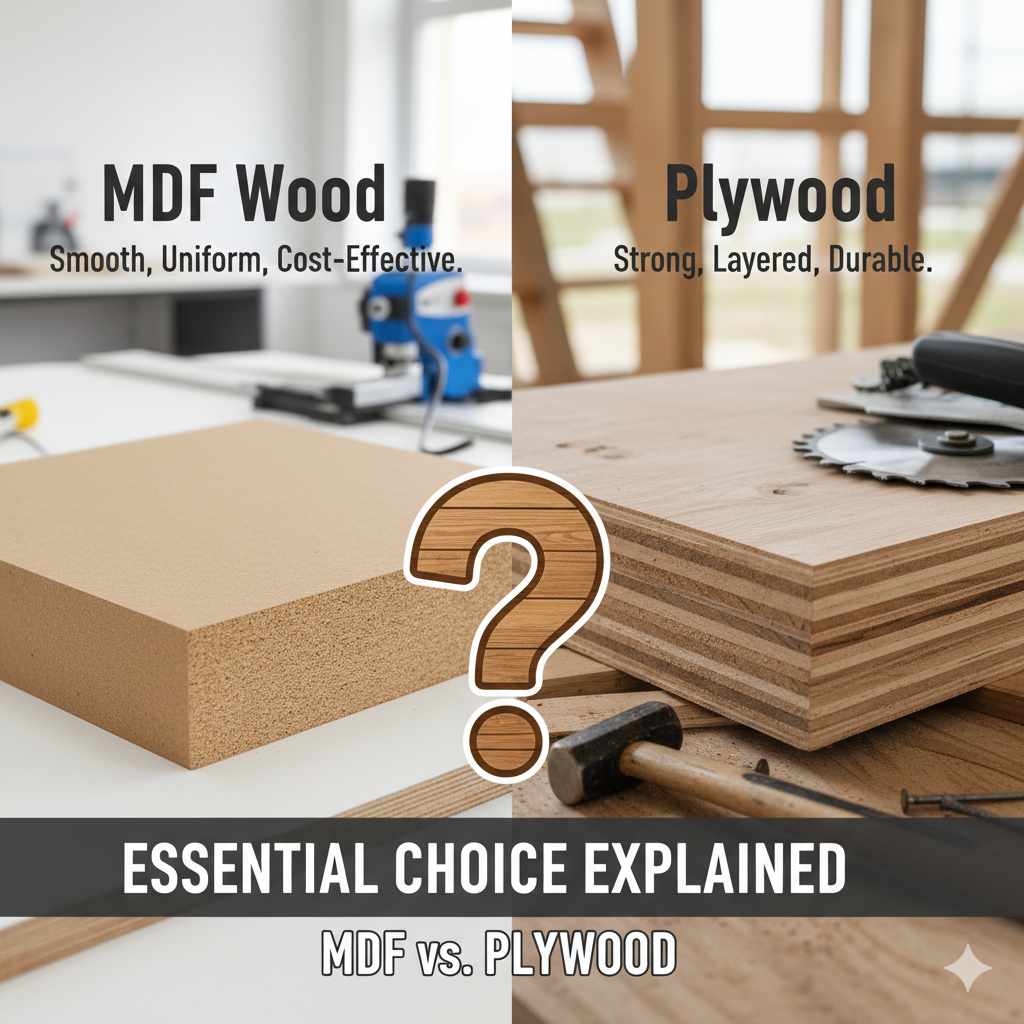

MDF Wood vs Plywood: Essential Choice Explained

MDF wood vs plywood: Choose the right material for your DIY projects! MDF is smooth and paintable, ideal for decorative pieces. Plywood is stronger and more durable, perfect for structural elements and shelving. Understanding their differences ensures your projects look great and last long.

Hello there, fellow makers! Deciding between MDF (Medium-Density Fiberboard) and plywood can feel like a woodland puzzle when you’re starting out. Both are fantastic engineered wood products, but they have unique strengths that make them shine in different situations. Getting this choice right from the start can save you time, effort, and ensure your projects turn out exactly how you envision them. Don’t worry, we’re going to break down exactly what each material is, how they’re made, and where they’re best used. By the end of this guide, you’ll be confidently picking the perfect board for your next creation!

What is MDF Wood?

