Why Does My Chainsaw Leak Bar Oil? Essential Fixes

Your chainsaw leaking bar oil is usually due to a cracked oil tank, faulty oiler system, or a worn-out oil cap. The good news is that most of these issues are simple to fix yourself with a few common tools, saving you time and money. We’ll guide you through diagnosing and repairing the leak step-by-step.

Hey there, fellow woodworkers and DIY adventurers! Md Meraj here. If you’ve ever picked up your trusty chainsaw, ready for a day of cutting, only to find a puddle of bar oil beneath it, you know how frustrating that can be. It’s a common issue, especially for those new to chainsaws, and seeing that oily mess can make you wonder if something is seriously wrong. But don’t worry! This isn’t usually a sign of a major problem.

More often than not, it’s a simple fix that you can tackle right in your own workshop. In this guide, we’ll break down exactly why your chainsaw might be leaking bar oil and walk you through how to fix it, so you can get back to your projects safely and efficiently. Let’s dive in and solve this oily mystery together!

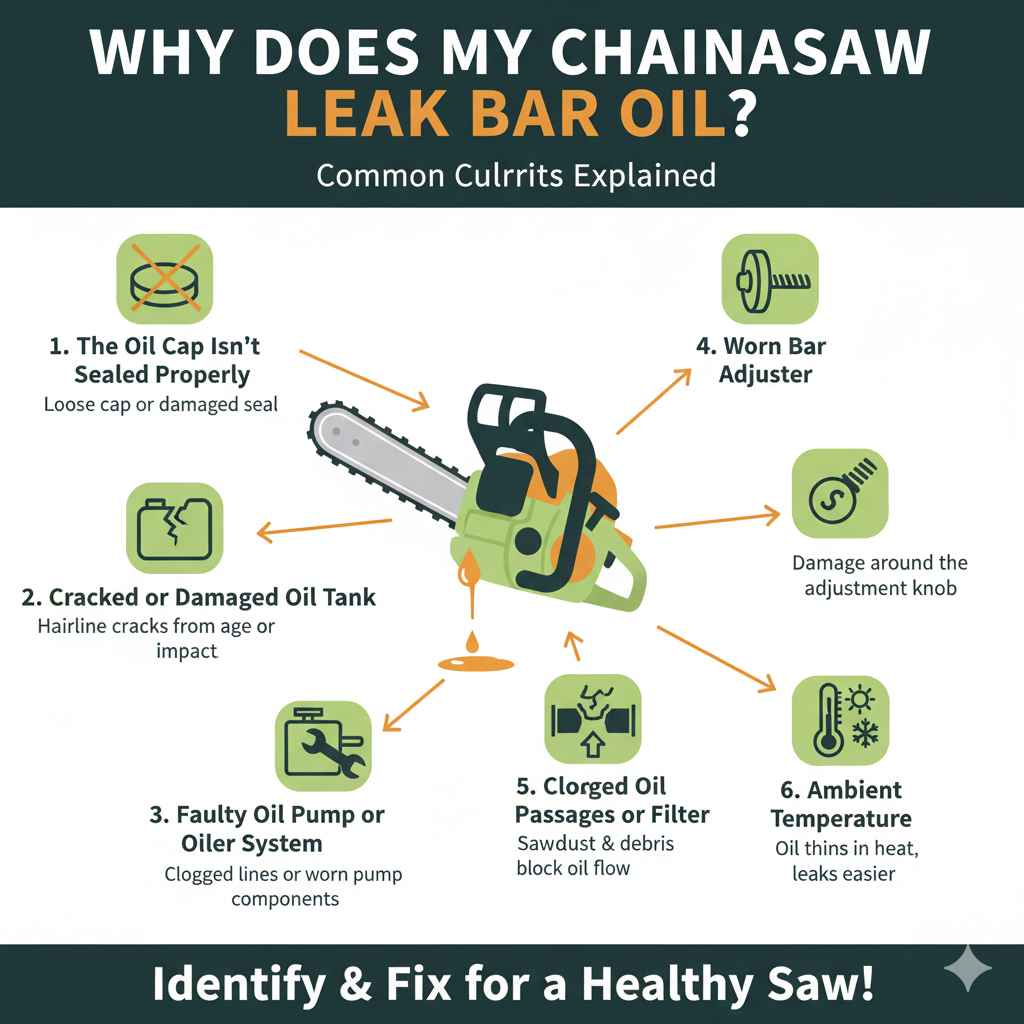

Why Does My Chainsaw Leak Bar Oil? Common Culprits Explained

A leaking bar oil can happen for several reasons, and understanding them is the first step to a quick fix. Bar oil, also known as chain oil, is crucial for lubricating the chain and guide bar, preventing wear and overheating. When it leaks, it not only makes a mess but can also mean your chain isn’t getting the lubrication it needs, which is bad for both the saw and your safety. Let’s explore the most frequent causes:

