Black Oxide vs Titanium Drill Bits: Essential Power

When it comes to drilling wood, metal, or even plastic, choosing the right drill bit can make all the difference. You’ve likely seen “black oxide” and “titanium” drill bits, but what’s the real difference? Black oxide bits are best for general wood and soft metal tasks due to their affordability and decent hardness, while titanium bits excel in harder materials and offer much longer life due to their superior durability and heat resistance. We’ll break down exactly which one you need for your next project.

Choosing the right drill bit might seem a little puzzling at first, especially when you’re just starting out in woodworking or DIY. You stand in the aisle, staring at a dizzying array of bits, each promising to be the best. Two common types are black oxide and titanium drill bits. They look different, and they feel different, but what does that mean for your projects? Don’t worry! It’s not as complicated as it seems. Understanding these basic differences will instantly boost your confidence and help you pick out the perfect tool for the job, making your drilling tasks smoother and more successful. Let’s dive in and make sense of these essential workshop companions.

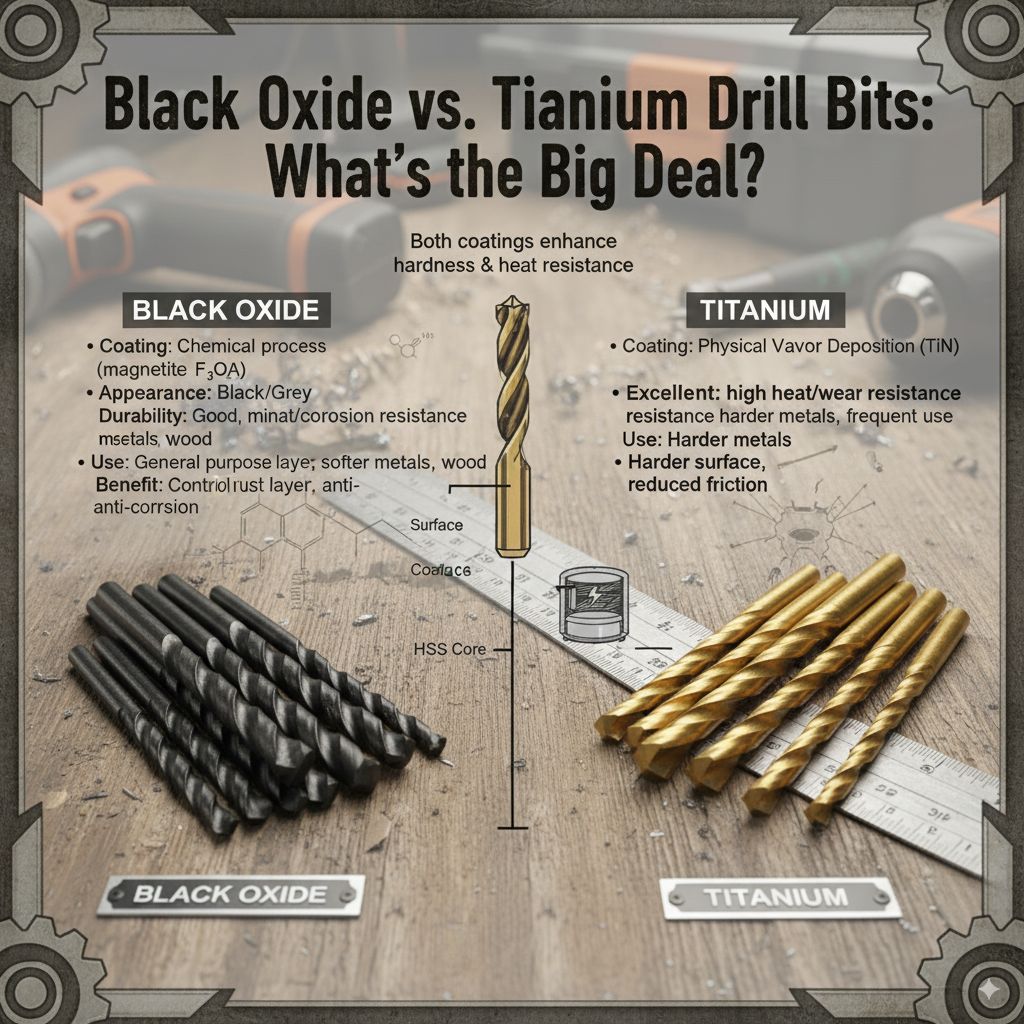

Black Oxide vs. Titanium Drill Bits: What’s the Big Deal?

