Why is MDF Used: Unveiling Its Hidden Strengths

MDF is used for its smooth surface and uniform density, which make it ideal for painting and machining. It is also cost-effective compared to solid wood.

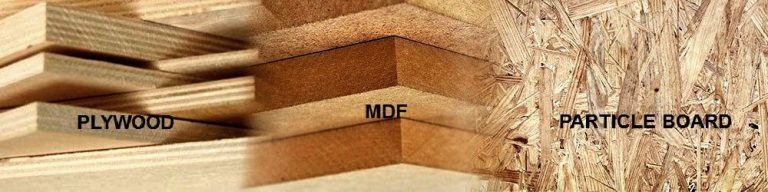

MDF, or Medium Density Fiberboard, is a popular material in furniture making and interior design. It is composed of wood fibers bonded with resin under high pressure and temperature. This process creates a strong, smooth, and uniform panel that is easy to work with.

MDF can be cut, drilled, and shaped without splintering, which makes it a favorite for intricate designs. Its smooth surface is perfect for painting, giving a flawless finish. Cost efficiency is another major benefit, as MDF is generally cheaper than solid wood, making it an attractive option for budget-conscious projects.

Cost-effective Material Choice

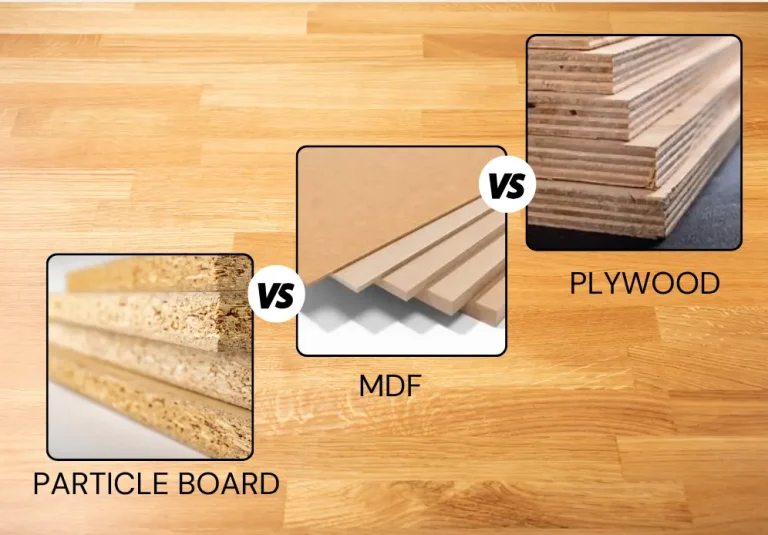

MDF costs less than solid wood. Solid wood is more expensive and heavy. MDF is lighter and easier to work with. Both materials can be painted, but MDF has a smoother finish. Solid wood is stronger and lasts longer.

Manufacturers save money using MDF. MDF is made from wood fibers and resin. It uses leftovers from other wood products. This makes it a cost-effective option. MDF can be shaped easily, reducing production costs. MDF is ideal for mass production. This helps manufacturers save time and money.

Versatility In Applications

MDF is highly sought after due to its smooth surface, making it ideal for painting and veneering. Its versatility allows usage in furniture, cabinetry, and decorative projects. This engineered wood offers consistent density, enhancing precision in cutting and shaping.

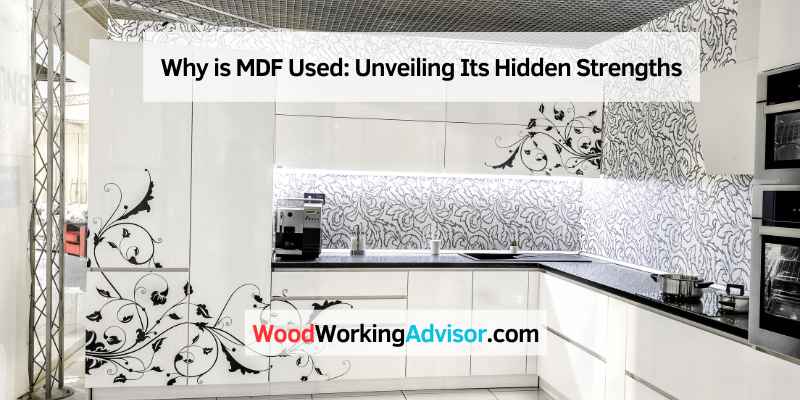

Furniture And Cabinetry

MDF is popular for making furniture and cabinets. It is smooth and easy to paint. The material can be cut into many shapes. This makes it perfect for custom designs. It is also strong and durable. Many kitchen cabinets are made from MDF. It can also be used for shelves and tables.

Decorative Projects And Crafting

MDF is great for decorative projects and crafting. It can be carved and sanded easily. People use it to make picture frames and wall art. It is also good for model building. MDF can be glued and painted easily. This makes it perfect for DIY projects. Many crafters love using MDF.

