What Does It Mean to Countersink a Screw: Detailed Guide

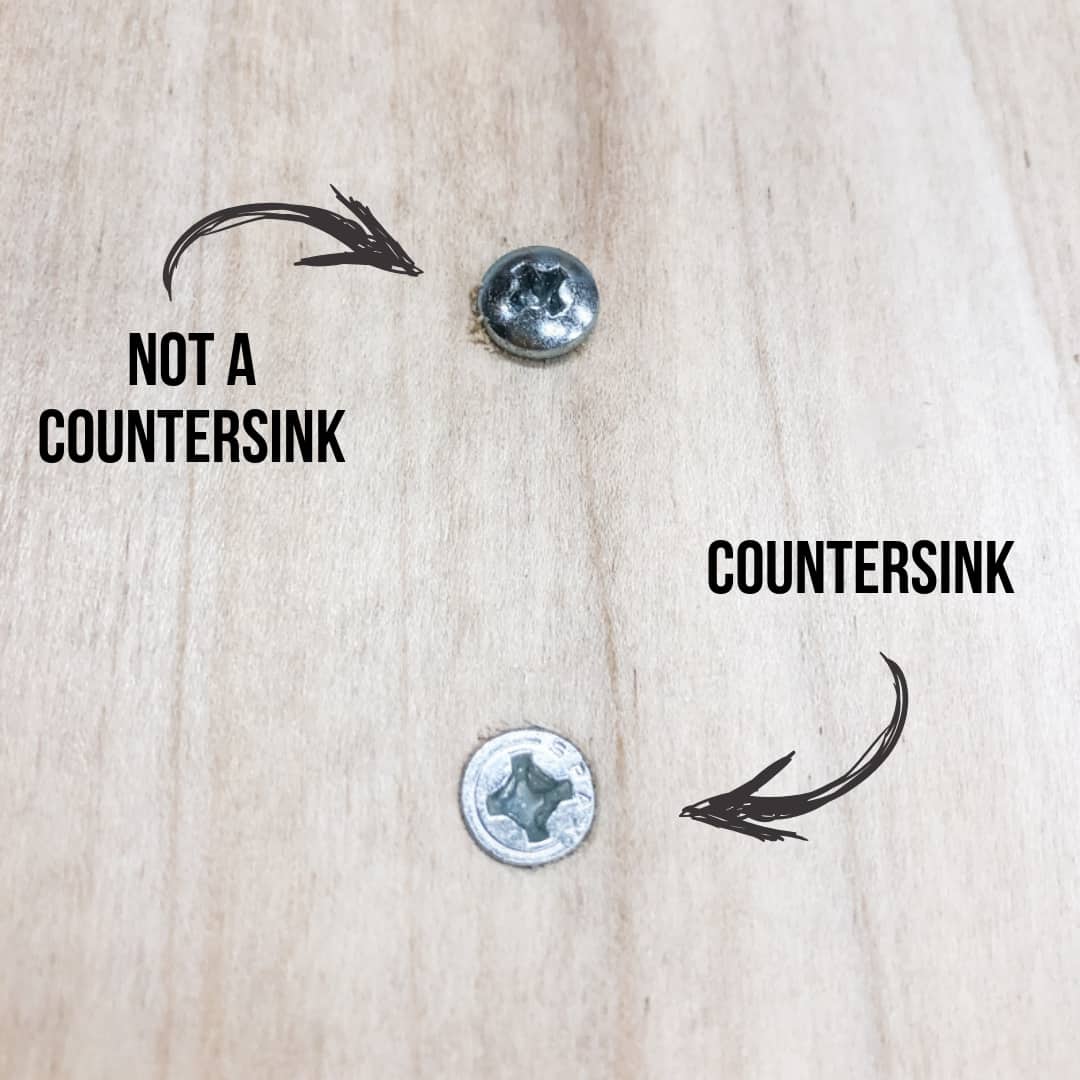

Countersinking a screw means creating a conical hole for the screw head. This allows the screw to sit flush with the surface.

Understanding how and why to countersink a screw is crucial for many DIY projects. It ensures a smooth finish and prevents wood or material from splitting. This technique is common in woodworking, metalworking, and construction. By countersinking screws, you achieve a professional look and structural integrity.

In this blog, we will explore the steps and benefits of countersinking screws. Whether you’re a beginner or have some experience, this guide will help you master the basics. Ready to dive into the world of countersinking? Let’s get started!

Credit: www.artofmanliness.com

Introduction To Countersinking

Countersinking a screw means making a hole in a surface. This hole allows the screw head to sit flush or below the surface. It prevents the screw head from sticking out. This is often done using a special drill bit called a countersink bit.

Countersinking is important in woodworking. It helps in making smooth surfaces. This prevents snagging on screw heads. It also improves the look of the finished piece. Many wood projects need this for a professional finish.