Think of your drill bits as the sharp teeth of your drill. They do all the hard work, biting into materials to create holes. For beginners, understanding the difference between common types like black oxide and titanium is a fundamental step towards mastering drilling. It’s not just about looks; it’s about performance, durability, and the materials you’ll be working with.

Understanding Drill Bit Coatings: The Role of Surface Treatment

The “black oxide” and “titanium” you see aren’t the base metal of the drill bit itself. These are coatings applied to a steel core, usually made from high-speed steel (HSS). These coatings are crucial because they enhance the bit’s hardness, lubricity, and resistance to heat and corrosion.

Black Oxide: This is a chemical process that creates a layer of magnetite (Fe₃O₄) on the surface of the steel. It’s essentially a controlled rust. This black coating gives the bit a slightly darker appearance and offers several minor benefits.

Titanium Nitride (TiN) Coating: This is a much harder and more durable coating applied through a physical vapor deposition (PVD) process. Titanium nitride is golden-yellow or sometimes iridescent. It’s significantly harder and more heat-resistant than black oxide.

The core material (HSS) is important too, providing the basic strength and flexibility. But the coating is what truly impacts how the bit performs and how long it lasts, especially when drilling tougher materials.

Black Oxide Drill Bits: The Workhorse for Wood and Soft Metals

Black oxide drill bits are a popular choice for many DIYers and woodworkers, and for good reason. They offer a great balance of performance and affordability, making them ideal for a wide range of common tasks.

What are Black Oxide Bits Made For?

These bits are primarily designed for drilling into softer materials. Their coating provides a little extra hardness and corrosion resistance compared to plain uncoated HSS bits, but they are not suited for very demanding jobs.

Wood: They cut through wood cleanly and efficiently without much effort. They’re perfect for pilot holes for screws, dowel holes, or general woodworking projects.

Plastics: Black oxide bits handle most plastics with ease, creating smooth, clean holes.

Soft Metals: They can drill into softer metals like aluminum and thin mild steel, but they will wear down faster than titanium bits when pushing their limits.

Pros of Black Oxide Drill Bits

Affordability: Generally, black oxide drill bits are less expensive than their titanium counterparts, making them a budget-friendly option.

Good for Woodworking: They perform exceptionally well in wood and many common DIY materials.

Corrosion Resistance: The black oxide coating helps prevent rust, extending the life of the bit when stored properly.

Availability: They are widely available at most hardware stores and online retailers.

Lubricity: The coating offers some self-lubricating properties, which can help reduce friction and heat buildup, though not as effectively as titanium.

Cons of Black Oxide Drill Bits

Limited Hardness: They are not as hard as titanium-coated bits, meaning they will dull faster when used on hard materials or for prolonged, heavy-duty tasks.

Heat Sensitivity: While better than uncoated bits, they are still more prone to overheating when drilling harder metals than titanium bits. This can lead to premature wear and reduced sharpness.

Not for Extremely Hard Materials: They are not recommended for drilling into hardened steel, stainless steel, or very dense hardwoods where extreme durability is needed.

How to Use Black Oxide Bits Effectively

To get the most out of your black oxide drill bits, especially when working with wood, remember a few key points:

1. Clean Cuts: Apply steady, consistent pressure. For wood, letting the bit do the work rather than forcing it will result in cleaner holes and less splintering.

2. Pilot Holes: Always drill pilot holes when driving screws, especially in hardwoods. This prevents the wood from splitting and makes driving the screw much easier.

3. Cooling: If drilling into metal, even soft metal, use a cutting fluid or lubricant to keep the bit cool and extend its life.

4. Maintenance: Clean your bits after use and store them in a dry place to prevent rust.

Titanium Drill Bits: The High-Performance Choice for Tough Jobs

Titanium drill bits, specifically those coated with titanium nitride (TiN), are the heavyweights when it comes to drilling durability and performance. If you frequently encounter harder materials or need bits that can withstand rigorous use, titanium is likely your best bet.

What are Titanium Bits Made For?

The superior hardness and heat resistance of titanium nitride make these bits ideal for drilling into a much wider range of materials, including those that would quickly wear out black oxide bits.

Hard Metals: They excel in drilling into materials like stainless steel, cast iron, and harder alloys.

