Brush vs Brushless Drill: Essential Power

Brush vs Brushless Drill: Essential Power for Your Projects

Choosing between a brush and brushless drill might seem confusing, but it’s simpler than you think! Brushless drills offer more power, last longer, and are more efficient than brushed drills. For woodworking beginners and DIYers, understanding this difference is key to picking the right tool for lasting project success and less frustration. Let’s break it down so you can power up your projects with confidence.

Hey there, aspiring woodworkers and DIY champions! Md Meraj here, ready to guide you through a tool decision that can truly make or break your projects: the difference between a brush drill and a brushless drill. It’s a common question, and honestly, it can feel a bit overwhelming with all the technical terms out there. But don’t you worry! We’re going to simplify it, just like we always do. Think of this as your friendly workshop chat, where we’ll uncover what makes these drills tick, why it matters for your DIY dreams, and how to pick the perfect one without feeling lost. Ready to learn how to make the best choice for your toolbox? Let’s dive in!

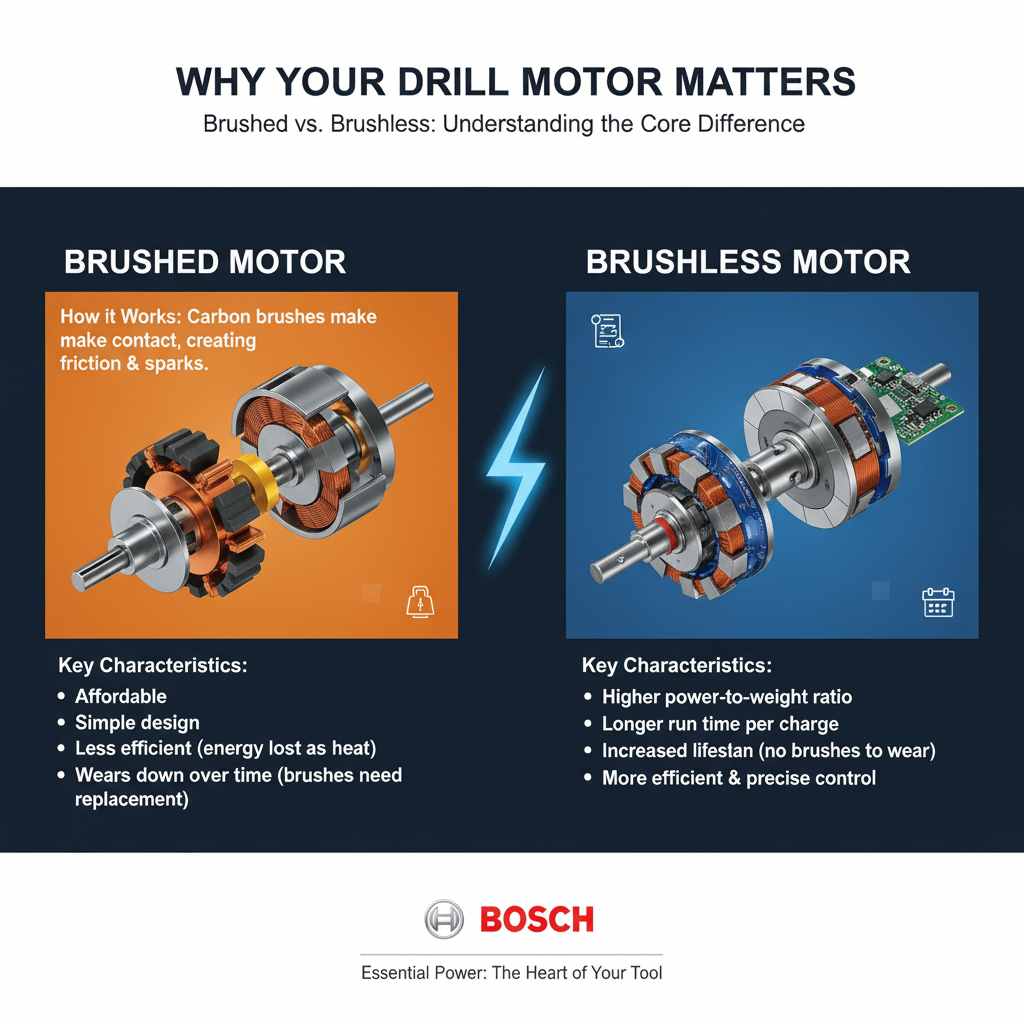

Why Your Drill Motor Matters

The heart of any drill is its motor. It’s what spins the chuck, driving screws and drilling holes. For a long time, the standard in drills was the “brushed” motor. It’s a tried-and-true design that has powered millions of projects. However, technology has marched on, bringing us the “brushless” motor. This new design offers some pretty significant advantages, especially for the home DIYer and woodworking hobbyist. Understanding the fundamental difference between how these two types of motors operate will help you make a smarter purchase and get more satisfaction from your tools.

