Ash Wood Lumber: Uses, Grades & Buying Guide

Imagine wanting to build a sturdy workbench for your garage, only to be overwhelmed by the sheer variety of wood types. You look at oak, pine, maple, and then ash, wondering which is the best choice for durability and aesthetics. If you’ve ever found yourself in this woodworking dilemma, you’re not alone.

This guide will demystify Ash Wood Lumber: Uses, Grades & Buying Guide, equipping you with the knowledge to make informed decisions for your projects, whether you’re a seasoned pro or just starting out.

All About Ash Wood Lumber

Ash wood is a popular choice for many woodworking projects due to its strength, hardness, and attractive grain. It’s known for its excellent shock resistance, making it ideal for items that need to withstand impact. The color of ash lumber can vary from a light creamy white to a darker brown, often with prominent, open grain patterns that can add a distinctive look to finished pieces.

Understanding the different types and grades of ash lumber will help you select the perfect material for your specific needs.

Understanding Ash Wood Properties

Ash trees are found in various parts of the world, but the most commonly used species for lumber are White Ash (Fraxinus americana) and European Ash (Fraxinus excelsior). White Ash, in particular, is highly prized in North America for its strength and workability. It’s a hardwood, meaning it’s denser and more durable than softwood.

- Hardness: Ash ranks high on the Janka hardness scale, indicating its resistance to denting and wear. This makes it suitable for flooring, tool handles, and furniture that sees a lot of use.

- Strength: It possesses good tensile strength and stiffness, allowing it to hold screws and nails well and support weight effectively.

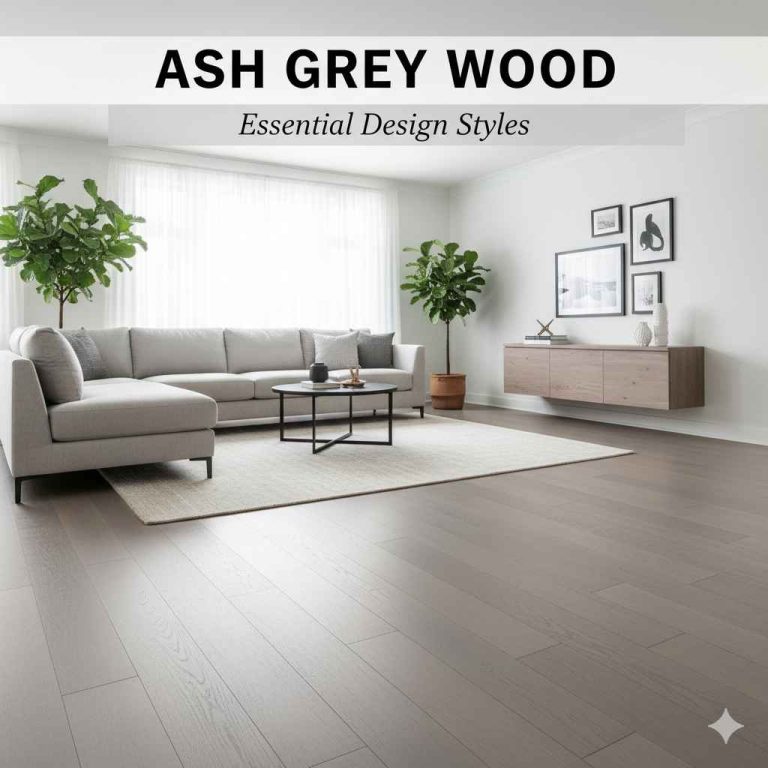

- Grain and Appearance: Ash typically features a straight, prominent grain pattern with a medium to coarse texture. The color ranges from pale yellow to light brown, sometimes with a greyish or reddish hue. The open pores can be filled for a smoother finish or left open for a more natural look.

- Workability: While it’s a hardwood, ash is generally easy to work with using both hand and power tools. It machines, sands, and glues well. However, its open grain may require filling before finishing for a perfectly smooth surface.

- Finishing: Ash takes stains and finishes very well, allowing for a wide range of aesthetic possibilities. The prominent grain can be highlighted with clear coats or accentuated with darker stains.

- Durability: It is resistant to shock and decay, making it a long-lasting material for various applications.