Wood and Plastics: While overkill for some basic wood tasks, they still perform excellently in these softer materials and will last significantly longer.

Composite Materials: Titanium bits can also handle certain composite materials that might be too abrasive for standard bits.

High-Volume Drilling: For tasks requiring drilling many holes, titanium bits are superior due to their extended life and ability to maintain sharpness.

Pros of Titanium Drill Bits

Exceptional Hardness: The titanium nitride coating is incredibly hard, allowing these bits to cut through tougher materials with ease.

Superior Durability: They are far more resistant to wear and tear, meaning they will last much longer than black oxide bits, especially under demanding conditions.

High Heat Resistance: Titanium nitride has a very high melting point, allowing the bits to withstand the extreme heat generated by drilling into hard metals. This reduces the risk of the bit overheating and losing its temper.

Reduced Friction: The smooth, hard coating results in less friction, allowing for faster drilling speeds and cleaner holes.

Versatility: They are suitable for a broad range of materials, from soft wood to tough metals.

Cons of Titanium Drill Bits

Higher Cost: Titanium drill bits are generally more expensive than black oxide bits. This initial investment can be a barrier for some users.

Can be Brittle: While durable, the very hardness that makes them excellent can also make them more prone to chipping or breaking if subjected to excessive side force or if dropped, especially smaller diameter bits.

Overkill for Some Tasks: For simple woodworking projects where you’re only drilling into soft pine, the extra performance and cost of titanium might not be necessary.

How to Use Titanium Bits Effectively

To maximize the benefits of your titanium drill bits:

1. Embrace Speed: Don’t be afraid to run your drill at a slightly higher RPM when drilling into harder materials. The heat resistance of titanium allows for this.

2. Use Lubricant: Always use a cutting lubricant or drilling fluid when drilling into metals, especially harder ones. This further reduces heat and friction, extending the bit’s life and improving hole quality.

3. Firm Pressure: Apply firm, consistent pressure. The bit is designed to handle it, and this helps it cut efficiently rather than just scraping.

4. Choose the Right Bit: While versatile, ensure you’re using the correct drill bit type for your specific material. For extremely hard or abrasive materials, cobalt bits might be even more suitable. You can learn more about drill bit materials at resources like Metalforming.com, which offers insights into machining metals.

Black Oxide vs. Titanium Drill Bits: A Direct Comparison

To help you make a quick decision, let’s put the key features side-by-side. This comparison table highlights the main differences and helps you see at a glance which bit might be best for your needs.

| Feature | Black Oxide Drill Bits | Titanium Drill Bits |

|---|---|---|

| Coating | Black Oxide (Magnetite) | Titanium Nitride (TiN) |

| Base Material | High-Speed Steel (HSS) | High-Speed Steel (HSS) |

| Primary Use Materials | Wood, Plastics, Soft Metals (Aluminum, thin mild steel) | Hard Metals (Stainless Steel, Cast Iron), Wood, Plastics, Composites |

| Hardness | Good (compared to uncoated HSS) | Excellent (significantly harder than black oxide) |

| Durability & Life | Moderate | Excellent (much longer lifespan) |

| Heat Resistance | Moderate | Excellent |

| Cost | Lower | Higher |

| Best For | General woodworking, DIY projects, occasional metal drilling | Frequent metal drilling, hardwood, demanding tasks, long-term projects |

| Caution | Will dull faster on hard materials. Prone to overheating in tougher metals. | Can be more brittle if misused. Higher initial cost. |

Which Drill Bit is Right for Your Project?

The choice between black oxide and titanium drill bits boils down to what you plan to drill and how often you’ll be doing it.

For the Woodworking Beginner: Starting with Wood

If your primary focus is woodworking—building furniture, shelves, or simple home decor projects—and you’re mostly working with standard construction lumber like pine, poplar, or even oak, black oxide drill bits are an excellent starting point. They are cost-effective and perform admirably in these softer materials. You’ll be able to drill pilot holes for screws, create holes for dowels, and make general utility holes with ease.

Recommendation: A good set of HSS black oxide drill bits is a fantastic foundational tool for any beginner woodworker. Prioritize a set with common fractional and metric sizes.