Credit: woodworking.stackexchange.com

Tools Needed

A countersink tool creates a conical hole for screws to sit flush with a surface. Essential tools include a drill, countersink bit, and screwdriver.

Drills

A drill is a must-have tool for countersinking screws. It helps make holes in wood or metal. Cordless drills are easy to use. They are light and portable. Always use the right drill bit for the job. Different materials need different bits. Make sure the drill bit is sharp. A dull bit can cause problems. Wear safety glasses to protect your eyes.

Countersink Bits

Countersink bits create a space for the screw head. They make the screw sit flush with the surface. Choose the right size for your screws. There are many types of countersink bits. Some have an adjustable depth stop. This helps control how deep the screw goes. Always keep bits clean and sharp. Dirty or dull bits can damage your work.

Types Of Countersinks

Fluted countersinks have many grooves. These grooves help remove material. They come in different sizes. Each size fits a specific screw. Fluted countersinks are great for wood. They are also used for metal. They provide a clean finish. This makes the screw sit flush. Many people prefer them for their projects.

Cross-hole countersinks have a hole through the side. This hole helps clear debris. It makes the tool last longer. They are also easy to use. Many people use them for metalwork. They also work well with wood. Cross-hole countersinks give a smooth finish. They are a good choice for many tasks.

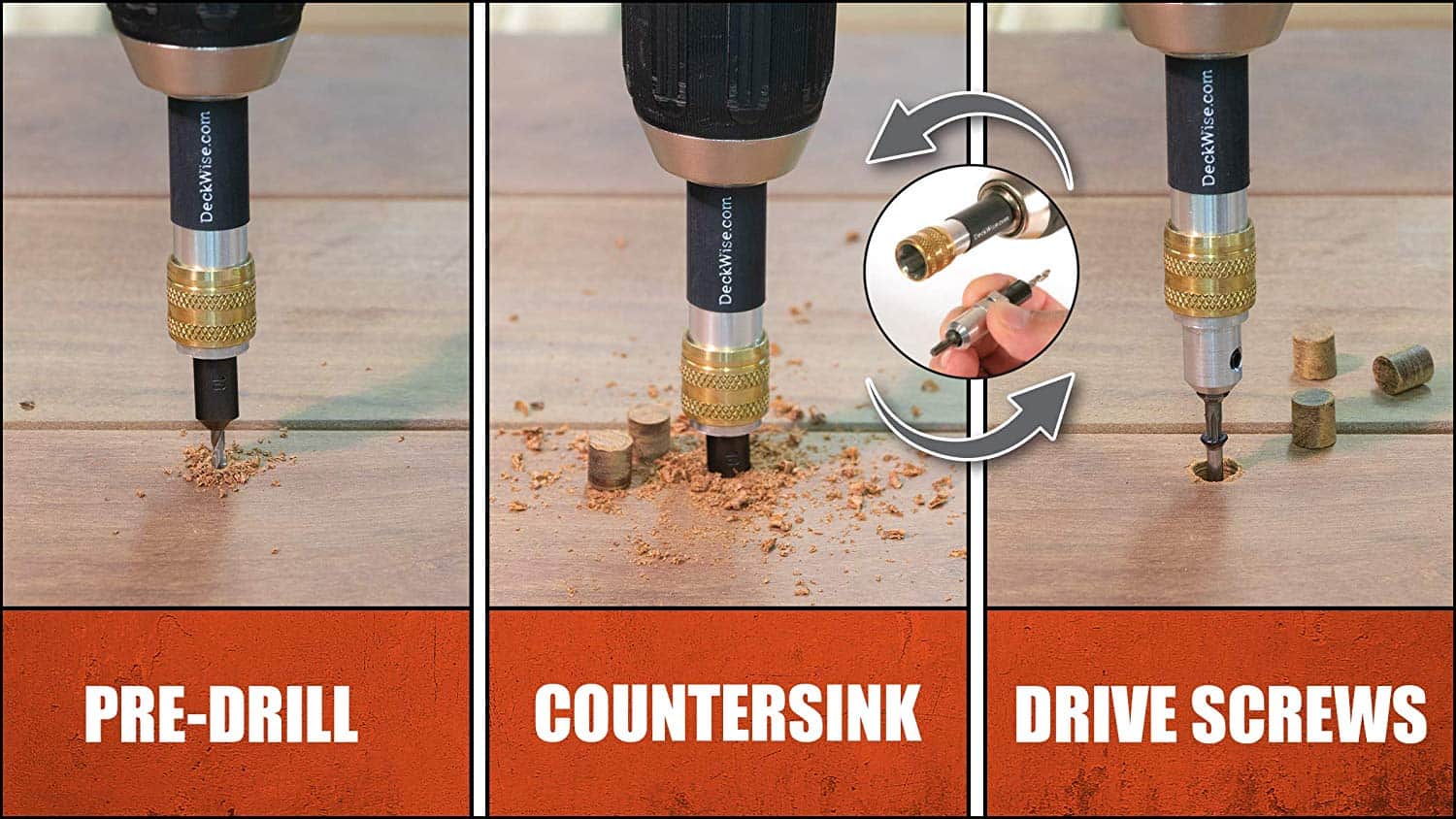

Step-by-step Process

First, find the exact place for your screw. Use a pencil to make a small dot. This dot will guide you. Be precise so the screw goes in the right place.

