Polyurethane Adhesives Market: Trends & Growth Insights

Are you curious about what makes polyurethane adhesives a standout choice in the vast world of bonding solutions? You’re about to discover why this versatile adhesive has become a staple across industries, from automotive to construction.

Imagine the convenience of using a product that offers not only strength but also flexibility and durability. As the demand for innovative materials grows, the polyurethane adhesives market is experiencing remarkable expansion, presenting exciting opportunities for businesses and consumers alike.

You will explore the driving forces behind this market’s growth, the cutting-edge applications of polyurethane adhesives, and how they can benefit your projects. Whether you’re a professional seeking the best adhesive for your needs or simply interested in the latest industry trends, this deep dive promises valuable insights. Stay with us, and uncover what makes polyurethane adhesives the glue that’s sticking around for the long haul.

Market Overview

Polyurethane adhesivesare used in many products. These adhesives are strong. They hold things together. They are used in cars and buildings. They are also used in shoes and furniture.

The demand for these adhesives is growing. More people are buying cars. More buildings are being built. This means more need for strong adhesives. Safetyis important. Polyurethane adhesives help make things safe.

Many companies sell these adhesives. They make them in different ways. Some are fast drying. Some are very strong. People choose based on what they need. Qualityis important. Good adhesives last longer.

Key Drivers

The automotive industry needs strong and flexible materials. Polyurethane adhesives provide this strength. They hold car parts together. This is important for cars. Car makers want lightweight materials. Polyurethane is light and strong. It helps cars go faster and use less fuel. This is why the demand is rising. More cars need these adhesives. It makes cars safer too.

Construction projects are growing fast. Builders need strong adhesives. Polyurethane sticks well to many surfaces. It helps buildings stand strong. This is good for tall buildings and homes. It keeps them safe from wind and rain. Many builders choose polyurethane for these reasons. It works well in hot and cold weather. This makes it the best choice for many projects.

Challenges Faced

Navigating the polyurethane adhesives market presents several challenges. Intense competition pressures companies to innovate and reduce costs. Environmental regulations demand sustainable production methods, often increasing expenses. Additionally, fluctuating raw material prices impact profit margins, requiring strategic sourcing and cost management.

Environmental Concerns

Polyurethane adhesives impact the environment. These products can release harmful chemicals. Protecting nature is important. Governments set strict rules. Companies must follow these rules. They need to find safer materials. This can be hard. Green alternatives are often costly. Research and development take time. Many businesses struggle with this. Keeping the planet safe is a big task. Everyone must work together.

Fluctuating Raw Material Prices

Raw materials are used to make polyurethane adhesives. Their prices change often. This affects production costs. Companies face challenges in planning budgets. Sudden price hikes can lead to losses. Businesses need to stay alert. They must adapt quickly. Finding stable suppliers is crucial. Some companies stockpile materials. This helps reduce risk. Managing costs is a daily struggle. This keeps the industry on its toes.

Credit: www.adhesivesmag.com

Regional Insights

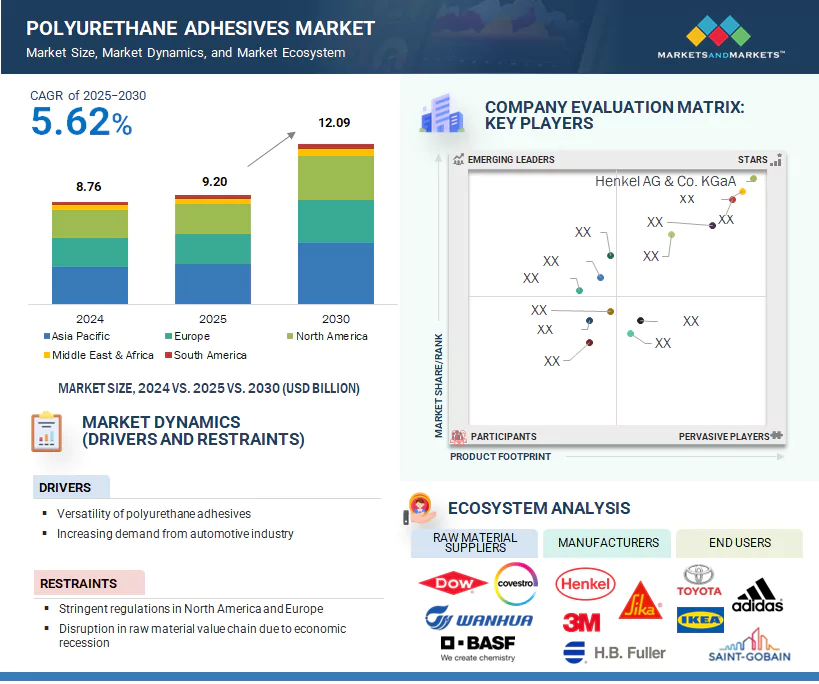

Polyurethane adhesives show strong growth in regions like Asia-Pacific and North America due to industrial demand. Europe sees steady expansion, driven by automotive and construction sectors. Emerging markets offer potential, with increasing infrastructure developments boosting adhesive usage.

North America

North America is a big market for polyurethane adhesives. The United States and Canada lead here. Many industries use these adhesives, like automotive and construction. These industries need strong and flexible materials. Polyurethane adhesives meet this need well. The demand is growing fast. Many companies are investing in research. They want to make better products. This growth is good for the market.

