Are Lathes Dangerous? Essential Safety Tips You Need to Know

Yes, lathes can be dangerous. Serious injuries can occur if not used properly.

Lathes are powerful tools used in various industries. They shape wood, metal, and other materials. But with great power comes great responsibility. Understanding the risks is crucial for safety. Improper use can lead to severe injuries. Even experienced users must stay cautious.

This blog will explore the dangers of lathes. We will discuss safety tips and best practices. This knowledge helps prevent accidents and ensures safe operation. Safety should always be the top priority when using lathes. So, let’s dive into the world of lathes and their potential hazards.

Credit: www.reddit.com

Introduction To Lathe Machines

A lathe is a tool used to shape materials. It rotates the material while a tool cuts it. This creates symmetrical shapes. Wood, metal, and plastic are common materials used with lathes. They are very precise. Even small details can be made with a lathe.

Lathes are used in many fields. In woodworking, lathes create table legs and bowls. Metalworking uses lathes to make parts for machines. Plastic parts for toys and gadgets are also made with lathes. They are versatile. Almost any shape can be made.

Potential Hazards Of Lathe Machines

Lathe machines can be dangerous if safety protocols are ignored. Risks include flying debris, entanglement, and severe cuts. Always prioritize safety.

Physical Injuries

Lathe machines can cause severe injuries. Fingers can get caught in the machine. Loose clothing can be pulled in, causing harm. The rotating parts are very dangerous. Flying debris can hit the eyes. Sharp tools can slip and cut hands. The machine can pinch fingers badly. High-speed parts can cause bruises or fractures. Safety equipment is important. Operators must stay alert.

Material Hazards

Some materials are toxic when machined. Dust from metals and plastics can be harmful. Inhalation of these particles is risky. Skin can react to certain materials. Flammable materials can catch fire. Sparks can ignite them. Proper ventilation is crucial. Using the right protective gear is essential. Careful handling reduces risks.

Personal Protective Equipment (ppe)

Wearing PPE is crucial when using a lathe. Safety goggles protect your eyes from flying debris. Gloves safeguard your hands from cuts and burns. Ear protection shields your ears from loud noises. A face shield offers extra protection for your face. Aprons or protective clothing keep your body safe from sharp objects and splashes. Steel-toed boots protect your feet from heavy items. Always wear the correct PPE to stay safe.

Ensure your PPE fits properly. Ill-fitting gear can be dangerous. Check your PPE for any damage before use. Replace damaged PPE immediately. Wear your PPE at all times while operating a lathe. Store your PPE in a clean, dry place. Clean your PPE regularly to maintain its effectiveness. Proper PPE use can prevent many accidents. Always be cautious and aware.

