5/8 vs 3/4 Plywood: Determining the Best Choice for Tasks

Choosing the right wood for a project can be tricky, especially when you’re starting. The difference between 5/8 vs 3/4 Plywood: Best Option for Projects often feels confusing, as the numbers can be tough to visualize. But don’t worry! We’ll break it down into simple terms. This guide provides a clear, step-by-step approach to help you figure out which plywood thickness works best for your needs. We’ll explore the key factors, making sure you feel confident in your decision.

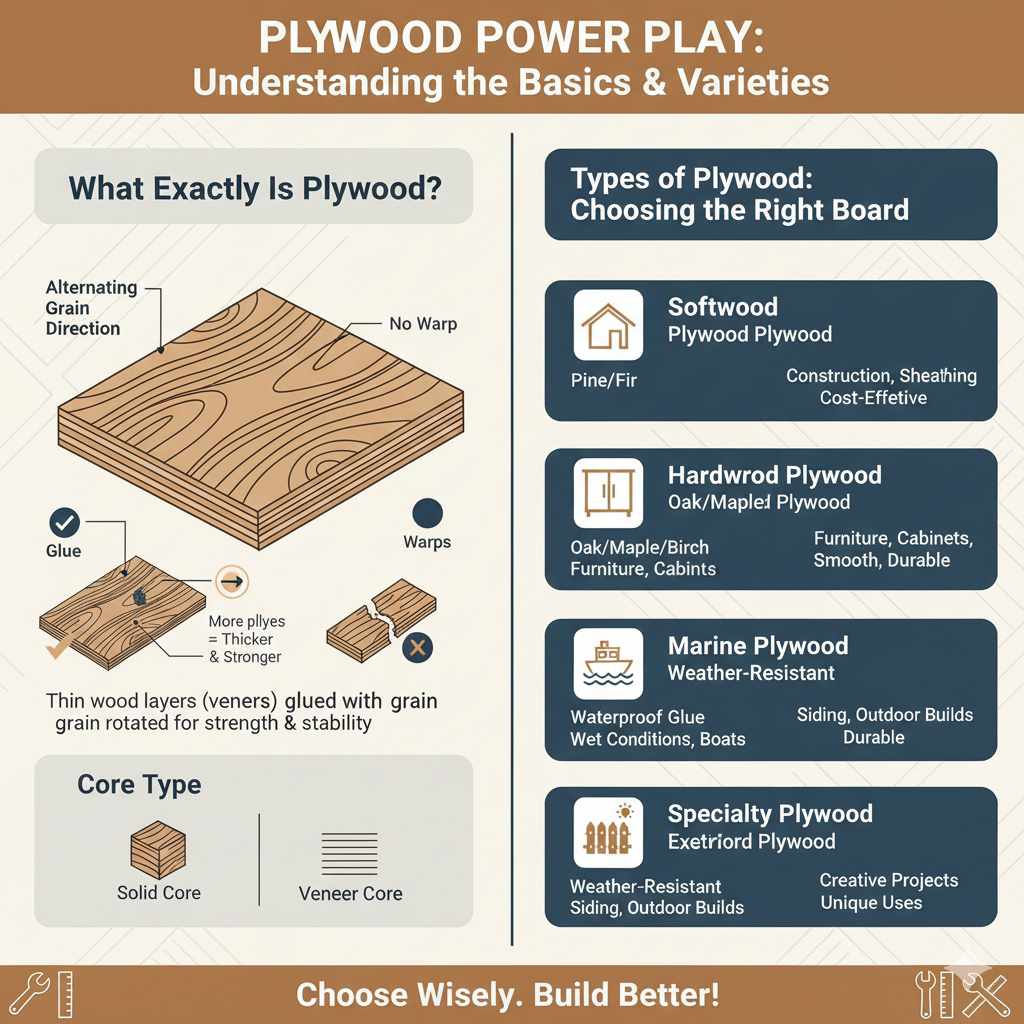

What Exactly Is Plywood and Why Does Thickness Matter?

