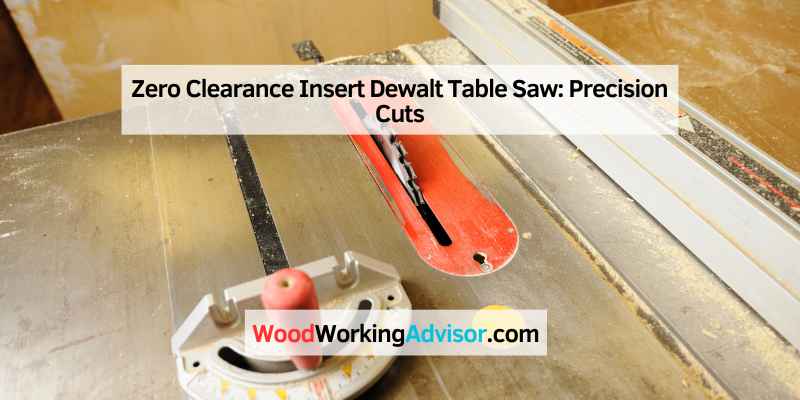

Zero Clearance Insert Dewalt Table Saw: Precision Cuts

The Zero Clearance Insert for Dewalt table saws enhances cutting accuracy by providing a snug fit around the blade. This insert minimizes tear-out and improves safety during cuts.

Dewalt table saws are popular among woodworkers and DIY enthusiasts for their reliability and precision. One essential accessory to maximize their performance is the Zero Clearance Insert. This component provides a tight fit around the blade, ensuring clean cuts with minimal splintering.

It also increases safety by preventing small pieces of wood from slipping into the blade. Many woodworkers appreciate how this insert accommodates various blade heights, making it versatile for different projects. Whether you’re making intricate cuts or simple rip cuts, a Zero Clearance Insert is a worthwhile investment for any Dewalt table saw user.

The Role Of Zero Clearance Inserts In Woodworking

Zero clearance inserts are essential for achieving clean and precise cuts in woodworking. They support the blade, reducing gaps that can cause issues. These inserts play a crucial role in enhancing the quality of your work.

Enhancing Precision In Cuts

Precision is vital in woodworking. A zero clearance insert offers several advantages:

- Better Blade Support: The insert tightly surrounds the blade.

- Improved Cut Accuracy: It minimizes side-to-side movement.

- Consistent Depth: Achieve uniform cuts every time.

Using a zero clearance insert leads to smoother edges and finer details. Woodworkers gain confidence in their cuts. This ensures a professional finish on every project.

Reducing Splintering And Tear-out

Splintering and tear-out can ruin your work. Zero clearance inserts help reduce these issues:

| Issue | Impact | Zero Clearance Benefit |

|---|---|---|

| Splintering | Rough edges on cuts | Minimized splintering for cleaner edges |

| Tear-out | Damaged wood fibers | Less tear-out, preserving material quality |

By using a zero clearance insert, woodworkers notice fewer imperfections. This enhances the overall quality of their projects. Quality cuts lead to better craftsmanship.

Zero Clearance Insert: A Closer Look

The Zero Clearance Insert for the Dewalt Table Saw enhances accuracy. It reduces tear-out and improves the quality of cuts. This insert is crucial for woodworkers seeking precision.

Material Composition And Durability

The Zero Clearance Insert uses high-quality materials. These materials ensure long-lasting performance and reliability.

- Phenolic Resin: Strong and resistant to wear.

- High-Density Plastic: Lightweight yet durable.

- Metal Reinforcements: Added strength to resist bending.

This combination of materials contributes to its durability. The insert withstands heavy use without damage. Users enjoy its longevity, making it a wise investment.

Design And Functionality

The design of the Zero Clearance Insert is user-friendly. It fits perfectly into the table saw. This design allows for clean cuts and minimal splintering.

| Feature | Description |

|---|---|

| Precision Fit | Ensures stability and accuracy during cuts. |

| Easy Installation | Quick to replace without tools. |

| Versatile Use | Works well with various wood types. |

This insert greatly improves cutting efficiency. Users achieve cleaner edges with less effort. The overall design enhances the table saw’s functionality.

Compatibility With Dewalt Table Saws

The Zero Clearance Insert is essential for precise cuts. It fits various Dewalt table saws perfectly. Knowing which model you own is crucial for the right fit. This ensures smooth operation and safety while cutting.

Identifying The Right Model

Identifying your Dewalt table saw model is easy. Check the model number on the front or side of the saw. Here’s a quick reference table for popular models:

| Model Number | Compatible Zero Clearance Insert |

|---|---|

| DWE7491RS | DWE7491 Zero Clearance Insert |

| DWE7485 | DWE7485 Zero Clearance Insert |

| DWE735B | DWE735B Zero Clearance Insert |

Ensure you choose the right insert for your model. This helps you achieve the best cutting results.

