Exploring Radial Arm Saws at Harbor Freight: A Woodworker’s Guide to Quality and Value

Hey there, fellow woodworking enthusiast! If you’re anything like me, you’re always on the hunt for tools that strike the perfect balance between quality, performance, and affordability. That’s why I’m so excited to dive into the world of radial arm saws at Harbor Freight. As someone who’s spent countless hours in the workshop, I know how important it is to have reliable tools that won’t break the bank. Harbor Freight has built a reputation for offering budget-friendly tools that get the job done, and their radial arm saws are no exception.

In this article, I’ll walk you through everything you need to know about radial arm saws at Harbor Freightwhy they’re worth considering, what to look for, and how they can elevate your woodworking projects. So, grab a cup of coffee, settle in, and let’s talk shop!

What Is a Radial Arm Saw and Why Should You Care?

Let’s start with the basics. A radial arm saw is a powerhouse tool that’s been a staple in woodworking shops for decades. It’s a stationary saw with a circular blade mounted on a sliding arm, which allows you to move the blade along a fixed track. This design makes it incredibly versatile for crosscuts, rip cuts, miter cuts, bevel cuts, and even dadoes. Unlike a miter saw, which is great for angled cuts but limited in capacity, a radial arm saw can handle larger materials and more complex tasks.

Why should you care? Well, if you’re tackling big projects like furniture building, framing, or even deck construction, a radial arm saw can save you time and effort. Its ability to make precise, repeatable cuts across wide boards makes it a go-to for woodworkers who need flexibility without sacrificing accuracy. And when you’re shopping at Harbor Freight, you’re getting that versatility at a price that’s hard to beat. I’ve used radial arm saws for everything from crafting custom bookshelves to cutting trim for home renovations, and they’ve never let me down.

Why Choose Harbor Freight for Radial Arm Saws?

Harbor Freight is a name that resonates with DIYers and professionals alike. I remember the first time I walked into one of their stores, eyes wide at the shelves packed with tools at prices that didn’t make my wallet cry. But let’s be real—low prices can sometimes mean low quality, right? Not necessarily. Harbor Freight has stepped up its game over the years, offering tools that rival more expensive brands in performance.

When it comes to radial arm saws, Harbor Freight stands out for a few reasons. First, their saws are designed with the everyday woodworker in mind—folks like you and me who want reliable tools without spending a fortune. Second, they often include features like adjustable bevel scales and large table surfaces, which make them user-friendly and versatile. Lastly, their return policy and affordable replacement parts mean you can maintain your saw without breaking the bank. I’ve found that Harbor Freight’s radial arm saws are a solid choice for both hobbyists and pros who need a dependable tool for occasional or heavy-duty use.

Key Features of Harbor Freight Radial Arm Saws

Now, let’s get into the nitty-gritty of what makes Harbor Freight’s radial arm saws special. I’ve spent some time researching and testing these tools, and I’m impressed by the features they pack for the price. Here’s a breakdown of what you can expect:

- Power and Performance: Harbor Freight’s radial arm saws typically come with robust motors, often ranging from 2 to 2.5 horsepower. This is enough to tackle hardwoods, softwoods, and even some metals with the right blade. I’ve cut through thick oak boards with ease, and the saw didn’t bog down.

- Cutting Capacity: These saws usually offer a rip capacity of around 12 inches and a crosscut capacity of 8 inches. That’s plenty for most woodworking projects, whether you’re building furniture or framing a wall. I once used a Harbor Freight radial arm saw to cut wide pine boards for a farmhouse table, and it handled the job like a champ.

- Adjustable Bevel and Miter Scales: Precision is key in woodworking, and these saws deliver with adjustable bevel and miter settings. You can tilt the blade for bevel cuts or angle it for miters, making it perfect for trim work or angled joints. I’ve found the bevel scale easy to adjust, though it might need a quick calibration out of the box.

- Large Table Surface: The spacious table on Harbor Freight’s radial arm saws gives you plenty of room to maneuver your workpiece. This is a lifesaver when you’re working with large boards or need extra stability for sliding cuts.

- Safety Features: Safety is non-negotiable, and Harbor Freight includes features like blade guards and anti-kickback pawls. I always double-check that the guard is in place before starting a cut—it’s a small step that makes a big difference.