Plywood is a type of engineered wood made from thin layers of wood veneer that are glued together. These layers, or plies, are stacked with their grain rotated at right angles to each other. This construction method gives plywood its strength and stability, making it less likely to warp or split compared to solid wood. The thickness of the plywood significantly impacts its strength, load-bearing capacity, and overall suitability for different projects. Choosing the correct thickness can be the difference between a successful build and a frustrating failure.

Plywood is a versatile material used in countless projects, from furniture making to construction. The choice between 5/8 and 3/4 inch plywood often comes down to the intended use and the required level of support. Thicker plywood offers superior strength and is typically used where the structure needs to bear heavier loads or withstand greater stress. Conversely, thinner plywood can be more cost-effective and easier to work with, making it a suitable option for lighter-duty applications.

Plywood Construction: Layers and Grain Direction

The core construction of plywood involves several layers of wood veneer, known as plies. Each ply is a thin sheet of wood that is glued to its neighboring layers. The unique aspect of plywood is the grain direction of each ply. The grain of each layer runs perpendicular to the layers above and below it. This alternating grain pattern adds considerable strength, and gives the plywood its dimensional stability. It also prevents the plywood from warping. When a force is applied to the wood, the cross-grain structure distributes the stress evenly across the entire sheet.

- Alternating Grain: The key to plywood’s strength is the alternating grain direction. This stops the wood from splitting or expanding and contracting in one direction.

- Glue: The adhesive used to bond the plies together is critical. It must be strong and water-resistant.

- Plies: The number of plies can vary, which will impact the thickness. The more plies, the thicker and stronger the plywood.

- Core Type: Some plywood uses a solid wood core, while others use a veneer core. This changes the overall strength.

The process of creating plywood begins with selecting quality wood. The wood is then peeled, cut into thin veneers, and dried. After this, glue is applied and the veneers are stacked with their grains running in opposite directions. The whole stack is then pressed under high pressure and heat. This bonds the plies together. The result is a strong, stable sheet material that is much more resistant to warping. Plywood is perfect for a range of uses because it is both strong and adaptable.

Types of Plywood: Understanding the Varieties

Not all plywood is created equal. Various types of plywood are created to meet particular needs. Understanding the various kinds of plywood will help you make the right choice for your project. Knowing the different types, the core differences and the best applications will make your task a lot easier.

- Softwood Plywood: This is the most common kind. It’s often made of pine or fir. It is used in construction and sheathing due to its cost-effectiveness.

- Hardwood Plywood: This is often used for furniture and cabinets. It’s known for its smooth surface and durability.

- Marine Plywood: Made with waterproof glue and strong wood, it is ideal for outdoor projects that may get wet.

- Exterior Plywood: Designed to withstand the elements, this is great for siding and outdoor structures.

- Specialty Plywood: This type has many uses. It can be bent or formed.

Choosing the right type is important. For indoor projects, hardwood plywood might be the best option. For an outdoor project, marine or exterior plywood might be more suitable. Choosing the right type for the project will affect both the cost and the quality.

