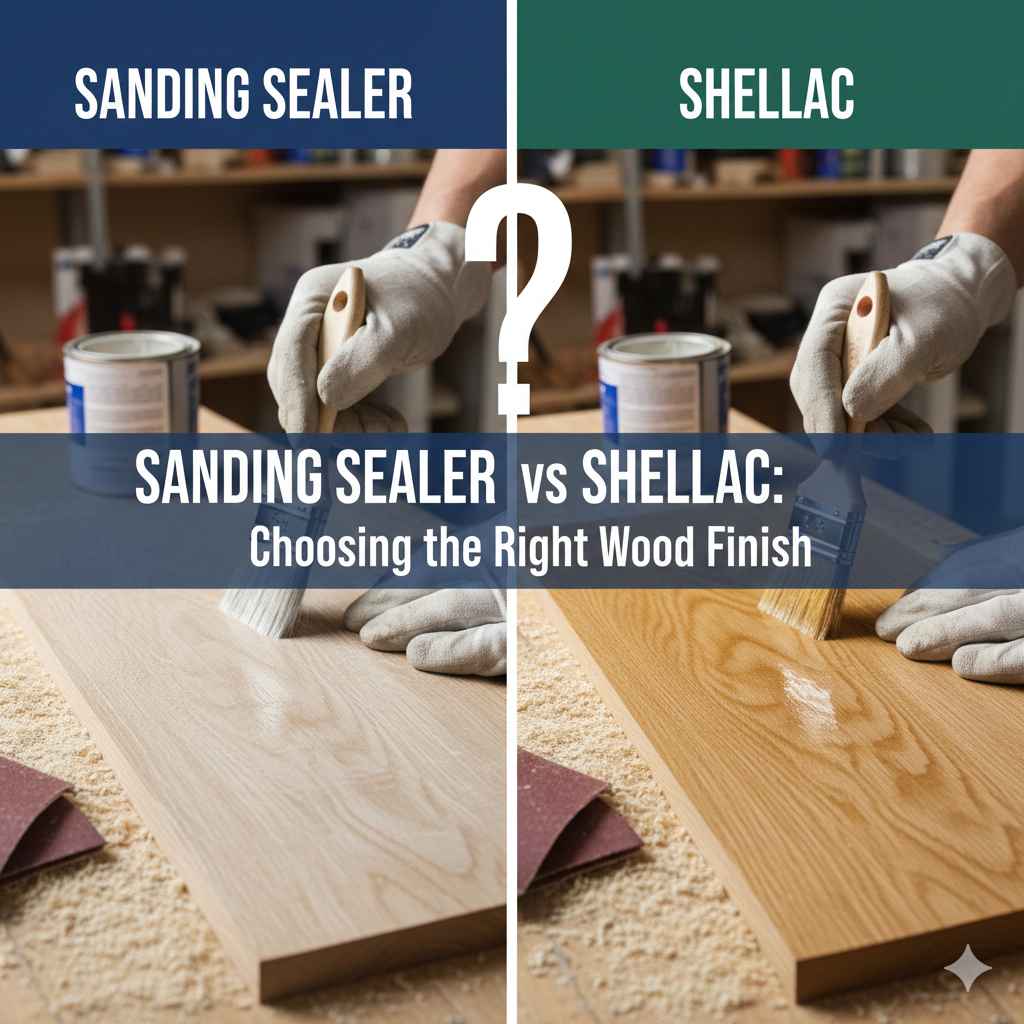

Sanding Sealer vs Shellac: Choosing the Right Wood Finish

Choosing between Sanding Sealer vs Shellac: When to Use Each can be tricky for anyone who’s new to woodworking. It can be hard to know which finish is best for your project, and all the terms can be confusing. Don’t worry, though! This guide will break down everything in a simple, easy-to-follow way. We’ll explore the main differences and show you how to pick the right option for your wood project, step-by-step. Let’s get started!

