Aluminum Oxide Vs Silicon Carbide Sandpaper: Essential Guide

Aluminum Oxide vs. Silicon Carbide Sandpaper: Make the Right Choice for Your Project.

Choosing between aluminum oxide and silicon carbide sandpaper is crucial for success. Aluminum oxide is a durable, versatile all-rounder perfect for wood and metal. Silicon carbide is sharper, more brittle, and ideal for achieving a super-smooth finish on harder materials like glass, plastic, and when removing paint. This guide simplifies the choice for beginners.

Hey fellow DIYers and aspiring woodworkers! Md Meraj here, ready to demystify another essential workshop question. Ever stood in front of a sandpaper display, feeling a little overwhelmed by the choices? You’re not alone! The two most common abrasive grains you’ll encounter are aluminum oxide and silicon carbide. Knowing which one to grab can make a world of difference in how smoothly your project turns out and how much effort you have to put in. Don’t worry, we’ll break it down simply, so you can confidently pick the right sandpaper every time. Let’s get sanding!

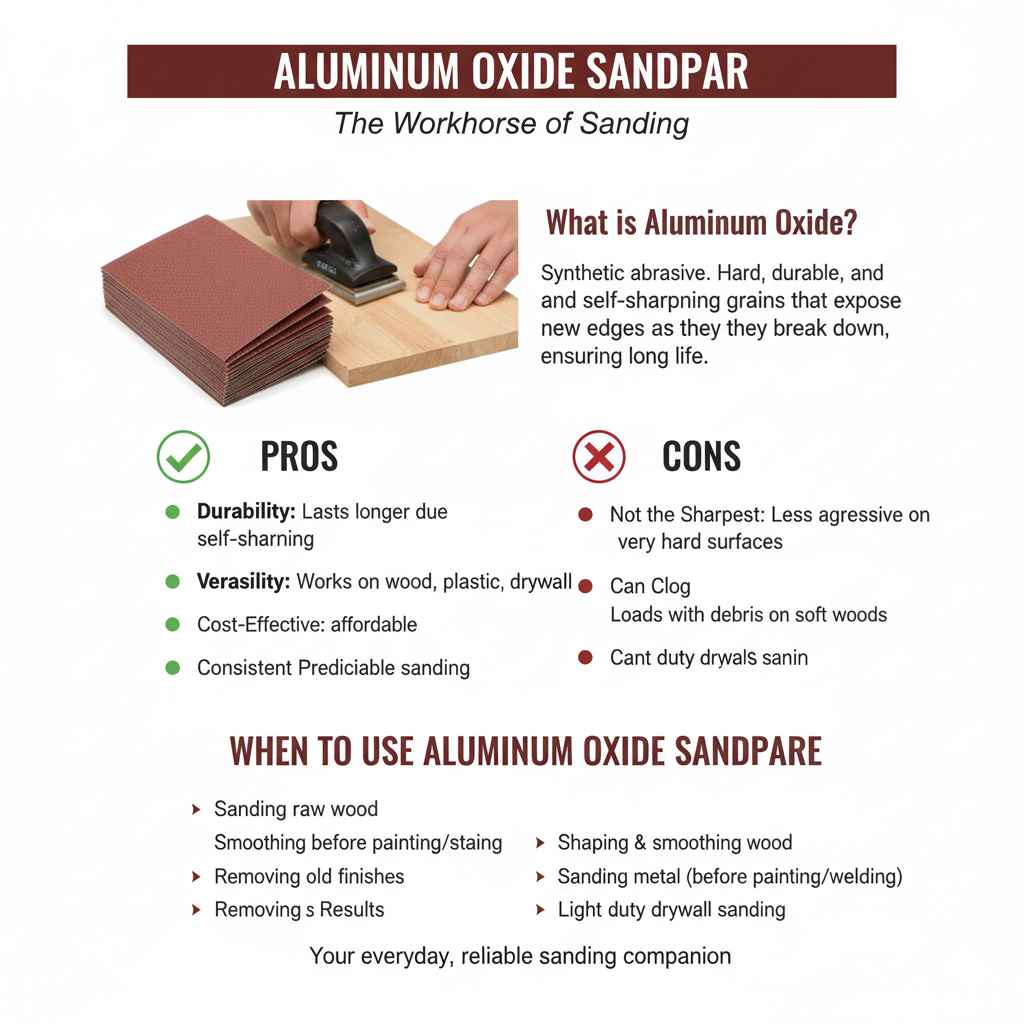

Aluminum Oxide Sandpaper: The Workhorse of Sanding

Aluminum oxide is likely the sandpaper you’ve seen most often. Think of it as the reliable, go-to tool in your sanding arsenal. It’s incredibly popular for a good reason: it’s tough, long-lasting, and works well on a wide variety of materials. If you’re just starting out or need a versatile sandpaper for general-purpose sanding, aluminum oxide is usually your best bet.

What is Aluminum Oxide?

Aluminum oxide is a synthetic abrasive that’s manufactured to be very hard and durable. When used as a grit on sandpaper, it forms sharp, angular grains. These grains fracture and break down gradually during use, exposing new sharp edges. This self-sharpening characteristic means aluminum oxide paper lasts a good long while before becoming completely dull. It’s also known for its toughness, meaning it can withstand a fair amount of pressure and friction without breaking apart easily.

Pros of Aluminum Oxide Sandpaper:

- Durability: It lasts longer because the grains break down slowly and resharpen themselves.

- Versatility: Works great on wood, metal, plastic, and even some drywall applications.

- Cost-Effective: Generally more affordable than silicon carbide, making it budget-friendly for DIYers.

- Consistent Results: Provides a predictable sanding experience for most common tasks.

Cons of Aluminum Oxide Sandpaper:

- Not the Sharpest: While durable, it might not cut as aggressively as silicon carbide on very hard surfaces.

- Can Clog: On softer woods or when creating a lot of dust, it can load up with debris, reducing its effectiveness.