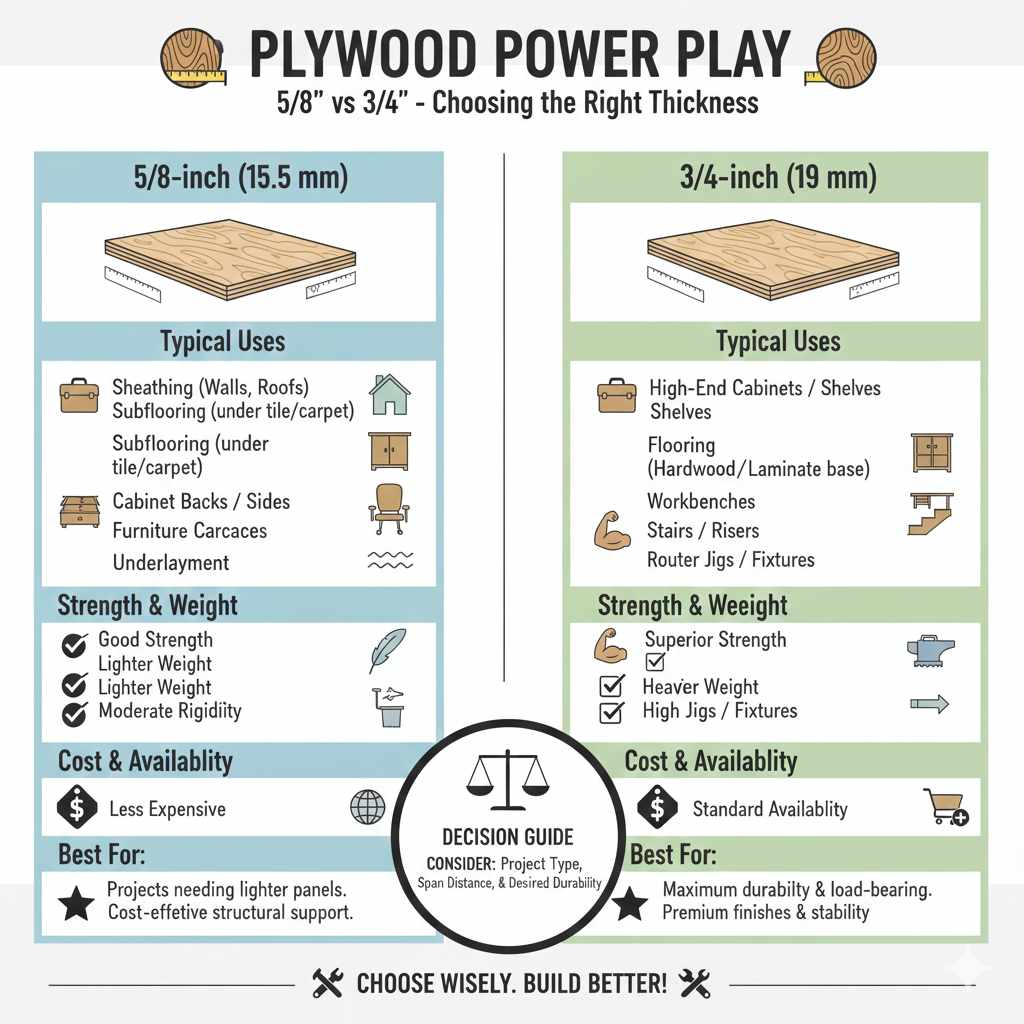

Comparing 5/8 Inch and 3/4 Inch Plywood: Key Differences

When selecting between 5/8 inch and 3/4 inch plywood, it’s crucial to understand their differences. These variations in thickness have a big impact on the plywood’s strength and suitability for different applications. This comparison will give you a clearer idea about which choice is right for your project. This will improve your construction task.

The main difference between 5/8 inch and 3/4 inch plywood lies in their thickness. The extra 1/8 inch of thickness can be a big deal in terms of strength, load-bearing capability, and overall stability. 3/4 inch plywood is noticeably more robust, making it the better choice for projects needing to carry a higher load. 5/8 inch plywood is more suited for projects where weight is a factor or the load will be minimal.

Strength and Stability: Load-Bearing Capacity

The extra thickness of 3/4 inch plywood gives it a significant advantage in terms of strength and load-bearing capacity. The thicker construction allows it to bear heavier weights and resist bending or sagging. This characteristic makes it suitable for projects that demand durability and structural integrity. 5/8 inch plywood, while still durable, might not be suitable for such high-stress applications.

- 3/4 Inch Plywood: Excellent for applications requiring a high degree of support. This includes flooring, shelving, and heavy-duty furniture where loads can be substantial.

- 5/8 Inch Plywood: More appropriate for situations where the load will be less. This can be suitable for lighter shelving or backing for projects.

- Span Length: The distance between supports also affects the strength. Thicker plywood can span a longer distance without sagging.

- Material Density: Higher-density plywood offers more strength and stability, regardless of thickness.

To put this into perspective, consider shelving. If you’re building shelves for books, 3/4 inch plywood would be a better choice to prevent sagging. However, for a decorative shelf holding light items, 5/8 inch plywood could be more than adequate. For applications requiring strength, the additional thickness of 3/4 inch plywood will always provide better performance.