Ease Of Customization

MDF is easy to cut and shape. It does not splinter like wood. You can make smooth curves with it. MDF is great for detailed designs. It can be used for making furniture and cabinets. MDF can be cut into any size you need. It is very versatile for many projects.

MDF has a smooth surface. This makes it easy to paint. You can use any color you like. MDF absorbs paint well. It makes your project look nice. You can also add different finishes. This gives it a professional look. MDF is great for creative projects. It lets you make beautiful things.

Consistency And Uniformity

MDF is favored for its consistency and uniformity in construction projects. It offers a smooth surface and uniform density, ideal for precise cutting and shaping. Its reliability ensures high-quality finishes in furniture and cabinetry.

Smooth Surface Quality

MDF has a smooth surface that is great for painting. Paint sticks well to it. Cabinets and shelves look professional when painted. The smoothness helps in applying finishes. No bumps or rough patches are found. This makes the job easier. It saves time and effort in surface preparation.

Lack Of Knots And Grain Variations

MDF does not have knots like natural wood. Knots can be hard to work with. The grain is consistent throughout the board. No surprises while cutting or shaping. This makes it reliable. Furniture and fittings look uniform and neat. Builders and carpenters prefer it for this reason.

Environmental Considerations

MDF is preferred for its eco-friendly properties, utilizing recycled wood fibers and reducing the demand for solid wood. Its manufacturing process minimizes waste and promotes sustainability in furniture and construction industries.

Use Of Recycled Wood Fibers

MDF uses recycled wood fibers. This process helps reduce waste. By using recycled materials, it saves trees. This makes MDF an eco-friendly choice. Many people choose MDF for this reason.

Sustainability And Emissions

MDF production can be more sustainable. It often uses less energy than other wood products. The process emits fewer pollutants. This helps to protect the environment. MDF can be a healthier option for builders and users.

Durability Factors

MDF is favored for its durability and resistance to warping. It offers a smooth surface perfect for painting or veneering. This engineered wood product withstands everyday wear and tear, making it ideal for furniture and cabinetry.

Resistance To Warping

MDF is known for its resistance to warping. This makes it a great choice for furniture. Even in humid conditions, MDF stays flat. It does not bend or twist easily. This makes it more reliable than solid wood. Solid wood can warp when exposed to moisture. MDF is also more stable over time. This is due to its uniform structure.

Longevity In Interior Uses

MDF lasts a long time in interior settings. It is often used for cabinets, shelves, and moldings. These items stay in good condition for many years. MDF is also easy to paint. The smooth surface holds paint well. This helps in maintaining a fresh look. Regular cleaning keeps it in top shape. Thus, MDF is a cost-effective choice for interiors.

Challenges And Drawbacks

MDF swells and breaks when wet. This makes it unsuitable for outdoor use. It can get damaged in humid environments. Bathrooms and kitchens may not be ideal. Waterproof coatings can help. Yet, they are not always effective. Swelling can ruin the structure. Repairs are often hard and costly.

MDF is weaker than real wood. It can’t hold heavy weights. Using it for load-bearing walls is risky. It may break under pressure. MDF is good for decorative items. Yet, it lacks strength for large structures. It can bend or crack under stress. Builders avoid it for strong frameworks.

Future Of MDF

Technological advancements in MDF production are making it stronger and more durable. New methods are used to make MDF more eco-friendly. These methods reduce waste and use less energy. MDF can now be made with better finishes and textures. This makes it look more like real wood. These advancements are opening new possibilities for MDF in different industries.

Emerging market trends show a growing demand for MDF. Many people prefer MDF for its cost-effectiveness. It is cheaper than real wood but still looks good. More companies are using MDF in furniture and home décor. This is because MDF can be easily customized. The trend is also influenced by the need for sustainable materials. MDF fits this need well, making it popular among consumers.

Frequently Asked Questions

What Are The Main Uses Of MDF?

MDF is used for furniture, cabinetry, and shelving. It’s also popular for decorative molding, paneling, and flooring. MDF provides a smooth surface for painting and veneering.

Why Do People Use MDF?

People use MDF because it is affordable, durable, and easy to work with. It has a smooth surface, ideal for painting and veneering. MDF is also environmentally friendly, using recycled wood fibers.

Why Use MDF Instead Of Wood?

MDF is cheaper than wood and resists warping. It offers a smooth surface ideal for painting. MDF is easier to cut and shape. It’s also more consistent in density and strength. Ideal for cabinets and furniture.

Conclusion

MDF remains a top choice for furniture and cabinetry. Its affordability and versatility make it popular. The material is easy to work with and offers a smooth finish. MDF’s consistent quality and strength provide reliable results. For many projects, MDF is the go-to option.

Consider MDF for your next woodworking project.