

Q2: How many coats of sealant are usually enough?

A: For standard, low-contact craft projects, three medium, thin coats provide excellent coverage. If the item will be frequently touched, handled, or exposed to moisture, aim for four to five coats. Always prioritize thin coats over thick ones.

Q3: How long should I wait between coats?

A: This depends entirely on the product. Water-based acrylic sprays might only need 30–60 minutes between coats. Polyurethane sprays usually need 2–4 hours between coats to be touch-dry and fully cured enough for a second pass. Always read the instructions on your specific can!

Q4: What should I do if my sealant settles in the cracks and makes the glitter look bumpy?

A: This usually happens with heavy spray application. Wait for the entire piece to cure (24 hours). Then, use very fine sandpaper (600 grit) to lightly and carefully sand down the high spots only. Wipe the dust away gently and apply one final, extremely light mist coat to restore the uniform sheen.

Q5: Can I seal the glitter before applying it to the wood?

A: Yes, but it’s often more trouble than it’s worth. You would spray the loose glitter, wait for it to cure, and then try to adhere that pre-sealed mass to the wood using glue—which makes adhesion very difficult. It is always easier to apply the adhesive, apply the loose glitter, let it dry, and then seal the finished surface on the wood.

Q6: Will the sealant change the color of my glitter?

A: Most clear acrylics and water-based polyurethanes are explicitly labeled as “non-yellowing” and should maintain the true color of holographic or metallic glitters. However, very heavy oil-based varnishes can impart a slight amber tone over time, which might affect cool-toned glitters (like silvers or blues). Stick to clear acrylic or water-based products for true color preservation.

Conclusion: Your Glitter is Locked and Loaded

You’ve done the hard work prepping the wood and applying that dazzling layer of sparkle. Now, you have the knowledge to lock it down professionally! Remember, sealing glitter on wood isn’t about one magic product; it’s about preparation, using thin coats, and being patient while those layers cure. Start light with your tack coat to secure the texture, and build up slowly to your desired level of protection and shine. Don’t rush the drying time, and you’ll end up with a robust, professional-looking piece that keeps its shine for ages. Go ahead, show off your beautiful, finished craft with confidence!