Workability and Cost: Ease of Use and Budget

Besides strength, workability and cost are also important factors to consider. 5/8 inch plywood is often lighter and easier to cut and maneuver than 3/4 inch plywood. This can be particularly helpful if you’re working solo or your project involves intricate cuts. At the same time, the cost can vary. 5/8 inch plywood is often a less expensive option than 3/4 inch.

- Cutting: 5/8 inch plywood is easier to cut with hand tools. It generates less resistance.

- Weight: The lighter weight of 5/8 inch plywood makes it easier to lift and manage, helping with installation.

- Cost: 5/8 inch plywood typically costs less, making it a better choice if you have a budget.

- Fasteners: Both thicknesses work well with screws and nails, but thicker plywood provides a better grip.

For example, if you’re building a simple toy box or a small bookshelf, 5/8 inch plywood could be a smart decision. It’s easier to work with, less expensive, and still strong enough for the job. On the other hand, for a large cabinet or a piece of furniture that will undergo heavy use, the added strength of 3/4 inch plywood will be worth the extra effort and cost.

| Feature | 5/8 Inch Plywood | 3/4 Inch Plywood |

|---|---|---|

| Thickness | 5/8 inch | 3/4 inch |

| Strength | Good for lighter loads | Excellent for heavier loads |

| Weight | Lighter | Heavier |

| Workability | Easier to cut and maneuver | More challenging to cut |

| Cost | Generally less expensive | Generally more expensive |

| Applications | Shelving, backing, lighter furniture | Flooring, heavy-duty furniture, structural components |

Real-World Examples: Project Scenarios and Best Choices

To help you choose, here are some project scenarios to showcase when to pick 5/8 or 3/4 inch plywood. These real-world examples show how thickness affects project outcomes. Examining these examples can provide clarity for your next build.

- Building a Bookshelf: For a small bookshelf, 5/8 inch plywood is likely enough. However, for a larger bookshelf that will hold many books, 3/4 inch plywood will give you better support and make the shelves less prone to sagging.

- Constructing a Workbench: A workbench needs to bear considerable weight and stand up to tough use. Here, 3/4 inch plywood is the clear choice. It will provide the strength required to handle tools and materials.

- Creating a Decorative Headboard: For a decorative headboard, 5/8 inch plywood would work well. It offers good stability, and it is easier to work with.

Each of these situations illustrates the importance of selecting the right plywood thickness based on the project’s needs.

Case Study 1: Building a Kitchen Cabinet

Consider a kitchen cabinet project. The construction would involve the cabinet box, shelves, and doors. Here, 3/4 inch plywood is often chosen for the cabinet box. It will provide the necessary strength to support the weight of dishes, cookware, and other items. 5/8 inch plywood may be used for the shelves, which are not subject to as much weight. Choosing the right material for each part of the cabinet guarantees it is both functional and durable.

- Cabinet Box: 3/4 inch plywood provides the structural support.

- Shelves: 5/8 inch plywood offers enough strength to hold items and is more cost-effective.

- Doors: 3/4 inch plywood provides a solid base for attaching hinges.

The choice between 5/8 inch and 3/4 inch plywood for a kitchen cabinet hinges on the demands placed on various components. Using the right plywood ensures structural integrity and extends the life of the kitchen cabinet.

Case Study 2: Designing a Custom Desk

For building a custom desk, the choice between 5/8 inch and 3/4 inch plywood depends on the desk’s design and use. If the desk is meant to hold heavy items, such as computers, monitors, and books, 3/4 inch plywood is preferred for the tabletop and legs. This ensures that the desk can withstand the weight. If the desk is designed for lighter use, such as writing, and it has additional supports, 5/8 inch plywood might be adequate.

- Tabletop: 3/4 inch plywood for heavy-duty use.

- Legs: 3/4 inch plywood, to support the desk.

- Drawer Sides/Backs: 5/8 inch plywood will work fine.

The goal is to balance strength, budget, and the intended use of the desk. These factors will guide you in making the right material choices.