For the DIYer Tackling Harder Materials

If your DIY projects often venture beyond simple wood and into metals like aluminum, thinner steel, or even brass, or if you work with hardwoods that are tougher than oak, you’ll want to consider upgrading to titanium. The added hardness and heat resistance will mean your bits stay sharp longer and don’t overheat and get damaged as quickly.

When to Choose Titanium:

Drilling into metal more than occasionally.

Working with hardwoods like maple or hickory.

When you need bits that will last through many projects.

If you use a drill press or impact driver frequently, as these can generate more heat.

For the Metalworker and Heavy-Duty User

If your projects involve frequent drilling into thick steel, stainless steel, or other very hard metals, then titanium drill bits are a must-have. For the absolute toughest jobs, even titanium might be outmatched, and you might look into specialized bits like cobalt or solid carbide. However, for most general metalworking and construction, titanium provides the best balance of performance, durability, and cost. For a deeper dive into drill bit types for metals, resources like MachineryLubricants.com offer detailed guides on tool selection for various materials.

Beyond Black Oxide and Titanium: Other Drill Bit Types

While black oxide and titanium are very common, especially for beginners, it’s good to know there are other types of drill bits out there for specialized needs.

Cobalt Drill Bits: These are made from high-speed steel alloyed with cobalt. Cobalt significantly increases hardness and heat resistance, making them ideal for drilling into extremely hard metals like stainless steel, titanium alloys, and hardened steel. They are generally more expensive and can be brittle.

Carbide Tipped Drill Bits: These have a small carbide tip brazed onto the end of a steel body. Carbide is exceptionally hard, excelling in drilling very abrasive materials like concrete, brick, or tile. They are often used as masonry bits.

Uncoated High-Speed Steel (HSS) Bits: These are the most basic and affordable. They are good for wood and soft metals but lack the enhanced durability and corrosion resistance of coated bits.

