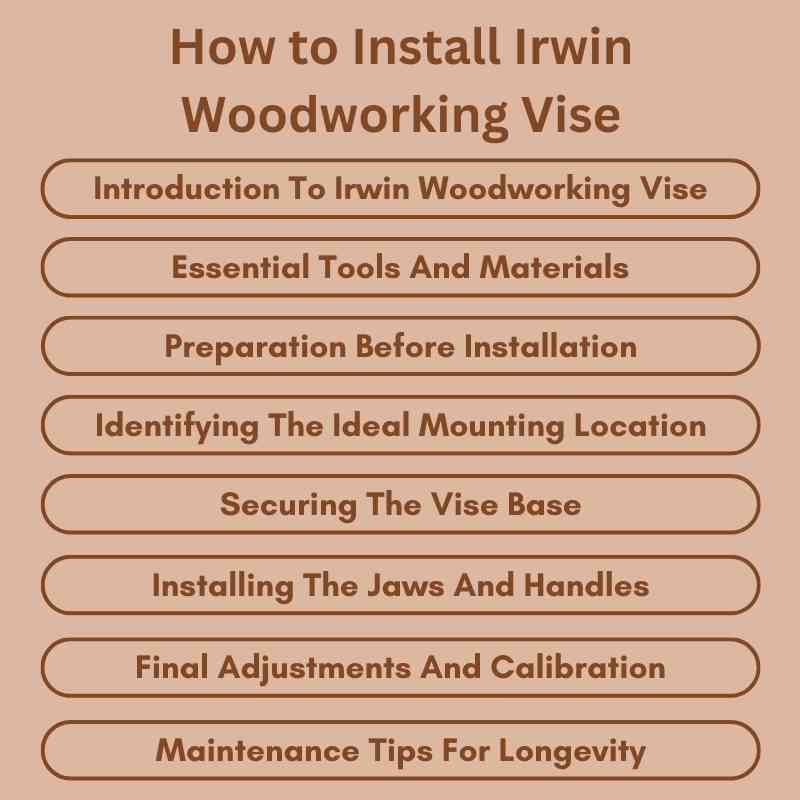

How to Install Irwin Woodworking Vise: Easy Steps

To install an Irwin woodworking vise, first, attach the vise to your workbench using the provided screws. Ensure it is aligned properly for optimal function.

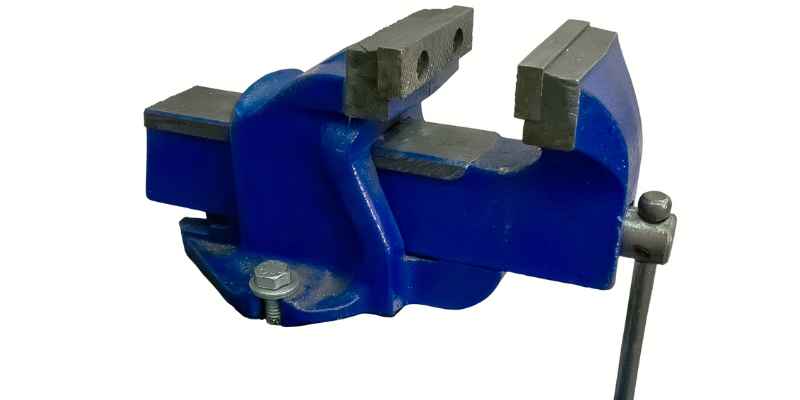

Installing an Irwin woodworking vise enhances your workspace efficiency and precision. This essential tool allows for secure clamping of materials, making it easier to perform intricate tasks. Whether you’re a seasoned woodworker or a DIY enthusiast, a reliable vise is crucial.

Installing it correctly maximizes its functionality and longevity. This guide walks you through the installation process step by step, ensuring you achieve a sturdy and well-aligned setup. With the right tools and a few simple techniques, you can transform your workbench into a productive area, ready for any woodworking project. Enjoy the benefits of a secure vise today!

Introduction To Irwin Woodworking Vise

A reliable vise is essential in woodworking. It helps hold wood securely. This allows for precise cuts and joints. Without a good vise, projects can become messy and difficult.

Irwin is known for its high-quality tools. Their woodworking vises are durable and efficient. Many woodworkers trust Irwin for their projects. The company has a long-standing reputation for excellence. Choosing an Irwin vise can enhance your woodworking experience.

Essential Tools And Materials

To install an Irwin woodworking vise, gather essential tools. Here is a list of the required tools:

- Drill

- Screwdriver

- Measuring tape

- Level

- Clamps

- Wrench

Choosing the right model of Irwin vise is important. Look for a model that fits your needs. Consider the size and jaw capacity. A good vise will last for years. Read reviews before making a decision. This helps ensure you pick the best one.

Preparation Before Installation

Start by choosing a clean, spacious workspace. This area should be free from clutter. Good lighting is also important for clear visibility.

Ensure you have all necessary tools ready. These may include a drill, screwdriver, and measuring tape. Gather your Irwin Woodworking Vise and any mounting hardware.

Prioritize safety by wearing protective gear. Use safety glasses to shield your eyes. Hearing protection is also wise if using loud tools.

Keep your fingers away from sharp objects. Always secure materials properly before cutting. Following these steps will create a safe environment for installation.