MDF, or Medium-Density Fiberboard, is a type of engineered wood product that’s made by breaking down hardwood or softwood into wood fibers, often using a process called defibrillation. These fibers are then combined with wax and a resin binder. Under high temperature and pressure, the mixture is formed into panels. The result is a very dense, smooth, and uniform material. Think of it like a very fine, compressed sawdust cake.

Because MDF doesn’t have a wood grain, it offers a consistent surface that is fantastic for finishing. It’s also very stable, meaning it doesn’t expand or contract as much with changes in humidity and temperature as solid wood does. This stability makes it a popular choice for indoor applications where a smooth finish is desired.

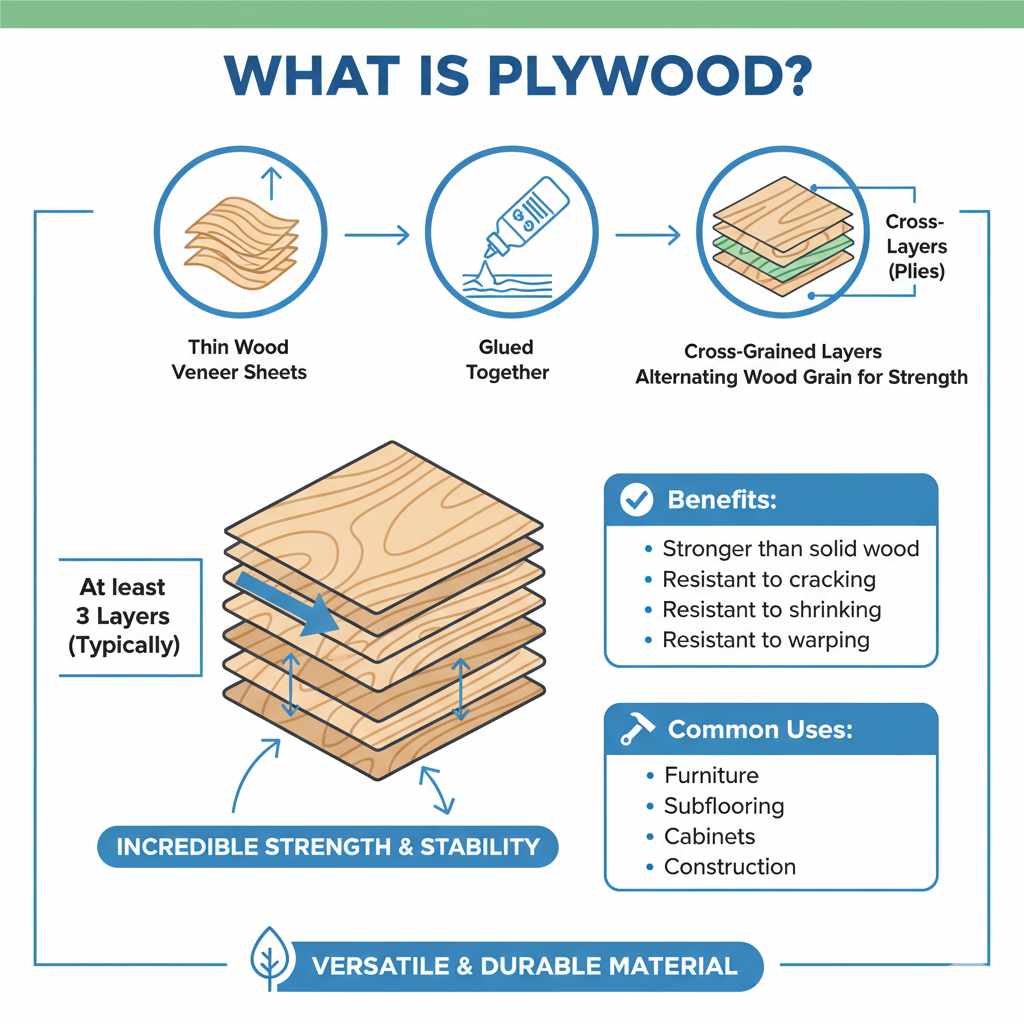

What is Plywood?**

Plywood, on the other hand, is made by taking thin sheets of wood veneer and gluing them together. These layers, called plies, are stacked on top of each other with their wood grain running in alternating directions. This cross-graining technique is what gives plywood its incredible strength and stability. Imagine building with thin, strong layers all working together.

The number of plies can vary, but typically plywood has at least three layers. This construction makes plywood much stronger than solid wood of the same thickness and resistant to cracking, shrinking, and warping. It’s a very versatile material, used in everything from furniture construction to subflooring.