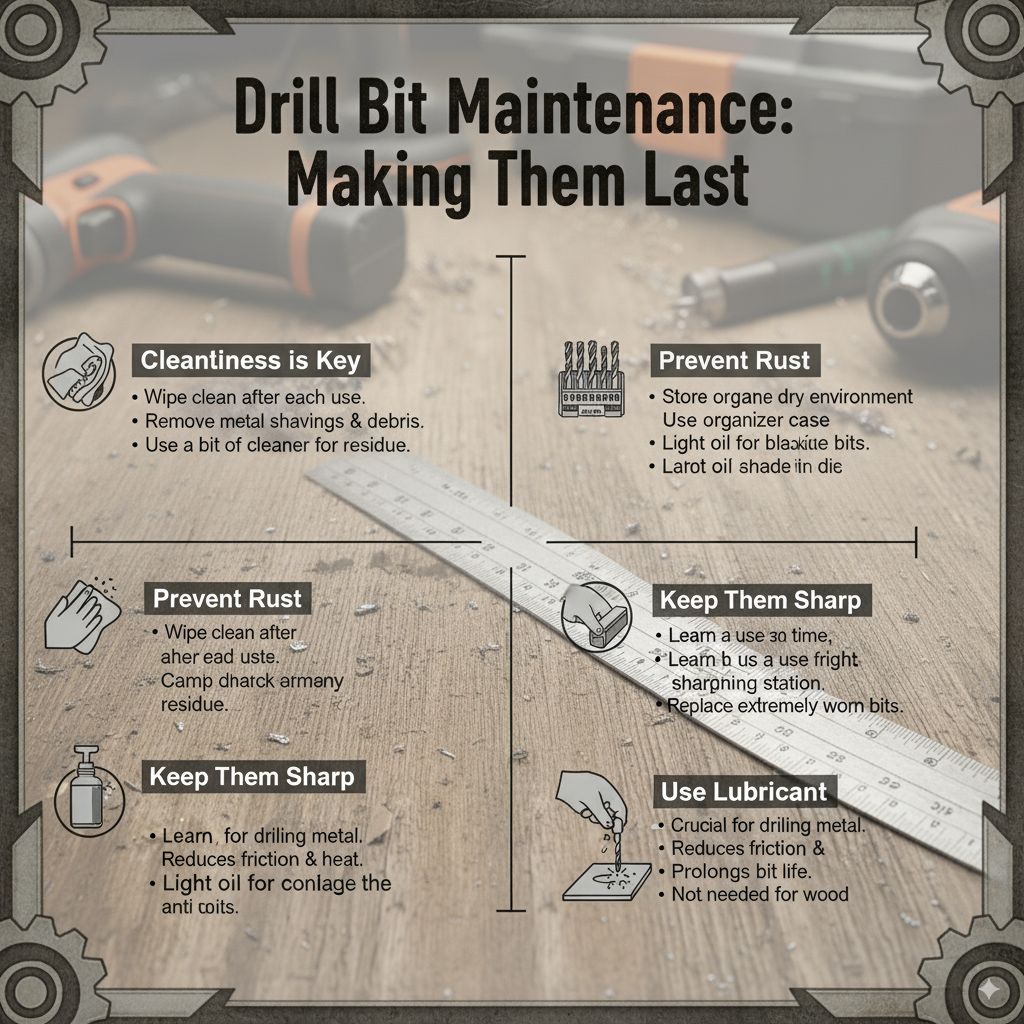

Drill Bit Maintenance: Making Them Last

Regardless of whether you choose black oxide or titanium, proper maintenance will significantly extend the life of your drill bits and ensure they perform their best.

1. Cleanliness is Key: After each use, especially when drilling into metal, wipe your drill bits clean. Use a rag to remove any metal shavings or debris. A little bit of cleaner can help too.

2. Prevent Rust: Store your drill bits in a dry environment. A drill bit organizer case is excellent for this, protecting them from moisture and keeping them organized. For black oxide bits, a light coating of oil can offer extra protection against rust.

3. Keep Them Sharp: Even the best drill bits will eventually dull. For occasional use, you might just replace a dull bit. For more frequent users, learn about sharpening drill bits. A sharpening station or even a simple file can help restore an edge to many bits, though extremely worn bits are often best replaced.

4. Use the Right Lubricant: When drilling metal, always use a cutting fluid or lubricant. This is crucial for both black oxide and titanium bits drilling in metal, as it significantly reduces friction and heat, prolonging the bit’s life and improving hole quality. For wood, lubrication isn’t typically needed.

Frequently Asked Questions (FAQ)

Q1: Are titanium drill bits always better than black oxide?

A1: Not necessarily better, but better suited for harder materials and more demanding tasks. Black oxide is often sufficient and more affordable for general woodworking and softer metals.

Q2: Can I use black oxide drill bits on metal?

A2: Yes, you can use black oxide drill bits on soft metals like aluminum and thin mild steel. However, they will wear out faster than titanium bits in these applications and require more care to avoid overheating.

Q3: How do I know when my drill bit is dull?

A3: A dull drill bit will require more force to drill a hole, it might start to ‘squeal’ or overheat quickly, produce shavings instead of chips, or create rough, burnished edges around the hole instead of a clean cut.

Q4: Does the gold color on some drill bits mean they are titanium?

A4: The bright gold color, or a golden-iridescent hue, often indicates a titanium nitride (TiN) coating, which is what we refer to as titanium drill bits. However, some ‘enhanced’ black oxide bits might have a slight bronze tint. Always check the product description if unsure.

Q5: What’s the difference between a twist drill bit and others?

A5: The term “twist drill bit” refers to the most common type of drill bit, which has helical flutes that spiral up the bit. These flutes help clear debris from the hole as you drill. Both black oxide and titanium bits are typically twist drill bits.

Q6: My drill bit feels very hot after drilling. What does that mean?

A6: Excessive heat indicates too much friction. This can be due to drilling too fast, applying too much pressure, or not using lubricant (especially in metal). Overheating can damage the temper of the steel and rapidly dull the bit, regardless of its coating. Slow down, ease up on pressure, and use lubricant if drilling metal.

Q7: Can I use the same drill bit set for wood and metal?

A7: While a good HSS set (like black oxide or titanium) can often tackle both, it’s best to have distinct bits or sets for frequent wood versus frequent metal drilling. Bits used heavily in metal will accumulate microscopic metal dust that can mar wood. And a bit dulled by metal will struggle in wood. Titanium bits are the most versatile if you must use one set for both.

Conclusion: Powering Up Your Projects

Choosing the right drill bit is a small detail that makes a big impact on your projects. For beginners diving into woodworking, a set of reliable black oxide drill bits is an economical and effective choice for most tasks involving wood and soft plastics. They offer good performance without a hefty price tag.

However, as your skills grow and you start tackling more challenging materials, especially metals or dense hardwoods, the upgrade to titanium drill bits makes a significant difference.