How To Master the Perfect 45 Degree Angle Cut in Wood

To measure and cut a 45 degree angle in wood, use a protractor or an angle-finder tool to determine the angle, then set your saw or miter box accordingly and make the cut. Cutting wood at a perfect 45 degree angle can be essential for various projects such as building furniture, installing moldings, or creating precise angles in carpentry work.

By following a few simple steps, you can accurately measure and cut a 45 degree angle in wood, ensuring the pieces fit together seamlessly. We will guide you through the process of measuring and cutting a 45 degree angle in wood, providing you with the knowledge and skills necessary to complete your woodworking projects successfully.

Choosing The Right Tools

When it comes to measuring and cutting a 45-degree angle in wood, choosing the right tools is crucial. Having the correct tools will not only make the job easier but also help you achieve precise and accurate cuts. In this section, we will discuss the two main tools you need to ensure your cuts are spot-on: selecting the right saw and purchasing the proper measuring tools.

Selecting The Right Saw

To create a clean and accurate 45-degree angle cut in wood, you need to choose the right saw for the job. There are different saws available in the market, but the most commonly used saw for this task is a miter saw. A miter saw allows you to make accurate angled cuts, making it the perfect choice for this task.

One key feature to look for when selecting a miter saw is the ability to tilt the blade to a 45-degree angle. This feature ensures that you can achieve the desired angle effortlessly. Additionally, opting for a saw with a laser guide will greatly enhance your precision and make aligning the cut even easier.

Purchasing The Proper Measuring Tools

Alongside selecting the right saw, it is essential to have the proper measuring tools in order to obtain accurate measurements for your 45-degree angle cut. Having precise measurements will help you achieve seamless joints and a professional finish. Here are a few measuring tools you should consider purchasing:

- Tape Measure: A tape measure is a staple in any woodworker’s toolkit. Look for a tape measure with both imperial and metric measurements for versatility.

- Miter Square: A miter square is specifically designed for measuring and marking angles. It allows you to easily set your desired 45-degree angle with precision.

- Protractor: A protractor is another handy tool that helps you accurately measure angles. Look for a protractor with clear markings and a locking mechanism to keep your measurements in place.

By investing in these measuring tools, you can ensure that your cuts are precise and your angles are on point. Remember, accuracy is key when it comes to achieving seamless joints and a professional finish in your woodwork projects.

Preparing The Workpiece

To measure and cut a 45-degree angle in wood, start by preparing the workpiece according to your project requirements. Take accurate measurements and use a miter saw or a miter box to make precise cuts. Make sure to secure the wood properly to ensure safety and accuracy.

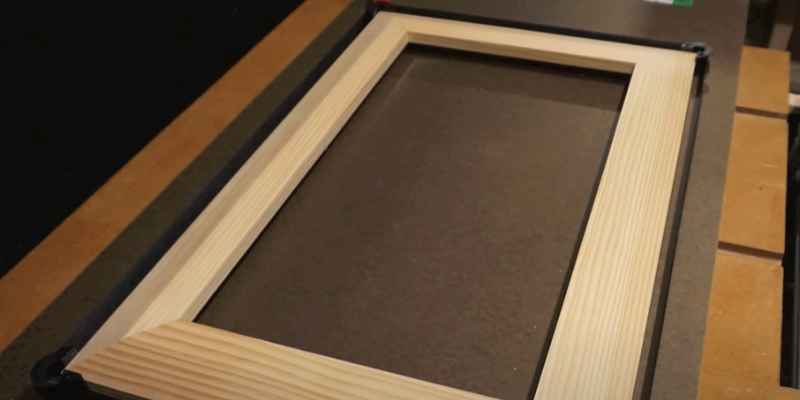

When it comes to woodworking, achieving precise angled cuts is essential for creating sleek and professional-looking projects. One such angle that frequently appears is the 45-degree angle. Whether you’re working on a picture frame, a furniture piece with mitered corners, or simply want to add some planking with an attractive joint, understanding how to measure and cut a 45-degree angle is crucial. In this section, we’ll dive into the first steps in the process – measuring and marking the angled cut line, and securing the wood for cutting.

Measuring And Marking The Angled Cut Line

Accurate measurements are the foundation of any successful woodworking project. When it comes to cutting a 45-degree angle, precision is key. The first step is to measure the length of the wood that needs the angled cut and mark it accordingly. Let’s break down the process into simple steps:

1. Measure the length: Using a tape measure, determine the desired length for your workpiece. Ensure the measurement is precise and in line with your project requirements.

