How Thick Is Engineered Hardwood Flooring? Essential Guide

Engineered hardwood flooring thickness typically ranges from 5/16 inch to 3/4 inch (about 8mm to 19mm). The most crucial part is the top wear layer, which can vary from a thin veneer (around 1mm) to a thicker lamella (up to 6mm), determining its durability and refinishing potential.

Choosing the right flooring for your home can feel tricky, right? Engineered hardwood is a popular pick, offering that beautiful wood look without some of the fuss of solid wood. But when you’re shopping, you’ll notice different thicknesses. You might wonder, “How thick is engineered hardwood flooring, really?” and “Does it matter?” It’s a common question, and understanding it is key to picking the best floor for your space and budget. Don’t worry, we’ll break it all down simply, so you can feel confident in your choice.

In this guide, we’ll explore the different thickness options, what makes up an engineered hardwood plank, and how the thickness impacts your floor’s look, feel, and longevity. Let’s get your questions answered and pave the way for a beautiful new floor!

Understanding Engineered Hardwood Flooring Thickness

When we talk about the “thickness” of engineered hardwood flooring, we’re referring to the total measurement from the very top of the wear layer down to the bottom of the backing. This total thickness is important, but it’s actually the thickness of the top layer – the hardwood itself – that truly matters for durability and how many times you can refinish it.