When to Use Aluminum Oxide Sandpaper:

If you’re working on a typical woodworking project, like making a shelf, a birdhouse, or refinishing an old table, aluminum oxide is your go-to. It’s perfect for:

- Sanding raw wood

- Smoothing out surfaces before painting or staining

- Removing old finishes from wood

- Shaping and smoothing wood

- Sanding metal before painting or welding

- Light duty drywall sanding

Think of it as your everyday, reliable sanding companion. It gets the job done efficiently for most common DIY tasks.

Silicon Carbide Sandpaper: The Precision Finisher

Now, let’s talk about silicon carbide. If aluminum oxide is the workhorse, silicon carbide is the precision finisher. It’s known for being incredibly sharp and brittle. This might sound like negative traits, but they actually make it fantastic for specific jobs where you need a super-fine finish or need to cut through hard materials quickly.

What is Silicon Carbide?

Silicon carbide is an extremely hard and sharp abrasive. Its grains are much sharper and more brittle than aluminum oxide. This means that when silicon carbide grains hit a surface, they break off more readily, creating a new sharp edge very quickly. However, because they are brittle, the grains don’t last as long under heavy pressure as aluminum oxide and can break down faster. This sharp, brittle nature makes it excellent for cutting through hard finishes and achieving very smooth surfaces.

Pros of Silicon Carbide Sandpaper:

- Sharpness: Cuts very quickly and aggressively, especially on hard materials.

- Fine Finishes: Excellent for achieving very smooth surfaces, often used for final finishing steps.

- Good for Wet Sanding: It holds up much better than aluminum oxide when used with water or lubricant, which helps wash away dust and prevent clogging, leading to a cleaner cut and a smoother finish.

- Ideal for Hard Materials: Works very well on glass, plastic, fiberglass, and hard metals.

Cons of Silicon Carbide Sandpaper:

- Brittleness: The sharp grains break away easily, so it doesn’t last as long as aluminum oxide under heavy pressure.

- Less Versatile: May not be the best choice for all woodworking applications, especially aggressive shaping.

- Can be More Expensive: Often costs a bit more than aluminum oxide sandpaper.

When to Use Silicon Carbide Sandpaper:

This is the sandpaper you reach for when you need a super-smooth finish or are working with materials that are tough to sand. It’s ideal for:

- Achieving a glass-smooth finish on wood, especially for fine furniture or intricate details.

- Sanding plastic components.

- Sanding fiberglass.

- Working with glass or ceramics (often with water).