Advanced Considerations: Beyond Basic Thickness

While the thickness of plywood is important, there are additional factors to consider to ensure you choose the best plywood. These considerations go beyond the thickness measurements. They will help you make a more informed decision for your project.

Beyond the simple choice between 5/8 and 3/4 inch plywood, several other factors can significantly impact the final outcome of your project. Things like the grade of plywood, the type of wood used, and the intended environment will influence the final decision. Ignoring these aspects might lead to unsatisfactory results.

Plywood Grade and Core Material

The grade of plywood and its core material can influence its performance. Plywood grades indicate the quality of the wood veneer and the number of imperfections, such as knots. Higher-grade plywood is free of defects. It is better for projects where appearance is a priority. Different core materials affect the plywood’s strength and stability. Veneer cores offer good strength, while composite cores provide a balance of cost and performance.

- A/C Grade Plywood: Excellent surface for painting.

- B Grade Plywood: Smooth, with some minor imperfections.

- C Grade Plywood: May have knots and imperfections.

- Veneer Core: Offers better strength.

- Composite Core: Balancing cost and performance.

Choosing the right grade and core material will improve the outcome of your project. If the look matters, pick high-grade plywood. For hidden construction elements, a lower grade might be suitable. Considering core material and grade ensures you pick the right plywood for your project.

Environmental Factors and Plywood

The environment where the project will be located has a significant effect on the plywood you should select. Moisture and weather conditions can make plywood warp and deteriorate. For outdoor or high-moisture settings, choose marine-grade plywood, which is made with waterproof glue and designed to withstand the elements. For indoor applications, standard plywood grades might be enough. Always account for environmental factors to ensure the longevity and durability of your project.

- Marine Grade: Best for outdoor use.

- Exterior Grade: Great for siding.

- Interior Grade: Suitable for indoor projects.

- Moisture Resistance: Consider moisture.

Picking the correct plywood based on environmental factors is a must. If the project will be exposed to water or weather, marine-grade or exterior-grade plywood is the best choice. This will protect against warping and increase the lifespan of your construction.

Frequently Asked Questions

Question: Is 3/4 inch plywood always better than 5/8 inch plywood?

Answer: No, 3/4 inch plywood isn’t always better. The best choice depends on your project’s needs. For projects needing extra strength, 3/4 inch is great. For other tasks, 5/8 inch plywood might be better if you need a lighter and more affordable material.

Question: Can I use 5/8 inch plywood for flooring?

Answer: While you technically could, it is not usually recommended. For flooring, 3/4 inch plywood or thicker is generally preferred to provide the necessary support and stiffness. Using thinner plywood can result in sagging or flex over time.

Question: How do I measure plywood thickness accurately?

Answer: Use a ruler or a caliper. Make your measurements at several points across the sheet to get the most accurate result. It’s also a good idea to measure both the 5/8 inch and the 3/4 inch plywood to see the difference.

Question: Is it easier to cut 5/8 inch or 3/4 inch plywood?

Answer: 5/8 inch plywood is generally easier to cut. It’s lighter and thinner, so hand tools and power saws will work with less effort. This makes it a great choice for beginners.

Question: Can I use screws or nails with either thickness of plywood?

Answer: Yes, both 5/8 inch and 3/4 inch plywood can be joined with screws or nails. However, 3/4 inch plywood will provide a better grip for the fasteners, which makes the joints stronger.

Final Thoughts

When you’re trying to figure out the right plywood for your project, knowing the differences between 5/8 vs 3/4 Plywood: Best Option for Projects is key. Keep in mind that 3/4 inch plywood gives you more strength, making it ideal for tasks where you need to carry heavier loads. If the project’s lighter or you need something easier to use, 5/8 inch plywood is a great choice. Considering your project’s needs, whether it’s the weight it needs to support or the cutting ease you desire, will guide your decision. Knowing the factors like strength, ease of cutting, and cost are also essential.

Now, you have the knowledge to pick the right plywood for your project. Be sure to measure carefully, plan your cuts, and think about your project’s environment. With the right information, you can get ready to start constructing your project with confidence.