1. The Oil Cap Isn’t Sealed Properly

This is the simplest and most common reason for bar oil leaks. If the cap isn’t screwed on tightly or if its seal is damaged, oil can seep out, especially when the saw is tilted or stored on its side. Think of it like a gas can – if the lid isn’t on tight, it’s going to leak!

2. Cracked or Damaged Oil Tank

Chainsaw tanks are usually made of plastic. Like any plastic component, they can become brittle over time due to age, exposure to sunlight, or impact. A hairline crack, even a small one, can easily allow bar oil to escape. This is more likely to happen if the saw has been dropped or subjected to rough handling.

3. Faulty Oil Pump or Oiler System

Modern chainsaws have an automatic oiling system that delivers oil to the bar and chain as you cut. This system includes an oil pump, lines, and a port that directs oil to the bar groove. If any part of this system is clogged, damaged, or worn out, it can cause leaks. For instance, a cracked oil line can let oil escape before it reaches the bar.

4. Worn or Damaged Bar Adjuster Assembly

Some chainsaws have an adjustable oiler mechanism that allows you to control the amount of oil delivered. The components involved in this adjustment, often a screw or knob, can wear down or become damaged, leading to leaks around that area.

5. Clogged Oil Passages or Filter

The oil system has various passages and sometimes a filter to prevent debris from entering the pump. If these get clogged with sawdust, oil residue, or dirt, it can create pressure buildup or reroute oil to unintended places, causing leaks.

6. Ambient Temperature Changes

While less common as a sole cause, significant temperature fluctuations can affect oil viscosity. If the oil becomes very thin in warmer temperatures, it might leak more readily from minor imperfections in seals or caps.

Diagnosing Your Chainsaw Oil Leak: A Step-by-Step Approach

Before you start unscrewing parts, let’s figure out exactly where the oil is coming from. A systematic approach will save you time and frustration. Safety first! Always ensure the chainsaw is off, the spark plug wire is disconnected, and the chain brake is engaged before performing any inspection or maintenance.

Step 1: Clean the Chainsaw Thoroughly

Start by cleaning away all existing oil and debris from the chainsaw, especially around the bar, chain, and oil tank area. This will allow you to pinpoint the source of any new leaks more easily. Use a degreaser and a clean rag.

Step 2: Inspect the Oil Cap and Filler Neck

Examine the oil cap closely. Is the rubber seal intact and free of cracks or tears? Is the cap threaded correctly? Make sure it’s screwed on TIGHTLY. Sometimes, just tightening the cap resolves the issue. Check the filler neck itself for any damage or cracks.

Step 3: Check the Oil Tank Integrity

Carefully inspect the entire oil tank for any visible cracks, especially around seams, mounting points, or the filler neck. Gently flex the plastic if it seems safe to do so, looking for hairline fractures. Sometimes, leaks appear as damp spots on the plastic.

Step 4: Examine the Oil Lines and Pump Area

Locate the oil pump and the lines leading from the tank to the bar. Are the lines securely attached? Do you see any signs of oil seeping from the pump housing or where the lines connect? This might require removing the side cover of the chainsaw, which provides access to these components. Always refer to your chainsaw’s owner’s manual for instructions on removing parts.

Step 5: Inspect the Guide Bar and Chain Area

Oil is supposed to be delivered to the groove of the guide bar. Look for leaks around where the bar bolts onto the saw as well as along the bar itself. Is the oil outlet port on the saw body clear or blocked? Sometimes, if the bar groove is excessively worn or dirty, oil can spill out from the sides of the bar.

Step 6: Test for Leaks (Carefully!)