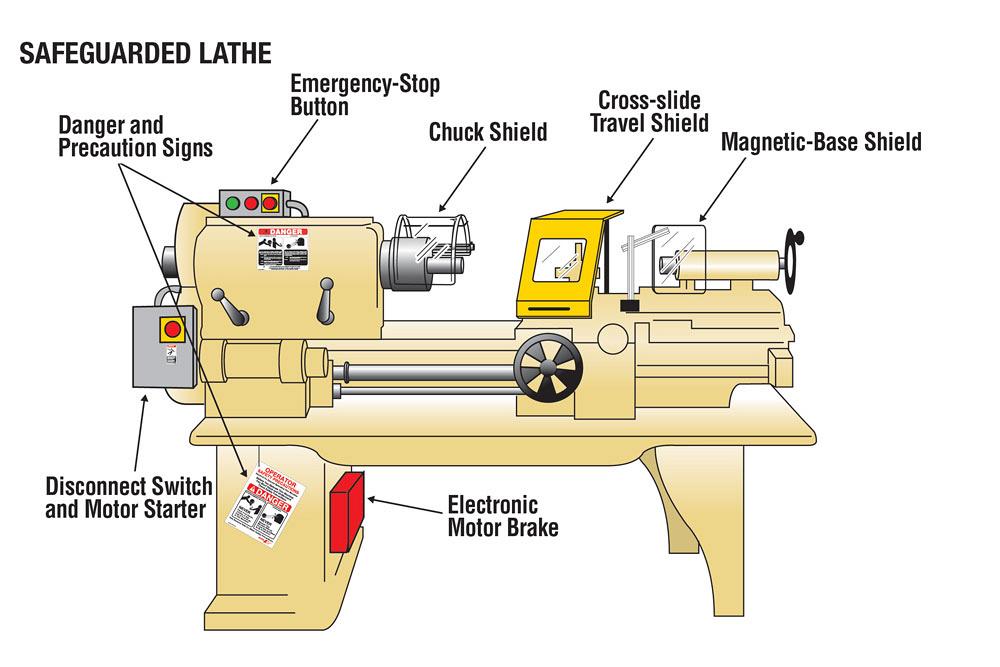

Safe Operating Procedures

Inspect the lathe for any damages or wear. Ensure all safety guards are in place. Check if the work area is clean and free of clutter. Verify that the lathe is properly lubricated. Ensure cutting tools are sharp and securely fastened. Wear appropriate safety gear like goggles and gloves. Keep a fire extinguisher nearby. Ensure good lighting around the lathe. Double-check the lathe speed settings.

Maintain a safe distance from the rotating parts. Never leave the lathe unattended while it is running. Avoid wearing loose clothing or jewelry. Keep hands away from the cutting area. Use a brush to remove chips, not hands. Always stand to the side of the lathe. Stop the lathe before making any adjustments. Be aware of the emergency stop button. Keep the workpiece securely fastened. Regularly check for vibration or unusual noises.

Maintenance And Inspection

Check the lathe’s lubrication levels daily. Ensure the machine has clean oil. Inspect belts for wear or damage. Tighten any loose bolts or screws. Clean chips and debris from the lathe. Check the alignment of the lathe bed. Inspect the chuck for wear. Ensure guards are in place.

Inspect the lathe before each use. Look for signs of wear or damage. Ensure all safety features work. Check the emergency stop button. Test the lathe at low speed first. Listen for unusual noises. Watch for vibrations. Examine cutting tools for sharpness. Ensure proper tool setup. Verify workpiece is secure. Address any issues immediately. Regular inspections help keep operators safe.

Training And Certification

Proper training and certification are crucial for safely operating lathes. These powerful machines can be dangerous without the right skills. Always follow safety procedures to avoid accidents.

Importance Of Training

Proper training is crucial for safe lathe operation. Without it, accidents can happen. Learning how to use the machine reduces risks. Knowing the parts and functions is key. Understanding safety rules prevents injuries.

Trained operators work more efficiently. They make fewer mistakes. This saves time and money. Employers should provide training. Workers should take it seriously. It can save lives.

Certification Programs

Certification programs validate a worker’s skills. They show that the operator is qualified. Certified workers are trusted more. They follow safety guidelines better.

Many organizations offer certifications. They include practical and written tests. Passing these tests proves competence. Certified operators have more job opportunities. Employers prefer certified workers. It ensures a safer workplace.

Emergency Procedures

Accidents can happen. Stay calm. Stop the lathe immediately. Turn off the power. Assess the situation quickly. Check for injuries. Do not move the injured person. Call for help. Inform the supervisor. Keep others away from the area. Wait for professional help.

Provide first aid if trained. Use a first aid kit. Clean wounds with water. Apply pressure to stop bleeding. Use bandages. Avoid touching open wounds. Monitor the injured person’s condition. Keep them calm and comfortable. Do not give them food or drink. Wait for medical professionals.

Credit: www.creativesafetysupply.com

Credit: www.canadianmetalworking.com

Frequently Asked Questions

Are Lathes Dangerous To Use?

Lathes can be dangerous if not used properly. Proper training, protective gear, and adherence to safety guidelines are essential.

What Are Common Lathe Accidents?

Common lathe accidents include entanglement, contact with sharp tools, and flying debris. Always maintain focus and follow safety protocols.

How Can I Stay Safe Using A Lathe?

To stay safe, wear protective gear, avoid loose clothing, and follow all safety instructions. Regularly inspect the lathe.

What Safety Gear Is Needed For Lathe Work?

Essential safety gear includes safety glasses, gloves, and a face shield. Always wear appropriate clothing and avoid loose items.

Conclusion

Lathes can be dangerous if not used correctly. Safety should always come first. Follow all guidelines and use protective gear. Proper training is crucial. Keep the workspace clean and organized. Regularly maintain the lathe to avoid malfunctions. Stay focused during operation.

Understand the risks and work smart. Safety measures help prevent accidents. Always respect the power of the lathe. Stay safe and enjoy your projects.