Common Uses for Ash Wood Lumber

The versatile nature of ash lumber lends itself to a wide array of applications. Its strength and appearance make it a go-to material for both functional and decorative woodworking.

- Furniture: Ash is a classic choice for fine furniture, from dining tables and chairs to beds and cabinets. Its durability ensures that furniture made from ash will last for generations, and its attractive grain adds visual appeal.

- Flooring: The hardness and wear resistance of ash make it an excellent option for hardwood flooring. It can withstand the foot traffic of busy households and maintain its beauty over time.

- Sporting Goods: Ash’s shock-absorbing qualities are ideal for items like baseball bats, tennis rackets, and hockey sticks. It can handle the impact and stress associated with these sports.

- Tool Handles: From hammers to shovels, tool handles made from ash are known for their strength and ability to absorb vibration, providing a comfortable and durable grip.

- Cabinetry and Millwork: Ash is frequently used for kitchen cabinets, paneling, and decorative millwork due to its attractive grain and ability to take finishes well.

- Bowing and Wood Bending: Ash has good flexibility and can be bent into various shapes, making it suitable for curved furniture pieces or architectural elements.

- Musical Instruments: Certain electric guitar bodies are made from ash, valued for its resonant tonal qualities and light weight, contributing to the instrument’s sound.

Ash Wood Grades Explained

Like most lumber, ash is graded to indicate its quality and the presence of defects. These grades help buyers understand what to expect from a piece of lumber and ensure they are getting material suitable for their project. The grading system can vary slightly by region and specific lumber association, but generally, they follow similar principles.

Understanding Hardwood Lumber Grades

Hardwood lumber grades are primarily based on the size and number of usable clear wood sections that can be obtained from a board. The goal is to provide a consistent standard for quality. The most common grading system for hardwoods in North America is established by the National Hardwood Lumber Association (NHLA).

Common Ash Lumber Grades (NHLA System)

Here’s a breakdown of the typical grades you’ll encounter when buying ash lumber, from highest to lowest quality:

| Grade | Description | Typical Uses |

|---|---|---|

| Firsts (FAS) | This is the highest grade. FAS lumber must yield at least 83.3% clear and usable wood from a standard 10-foot board, with a minimum width of 6 inches. Boards must be at least 8 feet long. Small knots and pinholes are acceptable, but larger defects are not. | High-end furniture, cabinetry, millwork, and any application where appearance is paramount. |

| Selects | Selects fall between FAS and No. 1 Common. They are similar to FAS but may have slightly more defects or be narrower and shorter. This grade is often used for pieces where a clear face is desired. | Furniture components, doors, and paneling. |

| No. 1 Common | This grade is very popular and versatile. It requires at least 66.7% clear wood from a board. Knots, wormholes, and small checks are generally permissible, as long as they don’t prevent the use of a good portion of the board. Boards are typically 4 inches or wider and 4 feet long or longer. | General furniture, utility cabinets, and projects where some character is acceptable or desired. |

| No. 2 Common | No. 2 Common must yield at least 50% clear wood. It will have more knots and defects than No. 1 Common, but it is still usable for many projects. This grade offers excellent value for projects where appearance is less critical or where defects can be worked around. | Craft projects, rustic furniture, utility shelving, and projects where a natural, character-filled look is desired. |

| Sound Wormy | This designation is often used in conjunction with other grades (e.g., No. 1 Common Sound Wormy). It indicates that the lumber has wormholes but they are sound and do not compromise the structural integrity of the wood. | Rustic furniture, accent pieces, and projects where wormholes add a desired aesthetic. |

When purchasing lumber, always ask about the grading system used. Knowing these grades will empower you to select the right material for your budget and project requirements.

Buying Ash Wood Lumber

Purchasing lumber can be an enjoyable experience when you know what to look for. Whether you’re visiting a local lumberyard or ordering online, there are key factors to consider to ensure you get quality ash wood that meets your project needs.

Where to Buy Ash Lumber

There are several avenues for sourcing ash lumber:

- Local Lumberyards: These are often the best places to buy lumber. You can physically inspect the wood, assess its grain and color, and get advice from knowledgeable staff. Many lumberyards specialize in hardwoods and offer a good selection of ash.

- Online Lumber Retailers: Many online stores sell lumber, often in pre-cut dimensions or by the board foot. This can be convenient, especially if local options are limited, but it means you can’t inspect the wood before purchase.