- Removing paint or varnish quickly and cleanly, especially when wet sanding.

- Getting a mirror-like finish on metal.

If you’ve ever struggled to get that perfectly smooth surface that feels like silk, or if you’re working on something delicate, silicon carbide is probably what you need.

Aluminum Oxide vs. Silicon Carbide: Key Differences at a Glance

Let’s put it all together in a simple comparison. Understanding these core differences will help you make the right choice every time.

| Feature | Aluminum Oxide Sandpaper | Silicon Carbide Sandpaper |

|---|---|---|

| Abrasive Grain | Tough, durable, angular grains that fracture slowly. | Extremely sharp, brittle grains that fracture quickly. |

| Durability | High; lasts a long time due to self-sharpening. | Moderate; breaks down faster under heavy pressure. |

| Cutting Action | Consistent, good for general-purpose sanding. | Very aggressive and fast, ideal for fine finishes. |

| Best Materials | Wood, metal, plastic, drywall. | Glass, plastic, fiberglass, hard metals, fine wood finishing. |

| Wet Sanding Suitability | Not ideal; can clog and break down faster. | Excellent; designed to work well with water or lubricants. |

| Cost | Generally more affordable. | Can be slightly more expensive. |

| Typical Use Cases | General woodworking, paint prep, metal prep, DIY projects. | Fine woodworking finishes, sanding delicate materials, paint removal, wet sanding. |

Choosing the Right Grit: A Universal Rule

No matter which type of sandpaper you choose, the ‘grit’ matters just as much. Grit refers to the coarseness or fineness of the abrasive. The number associated with the grit tells you how many abrasive particles are lined up across one inch of the sandpaper. A lower number means a coarser grit (more space between particles, larger particles), and a higher number means a finer grit (smaller particles, closer together).

Grit Scale Explained:

- Coarse Grits (e.g., 36-80): Used for rapid material removal, shaping, and removing old paint or finishes. These will leave a rougher surface.

- Medium Grits (e.g., 100-180): Good for smoothing out surfaces after coarse sanding or for general-purpose sanding.

- Fine Grits (e.g., 220-400): Used for smoothing surfaces before finishing (painting, staining, varnishing). They remove minor imperfections and prepare the surface.

- Very Fine Grits (e.g., 600-2000+): Used for ultra-fine finishing, polishing, and between-coat sanding for high-gloss finishes.

For most beginner projects, you’ll likely start with medium grits (like 100 or 120) and move up to finer grits (like 180 or 220) for smooth finishes.

How to Sand Effectively: Tips for Beginners

Using the right sandpaper is only half the battle! Here are some simple tips to make your sanding go smoothly and safely.

Essential Sanding Techniques:

- Always Start Coarse, End Fine: If you need to remove a lot of material or fix imperfections, begin with a coarser grit. Then, progressively move to finer grits to smooth out the scratches left by the previous grit. This is key to achieving a good finish.

- Sand with the Grain: For wood, always sand in the direction of the wood grain. Sanding across the grain leaves visible scratches that are very hard to remove.

- Apply Even Pressure: Don’t push too hard! Let the sandpaper do the work. Even, consistent pressure will give you a more uniform result.

- Keep it Clean: Regularly brush off dust from your workpiece and the sandpaper. For stubborn dust, a quick tap of the sandpaper on a hard surface usually works. If it’s heavily clogged, it’s time for a new sheet.

- Use a Sanding Block: For flat surfaces, using a sanding block (a simple piece of wood or a dedicated foam block) helps distribute pressure evenly and prevent you from creating dips or uneven spots.

- Check Your Work: Feel the surface with your hand as you go. You can also use a light source at an angle to see any remaining imperfections or scratches.

Safety First!

Sanding can create a lot of dust, which isn’t good for your lungs. Always remember to:

- Wear a dust mask or respirator.

- Consider safety glasses to protect your eyes from flying debris.

- Work in a well-ventilated area.

For more detailed information on woodworking safety, the Wood Magazine Safety Guide is a great resource.

Project Examples: When to Use Which Sandpaper

Let’s look at a couple of common projects to illustrate where each type of sandpaper shines.

Project 1: Building a Simple Pine Bookshelf

For this project, you’ll mostly be working with wood and might want a smooth finish before painting or staining.