If you can’t find an obvious external leak, you might need to refill the oil tank (don’t overfill) and let the saw sit for a few hours, or gently tilt it to different positions. Observe closely where any new oil appears. You can also try running the saw very briefly (safely!) and observe oil flow and any immediate leaks. Never run a saw without proper safety gear and in a controlled environment.

Essential Fixes for Chainsaw Bar Oil Leaks

Once you’ve identified the source of the leak, the fix is often straightforward. Here are the common solutions for each problem:

Fix 1: Tighten or Replace the Oil Cap and Seal

Problem: Loose or damaged oil cap/seal.

Solution:

- Ensure the cap is screwed on as tightly as possible.

- If the seal looks worn, cracked, or is missing, you’ll need a replacement. Most manufacturers offer replacement caps and seals for specific chainsaw models. You can usually find these online or at your local outdoor power equipment dealer.

Fix 2: Repair or Replace a Cracked Oil Tank

Problem: Cracked oil tank.

Solution:

- Minor Cracks: For very small, hairline cracks on a non-pressurized part of the tank, some DIYers have had success using a specialized plastic repair epoxy or a strong, oil-resistant adhesive. Clean the area thoroughly, roughen it slightly with sandpaper, apply the adhesive according to its instructions, and let it cure completely before refilling. This is often a temporary fix.

- Major Cracks or Leaks Near Seals: If the crack is larger, in a critical area, or if you want a permanent and reliable solution, replacing the entire oil tank is the best option. This can be a more involved repair. You’ll need to drain the fuel and oil, disconnect relevant lines, remove the old tank, install the new one, reconnect everything, and refill. Refer to your chainsaw’s service manual or seek professional help if you’re not comfortable with this.

For example, if you have a Stihl chainsaw, you can find specific replacement parts diagrams and part numbers on the Stihl USA website, which can help you identify the correct tank for your model.

Fix 3: Address Oil Pump and Oiler System Issues

Problem: Leaking oil pump, cracked oil lines, or blocked passages.

Solution:

- Clean Passages: Sometimes, oil passages can get blocked. You can try carefully cleaning them with a thin wire or compressed air. Consult your manual for the location of oil ports and filters. Replacement filters are generally inexpensive.

- Inspect and Replace Oil Lines: Check all rubber or plastic oil lines for cracks, kinks, or loose connections. If a line is damaged, it needs to be replaced. Ensure the new line is the correct size and material.

- Oil Pump Repair/Replacement: The oil pump itself is a more complex component. If it’s leaking or not functioning, it might be reparable in some cases by replacing seals, but often it requires replacing the entire pump unit. This is a repair that might be best left to a qualified service center if you’re not experienced with internal engine components.

Fix 4: Repairing Worn Bar Adjuster Assemblies

Problem: Leaks from the bar adjuster mechanism.

Solution:

- Check the adjuster screw and its surrounding seal or grommet. If it’s worn or damaged, replacing it is usually straightforward. Your chainsaw’s manual will show you how to access and replace this part.

Fix 5: Replacing Worn or Damaged Seals and Gaskets

Problem: Leaks around tank fittings, pump interfaces, or covers.

Solution:

- Many leaks can be traced to dried-out, cracked, or missing rubber seals and O-rings. These are generally inexpensive and relatively easy to replace. Carefully remove the old seal, clean the mating surfaces, and install the new seal according to your chainsaw’s manual. Common areas include around the oil filler neck, pump mounting points, and any access covers for the oil system.

Tools and Materials You Might Need

Having the right tools on hand makes any repair job much smoother. For fixing a bar oil leak, you’ll likely need:

| Tool/Material | Purpose |

|---|---|

| Screwdriver Set (Phillips and Flathead) | For removing covers, screws, and accessing components. |

| Pliers (Needle-nose and regular) | For gripping small parts, pulling hoses, and removing seals. |

| Shop Rags/Paper Towels | For cleaning up oil and surfaces. |

| Degreaser or Citrus Cleaner | To effectively remove oil and grease. |

| Gloves (Nitrile or Mechanic’s) | To protect your hands from oil and sharp edges. |

| Safety Glasses | Essential for protecting your eyes during any repair. |

| Replacement Parts (Cap, Seal, Oil Lines, Tank, etc.) | Specific to your chainsaw model, if the original is damaged. |

| Plastic Repair Epoxy/Adhesive (Optional) | For minor cracked tank repairs, use with caution. |

| Wire Brush or Pick | To clean out clogged oil passages. |

| Owner’s Manual/Service Manual | Crucial for model-specific instructions and part identification. |

Always ensure you have the specific replacement parts for your chainsaw model. Using generic parts can sometimes lead to further issues or improper fit. Reputable sources for parts include your local dealership or trusted online retailers specializing in outdoor power equipment.

