How to Dry Wood for Coasters: Quick & Effective Tips

To dry wood for coasters, cut the wood into desired shapes and allow it to air dry for several weeks. Alternatively, use a dehydrator or an oven at a low temperature to speed up the drying process.

Creating coasters from wood can be a rewarding DIY project. Properly dried wood ensures durability and prevents warping. Air drying is the most natural method, allowing moisture to escape slowly. This process can take weeks, depending on the wood thickness and humidity levels.

For quicker results, consider using an oven or a dehydrator. Both methods effectively reduce moisture content without compromising the wood’s integrity. Understanding how to dry wood correctly will enhance your coaster-making experience and result in beautiful, functional pieces for your home.

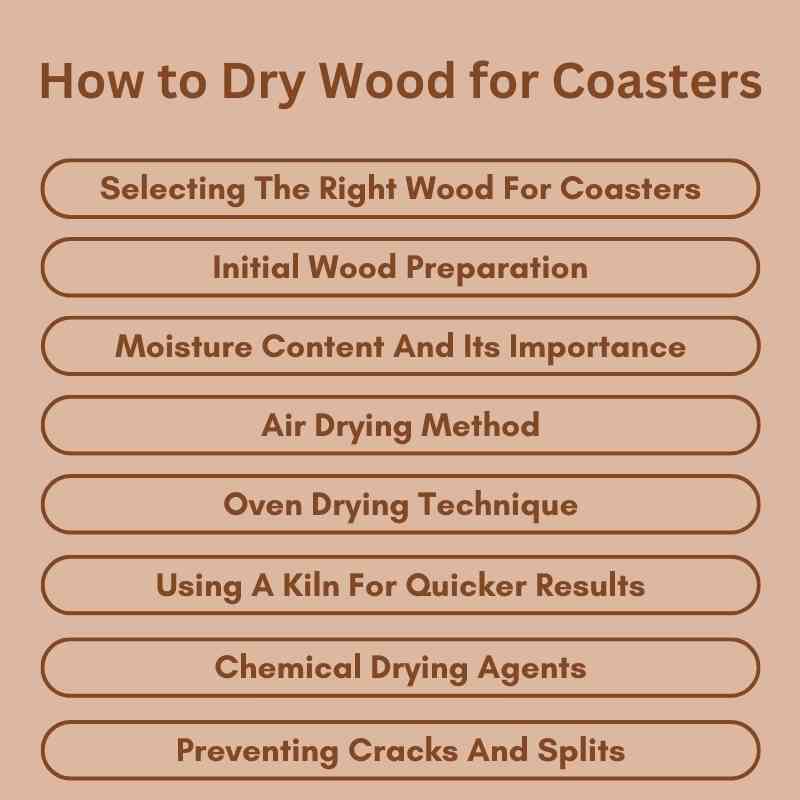

Selecting The Right Wood For Coasters

Choosing the right wood for coasters is essential. Popular wood types include oak, maple, and cherry. Each type has unique features.

Oak is strong and durable. Maple is lighter and has a fine grain. Cherry darkens over time, adding beauty.

| Wood Type | Durability | Aesthetic |

|---|---|---|

| Oak | High | Rich grain |

| Maple | Medium | Light color |

| Cherry | Medium | Warm tone |

Factors affecting wood choice include moisture resistance and ease of maintenance. Coasters must withstand spills and heat.

Always consider the wood’s ability to absorb moisture. Good choices prevent warping over time.

Initial Wood Preparation

Start by choosing the right wood type for coasters. Popular choices include oak, maple, and cherry. Cut the wood into small, even pieces. Aim for sizes around 4×4 inches for standard coasters.

Use a saw to make precise cuts. Always wear safety gear while cutting. After cutting, it’s time for sanding. Sand each piece to remove rough edges.

Begin with coarse sandpaper, then switch to finer grit. This process ensures a smooth finish. Sanding not only improves appearance but also helps wood dry evenly.

Make sure to sand all sides of the wood pieces. Pay extra attention to corners and edges. Proper sanding prepares the wood for the drying process.

Moisture Content And Its Importance

Understanding moisture content is key for making coasters. It affects durability and quality. Wood with too much moisture can warp or crack. Target moisture levels should be around 6% to 8% for best results.

To measure moisture levels, use a moisture meter. This tool is easy to use and gives quick readings. Check multiple spots on the wood for accuracy. Ensure the readings are consistent before proceeding.

Here’s a simple table for target moisture content:

| Wood Type | Target Moisture Content (%) |

|---|---|

| Oak | 6-8 |

| Pine | 8-10 |

| Birch | 6-8 |

Air Drying Method

To set up an outdoor drying area for wood, choose a sunny spot. This area should be well-ventilated and away from any moisture sources. Use level ground to prevent any water from pooling. Lay down a tarp or bamboo mat for wood placement. This helps air circulate around the wood.