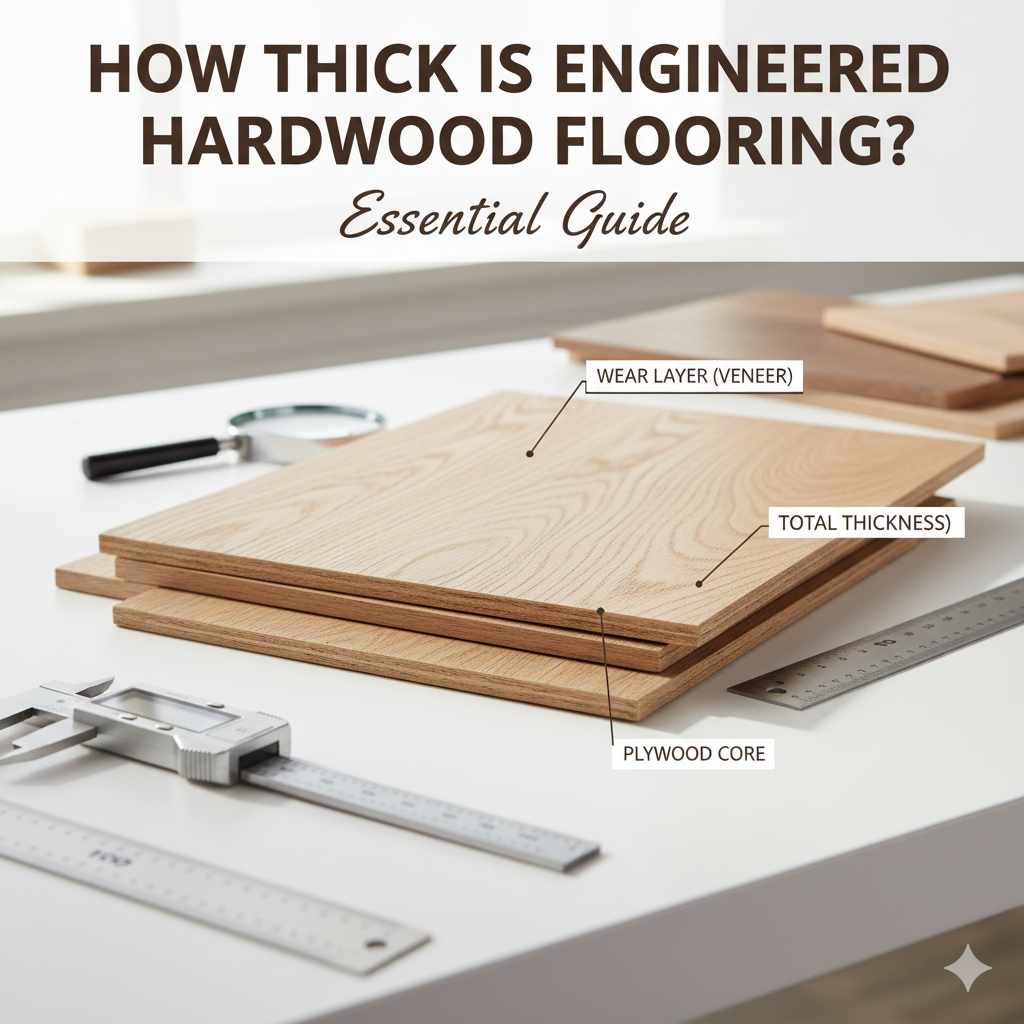

What Makes Up an Engineered Hardwood Plank?

Unlike solid hardwood, which is just one piece of wood, engineered hardwood is built like a sandwich. This construction gives it stability, making it less prone to expanding or contracting with changes in humidity and temperature, which is a big plus for many homes and climates.

- Top Layer (Wear Layer/Lamella): This is the beautiful, real hardwood veneer you see and feel. Its thickness is critical.

- Core Layers: These are typically made from plywood or high-density fiberboard (HDF). They provide strength and stability to the plank. The layers are cross-grained, which helps prevent warping.

- Backing Layer: The bottom layer, often made of a similar material to the core, provides support and balancing.

The way these layers are bonded together during the manufacturing process is what makes engineered hardwood so resilient.

Total Thickness vs. Wear Layer Thickness

It’s super important to know the difference between the overall plank thickness and the thickness of the wear layer.

- Total Thickness: This is the entire height of the plank. It affects how the floor sits in relation to other flooring types and how much “give” there might be underfoot. Common total thicknesses range from 5/16 inch to 3/4 inch.

- Wear Layer Thickness: This is the actual hardwood on top. It can range from a very thin veneer (around 0.5 mm to 1 mm) to a thicker lamella or sawn-cut veneer (2 mm to 6 mm or even more). The thicker this layer, the more durable the floor is and the more times it can be sanded and refinished.

When you’re looking at specifications, always check the wear layer thickness. This is the number that tells you about the floor’s long-term potential.

