Radial Arm Saw Vs Table Saw: Which is Right for Your Workshop?

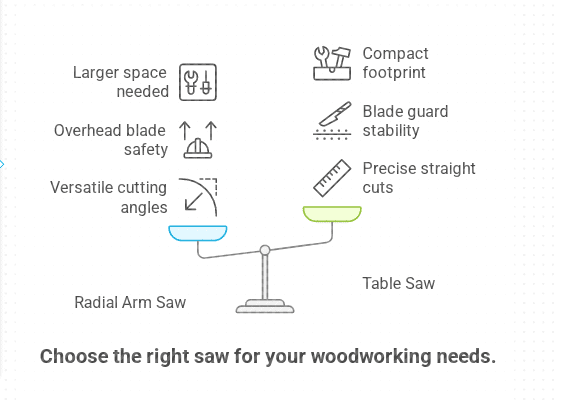

Woodworkers often face a tough choice between a radial arm saw and a table saw. Both tools offer unique benefits, but which one suits your needs best?

Understanding the differences between a radial arm saw and a table saw can help you make an informed decision. These powerful tools excel in different scenarios, and knowing their strengths and weaknesses is key. Whether you’re a hobbyist or a professional, choosing the right saw can impact your projects’ quality and efficiency.

In this blog post, we’ll explore the key features, advantages, and limitations of each saw. By the end, you will have a clearer idea of which tool is the right fit for your woodworking tasks. Let’s dive into the comparison and find out which saw meets your needs.

Credit: dustylumberco.com

Radial Arm Saw Features

The radial arm saw has a horizontal arm that holds the saw blade. This arm can move forward and backward. The blade can also rotate for angled cuts. The table is flat and supports the wood. The saw can be adjusted for different cuts.

People use the radial arm saw for cross-cutting wood. It is good for making precise cuts. It can also cut angles and grooves. It is often used in carpentry and woodworking.

The radial arm saw is versatile. It can make many types of cuts. It is easy to adjust. It is also good for repetitive cuts. The arm allows for smooth movement.

This saw can be large and heavy. It needs a lot of space. It can also be tricky to set up. Some people find it hard to use safely. It may not be good for heavy-duty work.

Table Saw Features

A table saw has a flat surface. The blade comes up from the center. It is often large and stable. The motor is powerful. The fence helps to guide the wood. The miter gauge allows for angled cuts. Safety features like blade guards are common.

Great for ripping boards. Used for cross cuts on wood. Precise cuts are easy to achieve. Often used in woodworking projects. Popular for furniture making. Excellent for cabinet building.

Accuracy is high. Versatile for many tasks. Speed is impressive. Durable and long-lasting. Safety features are good. Ease of use is notable.

Often expensive. Takes up space. Can be heavy. Needs regular maintenance. Not ideal for tight spaces. Noise can be an issue.

Performance Comparison

Both tools offer good cutting accuracy. Radial arm saws can make precise crosscuts. Table saws are better for long, straight cuts. Blade stability is key for both. Radial arm saws have a moving blade. Table saws have a fixed blade. This makes table saws more stable for some tasks.

Radial arm saws are easier for crosscuts. They need less setup. Table saws are simple for ripping wood. They have a flat surface. Safety features are important. Both saws need careful use. Radial arm saws need more space. Table saws are compact.

Radial arm saws can do many tasks. They cut, rip, and sand. Table saws are good for straight cuts. They can also cut angles. Radial arm saws handle big pieces better. Table saws are best for smaller tasks. Both saws serve different needs. Choose based on your projects.

:max_bytes(150000):strip_icc()/SPR-miter-saw-vs-table-saw-8628214-hero-ec319f55ad644508aec341c001e6e4fd.jpg)

Credit: www.thespruce.com

Safety Considerations

A radial arm saw has many safety features. The blade guard covers the blade well. This helps keep your hands safe. The saw also has a lock for the arm. This keeps the saw in place when not in use. The on/off switch is easy to reach. You can turn it off quickly if needed.

A table saw has a riving knife. This reduces kickback. The blade guard also helps keep hands safe. Anti-kickback pawls stop wood from moving back. This helps avoid accidents. The saw has an emergency stop button. You can stop the saw quickly if something goes wrong.