Europe

Europe also has a strong market for these adhesives. Germany, France, and the UK are key players. They use these adhesives in transportation and electronics. Many people are building houses and offices. This increases the demand for these adhesives. Also, European laws focus on eco-friendly products. Companies are making adhesives that are safe for the earth. This change is important for the market.

Asia Pacific

Asia Pacific is growing fast in this market. China, India, and Japan lead the way. They use polyurethane adhesives in construction and electronics. More people are moving to cities. This increases the need for housing and gadgets. Many factories are in Asia. They produce large amounts of adhesives. This region will keep growing in the future. The market looks strong and promising.

Technological Innovations

Scientists use advanced formulation techniquesto make adhesives better. They mix different materials to create stronger bonds. These bonds help things stick together well. The new methods make adhesives last longer and work in tough conditions. Safe methods are important for both people and the planet. So, these techniques are very helpful.

Many companies focus on sustainable solutionsfor adhesives. This means they use materials that are good for the Earth. These materials come from plants or recycled goods. They reduce waste and pollution. Using these solutions helps protect nature. It’s a smart way to keep our planet safe and clean.

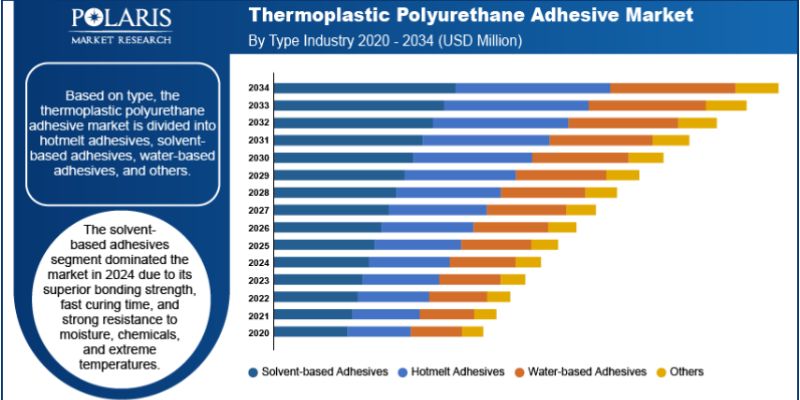

Credit: www.marketsandmarkets.com

Competitive Landscape

The polyurethane adhesives market sees intense competition among leading manufacturers, each striving for innovation. Companies focus on quality and cost-effectiveness to gain an edge.

Major Players

The polyurethane adhesives market includes many big companies. Henkel AG, 3M, and BASF SE are some of them. These companies lead in making quality adhesives. They are known worldwide for their products. H.B. Fuller and Dow are also key players. They offer a range of adhesive solutions. Arkema and Sika AG contribute to innovation in this field. Each company has unique strengths. Their products are used in many industries.

Strategic Partnerships

Companies form partnerships to grow faster. These partnerships help in sharing technology. They also help in reaching new markets. Joint ventures are common. They allow companies to work together. This makes production easier and cheaper. Collaborations with research institutes are also popular. They lead to better product development. Strategic alliances can improve a company’s market position. They also help in gaining a competitive edge. Such partnerships are a smart business move.

Future Prospects

Polyurethane adhesives are used in many industries. They bond materials like wood, metal, and plastic. This makes them versatile. New technologies are creating more ways to use them. For example, the automotive industry uses them for lightweight parts. This helps cars save fuel. They are also used in electronics for better performance. Innovationis driving demand for these adhesives. Their ability to bond different materials is unmatched. This opens doors to new projects and products.

The market for polyurethane adhesives is growing. Experts say it will expand rapidly. By 2025, it will be worth billions of dollars. Asiawill lead this growth. More factories and more projects use these adhesives. Europe and America will also see growth. The demand for strong bonds is increasing. This is because industries need reliable products. Polyurethane adhesives meet these needs. Their future looks bright and promising.

Credit: www.databridgemarketresearch.com

Frequently Asked Questions

What Are Polyurethane Adhesives Used For?

Polyurethane adhesives are versatile and used in various industries. They bond materials like wood, metal, and plastic. Common applications include automotive, construction, and footwear. Their flexibility and resistance to environmental factors make them ideal for diverse applications.

How Do Polyurethane Adhesives Work?

Polyurethane adhesives cure by reacting with moisture in the air. This process forms strong bonds between surfaces. They offer excellent adhesion, flexibility, and durability. This makes them suitable for bonding different substrates. Their chemical composition ensures long-lasting performance in various environments.

Are Polyurethane Adhesives Waterproof?

Yes, polyurethane adhesives are waterproof. They create strong, moisture-resistant bonds. This makes them ideal for outdoor applications. Their water resistance ensures durability in wet or humid conditions. This feature is crucial for construction and marine industries.

What Are The Benefits Of Polyurethane Adhesives?

Polyurethane adhesives offer strong bonds, flexibility, and durability. They are resistant to chemicals, heat, and moisture. This makes them versatile for various applications. Their ability to bond diverse materials increases their usability in different industries. They also provide excellent impact resistance.

Conclusion

The polyurethane adhesives market shows promising growth. Demand increases across many industries. Their versatility attracts manufacturers worldwide. Environmental concerns push for eco-friendly solutions. Companies invest in research and development. Innovation leads to better, stronger adhesives. Market competition drives quality improvements.

Consumers benefit from these advancements. Cost-effective options become more available. Future trends indicate sustainable growth. Businesses should stay informed to remain competitive. Exploring new applications can open opportunities. The market will continue to evolve. Staying updated is crucial for success.