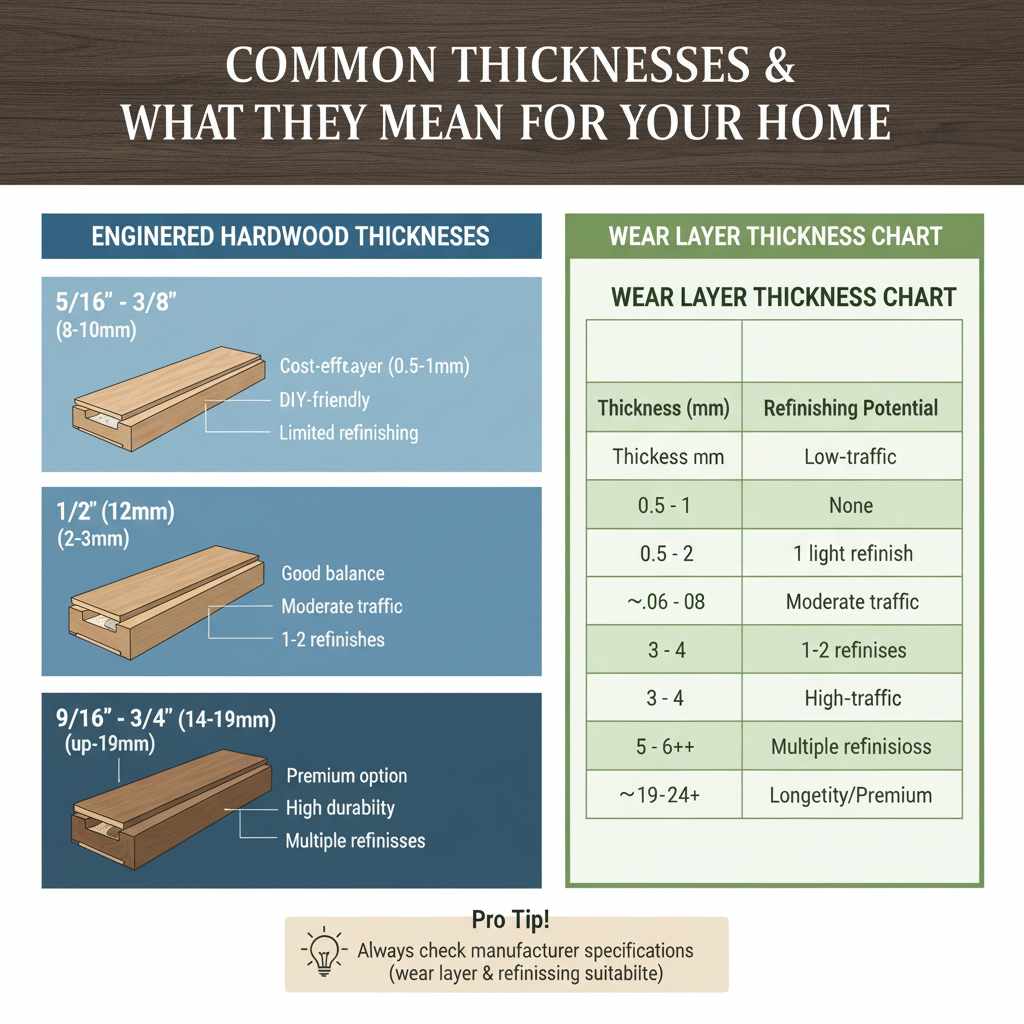

Common Thicknesses and What They Mean

Engineered hardwood flooring comes in a variety of total thicknesses, each with its own characteristics and ideal applications. Here’s a look at the common ranges and what to expect:

5/16 inch to 3/8 inch (8mm to 10mm)

Flooring in this thinner range is often more budget-friendly and easier to install, especially for DIYers. It’s a good choice for areas with less foot traffic or for aesthetic upgrades where extreme durability isn’t the top priority. The wear layer in these planks is usually on the thinner side (often around 0.5mm to 1mm).

- Pros: Cost-effective, easier handling, good for renovations where you need to match existing floor heights precisely.

- Cons: Limited refinishing potential due to thin wear layer, may not stand up as well to heavy traffic or wear and tear.

1/2 inch (12mm)

This is a very popular and common thickness for engineered hardwood. It offers a good balance of stability, durability, and price. Planks in this range often feature wear layers of 2mm to 3mm, which allows for at least one or two refinishing opportunities.

- Pros: Good balance of cost and quality, decent wear layer for moderate traffic, feels substantial underfoot.

- Cons: May not be as robust as thicker options for very high-traffic areas, refinishing potential is moderate.

9/16 inch to 3/4 inch (14mm to 19mm)

These are the thicker, more premium options. Engineered hardwood in this range often boasts substantial wear layers, sometimes up to 6mm. This means they can be sanded and refinished multiple times, much like solid hardwood, offering incredible longevity and the potential to refresh the look over the years.

- Pros: Excellent durability, substantial feel underfoot, high potential for refinishing (like solid hardwood), premium look and quality.

- Cons: Higher cost, can be heavier and more challenging to install, may raise floor heights significantly.

Wear Layer Thickness Chart

To help you visualize, here’s a quick look at how wear layer contributes:

| Wear Layer Thickness (mm) | Typical Wear Layer Thickness (inches) | Refinishing Potential | Best For |

|---|---|---|---|

| 0.5 – 1 | ~0.02 – 0.04 | None to very limited (buffing only) | Low-traffic areas, budget-friendly updates |

| 1.5 – 2 | ~0.06 – 0.08 | Possibly one light refinish/screen and recoat | Moderate traffic, general living spaces |

| 3 – 4 | ~0.12 – 0.16 | One to two refinishes | High-traffic areas, busy households |

| 5 – 6+ | ~0.19 – 0.24+ | Multiple refinishes (comparable to solid wood) | Longevity, potential for future style updates, premium applications |

Remember, a “wear layer” is measured in millimeters (mm) or sometimes mils (1 mil = 0.001 inch). So, a 3mm wear layer is roughly 120 mils.