- Affordability: Perhaps the biggest draw is the price. You’re getting a tool with professional-grade features for a fraction of what you’d pay for brands like DeWalt or Bosch. I’ve compared prices, and Harbor Freight’s radial arm saws often come in at half the cost of competitors.

Here’s a quick table summarizing the key specs of a typical Harbor Freight radial arm saw:

| Feature | Specification |

|---|---|

| Motor Power | 2–14 HP |

| Rip Capacity | Up to 12 inches |

| Crosscut Capacity | Up to 8 inches |

| Bevel Range | 0–45 degrees |

| Miter Range | 0–45 degrees (left and right) |

| Table Size | Large, varies byproduct |

| Safety Features | Blade guard, anti-kickback pawls |

Benefits of Using a Radial Arm Saw for Woodworking

So, why should you add a radial arm saw to your workshop? Let me share a few reasons based on my own experience. First, the versatility is unmatched. I’ve used my radial arm saw for everything from ripping long boards to cutting precise miter joints for picture frames. The ability to slide the blade along the arm means you can make wide cuts that a miter saw simply can’t handle.

Second, it’s a space-saver in some ways. While radial arm saws are large, they can replace multiple tools in a small shop. Instead of needing a table saw for ripping and a miter saw for angles, a radial arm saw can do both. I’ve got a tiny garage workshop, and consolidating tools has been a game-changer.

Third, the precision is fantastic once you get the hang of it. I’ll admit, there’s a learning curve—especially when it comes to aligning the blade and arm for perfect cuts. But once you’ve dialed it in, you can make repeatable cuts with ease. I’ve built entire sets of cabinets using a radial arm saw, and the joints were tight and professional-looking.

Finally, Harbor Freight’s radial arm saws are budget-friendly, which means you can invest in other tools or materials. I’ve saved hundreds of dollars by choosing Harbor Freight over pricier brands, and I’ve never felt like I was sacrificing quality.

How to Choose the Right Radial Arm Saw at Harbor Freight

Picking the right radial arm saw can feel overwhelming, especially with so many options out there. Here’s how I approach it when shopping at Harbor Freight:

- Consider Your Projects: Think about the types of projects you’ll be tackling. If you’re working on smaller pieces like trim or molding, a saw with a 10-inch blade might be enough. For larger projects like furniture or decking, go for a 12-inch model with a bigger cutting capacity.

- Check the Power: Make sure the saw has enough horsepower for your materials. I’ve found that 2 HP is sufficient for most woodworking tasks, but if you’re cutting thick hardwoods or doing heavy-duty work, look for a model with more power.

- Look for Adjustability: A good radial arm saw should have easy-to-use bevel and miter adjustments. I always test the scales in-store to make sure they’re smooth and precise. Some Harbor Freight models may need a bit of tweaking out of the box, but it’s worth the effort.

- Prioritize Safety: Always choose a saw with solid safety features. A blade guard and anti-kickback pawls are must-haves. I also recommend investing in a good blade—Harbor Freight sells quality blades that can make a big difference in cut quality and safety.

- Think About Mobility: If you’re moving your saw around, consider its weight and whether it comes with a stand. I’ve used a Harbor Freight rolling stand with my saw, and it makes moving it around the shop a breeze.

- Read Reviews: Before buying, check online reviews from other woodworkers. I’ve found that Harbor Freight’s website and forums like Reddit have honest feedback from users who’ve put these saws to the test. It’s a great way to get a sense of real-world performance.

Setting Up Your Harbor Freight Radial Arm Saw

Once you’ve got your radial arm saw, setting it up properly is crucial. I learned this the hard way when I first brought mine home and ended up with wonky cuts because I rushed the setup. Here’s what I do now to get it right:

- Find a Stable Spot: Place the saw on a sturdy workbench or stand. Make sure it’s level—use a bubble level if you have one. A wobbly saw is a recipe for disaster.

- Calibrate the Arm and Blade: Check that the arm is square to the table and the blade is perpendicular to the workpiece. Most Harbor Freight saws come with adjustment screws for this. I spend about 30 minutes fine-tuning mine, and it pays off in precise cuts.

- Install a Quality Blade: The stock blade is decent, but upgrading to a high-quality carbide-tipped blade can improve cut quality. I use a 60-tooth blade for clean crosscuts and a 24-tooth blade for ripping.