When to Call a Professional

While many chainsaw oil leaks are DIY-friendly, there are times when it’s wise to seek expert help. If you’ve gone through the diagnostic steps and can’t find the source of the leak, or if the repair involves complex components like the internal oil pump, it’s best to consult a professional. Additionally, if your chainsaw is still under warranty, attempting a repair yourself might void it. A qualified small engine mechanic has specialized tools and knowledge that can quickly and safely resolve even the trickiest issues. For those in the US, services like those offered by the Outdoor Power Equipment Institute (OPEI) can help you find a local authorized dealer or service center.

Preventing Future Bar Oil Leaks

Good maintenance practices can go a long way in preventing bar oil leaks and keeping your chainsaw in top condition. Here are some tips:

- Proper Storage: Always store your chainsaw upright in a clean, dry place. Avoid storing it on its side or upside down, as this can promote leaks from the oil reservoir. Ensure the oil cap is securely fastened.

- Regular Cleaning: Keep your chainsaw clean, especially around the bar, chain, and oil tank. Remove sawdust and debris that can clog oil passages or damage seals.

- Consistent Lubrication Check: Regularly check your bar oil level and ensure your oiling system is functioning by observing oil fling from the chain when the saw is running (safely!). Proper lubrication prevents excessive wear that can lead to leaks.

- Inspect Regularly: Before and after each use, give your chainsaw a quick once-over. Look for any signs of leaks, damaged parts, or loose fittings.

- Use the Right Oil: Always use good quality bar and chain oil designed for chainsaws. Using the wrong type of oil (like motor oil) can gum up the system and lead to problems.

- Handle with Care: Treat your chainsaw with respect. Avoid dropping it or subjecting it to unnecessary impacts that could crack the plastic components.

Frequently Asked Questions (FAQ)

Q1: Why is there oil on my chainsaw even when I haven’t used it?

A1: This is often due to a faulty oil cap not being sealed tightly, a cracked oil tank, or an issue with the oil pump system that’s allowing oil to seep out slowly over time. Even when not in use, gravity and temperature changes can encourage leaks if the sealing is compromised.

Q2: Is it safe to use my chainsaw if it’s leaking bar oil?

A2: It’s not ideal for two main reasons: safety and performance. A leak means you might be running low on oil, which can lead to the chain and bar overheating, binding, and potentially breaking. This poses a significant safety risk. Also, a leak can create a slipping hazard.

Q3: Can I just use regular motor oil instead of bar oil?

A3: No, you should not. Bar oil is specifically formulated to adhere to the chain and bar under high speeds and temperatures, and to resist being flung off. Motor oil is too thin, will likely fling off immediately, won’t lubricate effectively, and can clog the oiling system.

Q4: How often should I check my bar oil level?

A4: You should check your bar oil level before every use, just as you check your fuel. It’s a quick and essential step for safe and effective operation of your chainsaw.

Q5: My chainsaw leaks oil from the nose of the bar. What’s wrong?

A5: This usually indicates that the oiler port on the saw body or the groove in the guide bar is clogged with sawdust or debris, preventing proper oil flow. It can also mean excessive wear in the bar groove or a problem with the oil pump delivering too much oil that’s then spilling out.

Q6: Can I repair a cracked plastic gas tank on my chainsaw?

A6: While some minor fuel tank cracks can be patched with specific fuel-resistant epoxy or plastic welding, it’s often not recommended due to the flammability of gasoline. A leaking fuel tank is a significant safety hazard. For fuel tanks, replacement is usually the safest and most reliable option.

Conclusion

Dealing with a leaking chainsaw bar oil can seem daunting at first, but as we’ve explored, most common leaks stem from straightforward issues like a loose cap, a minor crack, or a clogged passage. By following a systematic diagnostic approach, armed with the right tools and a little patience, you can often identify the culprit and perform the necessary repairs yourself. Remember, safety is paramount – always disconnect the spark plug and engage the chain brake before working on your saw.