MDF Wood vs Plywood: Key Differences Explained

The main differences between MDF and plywood come down to their construction and how that affects their performance. Here’s a breakdown of the essential distinctions:

Construction and Composition

The way MDF and plywood are made is the root of their differing characteristics. MDF is essentially wood fibers pressed together with binders, creating a homogenous panel. Plywood is layers of thin wood veneers glued together, with the grain oriented in alternating directions for maximum strength.

Strength and Durability

Plywood generally boasts superior structural strength compared to MDF. The cross-laminated veneer construction makes it resistant to bending and breaking under load, especially when used for shelves or structural components. MDF is dense and strong for its weight, but it can snap under significant bending stress, particularly over longer spans. Plywood is also more resistant to impact damage.

Moisture Resistance

Neither material is a fan of prolonged direct moisture. However, standard MDF is particularly susceptible to swelling and disintegration when exposed to water. While plywood can delaminate or warp when wet, some grades are more water-resistant than others. For applications where moisture is a concern, you’ll need to look for specialized versions like moisture-resistant MDF or exterior-grade plywood, and always seal them thoroughly.

Finishing and Appearance

This is where MDF often shines for DIYers. Its perfectly smooth, grain-free surface makes it incredibly easy to paint or apply veneers to. You’ll get a flawless finish without any visible wood grain interrupting the look. Plywood, while it can be finished, will show the wood grain. This can be desirable for certain aesthetics, but it requires more preparation, like filling grain or using specific primers for a perfectly smooth painted finish.

Weight

MDF is generally denser and heavier than plywood of the same thickness. This can be an advantage if you’re looking for a solid, substantial feel, but it can make handling and installation more challenging, especially for larger pieces.

Cost

Typically, MDF is more affordable than plywood. This can make it a very attractive option for budget-conscious projects, especially when you achieve a painted finish rather than needing to beautifully showcase wood grain.

Machining and Working With Them

Cutting and shaping MDF can create very fine dust that needs careful management (more on safety later!). It cuts cleanly for smooth edges, but it can be prone to chipping if not handled carefully. Screws and nails can hold in MDF, but they may not have the same holding power as in plywood, especially on the edges of thin boards. Plywood is easier to work with in terms of tear-out when cutting if you use sharp blades. It holds fasteners exceptionally well due to its layered structure.

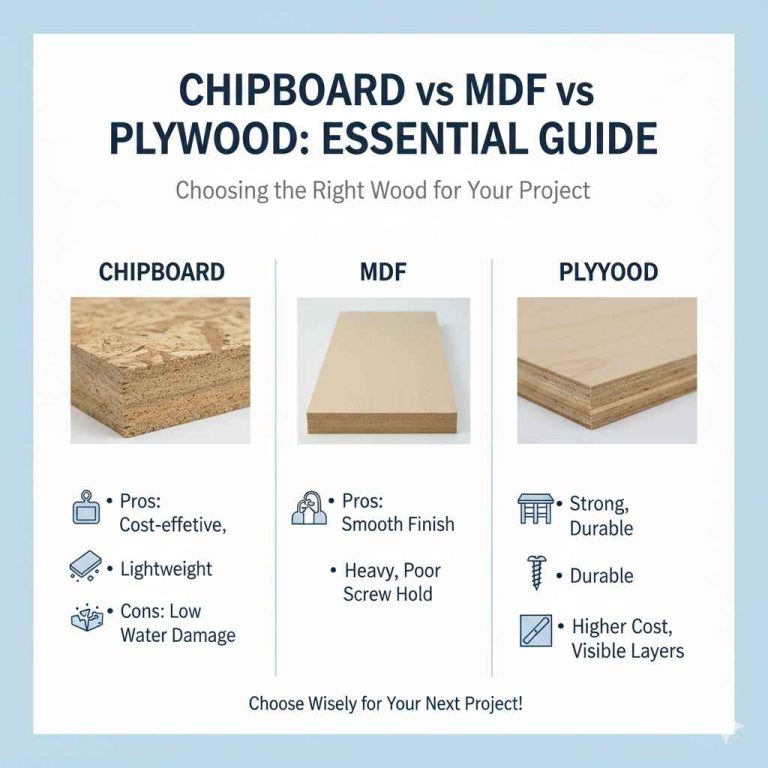

Table: MDF vs. Plywood At a Glance

Let’s summarize the key differences in a handy table to make your decision even easier:

