When Would a Builder Most Likely Use Marine Grade Plywood?

Imagine you’re standing on a construction site, overlooking the plans for a new project. The salty sea air rustles the blueprints, reminding you that this build is no ordinary task.

It’s a coastal structure, where durability is paramount. As you ponder the materials needed to withstand the harsh marine environment, one term comes to mind: marine grade plywood. But when exactly should you, as a builder, reach for this specialty material?

Whether you’re constructing a dock, a seaside home, or a boat, knowing when to use marine grade plywood can make or break your project. This article will dive deep into the scenarios where marine grade plywood becomes your best ally, ensuring your constructions stand strong against moisture and time. Stay tuned to discover the secrets of using marine grade plywood effectively, and ensure your builds not only survive but thrive in challenging conditions.

Credit: www.morganscloud.com

Marine Grade Plywood Basics

Marine grade plywood is special. It is made to resist water. Builders use it for wet areas. Boats, docks, and bathrooms need this wood. It has no gaps or voids. This makes it strong. Each layer is glued with water-resistant glue. It keeps the wood together. This plywood is smooth. It looks nice and is easy to paint. Builders love its quality. It lasts a long time.

This plywood is very tough. It stands up to moisture and rot. Bugs do not like it. This makes it a good choice for outdoor use. Builders trust it in harsh weather. It can handle rain and sun. It does not warp or bend easily. This plywood is used in many projects. It keeps its shape and strength. Builders need materials they can trust. Marine grade plywood is one of them.

Credit: www.totalboat.com

Common Applications

Marine grade plywood is perfect for building boats. It resists water very well. Boats need strong materials. Strong materials keep boats safe. Water can damage other woods. Marine plywood stays strong in water. Builders choose it for its reliability. It lasts long in wet places. It keeps boats afloat.

Marine plywood is great for docks. Docks are always near water. Water can be harsh on wood. Marine plywood handles water easily. This makes docks last longer. Builders use it for safety. It is strong and tough. Piers need sturdy wood too. Marine plywood is a good choice.

Homes near the coast need special wood. Marine plywood is used here too. Water and air near oceans are salty. This can ruin normal wood. Marine plywood stays strong in these places. Builders use it for homes near water. It keeps houses safe and durable.

Advantages In Construction

Marine grade plywood has excellent waterproof qualities. It keeps water out, even in heavy rain. Builders use it for boats and docks. Water does not harm this wood. The special glue is strong and waterproof. This makes it last long in wet places.

This plywood is tough in harsh environments. It does not rot easily. Builders choose it for outdoor projects. It stays strong in the sun and rain. This wood does not warp or crack. Its strength makes it a good choice.

Considerations For Use

Builders often choose marine grade plywood for projects needing high moisture resistance, like boats or docks. Its durability makes it ideal for outdoor furniture exposed to the elements. This plywood type ensures longevity in harsh environments.

Environmental Conditions

Marine grade plywood is used in wet places. It handles water and moisture well. Builders choose it for boats and docks. Water-resistant glue holds the layers together. Strong wood is used for extra durability. It can be exposed to rain and not damage easily. This makes it a top choice for outdoor projects. It stays strong and reliable even in wet environments.

Cost Implications

Marine plywood costs more than regular plywood. High-quality materials are used to make it. This increases its price. But it saves money in the long run. Durable and strong, it lasts for many years. Builders use it for special projects. The investment is worth it for lasting results. Choosing marine plywood helps avoid frequent repairs.

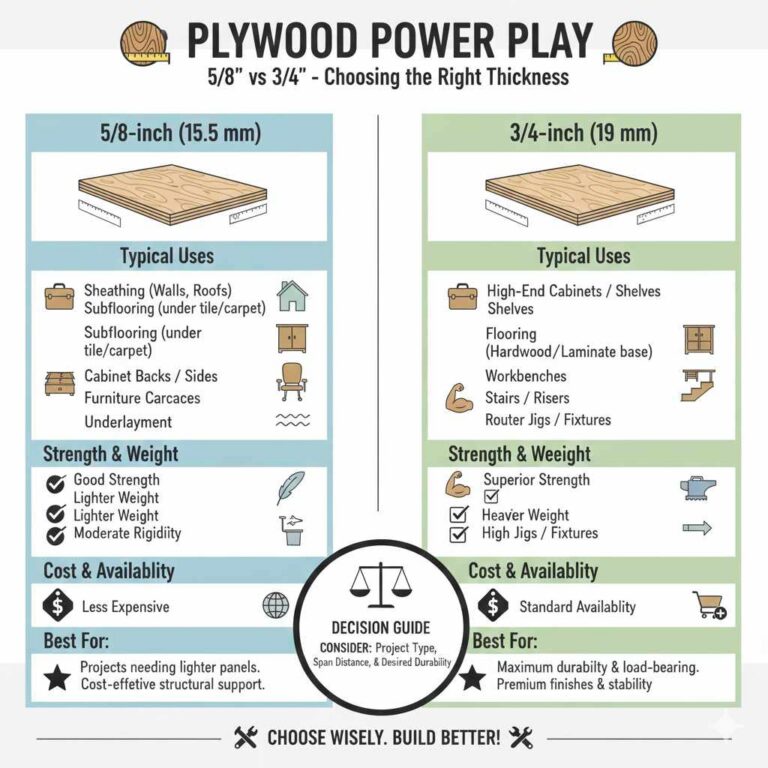

Alternatives To Marine Grade Plywood

Builders can use many waterproof materialsbesides marine plywood. One option is fiber cement board. It’s sturdy and resists water. Another choice is exterior-grade plywood. It handles moisture well but costs less. Plastic lumberis also strong and doesn’t rot. All these materials work well in wet places.

| Material | Cost | Performance |

|---|---|---|

| Marine Grade Plywood | High | Excellent |

| Fiber Cement Board | Moderate | Good |

| Exterior-Grade Plywood | Lower | Fair |

| Plastic Lumber | Moderate | Very Good |

Credit: www.youtube.com

Frequently Asked Questions

What Is Marine Grade Plywood Used For?

Marine grade plywood is used in environments exposed to moisture. Builders use it for boats, docks, and outdoor furniture. Its water-resistant properties make it ideal for these applications. It is also used in bathrooms and kitchens. This plywood type ensures durability and longevity in wet conditions.

Why Choose Marine Plywood Over Regular Plywood?

Marine plywood offers superior water resistance compared to regular plywood. Its construction ensures minimal voids, enhancing strength. This makes it ideal for humid or wet areas. Builders prefer it for long-lasting projects. It’s especially useful in environments where regular plywood would deteriorate quickly.

How Does Marine Plywood Resist Water Damage?

Marine plywood is manufactured with waterproof glue. This prevents delamination in wet conditions. Its layers are made from durable wood species. The construction ensures minimal gaps and voids, enhancing water resistance. This makes it suitable for marine and outdoor applications.

Is Marine Grade Plywood More Expensive?

Yes, marine grade plywood is typically more expensive. The cost reflects its superior durability and water resistance. Its high-quality materials and construction justify the price. Builders invest in it for projects requiring longevity. Over time, it proves cost-effective by reducing repair needs.

Conclusion

Marine grade plywood serves crucial roles in construction projects. Builders choose it for its water resistance. It lasts longer in wet conditions. This makes it perfect for boats and docks. The durability ensures safety and strength. Builders save time and costs with less maintenance.

Its reliability adds value to any project. Whether for a seaside home or a boat, this plywood shines. Quality matters in tough conditions. So, when moisture is a concern, marine grade plywood is the smart choice. It keeps structures sound and long-lasting.