Installation Process Simplified

Installing the Zero Clearance Insert is straightforward. Follow these steps:

- Turn off the table saw and unplug it.

- Remove the existing insert by lifting it out.

- Align the new Zero Clearance Insert with the opening.

- Press it down until it fits snugly.

- Plug in the saw and power it on.

Check the insert for any gaps. A proper fit enhances safety and cutting accuracy.

Benefits Of Using A Zero Clearance Insert On A Dewalt Saw

A Zero Clearance Insert for your Dewalt table saw greatly improves your woodworking experience. This tool provides a tight fit around the blade. It minimizes tear-out and enhances safety. Let’s explore the benefits in detail.

Improved Safety Measures

Safety is crucial when using power tools. A Zero Clearance Insert offers several safety advantages:

- Reduced Risk of Kickback: The insert prevents material from catching on the blade.

- Less Exposure: It keeps fingers farther from the blade.

- Stable Support: The insert provides better support for small pieces.

These factors contribute to a safer working environment. Always prioritize safety while using any power tool.

Enhanced Accuracy For Fine Woodworking

Precision is vital in fine woodworking. A Zero Clearance Insert improves accuracy in several ways:

- Clean Cuts: The tight fit minimizes chipping and splintering.

- Consistent Depth: The insert maintains a uniform depth during cuts.

- Better Alignment: It helps in aligning the workpiece with the blade.

Using this insert ensures your cuts are smooth and precise. Accurate cuts lead to better-fitting joints and a professional finish.

| Feature | Benefit |

|---|---|

| Reduced Kickback | Increases safety while cutting. |

| Minimized Tear-Out | Improves cut quality for fine woodworking. |

| Enhanced Support | Stabilizes small workpieces during cuts. |

Customizing Your Zero Clearance Insert

Customizing your Zero Clearance Insert for the Dewalt Table Saw enhances precision. This insert reduces tear-out and provides cleaner cuts. You can choose between DIY options or pre-made inserts. Each has its benefits.

DIY Versus Pre-made Inserts

Choosing between DIY and pre-made inserts depends on your needs.

- DIY Inserts:

- Cost-effective

- Personalized fit

- Allows for creativity

- Pre-made Inserts:

- Quick to use

- Consistent quality

- Less time-consuming

Both options suit different skill levels and preferences.

Step-by-step Creation Guide

Creating a DIY Zero Clearance Insert is simple. Follow these easy steps:

- Gather materials: plywood, adhesive, and a saw.

- Measure the opening in your table saw.

- Cut the plywood to fit the opening.

- Sand the edges for a smooth finish.

- Apply adhesive to secure the insert.

- Let it dry completely.

This process creates a custom fit that enhances your cutting experience.

| Feature | DIY Inserts | Pre-made Inserts |

|---|---|---|

| Cost | Low | Moderate |

| Time Required | More time | Less time |

| Customization | High | Limited |

| Skill Level | Basic skills needed | No skills required |

Choosing the right insert enhances your woodworking projects. Enjoy the benefits of a customized approach.

Maintenance Tips For Longevity

Maintaining your Zero Clearance Insert Dewalt Table Saw is essential for optimal performance. Regular care extends its lifespan and keeps it in top shape.

Cleaning And Care

Proper cleaning ensures your insert functions well. Follow these simple steps:

- Dust Removal: Use a soft brush or compressed air to remove dust.

- Surface Wipe: Wipe the insert with a damp cloth to eliminate grime.

- Check for Debris: Inspect for any stuck material after use.

Store the insert in a dry area. Avoid exposure to moisture to prevent rust. Regularly check the insert for wear and tear. Keeping it clean helps maintain precision cuts.

When To Replace Your Insert

Knowing when to replace your insert is crucial. Look for these signs:

| Sign | Action |

|---|---|

| Cracks or Chips | Replace immediately to ensure safety. |

| Excessive Wear | Consider replacing if cuts become uneven. |

| Difficulty Fitting | Replace if it doesn’t fit snugly anymore. |

Inspect your insert regularly. Proper maintenance and timely replacement enhance performance. Keep your Dewalt Table Saw running smoothly for years.

Troubleshooting Common Issues

Using a Zero Clearance Insert on your Dewalt Table Saw can enhance your cutting precision. However, issues may arise. Identifying and resolving these problems is essential for optimal performance. Below are common issues and their solutions.

Fit And Alignment Problems

Fit and alignment issues can affect the quality of your cuts. Here are some common signs:

- Insert does not sit flush with the table.

- Visible gaps between the insert and the saw table.

- Difficulty in making straight cuts.