For the time frame of air drying, expect it to take several weeks. The exact time depends on wood type and thickness. Generally, thinner pieces dry faster than thicker ones. Humidity also affects drying time. Monitor the wood regularly for dryness.

Oven Drying Technique

Oven drying wood for coasters is simple. Follow these easy steps to get started.

Step 1: Preheat the oven to 200°F (93°C).

Step 2: Cut the wood into thin pieces. Thinner pieces dry faster.

Step 3: Place the wood on a baking sheet. Make sure they don’t touch.

Step 4: Bake the wood for 1 to 2 hours. Check every 30 minutes.

Step 5: Remove the wood when it’s dry. Allow it to cool.

Keep the temperature steady. High heat can crack the wood. Always monitor the drying process.

Using A Kiln For Quicker Results

Using a kiln for drying wood offers many benefits. It speeds up the drying process significantly. This is important for making coasters quickly.

Kiln drying also helps prevent cracks and warping. Even moisture levels are easier to achieve in a kiln. Properly dried wood lasts longer and looks better.

Another advantage is that kiln drying kills pests and fungi. This keeps the wood safe for use in homes. It is a more efficient method compared to air drying.

| Benefit | Description |

|---|---|

| Speed | Drys wood faster than air drying. |

| Prevention | Reduces risk of cracks and warping. |

| Longevity | Improves durability and appearance. |

| Pest Control | Kills harmful pests and fungi. |

Chemical Drying Agents

Chemical drying agents help speed up the drying process of wood. Various types exist, each with unique benefits. Here are some common types of chemical agents:

- Ethylene Glycol: This agent is effective for preventing cracking.

- Acetone: A fast-drying option that removes moisture quickly.

- Denatured Alcohol: It evaporates quickly and aids in drying.

Application procedures vary based on the agent used. Start by preparing the wood surface. Apply the chosen agent evenly on the wood. Let it sit for the recommended time. After that, rinse the wood thoroughly. Drying times will differ based on the agent chosen. Always follow safety guidelines during use.

Preventing Cracks And Splits

Sealing the ends of the wood is very important. This helps to prevent cracks and splits. Use a good quality sealer to coat the ends. Apply a thin layer and let it dry completely. This step keeps moisture from entering the wood.

Monitoring the drying process is crucial. Check the wood regularly for any signs of damage. Keep the wood in a dry area with good air circulation. Avoid placing it in direct sunlight. This can cause uneven drying, which leads to warping.

Using a moisture meter can help track moisture levels. Aim for a moisture content of about 6-8% for coasters. This will ensure the wood remains stable. Taking these steps will help create beautiful and durable coasters.

Finishing Touches For Your Coasters

Final sanding gives your coasters a smooth finish. Use fine-grit sandpaper for best results. Sand the edges and surfaces gently. This helps remove any rough spots.

Choosing the right finish is key for durability. Options include oil, varnish, or polyurethane. Each finish offers different looks and protection levels. Test finishes on a scrap piece first.

Keep in mind that oil enhances natural wood grain. Varnish provides a hard, glossy surface. Polyurethane offers strong protection against moisture. Select a finish that matches your style.

Maintenance And Care Of Wooden Coasters

Wooden coasters need regular cleaning to stay beautiful. Use a damp cloth to wipe them. Avoid soaking the coasters in water. A mild soap can help remove tough stains. Always dry them immediately with a soft towel.

For long-term storage, keep coasters in a cool, dry place. Avoid direct sunlight to prevent fading. Use a breathable bag or box to protect them from dust. This keeps the wood looking fresh and new.

Frequently Asked Questions

How Long Does It Take To Dry Wood For Coasters?

Drying wood for coasters typically takes one to two weeks. The time depends on wood type, thickness, and humidity levels. Using a dehumidifier can speed up the process. Ensure the wood is stored in a well-ventilated area to prevent mold and warping.

What Is The Best Way To Dry Wood Quickly?

The best way to dry wood quickly is by using a kiln. Kiln drying reduces moisture content efficiently. Alternatively, you can use a dehumidifier in a controlled space. Air drying is slower but effective for thicker pieces. Always monitor moisture levels to ensure even drying.

Can I Use Air Drying For Wood Coasters?

Yes, air drying is suitable for wood coasters. It’s a natural method that can preserve the wood’s integrity. Place the wood in a dry, well-ventilated area. Ensure it’s stacked properly to promote airflow. This method may take longer than other drying techniques.

Should I Seal Wood Before Drying For Coasters?

Sealing wood before drying is not recommended. It can trap moisture inside, leading to warping. Instead, allow the wood to dry naturally. Once fully dried, apply a suitable sealant for protection. This ensures a smooth finish and longevity for your coasters.

Conclusion

Drying wood for coasters is a rewarding process. Proper techniques ensure durability and beauty. Take your time to prevent cracks and warping. Remember, well-dried wood enhances the quality of your coasters. Enjoy the satisfaction of creating unique, handmade items that serve both function and style in your home.

Happy crafting!