Factors Influencing Flooring Thickness

Beyond just preference, several factors influence the thickness of engineered hardwood planks, and why certain thicknesses are more common or suitable for different situations:

Material Quality and Construction

The quality of the wood veneer and the core layers plays a huge role. Higher-end engineered wood flooring often uses thicker, premium veneers and more stable core materials, leading to overall thicker planks and more durable wear layers. Manufacturers invest more in these thicker options to offer a product closer to the performance of solid hardwood.

Installation Method

The way your floor is installed can also be a factor. Some thinner engineered wood floors, particularly those with click-lock systems, are designed for floating installations. Thicker, heavier planks might be better suited for glue-down or nail-down methods, which provide a more secure and substantial feel. The installation method doesn’t directly affect the plank’s thickness but is often correlated with the product’s design and intended use.

Performance and Durability Requirements

This is perhaps the most crucial factor. If you have a busy household with pets and children, high traffic in hallways, or an active lifestyle, you’ll want a thicker wear layer – and likely a thicker overall plank – for better durability and resistance to dents and scratches. For a guest room or a home office with minimal traffic, thinner options might suffice.

Aesthetics and Feel

Thicker planks can sometimes offer a more luxurious and substantial look and feel. The thicker the plank, the deeper the bevels can be, and the more prominent the grain can appear. While appearance is subjective, many homeowners appreciate the weight and presence of a thicker, higher-quality engineered wood floor.

Cost Considerations

As with most things in home improvement, thicker engineered hardwood flooring with a substantial wear layer often comes with a higher price tag. The cost reflects the quality of materials, the amount of real wood used in the wear layer, and the manufacturing processes involved in creating a more durable product. Budget-friendly options generally sacrifice wear layer thickness and overall plank dimension.

How Enginnered Hardwood Thickness Affects Your Home

The thickness of your engineered hardwood flooring isn’t just a number; it has practical implications for your home’s comfort, longevity, and even its value. Let’s explore these impacts:

Durability and Longevity

As we’ve discussed, the wear layer is the hero here. A thicker wear layer (3mm or more) on a quality engineered plank means it can withstand more wear and tear. It can also be refinished. This means a beautiful floor can last for decades, adapting to your style as trends change. A thin wear layer might mean you’re looking for a new floor sooner rather than later.

Sound and Comfort Underfoot

Thicker, denser engineered hardwood floors often feel more solid and substantial underfoot. They can also help to dampen sound, reducing echoes and the “hollow” sound sometimes associated with thinner floating floors. This can make rooms feel more comfortable and acoustically pleasing. While underlayment also plays a role in sound reduction, the inherent mass of a thicker plank is a significant factor.

Installation Considerations

Subfloor requirements: Most engineered hardwood can be installed over various subfloors, including concrete and plywood. Generally, thicker planks are more forgiving on slightly uneven subfloors, but proper preparation is always recommended. For expert advice on subfloor preparation, you can refer to resources like Building Science Information, which offers insights into building envelope moisture control, essential for flooring longevity.

Transitions to other floors: When installing engineered hardwood next to existing flooring, its thickness is crucial. A significantly thicker new floor will create a noticeable height difference at doorways. This necessitates transition strips or adjustments to ensure a smooth and safe passage. Thinner planks might integrate more seamlessly into existing floor heights.

DIY vs. Professional Installation: Thinner, lighter planks are often easier for DIYers to handle and cut. Thicker planks can be heavier and require more robust tools and potentially more physical effort. However, thicker planks may offer more forgiving installation systems like click-lock.

Maintenance and Refinishing

The ability to refinish your floor is a major advantage of engineered hardwood, but it’s directly tied to wear layer thickness. Floors with thin wear layers (under 2mm) can typically only be “screened and recoated” to refresh the finish, not fully sanded down to bare wood. Those with thicker wear layers (3mm+) can undergo one or more full sandings and refinishing jobs, essentially giving you a “new” floor, which is a fantastic benefit for long-term ownership. Always consult the manufacturer’s recommendations for refinishing.