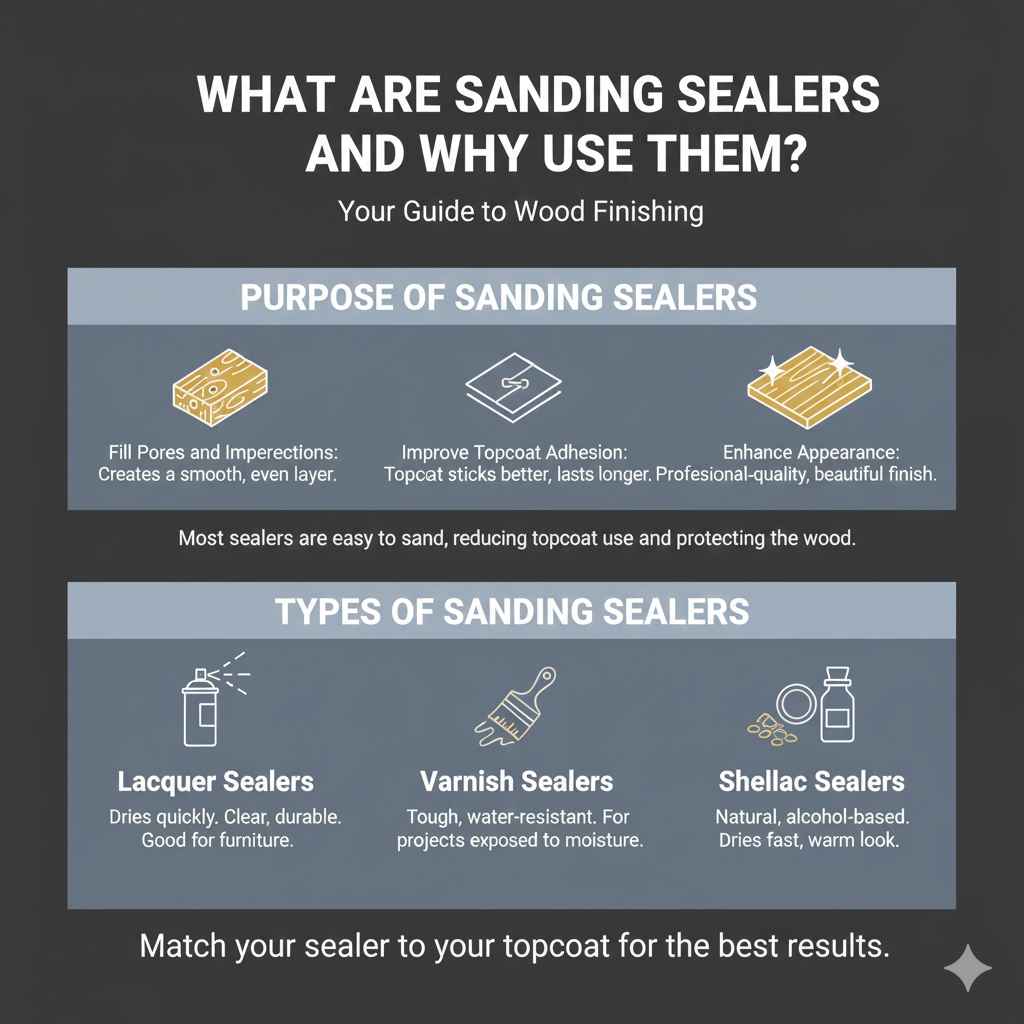

What Are Sanding Sealers and Why Use Them?

Sanding sealers are specifically made to prepare wood surfaces before applying a topcoat. They are designed to seal the wood, filling small pores and imperfections, creating a smooth surface for your final finish. This helps the topcoat adhere better, resulting in a more even and professional look. Think of it as the foundation for your paint job on wood. There are different types of sanding sealers available, including those made from lacquer, varnish, and shellac.

