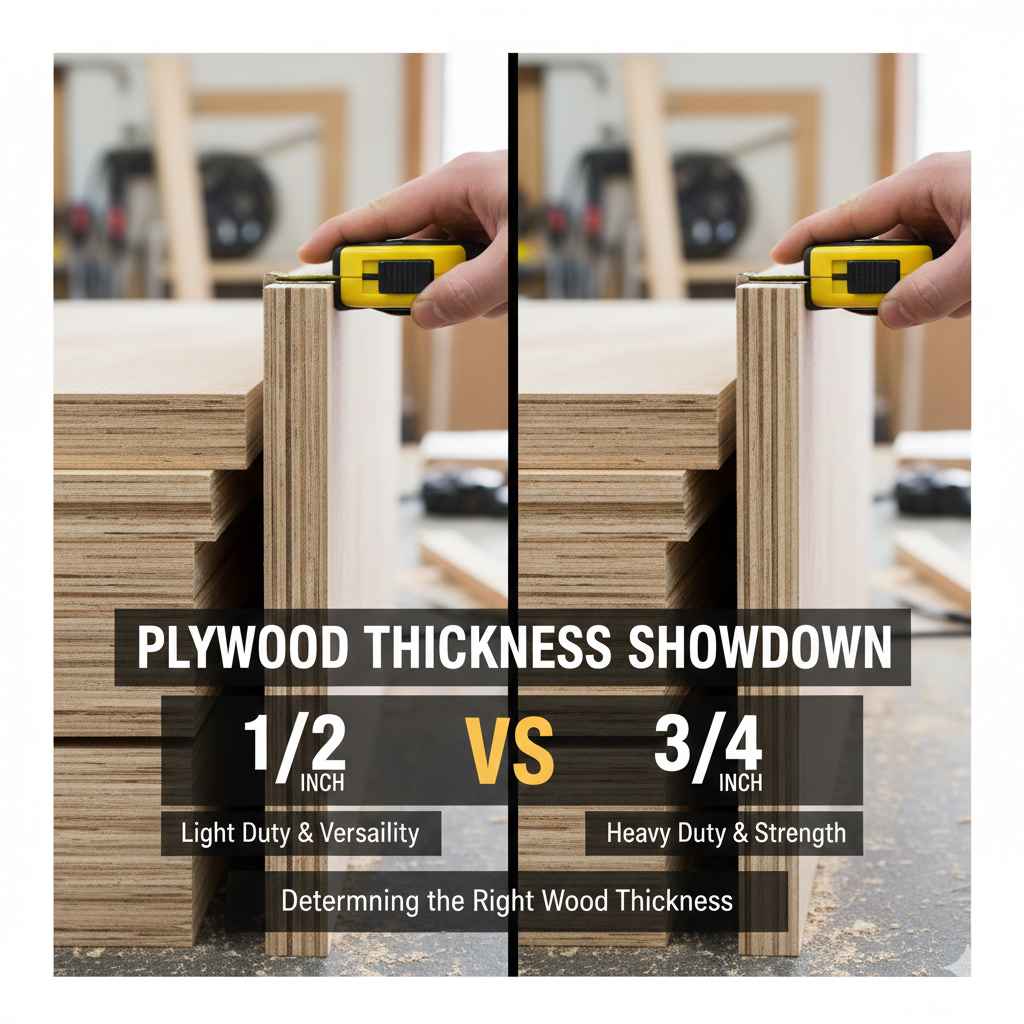

1/2 vs 3/4 Plywood: Determining the Right Wood Thickness

Choosing the right plywood thickness can be tricky, especially when you’re just starting a project. Deciding between 1/2 vs 3/4 Plywood: Which Thickness Is Best? is a common question because both have different uses and strengths. Don’t worry if it feels a little confusing at first; we’re here to break it down in a way that’s easy to follow. We’ll explore the main differences and help you pick the perfect plywood for your needs, so you can build with confidence. Let’s get started!