| Feature | MDF Wood | Plywood |

|---|---|---|

| Construction | Wood fibers, wax, resin binders; homogenous | Layers of wood veneer glued with alternating grain |

| Strength | Good density, can be brittle over spans | High tensile strength, durable, less prone to breaking |

| Moisture Resistance | Poor (swells easily) | Moderate (can delaminate/warp); better in exterior grades |

| Finish | Extremely smooth, no grain, ideal for painting | Visible wood grain, can be painted or stained |

| Weight | Denser and heavier | Lighter for its strength |

| Cost | Generally more affordable | Slightly more expensive |

| Fastener Holding Power | Moderate; edge holding can be weak | Excellent |

| Best For | Cabinet doors, decorative mouldings, painted furniture, craft projects | Shelving, cabinets, subflooring, structural components, furniture frames |

When to Choose MDF Wood

There are many situations where MDF is the superior choice for your DIY projects. If your project involves creating smooth, painted surfaces or intricate decorative details, MDF is often your best friend.

Projects Ideal for MDF:

- Cabinet Doors: The smooth, paintable surface of MDF is perfect for creating a flawless finish on cabinet doors. You can router intricate designs into it without worrying about grain tear-out.

- Decorative Moldings and Trim: For a professional, painted look, MDF moldings are excellent because they offer a consistent, smooth surface.

- Painted Furniture: If you’re building a piece of furniture, like a bookshelf or side table, that you intend to paint, MDF provides an unmatched smooth finish.

- Wainscoting and Wall Panels: For a clean, modern look, MDF panels are a popular and cost-effective choice.

- Craft Projects: For smaller craft items, signs, or cutouts that will be painted or decorated, MDF’s uniformity and smooth surface are a dream to work with.

- Speaker Enclosures: The density of MDF makes it excellent for acoustic properties, reducing resonance and vibration, which is why it’s frequently used in speaker boxes.

When to Choose Plywood

Plywood’s strength and durability make it the go-to material for projects that need to hold weight, withstand stress, or have a more structural role.

Projects Ideal for Plywood:

- Shelving: For robust shelving that needs to support significant weight, like in garages, workshops, or even kitchens, plywood is the champion. Its resistance to sagging is crucial.

- Cabinet Boxes: While MDF can be used for doors, the actual boxes of cabinets benefit from plywood’s strength and durability, especially if they will be holding heavy items.

- Furniture Frames: For the underlying structure of furniture, like the carcass of a desk or the frame of a sofa, plywood offers better stability and fastener-holding power.

- Subflooring and Underlayment: Plywood is a standard material for subfloors in construction due to its strength and stability.

- Workbenches and Shop Furniture: Projects in a workshop need to be tough. Plywood’s durability makes it ideal for heavy-duty work surfaces and benches.

- Outdoor Projects (with appropriate grade and sealing): Exterior-grade plywood, specifically designed to resist moisture, can be used for outdoor furniture, sheds, or playhouses. Always ensure it’s properly sealed.

- Veneered Projects: If you want a real wood grain look, high-quality plywood with a good top veneer can be stained and finished to look like more expensive hardwoods.

Working Safely with MDF and Plywood

As a woodworking mentor, safety is always my top priority, and it’s crucial when working with these materials. Both MDF and plywood produce dust when cut, but MDF dust is particularly fine and can be a respiratory irritant.

Essential Safety Gear:

- Dust Mask or Respirator: Always wear a good quality dust mask or, ideally, a respirator designed for fine particulate matter when cutting, sanding, or routing MDF. Look for NIOSH-approved masks. For more information on respiratory protection, the NIOSH website offers valuable guidance.

- Safety Glasses: Protect your eyes from sawdust and flying debris.

- Hearing Protection: Power tools can be loud; earplugs or earmuffs are essential.

- Work Gloves: Protect your hands from splinters and abrasions.

Best Practices for Cutting and Sanding:

- Use Sharp Blades: Sharp blades make cleaner cuts and reduce the amount of dust produced. For MDF, a dedicated multi-purpose blade or a blade with more teeth can provide a smoother cut. For plywood, sharp combination blades work well.

- Work in a Well-Ventilated Area: If possible, work outdoors or in a garage with the door open. If working indoors, use a dust collection system or fan to help clear the air.

- Clean Up Thoroughly: After cutting or sanding, clean up dust immediately using a vacuum with a HEPA filter. Dry sweeping can stir up fine dust.