Sanding sealers are generally clear or slightly tinted, so they don’t change the wood’s color significantly. They’re also designed to be easy to sand, so you can achieve a perfectly smooth surface. This creates a more beautiful result that highlights the natural beauty of the wood. The right sanding sealer ensures your topcoat looks good, stays on longer, and protects the wood from damage.

Purpose of Sanding Sealers

The main purpose of a sanding sealer is to prepare the wood for a topcoat. It essentially fills the tiny imperfections on the wood’s surface, creating a smooth, even layer. This creates a better surface for your topcoat to stick to, helping it last longer and look better. You can think of it like putting primer on a wall before painting.

- Fill Pores and Imperfections: Sanding sealers work to fill the open pores and tiny holes in wood.

- Improve Topcoat Adhesion: A smooth surface lets the topcoat stick better.

- Enhance Appearance: The result is a much nicer, more professional finish.

Most sealers are easy to sand, so you can achieve that perfectly smooth surface you want for your topcoat. By using a sanding sealer, you can reduce how much topcoat you use, which saves you money. Also, they protect the wood from the topcoat’s solvents.

Types of Sanding Sealers

There are different types of sanding sealers, each made with different materials. The most common types are lacquer-based, varnish-based, and shellac-based. The material each is made from affects how they perform, how they dry, and what kind of finish they create.

- Lacquer Sealers: These sealers dry quickly and create a clear, durable surface. They’re good for furniture and projects that need a fast drying time.

- Varnish Sealers: Varnish sealers are tougher and water-resistant. They work well for projects exposed to moisture.

- Shellac Sealers: Shellac sealers are made from natural shellac flakes dissolved in alcohol. They dry fast, are easy to sand, and give a warm, traditional look.

When selecting a sanding sealer, consider the type of wood you’re using and the topcoat you plan to apply. Match your sealer to your topcoat (e.g., use a lacquer sealer with lacquer topcoat). The right choice is essential for getting the best results.

Shellac Explained: Properties and Advantages

Shellac is a natural resin secreted by the lac bug. It’s used as a wood finish, food glaze, and binder. This substance is an amazing choice for finishing wood projects, and it’s been a favorite for centuries. It gives wood a beautiful, warm glow, and it’s very easy to work with.

Shellac comes from the lac bug, native to Southeast Asia. The bugs feed on trees, and shellac is a byproduct of their digestion. The resin is collected, processed, and sold as flakes or a premixed liquid. Shellac gives wood a beautiful appearance and is considered a “breathable” finish, meaning it allows some moisture to pass through, unlike some other finishes.

Properties of Shellac

Shellac has unique properties that make it a favorite for woodworkers. It dries quickly, allowing you to finish your project sooner. It also has a natural warmth and clarity that enhances the wood’s grain. However, it’s not the toughest finish and can be damaged by water and alcohol.

- Fast Drying: Dries fast, letting you finish projects quicker.

- Natural and Non-Toxic: Made from a natural resin, making it safe to use.

- Easy to Apply: Can be applied with a brush, rag, or spray, making it versatile.

- Beautiful Finish: Provides a warm, rich tone that enhances wood grain.

- Easy to Repair: Scratches or blemishes can be easily touched up.

One of the main advantages of shellac is its ease of use. It’s forgiving, easy to apply, and can be repaired easily. It is excellent for furniture, musical instruments, and antique restoration. Shellac is an excellent choice for a beautiful finish that’s easy to work with.

Advantages of Using Shellac

Shellac offers several advantages that woodworkers love. Its ease of use and beauty make it a fantastic option for a variety of projects. It is an excellent choice for beginner woodworkers.

- Ease of Application: Can be applied with a brush, spray, or rag.

- Quick Drying Time: Allows for multiple coats in a single day.

- Excellent Adhesion: Shellac sticks to many surfaces.

- Natural Look: Enhances the wood’s natural grain and color.

- Easy to Repair: Can be repaired easily with more shellac.

Shellac is known for its ability to enhance the wood’s grain and color, which is why it’s so popular. It dries quickly and is easy to apply. Shellac gives a classic, beautiful finish that is hard to match with other products.