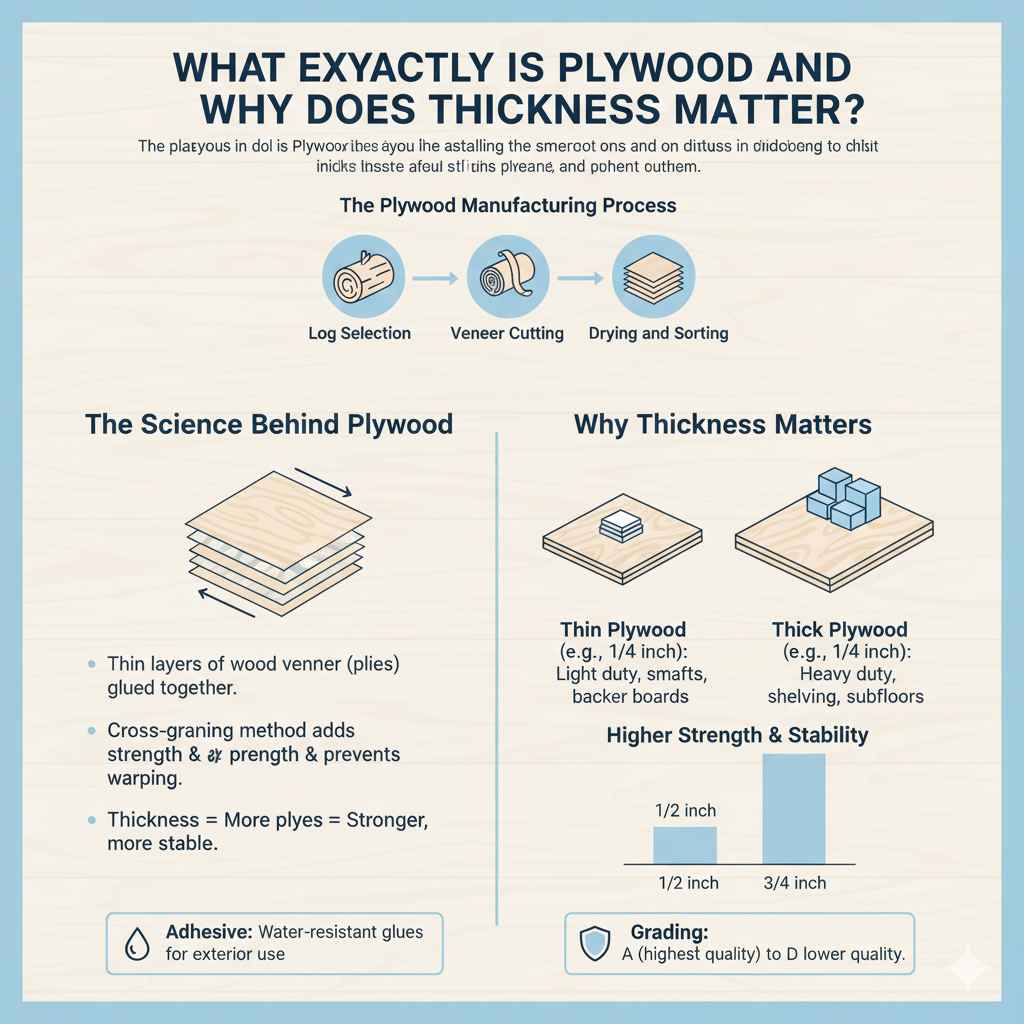

What Exactly Is Plywood and Why Does Thickness Matter?

Plywood is a type of engineered wood made from thin layers of wood veneer that are glued together. These layers, also called plies, are stacked with the grain of each layer running perpendicular to the one below it. This cross-graining method makes plywood incredibly strong and resistant to warping, cracking, and splitting compared to solid wood. The thickness of the plywood is determined by the number and thickness of these plies.