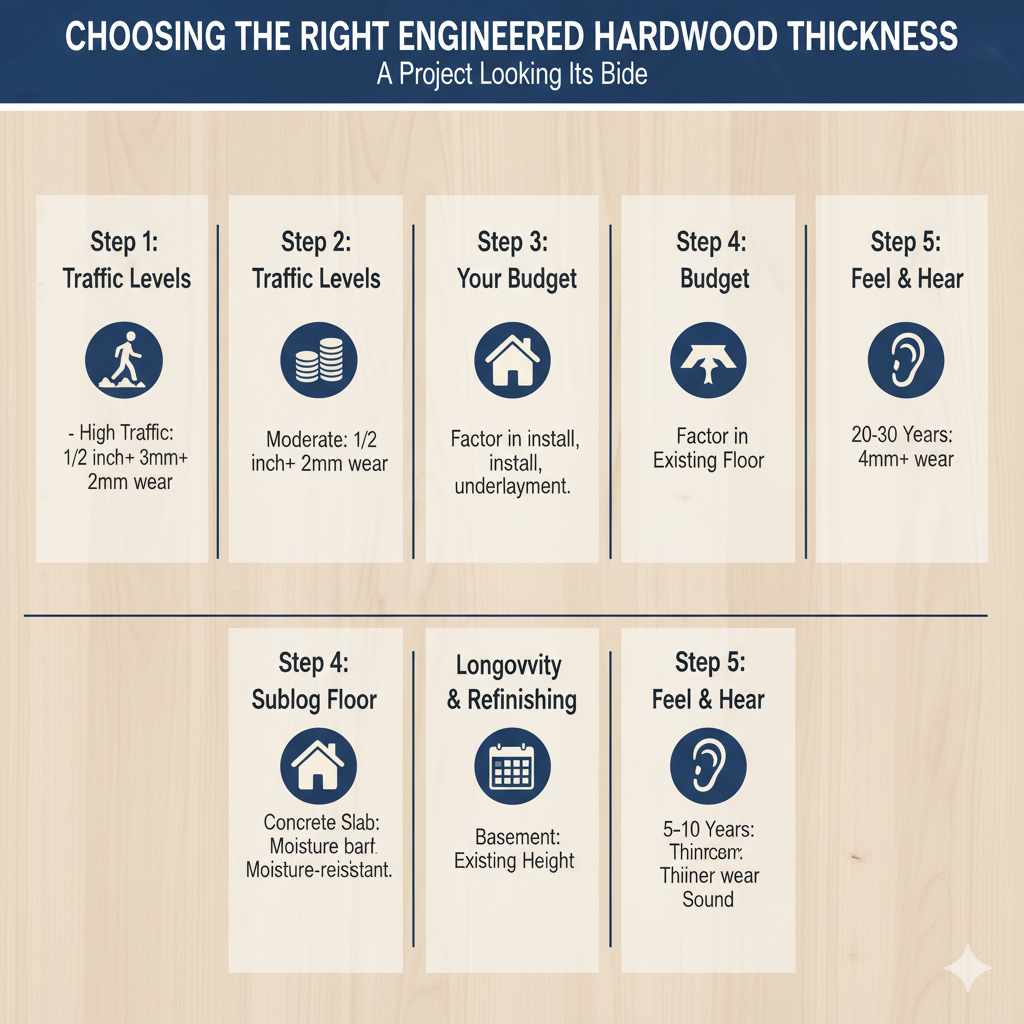

Choosing the Right Thickness for Your Project

Selecting the perfect engineered hardwood thickness involves balancing your needs, budget, and desired outcome. Here’s a breakdown to guide your decision:

Step 1: Assess Your Traffic Levels

- High Traffic: Think hallways, family rooms, kitchens, and areas with pets or children. Opt for thicker planks (1/2 inch or more) with substantial wear layers (3mm+).

- Moderate Traffic: Bedrooms, dining rooms, or living rooms with less daily use might be fine with 1/2 inch planks with wear layers around 2mm.