Sanding Sealer vs Shellac: When to Use Each

Choosing between a sanding sealer and shellac depends on your project’s needs. Both have unique benefits, but they are used for different reasons. Sanding sealers prepare the wood for a topcoat by filling the pores and creating a smooth surface. Shellac acts as a finish and offers a warm, traditional look.

Understanding the key differences will help you choose the right product. Sanding sealers work primarily to prepare the surface, while shellac provides a finish. You might use both on a project, but each serves a different role in the process. This choice affects the final appearance, durability, and how much work you have to do.

When to Use Sanding Sealer

Use a sanding sealer when you want to prepare the wood for a topcoat. The goal is to create a smooth surface that helps the topcoat stick and look its best. This is especially helpful for woods with open pores, like oak or mahogany. A sanding sealer can also prevent the topcoat from soaking into the wood too much.

- Before Applying a Topcoat: It’s designed to prepare the wood for paint, varnish, or lacquer.

- On Porous Woods: Woods like oak benefit from sanding sealers, as they fill the pores.

- To Improve Topcoat Adhesion: Helps the topcoat stick better.

For best results, use a sanding sealer that is compatible with your topcoat. This means if you plan to use lacquer as your topcoat, the sealer should also be a lacquer-based product. Choose the sealer based on the type of topcoat you are using.

When to Use Shellac

Use shellac when you want a beautiful, traditional wood finish. It’s perfect for furniture, cabinets, or any project where you want a classic look. Shellac can be used as a stand-alone finish, or as a sealer under other topcoats. It’s often used on musical instruments because of its acoustic properties.

- For a Traditional Finish: Shellac provides a warm, rich tone.

- On Furniture: Great for adding beauty and protection to furniture pieces.

- For a Quick Finish: Dries quickly and can be applied easily.

Shellac is perfect for many projects, and it’s easy to apply. Shellac is a good option for people just starting out with wood finishing, as it’s very forgiving. Keep in mind that it’s not the most water-resistant finish, so consider the project’s environment.

Comparing Features: Sanding Sealer vs. Shellac

Let’s compare the key differences between sanding sealers and shellac. Each has unique qualities that make it suitable for specific projects. The main purpose of a sanding sealer is to prepare the wood for a topcoat, while shellac acts as a finish. You might use both on a project, with each serving a unique function.

Comparing these two products involves looking at their functions, how they dry, and their durability. By seeing these differences, you can better match the product to your needs. This comparison helps you decide the best approach for each project, ensuring a good result.

| Feature | Sanding Sealer | Shellac |

|---|---|---|

| Primary Function | Prepares the wood for the topcoat | Provides a finish and protects the wood |

| Drying Time | Usually very fast | Fast |

| Durability | Varies, depending on the type | Good for indoor use, less resistant to water and alcohol |

| Application | Brush, spray, or wipe-on | Brush, spray, or wipe-on |

| Appearance | Clear or slightly tinted | Warm, natural, and glossy |

Functionality

The main difference between sanding sealers and shellac is what they do. Sanding sealers are used to fill pores, seal the wood, and prepare the surface for a topcoat. Shellac, however, is a wood finish. It’s applied as the final layer to protect and beautify the wood. It can be used as a stand-alone finish or as a base coat before adding other finishes.

- Sanding Sealers: Prepare the wood for the topcoat.

- Shellac: Finishes and protects the wood.

The functionality of each determines when to use them. Use sanding sealers when the main goal is to improve the surface and prepare it for other coats. Use shellac when you want a beautiful finish that highlights the wood’s natural grain and offers protection. This will guide your choices based on your project needs.

Drying Time and Application

Both sanding sealers and shellac dry quickly, but their drying times can vary. Most sealers dry fast. Shellac also dries quickly, which makes it easy to apply multiple coats in a day. The fast drying time of both products helps make woodworking projects faster.