The thickness of plywood is important because it affects how strong and stable it is. Thicker plywood can support more weight and resist bending better than thinner plywood. Different projects require different levels of support and durability, so choosing the correct thickness is important. A thin piece might be perfect for a small craft project, while a thicker one is needed for something like a sturdy shelf.

The Plywood Manufacturing Process

Understanding how plywood is made gives you insight into its strengths. The process starts with peeling logs into thin sheets of veneer. These veneers are then dried to remove moisture and sorted based on quality. Next, these veneers are coated with adhesive and arranged in alternating grain directions. The stack is then placed in a large press and subjected to high pressure and heat, which fuses the veneers together into a solid panel. The final step involves trimming the edges and sanding the surface for a smooth finish.

- Log Selection: The process begins with selecting suitable logs. Softwoods like pine or fir are used for general purposes, while hardwoods like oak or maple are preferred for their durability and attractive appearance.

- Veneer Cutting: Logs are peeled into thin sheets called veneer, which form the individual layers (or plies) of the plywood. Rotary peeling is the most common method, producing large, continuous sheets.

- Drying and Sorting: The veneer sheets are dried to reduce moisture content and prevent warping. They are then sorted based on their quality and appearance, which influences where they are used within the plywood panel.

The strength of plywood also depends on the type of adhesive used and the quality control during manufacturing. Water-resistant glues are typically used for exterior applications, and the overall quality of the plywood is indicated by its grading, such as A, B, C, or D, where A is the highest quality.

Comparing 1/2 vs 3/4 Plywood: Key Differences

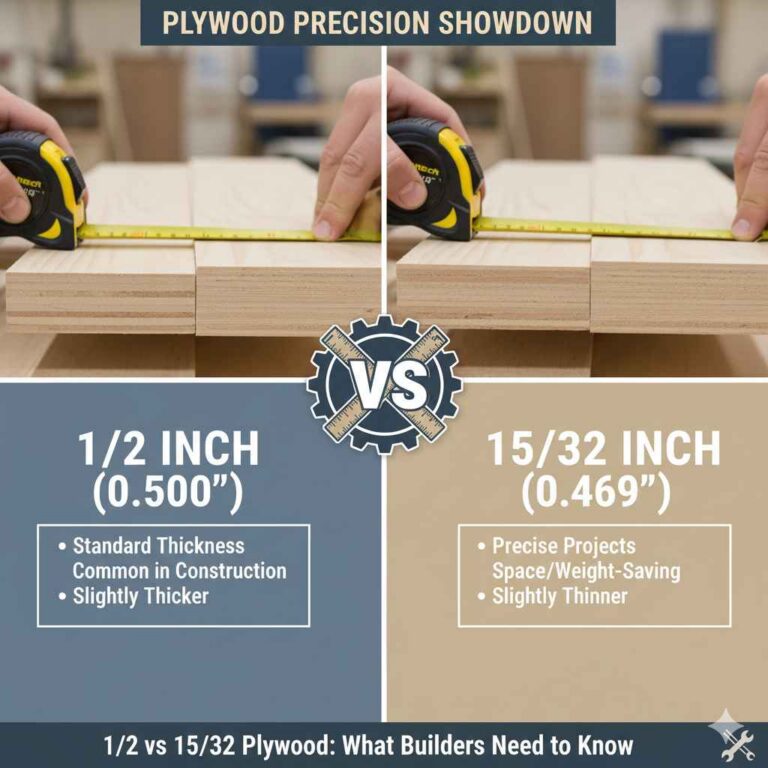

The most important difference between 1/2 vs 3/4 Plywood: Which Thickness Is Best? is, of course, the thickness. 1/2 inch plywood is about half the thickness of 3/4 inch plywood, and this difference directly impacts its strength and the uses it’s appropriate for. The choice between these two often boils down to the project’s requirements, including how much weight it will bear, what kind of stress it will face, and the overall look you want to achieve.