To fix these issues:

- Check for debris under the insert.

- Ensure the insert is compatible with your table saw model.

- Adjust the insert’s position until it is level.

- Use shims if necessary to eliminate gaps.

Solving Insert Lift And Stability Concerns

Insert lift can cause uneven cuts and safety hazards. Here’s how to tackle this issue:

- Inspect the insert for warping or damage.

- Ensure the locking mechanism is fully engaged.

- Examine the table saw surface for flatness.

Follow these steps for stability:

| Step | Action |

|---|---|

| 1 | Remove the insert and clean the area. |

| 2 | Reinstall the insert, ensuring a secure fit. |

| 3 | Test the insert by making a few cuts. |

Regular maintenance keeps your Dewalt Table Saw and Zero Clearance Insert in top shape. This ensures safety and accuracy for all your woodworking projects.

Expert Tips For Optimal Use

Maximize your Dewalt table saw’s performance with these expert tips. Proper techniques and accessories enhance cutting precision. Follow these steps for the best results.

Fine-tuning For Precision Cuts

Achieving precision cuts requires careful adjustments. Use these tips to fine-tune your settings:

- Blade Alignment: Ensure the blade is parallel to the miter slot.

- Height Adjustment: Set the blade height just above the material.

- Bevel Angle: Check and adjust the bevel angle for accurate cuts.

- Test Cuts: Make test cuts on scrap material before main projects.

Regularly check these settings. Small changes improve your accuracy significantly.

Accessorizing For Multi-material Cutting

Using the right accessories enhances your table saw’s versatility. Here are essential accessories:

| Accessory | Purpose |

|---|---|

| Zero Clearance Insert: | Reduces tear-out for cleaner cuts. |

| Featherboards: | Keeps material steady during cuts. |

| Push Sticks: | Increases safety while guiding workpieces. |

| Crosscut Sled: | Improves accuracy for crosscuts. |

Each accessory serves a specific purpose. Choose what fits your projects best. Experiment with different tools for optimal results.

User Experiences And Recommendations

The Zero Clearance Insert for the Dewalt Table Saw has gained popularity among users. Many woodworkers appreciate its precision and ease of use. This section covers real user experiences and expert recommendations.

Case Studies: Success Stories

Several woodworkers have shared their success stories after using the Zero Clearance Insert. Here are a few notable examples:

- Mark J. – A hobbyist who improved his accuracy by 30%. He noted that the insert reduced tear-out significantly.

- Linda T. – A professional cabinet maker who achieved cleaner cuts. She praised the insert for its durability and fit.

- James R. – An amateur builder who completed projects faster. He mentioned the insert’s ease of installation.

These stories highlight how the Zero Clearance Insert enhances performance. Users recommend it for both precision and efficiency.

Top Picks From Professional Woodworkers

Professional woodworkers have specific recommendations for the Zero Clearance Insert. Here are their top picks:

| Woodworker | Recommendation | Reason |

|---|---|---|

| Tom S. | Custom-made inserts | Perfect fit for unique projects |

| Sarah W. | High-quality MDF inserts | Great for smooth finishes |

| Rob L. | Plastic inserts | Lightweight and easy to handle |

These recommendations reflect the diverse needs of woodworkers. Each option offers unique benefits for various projects.

Frequently Asked Questions

What Is A Zero Clearance Insert?

A zero clearance insert is a table saw accessory that provides a tight fit around the blade. It minimizes gaps, reducing tear-out and improving cut quality. This feature is especially beneficial for making precise, clean cuts in various materials. It enhances both safety and accuracy during woodworking projects.

How Do I Install A Zero Clearance Insert?

To install a zero clearance insert, first, remove the standard insert from your table saw. Align the new insert with the blade, ensuring a snug fit. Secure it in place, making sure it’s level with the table surface. Finally, test the insert by making a few cuts for accuracy.

Why Use A Zero Clearance Insert?

Using a zero clearance insert improves cut quality by reducing material tear-out. It also enhances safety by offering better support for the workpiece. Additionally, this insert allows for more precise cuts, especially in delicate materials. Overall, it is a worthwhile investment for serious woodworkers.

Can I Make My Own Zero Clearance Insert?

Yes, you can make your own zero clearance insert using plywood or MDF. Measure and cut the material to fit your table saw’s opening. Then, create a slot for the blade using a table saw or jigsaw. This custom insert can improve your cutting performance and save money.

Conclusion

The Zero Clearance Insert for your Dewalt table saw enhances precision and reduces tear-out. This upgrade is vital for woodworkers seeking clean cuts. Investing in this accessory will improve your overall cutting experience. Don’t underestimate the impact of a quality insert on your projects.

Make your woodworking tasks more efficient and enjoyable today.