- Sanding Sealers: Quick drying and easy to sand.

- Shellac: Dries quickly, allowing for multiple coats.

Both products are applied using a brush, spray, or wiping on. Choose the method based on your project and the desired result. Fast drying times allow for quicker work on your project.

Durability and Appearance

Durability and appearance are vital factors when choosing between sanding sealers and shellac. Sanding sealers vary in durability, depending on their formula. Shellac is known for its beautiful appearance, providing a warm, rich tone to the wood. Shellac is less water-resistant compared to other finishes.

- Sanding Sealers: Vary in durability depending on the formulation.

- Shellac: Offers a warm, traditional look but is not as water-resistant.

Keep these factors in mind when choosing between the two. The perfect choice depends on the project needs. Consider what the wood will be used for and how it will be exposed to the elements. This will help you select the right finish and achieve the result you want.

Sample Scenarios and Real-World Applications

To really see the difference between sanding sealer and shellac, let’s explore real-world examples. These scenarios showcase how these products are used in various woodworking projects. Each situation highlights the strengths of each product. See how these finishes can bring out the best in wood.

These examples provide practical insights into the situations where each finish will shine. You’ll understand how to apply the right product for the specific needs of your project. These case studies will help you make a smart decision.

Scenario 1: Refinishing an Antique Table:

An antique table needs to be restored to its original beauty. The table has some minor scratches and imperfections. You want to preserve the table’s traditional look while also providing it with some protection. Shellac would be an ideal finish in this case. Shellac can match the original finish and make the wood shine. The shellac will bring back the beauty of the table. A sanding sealer might be used first to fill in minor imperfections before the shellac is applied. This creates a surface ready for shellac and prevents the finish from soaking into the wood.

Scenario 2: Building a New Bookshelf:

A new bookshelf is being built from oak. Oak has open pores and needs to be sealed before finishing. The goal is to get a smooth, durable finish. In this situation, a sanding sealer is applied first. This will fill the pores and prepare the wood for a topcoat like varnish or lacquer. After the sanding sealer has dried and been sanded, the topcoat is applied. This will result in a smooth, beautiful finish. If a shellac finish is wanted, a shellac-based sanding sealer can be used.

Frequently Asked Questions

Question: Can I use shellac as a sanding sealer?

Answer: Yes, shellac can be used as a sanding sealer, especially if you intend to use shellac as your topcoat. Apply a thin coat of shellac, let it dry, sand it lightly, and then apply your topcoats.

Question: Does sanding sealer change the color of the wood?

Answer: Most sanding sealers are clear or slightly tinted, so they don’t change the wood’s color very much. They are meant to fill pores and prepare the surface without altering the wood’s natural hue.

Question: How many coats of sanding sealer should I apply?

Answer: Generally, one or two coats of sanding sealer are enough. Always follow the manufacturer’s instructions, but the goal is to create a smooth surface, not to build up a thick layer.

Question: Is shellac waterproof?

Answer: Shellac is not fully waterproof. It has some water resistance, but it’s not ideal for areas exposed to water or high humidity. It can be damaged by water and alcohol.

Question: What’s the best way to apply sanding sealer and shellac?

Answer: Sanding sealer and shellac can be applied with a brush, spray, or wipe-on method. The best method depends on the project and your experience. Spraying gives the smoothest finish, but brushing and wiping are good for beginners.

Final Thoughts

Choosing between a sanding sealer and shellac comes down to your project’s goals. Sanding sealers are meant to prepare the wood, filling imperfections and making a smooth base for your topcoat. Shellac, however, is a finish in itself, offering a classic look and easy application. You may even use both, as they each serve different purposes.

Consider the type of wood and the project’s use when deciding. If you want a perfectly smooth surface for paint or a durable topcoat, start with a sanding sealer. If you want a traditional look and easy application, shellac is a great choice. Explore with both finishes, and experiment to see what works best for you and your projects. Now you have the knowledge to pick the right finish for every project!