- Router Safety: When routing the edges of MDF or plywood, use appropriate router bits and follow safe routing practices. Ensure your workpiece is securely clamped.

Finishing Tips for MDF and Plywood

How you finish these materials will significantly impact the final look and durability of your project.

Finishing MDF:

MDF is a painter’s dream. Its smooth, non-porous surface takes paint beautifully. For the best results:

- Prime: Always start with a good quality primer. This seals the surface, prevents the paint from soaking in unevenly, and provides a smooth base. You might need two coats.

- Sand Lightly: After priming, a light sanding with fine-grit sandpaper (like 220 grit) will knock down any raised fibers and create an ultra-smooth surface.

- Paint: Apply your chosen paint in thin, even coats. Latex or acrylic paints work well.

- Edge Sealing: The most vulnerable part of MDF is its edges, which can absorb finish and potentially swell. Sealing the edges thoroughly with primer or a specialized edge sealer is highly recommended.

Finishing Plywood:

Plywood can be painted or stained. The key is preparing the surface correctly.

- Sanding: Start with a medium-grit sandpaper (e.g., 120 grit) and progress to finer grits (e.g., 180-220 grit) to smooth the surface. Sand with the grain.

- Grain Filling (Optional but Recommended for Painting): If you want a perfectly smooth painted finish, you may need to use a grain filler to fill in the subtle texture of the wood grain.

- Staining: Apply wood conditioner first to prevent blotching, then apply your stain. Test on scrap pieces.

- Painting: Use a good primer suitable for wood. You might still see faint grain lines, which can add character or be minimized with careful priming and sanding. Then apply your chosen paint.

- Sealing: Always finish with a protective topcoat, such as polyurethane or varnish, to protect against wear and moisture.