2. Mark the cut line: Once you have the length, transfer that measurement onto the wood. To do this, use a pencil or a marking knife to make a clear and visible line along the length of the wood’s surface. Ensure the line is straight and accurate.

3. Calculate the angle: For a 45-degree angle, you don’t need any complex math. Simply use a carpenter’s square or an adjustable protractor to mark the 45-degree angle from the cut line you just made. This will indicate where you need to cut.

4. Double-check your measurements: Before moving forward, take a moment to review your measurements. Verify that the length and angle are correctly marked to avoid any mistakes later on.

Remember, taking the time to measure and mark accurately will save you from potential errors and wastage of materials.

Securing The Wood For Cutting

Now that you’ve marked your angled cut line, it’s time to secure the wood in a stable position for cutting. This step helps ensure safety and precision during the cutting process. Here’s what you need to do to secure the wood effectively:

1. Use clamps: Start by using clamps to secure the wood firmly onto a workbench or a sturdy surface that won’t move or wobble. Make sure that the part to be cut is left exposed, allowing you to work on it comfortably.

2. Consider a secure base: Depending on the size and shape of your workpiece, you may need additional supports to provide stability. For longer pieces, consider using supports or sawhorses to avoid any sagging or bending.

3. Stabilize small pieces: If you’re working with smaller pieces of wood, you can use a vise to hold them securely in place. This will allow you to have both hands available for handling the saw without worrying about the wood moving.

By taking the time to properly secure your wood, you’ll be able to cut with precision and confidence, minimizing the risk of accidents and errors.

Now that you’ve learned the first steps in preparing the workpiece – measuring and marking the angled cut line and securing the wood for cutting – you’re one step closer to mastering the art of creating clean and accurate 45-degree angle cuts in wood. Without a doubt, these foundational steps will set the stage for a successful woodworking project. So let’s move on to the next step – executing the cut itself.

Making The 45 Degree Angle Cut

Learn how to measure and cut a precise 45-degree angle in wood with these easy-to-follow instructions. Achieve professional-looking results and enhance the accuracy of your woodworking projects.

Adjusting The Saw Blade Angle

To make a precise 45-degree angle cut in wood, the first step is to adjust the angle of the saw blade. Start by loosening the saw blade tilt lock knob, which is usually located on the front or side of the saw. Gradually turn the tilt adjustment wheel until the blade is set to a 45-degree angle. Tighten the lock knob firmly to secure the blade in place. This adjustment ensures that the saw will cut at the desired angle, allowing for a clean and accurate result.

Ensuring A Controlled And Smooth Cut

Creating a controlled and smooth 45-degree angle cut requires careful planning and execution. To begin, measure and mark the wood according to your desired cutting dimensions. Using a pencil or marker, draw a straight line along the length of the wood, indicating the path of the cut. This line will serve as a guide for when you are making the actual cut.

Before starting the saw, ensure a firm grip on the wood to maintain control throughout the cutting process. Place the wood firmly against the fence or miter gauge, aligning the marked cutting line with the blade. Keep your hands clear of the blade and use a push stick or block to feed the wood through the saw. This will prevent any accidental slips and keep your hands safe from potential injuries.

When cutting the wood, maintain a steady and consistent forward motion, allowing the saw blade to do the work. Applying excessive force or rushing the cut can result in an uneven or jagged edge. Take your time and let the saw blade smoothly slice through the wood, creating a clean and precise 45-degree angle cut.

Remember to always wear appropriate safety gear, such as safety glasses and ear protection, when operating power tools. Additionally, ensure a well-lit work area to make accurate measurements and clearly see the cutting path.

By following these steps, you can confidently measure and cut a 45-degree angle in wood, achieving professional-looking results. Practice makes perfect, so don’t be discouraged if your first few attempts are not perfect. With time and patience, you will master this essential woodworking technique.

Finishing And Fine-tuning The Cut

In woodworking, precision is key when it comes to creating seamless 45-degree angle cuts in wood. Once you have successfully measured and cut the angle, it’s time to shift your focus to finishing and fine-tuning the cut. This step is crucial to achieve a professional-looking result and ensure the structural integrity of your project. In this section, we will explore the necessary steps to sand the cut surface and check the cut for precision.

Sanding The Cut Surface

After making the 45-degree angle cut, you may notice that the edges and surfaces are rough or uneven. To achieve a smooth and flawless finish, sanding is essential. Here’s how you can effectively sand the cut surface:

- Begin by using a coarse-grit sandpaper, such as 80 or 100 grit, to remove any large imperfections or rough spots on the cut.