Next, choose a drill bit smaller than the screw. Place the drill on the dot you made. Drill a straight, shallow hole. This hole is called the pilot hole. It helps the screw go in easily. Make sure the hole is not too deep or wide.

Common Mistakes

Countersinking a screw involves creating a conical hole for the screw head to sit flush with the surface. This prevents the screw from sticking out and ensures a smooth finish. Avoiding common mistakes like drilling too deep or not deep enough is essential for a proper fit.

Incorrect Depth

Using the wrong depth is a common mistake. If the hole is too deep, the screw will sit too low. This can cause a weak joint. On the other hand, a shallow hole leaves the screw head above the surface. This can be dangerous and look bad. Always measure the depth you need first. Use a depth gauge if possible. This helps ensure the screw fits just right.

Wrong Bit Size

Choosing the wrong bit size can ruin your work. A bit that is too large makes the hole too big. The screw will not hold well. A too-small bit size means the screw will not fit. This can split the wood. Always match the bit size to the screw size. Check the packaging for guidance. Use a bit that matches the screw perfectly. This makes sure the screw fits snugly.

Applications Of Countersinking

Countersinking in carpentry makes woodwork smooth. Screws fit flush with the wood surface. This helps prevent snags and gives a cleaner look. Furniture, cabinets, and shelves often use this technique. It helps in joining pieces tightly together. Holes are drilled before screws are inserted. This avoids wood splitting.

Metalwork also benefits from countersinking. It keeps screws or bolts flush with the metal surface. This is important for machinery and tools. It reduces wear and tear. Countersunk screws make metal parts fit better. This ensures safety and longevity. Aircraft and automobiles often use countersinking. It helps in aerodynamics and streamlined design.

Benefits Of Countersinking

Countersinking a screw makes surfaces smooth. No screw heads stick out. This looks neat and tidy. Furniture and woodwork appear more professional. The screw holes are less visible. Paint or varnish covers the area evenly. This gives a clean finish. People enjoy looking at well-finished items.

Countersinking helps prevent wood splitting. The screw sits flush with the surface. Less stress on the material means it lasts longer. This is important for structural integrity. Items stay strong and secure over time. Countersinking protects both the screw and the material. This increases the lifespan of the item.

Troubleshooting Tips

Countersinking a screw involves creating a conical hole so the screw head sits flush with or below the surface. This prevents protrusions and ensures a smooth finish. Properly countersinking improves both aesthetics and safety.

Fixing Misaligned Screws

Misaligned screws can cause many issues. One way to fix this is to first remove the screw. Then, realign the hole with a drill. Re-drill the hole if needed. Next, insert the screw again. Check to see if it is straight. If it is still not straight, use a larger screw. This helps to fill the hole better. Using a countersink bit can also help. It makes the screw sit flush with the surface.

Dealing With Splintering

Splintering happens when wood breaks apart. To prevent this, use a sharp drill bit. Drill slowly and steadily. You can also use tape on the wood. Place tape over the area where you will drill. This keeps the wood from breaking. Another tip is to start with a small drill bit. Then, use a larger bit to finish the hole. Countersinking also helps. It makes the screw go in smoothly.

Credit: www.thehandymansdaughter.com

Frequently Asked Questions

What Is Countersinking A Screw?

Countersinking a screw means creating a conical hole in the material. This allows the screw head to sit flush with or below the surface.

Why Is Countersinking Important?

Countersinking is important for a smooth, finished look. It also helps prevent the screw head from protruding and catching on objects.

How Do You Countersink A Screw?

You countersink a screw by using a countersink bit. Drill a conical hole, then insert the screw so its head sits flush.

What Tools Are Needed For Countersinking?

For countersinking, you need a drill and a countersink bit. These tools create the conical hole for the screw head.

Conclusion

Countersinking a screw creates a flush finish. This improves the overall look. It also prevents snagging on the screw head. Countersinking allows for a smoother surface. This technique is easy to learn and apply. You only need a few basic tools.

It benefits many projects, from woodworking to metalwork. Understanding countersinking adds value to your work. Try it on your next DIY project. Experience the difference it makes.