The materials, techniques, and final appearance can differ greatly. 1/2 inch is lighter and more flexible, making it ideal for certain applications. 3/4 inch is significantly stronger and more resistant to bending, making it a better choice for structural elements. Other factors, like cost, availability, and the specific requirements of your project, also play a role in making the right choice.

Strength and Durability

The main advantage of 3/4 inch plywood is its increased strength. It’s much less likely to bend or flex under heavy loads compared to 1/2 inch plywood. This makes it a better choice for projects that require a lot of support, like shelves, cabinets, and flooring. The added thickness also makes 3/4 inch plywood more resistant to impact damage and wear and tear. It can withstand greater force without showing signs of damage, making it suitable for areas with frequent use.

- Load-Bearing Capacity: 3/4 inch plywood can handle significantly more weight than 1/2 inch. This is because the thicker panel has a larger cross-sectional area, allowing it to distribute weight more effectively. This is important for projects like countertops or shelves that need to support heavy objects.

- Resistance to Sagging: Over time, even with proper support, thinner plywood can start to sag under the weight of items placed on it. 3/4 inch plywood resists this sag far better due to its greater stiffness.

- Impact Resistance: Thicker plywood is more resistant to dents, scratches, and other damage. This makes it an ideal option for areas that get a lot of use, such as floors or work surfaces.

For example, if you’re building a bookshelf and plan to store heavy books on it, you should probably use 3/4 inch plywood. Using 1/2 inch might cause the shelves to bow over time. On the other hand, for a light-duty project like the back of a small cabinet, 1/2 inch might be perfectly adequate. These differences in strength and durability have a big impact on a project’s life and function.

Cost and Availability

Typically, 3/4 inch plywood costs more than 1/2 inch plywood, although this can vary based on the wood species, quality grade, and where you buy it. The increased cost of 3/4 inch is usually a direct result of the greater amount of wood used in its manufacture. The availability of both thicknesses is generally good at most hardware stores and lumberyards. However, some specialized types, like marine-grade plywood or plywood with specific finishes, might be more available in one thickness than the other.

- Material Costs: The additional material used in 3/4 inch plywood accounts for the price difference. The cost of labor can be similar for both thicknesses, but the cost of the raw materials is higher for the thicker option.

- Project Budget: If you’re working with a tight budget, choosing 1/2 inch plywood might allow you to complete your project. However, make sure that it will be suitable for the load-bearing requirements.

- Regional Differences: Prices can vary a little from place to place. The prices might be different based on supply and demand, local lumber availability, and shipping costs.

Before beginning, check prices at local suppliers to compare costs. If you’re building multiple projects, you might consider buying plywood in bulk to take advantage of any possible savings. Also, keep in mind that the value you get often relates to your project needs. For some projects, the extra cost of 3/4 inch plywood is worth it for the added strength and durability. However, if your needs are minimal, or the project’s budget is tight, 1/2 inch plywood can provide a cost-effective solution.

Choosing the Right Plywood Thickness for Your Project

Choosing between 1/2 vs 3/4 Plywood: Which Thickness Is Best? comes down to matching the wood to the job. Consider what you are building, how it will be used, and the loads it will bear. It’s essential to properly assess the requirements of your project to choose the right material. This will not only make the construction process simpler but also guarantee the project’s durability and overall success.

Factors to consider include structural support, weight requirements, and aesthetic preferences. The environment in which the project will be used is also an important factor. For example, furniture that is exposed to moisture must be built using materials that resist moisture damage. Each choice comes with its own trade-offs, so it is necessary to consider all of them before making your decision.

Project-Specific Examples

Here are some real-world examples to help clarify when to use 1/2 or 3/4 inch plywood. These examples demonstrate the practical applications of each thickness, taking into account their unique strengths and weaknesses.