- Next, switch to a medium-grit sandpaper, around 150 or 180 grit, to further smooth the surface and eliminate any visible marks left by the coarse-grit sandpaper.

- To achieve a fine finish, use a fine-grit sandpaper, such as 220 grit, to sand the surface until it feels smooth to the touch.

- Don’t forget to lightly sand the edges to remove any sharp corners or splinters.

- Finally, wipe away the dust with a clean, dry cloth or use a vacuum to ensure a clean surface before moving on to the next step.

Checking The Cut For Precision

Ensuring that the 45-degree angle cut is precise is vital for the overall fit and stability of your woodworking project. Follow these steps to check the cut for accuracy:

- Use a combination square or a 45-degree angle gauge to measure the angle of the cut. Place the square or gauge against the cut and ensure that the blade aligns perfectly with the edge.

- Inspect the joint created by the angled cut. The two pieces of wood should fit tightly together without any gaps or misalignments.

- If you detect any gaps or misalignments, make necessary adjustments by re-cutting or sanding the edges until the joint fits snugly.

By diligently sanding the cut surface and closely inspecting the precision of the 45-degree angle cut, you will achieve a professional and accurate result in your woodworking project. These finishing and fine-tuning steps are essential to ensure the strength and longevity of your creation.

Tips For Achieving Success

Want to achieve success in woodworking? Learn how to measure and cut a 45-degree angle in wood with these expert tips. Mastering this technique will elevate your woodworking projects to a whole new level.

In order to measure and cut a precise 45-degree angle in wood, there are a few tips that can help you achieve success. These tips will ensure that your cuts are accurate, clean, and safe. Whether you’re a seasoned woodworker or just starting out, following these guidelines will help you master the art of cutting a 45-degree angle with ease.

Practice On Scrap Wood First

Before attempting to cut a 45-degree angle on your desired piece of wood, it is highly recommended to practice on scrap wood first. This allows you to familiarize yourself with the process and gain confidence in your skills.

Here are a few steps you can follow:

- Step 1: Select a piece of scrap wood that is similar in thickness and quality to your intended material.

- Step 2: Set up your miter saw or table saw according to the specifications of a 45-degree angle cut. Double-check that the angle is set accurately.

- Step 3: Place the scrap wood securely against the saw fence, ensuring it is snugly in place.

- Step 4: Gently push the scrap wood through the saw, maintaining a steady and controlled motion.

- Step 5: Inspect the cut to ensure it is clean, straight, and accurate. Adjust the angle if necessary and repeat the process until you feel comfortable with the technique.

By practicing on scrap wood, you minimize the risk of making mistakes on your actual project and can refine your technique before moving on to more valuable materials.

Maintaining Safety Measures

When working with power tools and sharp blades, it is crucial to prioritize safety. Here are some essential safety measures to follow when measuring and cutting a 45-degree angle in wood:

- Wear Protective Gear: Always wear safety glasses, ear protection, and a dust mask to shield yourself from potential hazards.

- Proper Tool Usage: Ensure that you are using the correct tool and that it is in good working condition. Follow all manufacturer guidelines and instructions when operating the tool.

- Firmly Secure the Wood: Use clamps or vices to secure the wood firmly in place before making any cuts. This helps maintain stability and prevents any accidental slips or movement.

- Avoid Obstructions: Clear your workspace of any unnecessary clutter or obstacles that may hinder your movements or compromise safety.

- Measure Twice, Cut Once: Double-check your measurements before making any cuts. This ensures accuracy and prevents any wastage of materials.

- Always Cut Away From Yourself: Position yourself in a way that allows you to make cuts away from your body, reducing the risk of injury.

- Take Breaks: Fatigue can lead to accidents. Take regular breaks to maintain focus and prevent any loss of concentration.

By strictly adhering to these safety measures, you can confidently measure and cut your wood at a 45-degree angle while minimizing any potential risks or accidents.

Conclusion

To sum it up, mastering the art of measuring and cutting a 45-degree angle in wood is essential for any DIY enthusiast or professional carpenter. By following the step-by-step instructions provided in this guide, you can ensure precise and accurate cuts every time.

Remember, practice makes perfect, so don’t be discouraged if it takes a few tries to get it right. With time and patience, you’ll become a pro at creating beautiful angled cuts in wood. Happy woodworking!