- Low Traffic: Guest rooms or formal spaces could potentially use thinner options (5/16 to 3/8 inch) with thinner wear layers, but durability is still important for longevity.

Step 2: Consider Your Budget

Thicker planks and those with thicker wear layers generally cost more. Determine how much you’re willing to invest. Remember to factor in installation costs, underlayment, and any necessary prep work.

Step 3: Evaluate Your Subfloor and Existing Flooring

If you’re installing over a concrete slab, engineered hardwood is a great choice, but check manufacturer guidelines for moisture barriers. If transitioning to another floor, measure the height difference and see how different plank thicknesses will affect it. For basement installations, look into specialized moisture-resistant engineered options, regardless of thickness.

Step 4: Think About Longevity and Refinishing

Do you want a floor that can be refreshed to adapt with your style over the next 20-30 years? If so, prioritize thicker wear layers (4mm+). If you plan to move in 5-10 years or simply want a beautiful update without long-term refinishing plans, thinner options might be perfectly adequate.

Step 5: Feel and Hear the Difference

If possible, visit a showroom and walk on different types of engineered hardwood. Pay attention to how they feel underfoot. A thicker plank often feels more solid and less hollow. This tactile experience can be a deciding factor for many!

Frequently Asked Questions (FAQ)

Q1: What is the most common thickness for engineered hardwood flooring?

The most common thickness you’ll find is 1/2 inch (12mm). This thickness offers a good balance of stability, feel, and price, and often comes with a decent wear layer for most residential uses.

Q2: Can all engineered hardwood floors be refinished?

No, not all of them. It depends entirely on the thickness of the top hardwood wear layer. Planks with very thin wear layers (under 2mm) can usually only be screened and recoated, not fully sanded down. Thicker wear layers (3mm or more) can typically be refinished multiple times.

Q3: How do I know if a floor is good quality based on its thickness?

While thickness is a factor, the wear layer thickness is a better indicator of quality and durability than the total plank thickness alone. Higher quality generally means a thicker, more substantial wear layer paired with a stable, well-constructed core.

Q4: Will thicker engineered hardwood floors be louder than thinner ones?

Generally, thicker engineered hardwood can be less prone to that hollow sound you might hear from very thin floating floors, especially when paired with a good underlayment. The extra mass helps to dampen sound and create a more solid feel underfoot.

Q5: Is a thicker engineered hardwood floor always better?

Not necessarily better, but often more durable and long-lasting. A thicker floor with a substantial wear layer is ideal for high-traffic areas and offers more refinishing potential. However, for lower-traffic areas or when budget and height are key considerations, thinner options can be perfectly suitable.

Q6: What is the typical wear layer thickness for a long-lasting floor?

For a floor that is expected to last for many years and be refinishable, look for a wear layer of at least 3 millimeters (mm). Wear layers of 4mm, 5mm, or even 6mm offer even more longevity and refinishing opportunities, making them comparable to solid hardwood in this regard.

Q7: How does engineered hardwood thickness compare to laminate or vinyl flooring?

Engineered hardwood planks are typically thicker than most laminate or luxury vinyl plank (LVP) flooring. For instance, a 1/2 inch engineered hardwood floor is significantly thicker than most 8mm to 12mm laminate and LVP options. However, the comparison is structural and material-based; LVP and laminate are often more water-resistant and less expensive.

Conclusion

Navigating the world of engineered hardwood flooring thickness doesn’t have to be complicated. We’ve learned that while the total plank thickness matters for its feel and installation, it’s the wear layer – that top layer of real wood – that truly dictates the floor’s durability and how long it will serve your home. From thinner, budget-friendly options perfect for low-traffic areas to robust, thick planks with substantial wear layers that can be refinished for decades, there’s a solution for every need and budget.

By understanding the construction of engineered hardwood and considering your home’s specific demands – traffic levels, desired longevity, and aesthetic goals – you can confidently choose a flooring that not only looks beautiful but also performs exceptionally. Don’t hesitate to ask retailers for detailed specifications about the wear layer and consider visiting showrooms to experience the quality of different options firsthand.