Identifying The Ideal Mounting Location

Choosing the right mounting location for your Irwin woodworking vise is crucial. Consider the workspace you have available. Ensure there is enough room for tools and materials.

Look at how you will use the vise. The height matters for comfort and efficiency. A good rule is to mount it at waist level. This position helps prevent strain on your back.

Check for a sturdy surface to attach the vise. A strong workbench will give you the best support. Make sure the area is clear of obstacles for easy access.

Mark the mounting area with a pencil. Use a level to ensure it is straight. Double-check your measurements before drilling any holes.

Securing The Vise Base

To secure the vise base, start by marking the position on your workbench. Choose a spot that is easy to reach. Use a straight edge to draw a line for alignment.

Next, drill pilot holes in the workbench. These holes make it easier to attach the vise. Use a drill bit that matches the size of the screws.

Once the pilot holes are ready, it’s time to attach the vise. Align the vise over the holes. Insert screws through the vise holes into the pilot holes. Tighten the screws to secure the vise firmly.

Installing The Jaws And Handles

To align the jaw plates, first, ensure they are clean. Place the vise on a sturdy surface. Adjust the plates so they fit snugly together. Check the alignment by tightening the screws lightly. Make sure both plates are parallel. This helps in smooth operation.

Assembling the main handle requires careful steps. Start by inserting the handle into the hole. Tighten the screw securely to hold it in place. Ensure the handle turns easily. If it feels stiff, check for any obstructions. A well-assembled handle improves the vise’s functionality.

Final Adjustments And Calibration

To ensure smooth operation of your Irwin woodworking vise, check the alignment. Misalignment can cause poor performance. Adjust the screws to align the jaws. This will help them close evenly.

Test the movement of the vise. It should open and close without sticking. If it does, make small adjustments to the alignment. Repeat the testing until it moves easily.

Lubricate the moving parts. Use a light oil to prevent rust. This will help the vise last longer and work better.

Finally, check all fasteners. Ensure they are tight and secure. Loose parts can lead to problems during woodworking.

Maintenance Tips For Longevity

Regular cleaning is essential for your Irwin woodworking vise. Use a soft cloth to remove dust and debris. Clean the jaws and screw with a gentle brush. Regularly apply a light oil to keep the mechanism running smoothly. This prevents rust and ensures easy adjustments.

Periodic inspection helps catch wear and tear early. Check the jaws for any signs of damage. Ensure that the screw turns freely without resistance. Look for any loose parts that may need tightening. Taking these steps can significantly extend the life of your vise.

Common Issues And Troubleshooting

Misalignment can happen during installation. Check the jaw alignment first. Use a straight edge to ensure they are even. Adjust the mounting screws if necessary. Tightening them can help fix the issue.

Sticking or binding is another common problem. This often occurs due to debris or dirt. Clean the guides and rails regularly. Apply wax or oil for smoother movement. If the vise still sticks, inspect for damaged parts.

Enhancing Your Vise With Accessories

Adding protective jaw pads to your Irwin woodworking vise is essential. These pads prevent damage to wood surfaces. They also help maintain grip and stability.

Custom modifications can enhance your vise’s performance. Consider adding extensions for wider projects. Use clamps for extra support on heavier pieces. Rubber grips can make handling easier and safer.

| Modification | Benefit |

|---|---|

| Protective Jaw Pads | Prevent damage to wood |

| Extensions | Support wider projects |

| Rubber Grips | Enhance safety and comfort |

| Clamps | Provide extra support |

Real-world Application And Projects

Using the Irwin woodworking vise can make many projects easier. Here are some great project ideas:

- Furniture making: Create tables or chairs with precision.

- Cabinet building: Perfect for holding wood while assembling cabinets.

- Wooden toys: Craft safe and fun toys for children.

- Home repairs: Use it to fix broken furniture or items.

Experienced woodworkers share these valuable tips:

- Always secure the vise tightly to avoid slipping.

- Use a soft cloth to protect your wood while clamping.

- Regularly check for loose screws to keep the vise safe.

Frequently Asked Questions

How Do I Choose The Right Irwin Woodworking Vise?

Choosing the right Irwin woodworking vise depends on your project needs. Consider the size of your workpieces and the type of woodworking you’ll do. A larger vise offers more clamping force, while a smaller one is easier to handle. Evaluate your workspace to find the best fit.

What Tools Are Needed For Vise Installation?

To install an Irwin woodworking vise, you’ll need a few basic tools. Gather a drill, screwdriver, and measuring tape. A level will help ensure proper alignment. Additionally, having clamps on hand can make the installation process smoother and more efficient.

Can I Install The Vise On Any Workbench?

Most Irwin woodworking vises can be installed on various workbenches. Ensure your workbench is sturdy and has enough space for the vise. Consider the thickness of your workbench top, as it should accommodate the mounting hardware. Always follow the manufacturer’s guidelines for optimal installation.

How Do I Maintain My Woodworking Vise?

Maintaining your Irwin woodworking vise is straightforward. Regularly clean it to remove sawdust and debris. Lubricate the moving parts to ensure smooth operation. Inspect for any wear or damage and address issues promptly to extend the life of your vise.

Conclusion

Installing an Irwin woodworking vise enhances your workspace. With the right tools and steps, you can achieve a secure fit. This upgrade will improve your woodworking projects and efficiency. Enjoy the benefits of a well-installed vise. Happy woodworking, and may your future projects be smooth and successful!