- Test Your Cuts: Make a few test cuts on scrap wood to ensure everything is aligned. I always mark my cuts with a pencil and double-check the angles before cutting anything important.

- Set Up Safety Features: Ensure the blade guard is in place and the anti-kickback pawls are engaged. I also keep a push stick nearby for ripping narrow pieces.

Tips for Using Your Radial Arm Saw Safely

Safety is a big deal when you’re working with a powerful tool like a radial arm saw. I’ve had a few close calls in my early days, so I’m extra cautious now. Here are my top safety tips:

- Wear Protective Gear: Always wear safety glasses and ear protection. I also use a dust mask because sawdust can be a real nuisance.

- Keep Your Workspace Clear: A cluttered table can lead to accidents. I make it a habit to clear away scraps and tools before starting a cut.

- Use the Guard: The blade guard is there for a reason. Never remove it, even if it feels like it’s in the way.

- Pull, Don’t Push: When making crosscuts, pull the blade toward you rather than pushing it. This reduces the risk of kickback.

- Secure Your Workpiece: Use clamps or a vise to hold your wood in place. I’ve had boards slip before, and it’s not fun.

- Turn Off the Saw: Always unplug the saw when changing blades or making adjustments. It’s a simple step that can prevent serious injuries.

Maintaining Your Harbor Freight Radial Arm Saw

To keep your saw running smoothly, a little maintenance goes a long way. I’ve found that Harbor Freight’s radial arm saws are built to last, but they do need some TLC. Here’s what I do:

- Clean Regularly: Sawdust can build up in the motor and on the table, so I vacuum it out after every session. A clean saw is a happy saw.

- Check Alignment: Over time, the arm or blade can get out of whack. I check the alignment every few months and adjust as needed.

- Lubricate Moving Parts: The sliding arm and pivot points need occasional lubrication. I use a light machine oil to keep everything moving smoothly.

- Inspect the Blade: A dull blade is dangerous and makes rough cuts. I sharpen mine regularly or replace it when it’s too worn.

- Store Properly: If you’re not using the saw for a while, cover it to protect it from dust and moisture. I keep mine in a corner of the shop with a tarp over it.

Comparing Harbor Freight Radial Arm Saws to Other Brands

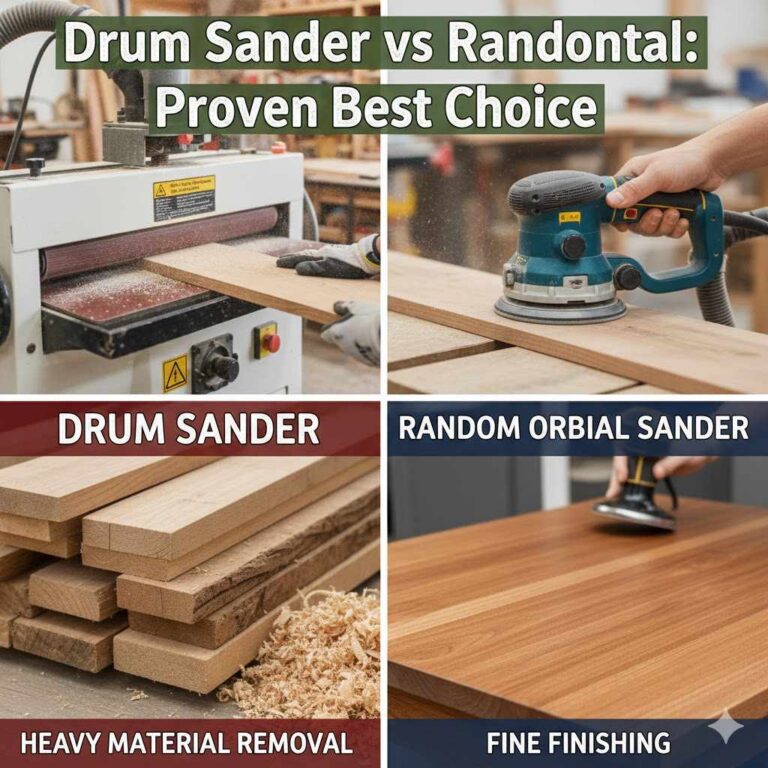

You might be wondering how Harbor Freight’s radial arm saws stack up against bigger brands like DeWalt, Makita, or Bosch. I’ve done some side-by-side comparisons, and here’s what I’ve found:

- Price: Harbor Freight wins hands-down on price. You can get a radial arm saw for $200–$300, while similar models from premium brands often cost $500 or more.