Always wear safety glasses. Keep hands away from the blade. Use push sticks for small pieces. Keep the work area clean. Do not wear loose clothes. Tie back long hair. Check all safety features before use. Follow the manufacturer’s instructions.

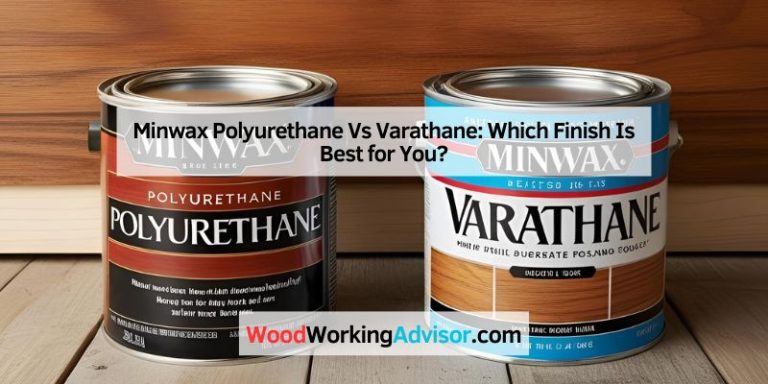

Cost And Maintenance

The initial cost of a radial arm saw is higher. A table saw is cheaper to buy. Both tools need a sturdy base. A good base will cost more.

Table saws are easy to maintain. They have fewer moving parts. Radial arm saws need more care. They have many moving parts. Regular checks are important for both.

Table saws are cost-effective for most users. They are less costly to maintain. Radial arm saws can be expensive over time. The choice depends on your needs.

Space And Portability

A radial arm saw needs more space than a table saw. Its arm extends out, taking up more room. A table saw is compact. It fits in smaller spaces easily. Space matters a lot, especially in small workshops. Choosing the right saw can save space and make work easier.

A table saw is easier to move. It is smaller and lighter. Radial arm saws are heavy and hard to carry. Portability is key for those who need to move their tools often. Consider the weight and size when choosing your saw. Think about your space and how often you move tools.

User Skill Level

Choosing between a radial arm saw and a table saw depends on your skill level. Beginners may find table saws easier to use. Radial arm saws require more precision and experience.

Beginner Friendly

Radial arm saws are good for beginners. They are easier to use. You can see the blade. This helps make accurate cuts. Table saws are harder for beginners. The blade is below the table. You can’t see the blade as well. This makes cuts less accurate. Radial arm saws need less skill. Table saws need more skill. Beginners may struggle with table saws. Radial arm saws are safer. They help prevent accidents. Table saws can be dangerous for new users.

Advanced Applications

Radial arm saws are good for basic cuts. They are limited in use. Table saws are better for advanced tasks. They can cut large wood pieces. They can make complex cuts. Table saws can do more jobs. They are preferred by experts. Radial arm saws are less versatile. Table saws are more versatile. Experts use table saws for tough projects. Radial arm saws are not ideal for advanced work.

Credit: dustylumberco.com

Frequently Asked Questions

Which Is Safer, A Table Saw Or A Radial Arm Saw?

A table saw is generally considered safer than a radial arm saw. Table saws have better blade control and safety features. Radial arm saws can be more hazardous due to their exposed blade and potential for kickback. Always follow safety guidelines regardless of the tool used.

Why Did They Stop Making Radial Arm Saws?

Manufacturers stopped making radial arm saws due to declining demand, safety concerns, and the rise of more versatile tools like miter saws.

What Are The Advantages Of Radial Sawing?

Radial sawing offers better wood yield, reduces wastage, and enhances stability. It produces consistent grain patterns, improving aesthetic appeal. This method also minimizes defects and increases durability.

What Advantages Does The Band Saw Have Over The Table Saw?

A band saw offers greater versatility, allowing for intricate cuts and curves. It is safer for cutting irregular shapes and resawing. Band saws also waste less material due to their thinner blades.

Conclusion

Choosing between a radial arm saw and a table saw depends on your needs. Radial arm saws are versatile and great for crosscuts. Table saws offer precision and are ideal for rip cuts. Both tools have their strengths. Consider what types of projects you do most often.

Your decision should match your specific requirements. Think about space, safety, and budget too. Happy woodworking!