- Material: Pine wood.

- Best Sandpaper Type: Aluminum Oxide.

- Grits You Might Use:

- Start with 100-grit aluminum oxide to smooth out saw marks or rough edges.

- Move to 150-grit aluminum oxide to further refine the surface.

- Finish with 220-grit aluminum oxide for a smooth surface ready for paint or stain.

- Why: Pine is a relatively soft wood, and aluminum oxide’s durability and versatility make it perfect for this common woodworking task. It will provide excellent results without being overly aggressive.

Project 2: Refinishing an Old Wooden Table with Varnish

This project involves potentially rough old finishes and a desire for a smooth, professional-looking final coat.

- Material: Old wood with existing varnish/paint.

- Best Sandpaper Type: You’ll likely use both!

- Grits and Types You Might Use:

- To strip old finish: Start with coarse 80-grit aluminum oxide to quickly remove thick layers.

- For initial smoothing: Move to 120-grit aluminum oxide to prepare for finer grits.

- For a super-smooth surface before final coat: Switch to 320-grit silicon carbide. This is where silicon carbide really shines – it will give you a very fine, buffed look that aluminum oxide might struggle to match at these super-fine grits.

- For between coats (if applying multiple layers of varnish): Use very fine 400-grit silicon carbide.

- Why: Aluminum oxide handles the heavy lifting of stripping and initial smoothing. Silicon carbide is excellent for achieving that ultra-smooth, non-scratch finish after the bulk of material is removed, especially at very high grits where its sharpness makes a difference. Check out these tips on how to sand wood for more details.