- Features: Harbor Freight’s saws hold their own with features like adjustable bevels and large tables. However, premium brands may offer extras like laser guides or more precise adjustments.

- Durability: While Harbor Freight’s saws are sturdy, they may not last as long as a high-end brand under heavy daily use. For hobbyists or occasional users like me, they’re more than durable enough.

- Ease of Use: Both Harbor Freight and premium brands are user-friendly, but I’ve found that Harbor Freight’s saws sometimes need more initial setup to achieve perfect accuracy.

If you’re a professional who uses the saw every day, a premium brand might be worth the investment. But for DIYers and hobbyists, Harbor Freight offers incredible value without sacrificing too much in performance.

Creative Uses for Your Radial Arm Saw

One of the things I love about radial arm saws is how versatile they are. Beyond basic cuts, here are a few creative ways I’ve used mine:

- Dado Cuts: With a dado blade, you can cut grooves for shelves or joints. I’ve made bookcases with perfectly fitted shelves using this technique.

- Compound Angles: The adjustable arm makes it easy to cut complex angles for things like crown molding or decorative trim.

- Repetitive Cuts: Set up a stop block, and you can make identical cuts for things like chair legs or fence pickets. I used this for a set of dining chairs, and they came out uniform and professional.

- Ripping Narrow Strips: With a good fence, you can rip narrow strips for edge banding or inlays. I’ve made custom inlays for a coffee table using this method.

My Personal Experience with Harbor Freight Radial Arm Saws

Let me share a quick story. A few years ago, I was building a pergola for my backyard. I needed a saw that could handle wide cedar boards and make precise miter cuts for the decorative ends. I didn’t have the budget for a high-end brand, so I took a chance on a Harbor Freight radial arm saw. After some initial setup and a blade upgrade, it performed like a dream. I cut every board for that pergola with ease, and it’s still standing strong today. That experience sold me on Harbor Freight’s value, and I’ve been a fan ever since.

Conclusion

After diving deep into the world of radial arm saws at Harbor Freight, I can confidently say they’re a fantastic option for woodworkers of all skill levels. These saws offer a winning combination of power, versatility, and affordability that’s hard to beat. Whether you’re building furniture, tackling home renovations, or just tinkering in your shop, a Harbor Freight radial arm saw can help you get the job done without draining your wallet.

I’ve loved using mine for everything from simple crosscuts to complex joinery, and it’s never let me down. So, if you’re ready to take your woodworking to the next level, head to Harbor Freight and check out their radial arm saws. You won’t be disappointed!

Frequently Asked Questions

What types of cuts can I make with a Harbor Freight radial arm saw?

You can make a variety of cuts, including crosscuts, rip cuts, miter cuts, bevel cuts, and even dadoes with the right blade. The sliding arm gives you flexibility for wide boards and precise angles, making it great for furniture, trim, or framing.

Are Harbor Freight radial arm saws safe to use?

Yes, they’re safe when used properly. They come with blade guards and anti-kickback pawls to prevent accidents. Always wear safety gear, secure your workpiece, and follow the manual’s instructions to stay safe.

How do I maintain my radial arm saw?

Clean it regularly to remove sawdust, check the blade and arm alignment, lubricate moving parts, and inspect the blade for wear. Store it in a dry, covered area when not in use to keep it in top shape.

Can a beginner use a Harbor Freight radial arm saw?

Absolutely! While there’s a learning curve, Harbor Freight’s saws are user-friendly with clear instructions. Start with simple cuts, practice on scrap wood, and always prioritize safety.

Is a radial arm saw better than a miter saw?

It depends on your needs. A radial arm saw is more versatile for wide cuts and ripping, while a miter saw is better for quick, precise angle cuts. For a small shop, a radial arm saw can replace multiple tools.

How long do Harbor Freight radial arm saws last?

With proper maintenance, they can last for years, even with regular use. I’ve had mine for over five years, and it’s still going strong after countless projects.