- Bookshelf Construction: A bookshelf designed to hold numerous books and other objects would ideally use 3/4 inch plywood for the shelves. This will provide the necessary strength and resistance to sagging. The sides and back of the bookshelf could potentially use 1/2 inch plywood to save on material costs, and to reduce overall weight.

- Cabinet Building: For kitchen cabinets, 3/4 inch plywood is best for the cabinet frames and shelves. It needs to be able to handle the weight of dishes, food, and other kitchen items, as well as resist the wear and tear of daily use. 1/2 inch plywood can be used for the cabinet doors and sides if they do not bear substantial weight, and only require a flat surface.

- Flooring Installation: When laying a plywood subfloor, 3/4 inch plywood is standard for most applications because it provides the necessary rigidity and support. It helps to ensure that the finished floor remains stable and does not flex or creak over time. In some situations, 5/8 inch can be used, but this decision must be made by taking into consideration the spacing between the floor joists.

These examples highlight the different applications where each plywood thickness excels. These differences are due to the load-bearing requirements, wear-and-tear expectations, and aesthetic goals. Considering such factors will enable you to make a more informed choice for your specific project.

Weight Considerations and Load-Bearing Calculations

The weight that plywood can bear is crucial. Knowing how much weight a shelf or cabinet can handle ensures your project will last. If you load it with more weight than it can bear, it can sag and fail. It’s also crucial to consider the weight of the plywood itself. This is especially important for larger projects, as it can significantly affect the ease of construction and overall stability. If you’re building something large or requiring heavy-duty performance, using thicker plywood can be important.

| Plywood Thickness | Typical Applications | Approximate Load Capacity (per linear foot, evenly distributed) |

|---|---|---|

| 1/2 inch | Cabinet backs, drawer bottoms, crafts | 10-20 lbs |

| 3/4 inch | Shelves, cabinet frames, subflooring | 25-40 lbs |

These values are estimates. Actual load capacity can vary based on plywood grade, the distance between supports, and the type of wood. Always support a project adequately. Using thicker plywood when possible can help to improve the stability and lifespan of your projects.

FAQ: Frequently Asked Questions

Question: Is 1/2 inch plywood strong enough for a bed frame?

Answer: For a bed frame, 3/4 inch plywood is generally recommended due to its greater strength and ability to withstand the weight and use the bed will experience.

Question: Can I use 1/2 inch plywood for exterior projects?

Answer: It’s generally not recommended. 3/4 inch plywood is better. If you use 1/2 inch plywood for an outdoor project, be sure to use exterior-grade plywood and apply a waterproof sealant.

Question: What’s the best way to cut plywood?

Answer: To avoid splintering, use a circular saw with a fine-tooth blade specifically designed for plywood. When cutting, make sure the good side of the plywood faces up.

Question: How do I know if I need to use 1/2 or 3/4 inch plywood?

Answer: Think about what you’re building and how much weight it needs to hold. For heavier loads and greater durability, go with 3/4 inch. For lighter projects where weight and cost are concerns, 1/2 inch plywood might work.

Question: Can I use screws or nails with either type of plywood?

Answer: Yes, both can be joined using screws or nails. It’s often easier to drive screws into 3/4 inch plywood because it’s thicker and less likely to split. Pre-drilling can prevent splitting.

Final Thoughts

Choosing between 1/2 vs 3/4 Plywood: Which Thickness Is Best? boils down to what you’re building and how you intend to use it. 3/4 inch plywood stands out when strength and durability are key; for projects that need to handle weight or endure wear and tear, it is the clear choice. 1/2 inch plywood shines for lighter-duty tasks. It offers a good balance of cost and function for those projects that don’t need the extra support. Think of each as a tool for a specific job.

Take the time to assess your project’s needs. Consider the environment, what kind of use the finished product will see, and how much weight it must bear. Check the load-bearing requirements, compare prices at your local lumber stores, and don’t hesitate to ask for advice from experienced woodworkers. With these details, you’ll be able to confidently choose the right plywood thickness and set yourself up for a successful build.