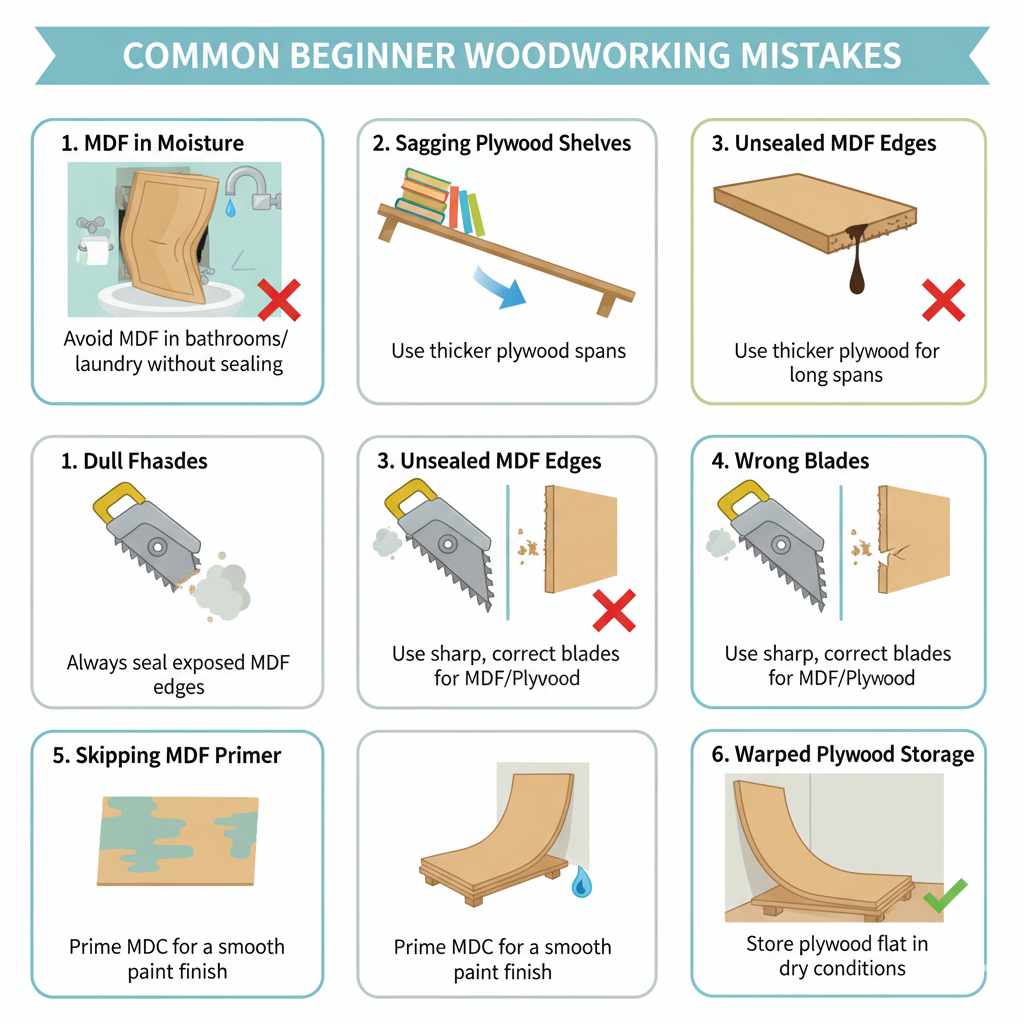

Common Beginner Mistakes to Avoid

As you embark on your woodworking journey, it’s natural to make a few missteps. Here are some common mistakes beginners make when choosing and using MDF and plywood, and how to steer clear of them:

- Using MDF in High-Moisture Areas: Putting MDF in bathrooms, laundry rooms, or basements without significant, long-term sealing is a recipe for swelling and damage. Plywood, especially exterior grade, is a much safer bet.

- Underestimating Plywood Strength for Shelving: Many beginners might choose a thinner plywood for shelves and find they sag over time. Always factor in span length and thickness needed for the weight your shelves will hold. Consult resources from organizations like the Woodworking Network for guidance on proper material thickness and support.

- Not Sealing MDF Edges: Forgetting to seal the exposed edges of MDF is a common oversight that can lead to moisture damage and a less professional finish.

- Using the Wrong Blades: Cutting MDF with a dull blade or a blade not designed for it will result in a rough edge and excessive dust. Similarly, using an inappropriate blade for plywood can cause splintering and tear-out.

- Skipping Primer on MDF: Trying to paint MDF directly without priming will result in an uneven, splotchy finish as the paint absorbs into the fibers inconsistently.

- Warping Plywood: If you’re not careful when storing or handling plywood, especially in humid conditions, it can warp. Store it flat and off the ground.

Frequently Asked Questions (FAQ)

Q1: Can I use MDF for outdoor projects?

Generally, no. Standard MDF is not designed for exposure to the elements and will swell and break down when wet. For outdoor projects, you would need to use exterior-grade plywood or specially treated woods, and always ensure they are properly sealed and painted.

Q2: Which material is better for cutting intricate designs?

MDF is often preferred for intricate designs, especially when using a CNC router or jigsaws for decorative cutouts. Its uniform density means there’s no grain to tear out, providing clean edges for detailed work.

Q3: Is plywood stronger than MDF?

Yes, in terms of structural strength and resistance to bending and breaking, plywood is generally stronger than MDF. This makes it a better choice for heavy-duty shelving and structural applications.

Q4: Which is easier to paint, MDF or plywood?

MDF is typically easier to paint to a perfectly smooth, flawless finish because it has no wood grain. Plywood can be painted, but you will need to prepare the surface carefully, possibly using grain filler, to achieve a similar smooth result.

Q5: Does MDF warp like plywood?

MDF is very stable and less prone to wrapping than plywood due to its homogenous composition. However, it is susceptible to swelling if it absorbs moisture, which can cause distortion.

Q6: Can I screw into MDF and plywood?

Yes, you can screw into both. Plywood generally has better screw-holding power, especially on the edges, due to its layered structure. For MDF, screws hold well in the face, but edge-holding can be weaker, and it’s often recommended to use longer screws or pre-drill pilot holes to prevent splitting.

Q7: Which material is more eco-friendly?

This is a complex question. Both are engineered wood products made from byproducts or fast-growing trees. MDF uses resin binders that can sometimes be a concern, while plywood’s adhesives and the forestry practices used for veneer production vary. Some manufacturers offer MDF and plywood made with low-VOC (Volatile Organic Compound) or formaldehyde-free adhesives, which are more environmentally friendly options. Always check product certifications.

Conclusion

Choosing between MDF wood and plywood isn’t about one being definitively “better” than the other. It’s about understanding their unique properties and selecting the material that’s the right tool for the job.

If your heart is set on a smooth, flawless painted finish for cabinet doors, decorative trim, or stylish furniture, MDF is likely your champion. Its uniform surface and affordability make it incredibly appealing for these applications.

However, when strength, durability, and structural integrity are paramount – think robust shelving, sturdy cabinet frames, or workshop furniture – plywood steps up as the clear winner.