- Sawmills: Direct from a local sawmill can sometimes offer better prices, especially for larger quantities. However, sawmills may not always grade their lumber to the same standards as retail lumberyards.

- Woodworking Supply Stores: Some larger woodworking stores carry a selection of hardwoods, though their stock might be more limited than dedicated lumberyards.

What to Look for When Buying

Regardless of where you buy, keeping a few things in mind will help you select good quality ash lumber:

- Moisture Content: Lumber is typically sold either green (high moisture content) or kiln-dried (lower moisture content). For most furniture and interior projects, kiln-dried lumber is preferred because it is more stable and less prone to warping or shrinking. Look for lumber labeled as kiln-dried, typically around 6-8% moisture content for interior use.

- Grain Pattern: Decide if you prefer a straight, uniform grain or one with more character and knots. The grade will heavily influence this. For a clean, modern look, opt for higher grades. For a rustic or natural feel, lower grades with more character might be perfect.

- Color Consistency: Ash can have color variations. If you need a very uniform color, look for boards that are closely matched. If you’re using stains, this becomes less critical as the stain will help unify the color.

- Surface Quality: Inspect boards for significant defects like deep checks, splits, rot, or excessive cupping. While some defects are acceptable depending on the grade, major issues can render a board unusable.

- Board Dimensions: Ensure the dimensions (thickness, width, and length) are suitable for your project. Lumber is often sold by the board foot, which is a measure of volume (1 board foot = 1 inch thick x 12 inches wide x 1 foot long).

- Storage Conditions: If buying from a lumberyard, observe how the wood is stored. Is it kept dry and off the ground? Proper storage prevents warping and moisture damage.

Calculating Lumber Needs

It’s always wise to buy a little more lumber than you think you’ll need. This accounts for mistakes, waste from cutting around defects, and unforeseen issues. A general rule of thumb is to add 10-15% to your calculated lumber requirement.

Frequently Asked Questions

Question: Is ash wood good for outdoor furniture?

Answer: Ash wood is moderately durable and can be used for outdoor furniture, especially if treated with a protective finish. However, it is not as naturally resistant to decay and insects as some other hardwoods like cedar or teak, so regular maintenance will be required to ensure longevity in outdoor conditions.

Question: How does ash compare to oak wood?

Answer: Ash is generally harder, denser, and more shock-resistant than oak, making it a better choice for applications requiring high impact resistance like tool handles or sports equipment. Oak is often more widely available and can be less expensive. Both woods have attractive grain patterns and take finishes well, but ash typically has a more prominent, open grain.

Question: Can I paint ash wood lumber?

Answer: Yes, ash wood lumber can be painted. Its relatively smooth surface and ability to take finishes make it a good candidate for painting. For the best results, ensure the wood is properly prepared by sanding and priming it before applying paint.

Question: Is ash wood prone to warping?

Answer: Like all solid wood, ash can warp if not properly dried and acclimated to its environment. Kiln-dried ash lumber is much more stable than green lumber. Proper storage and handling after purchase, especially for projects intended for stable environments, will minimize warping risk.

Question: What is the best way to finish ash wood?

Answer: Ash wood can be finished in many ways. A clear finish like polyurethane or varnish will highlight its natural grain and color. Stains can be used to achieve different hues, but due to its open grain, a wood filler might be necessary before staining for a perfectly smooth finish.

Oil finishes also work well, providing a natural look and feel.

Final Thoughts

Selecting the right wood is a foundational step for any woodworking project, and understanding ash wood lumber its uses grades and buying guide provides a clear path forward. Whether you’re aiming for the clean lines of modern furniture, the dependable performance of a tool handle, or the inviting warmth of hardwood floors, ash offers a compelling blend of strength beauty and workability. By familiarizing yourself with its properties and the grading systems like NHLA you can confidently identify lumber that matches your project’s demands and your budget.

Always inspect the wood carefully at your local lumberyard or when ordering online paying attention to moisture content grain characteristics and any potential defects. Remember that buying slightly more than you calculate can save you from project delays. Armed with this knowledge you’re well-prepared to select ash lumber that will not only serve its purpose but also contribute significantly to the aesthetic appeal and longevity of your creations.

Get ready to transform your ideas into tangible pieces of craftsmanship with the reliable character of ash.