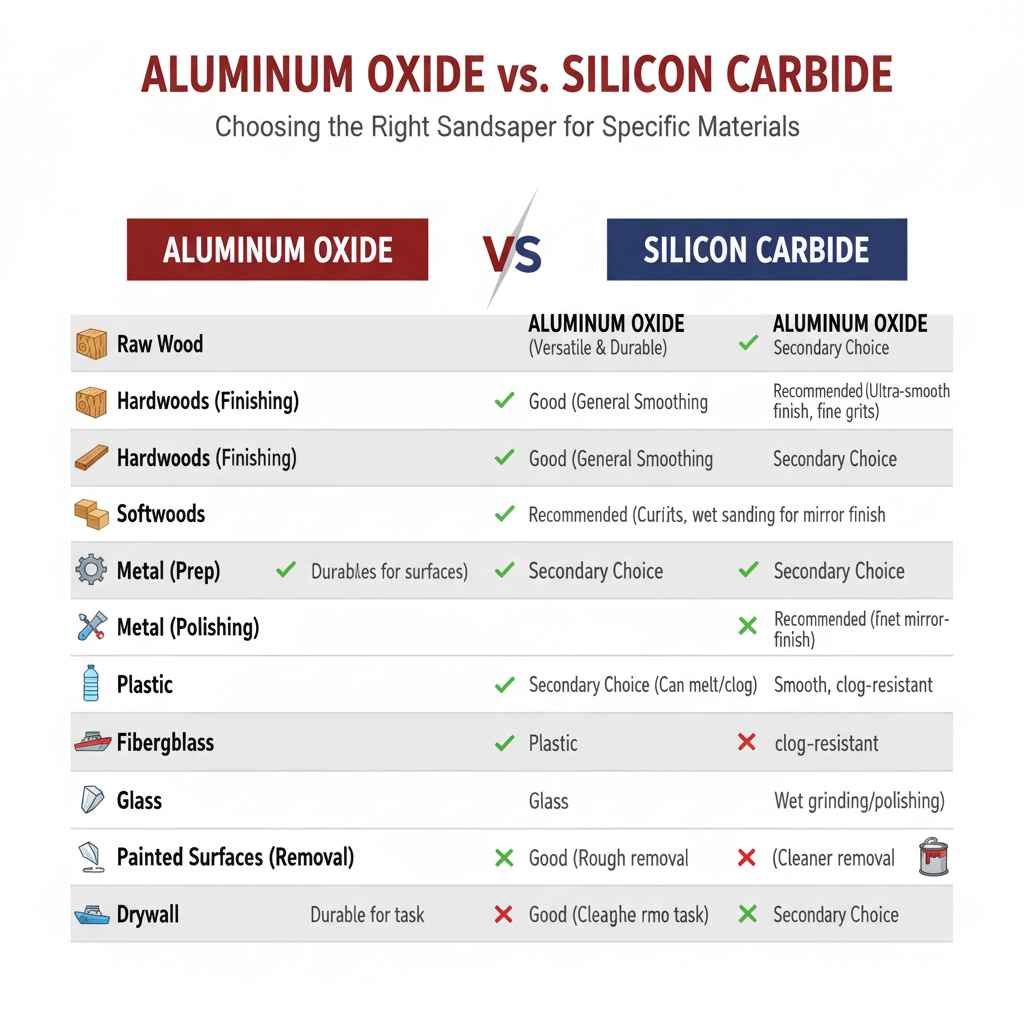

Aluminum Oxide vs. Silicon Carbide for Specific Materials

Let’s recap which sandpaper tends to be best for common materials you might encounter:

- Raw Wood: Aluminum Oxide (versatile and durable for general use).

- Hardwoods (like Oak or Maple) for Finishing: Both can work. Aluminum oxide for general smoothing. Silicon carbide for the final ultra-smooth, pre-finish sanding, especially at finer grits.

- Softwoods (like Pine or Fir): Aluminum Oxide (cuts well without being overly aggressive).

- Metal (before painting/welding): Aluminum Oxide (durable for metal surfaces).

- Metal (for polishing): Silicon Carbide (especially at very fine grits and often with water for a mirror finish).

- Plastic: Silicon Carbide (cuts cleanly without melting or clogging as easily).

- Fiberglass: Silicon Carbide (ideal for its smooth, clog-resistant finish).

- Glass: Silicon Carbide (often used wet for grinding or very fine polishing).

- Painted Surfaces (removing paint): Aluminum Oxide (for rough removal) or Silicon Carbide (for cleaner removal, especially if wet sanding).

- Drywall: Aluminum Oxide (typically used for its durability in this task).

Frequently Asked Questions (FAQ)

Q1: Can I use aluminum oxide sandpaper on glass?

While possible for very light tasks, it’s generally not recommended. Silicon carbide is much better suited for glass because it’s sharper and often used wet, which prevents scratching and clogging.

Q2: Which is better for removing old paint: aluminum oxide or silicon carbide?

For aggressive removal of thick paint layers, aluminum oxide in coarser grits works well. For cleaner removal, especially with less dust, or for finishing the surface after paint removal, silicon carbide is often preferred, particularly when used wet.

Q3: How do I know when to switch grits?

You switch grits when the scratches from the previous, coarser grit are no longer visible. After sanding with a grit, the surface should feel noticeably smoother. Always move to a finer grit to remove the scratches left by the coarser one.

Q4: Can I use silicon carbide for heavy-duty wood shaping?

While it is sharp, silicon carbide’s brittleness means it can break down quickly under heavy pressure, making it less ideal for aggressive wood shaping compared to the durability of aluminum oxide. Aluminum oxide is usually the better choice for heavy wood removal or shaping.

Q5: When is wet sanding a good idea?

Wet sanding is ideal when you want an exceptionally smooth finish, want to minimize dust, prevent clogging, or work with materials like automotive finishes, glass, or certain plastics. Silicon carbide sandpaper is specifically designed to perform well when wet.

Q6: Do I need both types of sandpaper in my workshop?

For a well-rounded DIYer, having both is highly beneficial! Aluminum oxide will handle the bulk of your general woodworking and metal prep, while silicon carbide will be your go-to for fine finishing, plastics, and specialized tasks.

Conclusion: Your Sanding Confidence Starts Now!

So there you have it! You’re now equipped to navigate the world of sandpaper like a pro. Remember, aluminum oxide is your durable, versatile friend for most woodworking and metal tasks, great for general sanding and long-lasting performance. Silicon carbide, with its sharp, brittle nature, is your secret weapon for achieving those super-smooth finishes, tackling hard materials like glass and plastic, and excelling in wet sanding applications.

Don’t be afraid to experiment! Grab a few sheets of each type in grits relevant to your next project. Feel the difference, see how they perform, and pay attention to the finish they leave.