Understanding Brushed Drills: The Classic Choice

Brushed drills are the veterans of the power tool world. They’ve been around forever and are the reason many of us started our DIY journeys. They work using a clever system of carbon brushes that make electrical contact with a rotating part called the rotor (or armature). This contact allows electricity to flow, creating the magnetic fields that make the motor spin.

Here’s a simple way to picture it: imagine little switches (the brushes) constantly tapping a spinning wheel to keep it turning.

How a Brushed Motor Works

1. Power Input: Electricity enters the motor.

2. Brush Contact: The carbon brushes press against the commutator (a segmented part of the rotor).

3. Electrical Flow: This contact allows electricity to flow to the coils on the rotor.

4. Magnetic Field Creation: The electrical current creates a magnetic field in the rotor.

5. Rotation: This magnetic field interacts with the stationary magnetic field of the stator (the outer part of the motor), causing the rotor to spin.

6. Commutation: As the rotor spins, the brushes move across different segments of the commutator, reversing the electrical current direction in the rotor coils. This “switching” action is crucial for continuous rotation.

Pros of Brushed Drills

Affordability: Generally, brushed drills are less expensive to manufacture, which translates to a lower price point for consumers. This makes them a very attractive option for beginners or those on a tighter budget.

Simplicity: The design is relatively straightforward and has been around for a very long time, meaning repairs, if needed, can sometimes be simpler.

Wide Availability: You’ll find a vast selection of brushed drills from numerous brands, making them easy to find in nearly any hardware store or online.

Cons of Brushed Drills

Wear and Tear: Those carbon brushes are designed to wear down over time. They are a consumable part, meaning they will eventually need to be replaced, adding a small maintenance cost and potential downtime to your projects.

Heat Generation: The friction between the brushes and the commutator creates heat. This can lead to the motor becoming less efficient and potentially overheating during prolonged, heavy-duty use.

Less Power & Efficiency: Brushed motors tend to be less efficient in converting electrical energy into rotational power compared to their brushless counterparts. This means they might not have the same raw power or runtime on a battery charge.

More Noise: The physical contact of the brushes can also contribute to a louder operating noise.

Exploring Brushless Drills: The Modern Powerhouse

Brushless drills are the newer generation of power tool technology. Instead of relying on physical brushes to conduct electricity, they use electronic controls called a “controller” or “driver” to manage the motor. This means the motor itself has no brushes to wear out. The electricity is delivered directly to electromagnets in the motor’s housing (the stator), and magnets on the rotor do the spinning.

Think of it like a high-tech remote control for the motor, making everything smoother and more efficient.

How a Brushless Motor Works

1. Electronic Control: The drill’s controller detects the rotor’s position.

2. Targeted Power: Based on the rotor’s position, the controller sends precise electrical pulses to specific coils in the stator.

3. Magnetic Field Interaction: These energized coils create magnetic fields that attract or repel the permanent magnets on the rotor.

4. Efficient Rotation: This precisely timed interaction causes the rotor to spin smoothly and powerfully.

5. No Brushes Needed: Because the electricity is switched electronically, there’s no need for physical brushes making contact.

Pros of Brushless Drills

Increased Power & Torque: Brushless motors are generally capable of delivering more power and torque. This means they can handle tougher jobs, like driving long screws into dense wood or drilling larger holes, with less effort.

Greater Efficiency: They are significantly more efficient, meaning they can get more work done on a single battery charge. This translates to longer runtimes and less time spent swapping batteries or charging.

Longer Motor Life: With no brushes to wear out, the motor itself lasts much longer. This means fewer potential repairs and a more durable tool investment.

Less Heat: The absence of brush friction means they run cooler, which helps maintain performance during demanding tasks and contributes to the motor’s longevity.

Quieter Operation: Generally, brushless drills operate more quietly than brushed models.

Compact Design: Brushless motors can often be made more compact, allowing for lighter and more ergonomic drill designs.

Cons of Brushless Drills

Higher Cost: The advanced technology and electronic controls make brushless drills more expensive upfront compared to brushed models.

Controller Complexity: While more durable, the electronic controller is a more complex component. If it fails, replacement can be more costly than replacing simple carbon brushes.

Brush vs Brushless Drill: A Direct Comparison

To really get a clear picture, let’s put them side-by-side. This table highlights the key differences you’ll encounter when choosing your next drill.

When to Choose Which: Practical Advice for Beginners

So, Md Meraj, which one should I buy? This is the million-dollar question for many starting out! It truly depends on your needs and budget.

When a Brushed Drill Might Be Your Best Start:

Limited Budget: If you’re just dipping your toes into DIY or woodworking and need a functional drill without breaking the bank, a brushed drill is a fantastic, reliable option. You can get a lot of work done with a good quality brushed drill.

Infrequent or Light Use: If you only plan to use your drill for occasional tasks around the house, like hanging shelves, assembling flat-pack furniture, or small home repairs, a brushed drill will serve you perfectly well for years.

Basic Projects: For simple drilling tasks and driving small-to-medium screws, a brushed drill has sufficient power.

When a Brushless Drill is Worth the Investment:

Frequent or Heavy Use: If you plan on spending a lot of time in your workshop, tackling larger projects, or using your drill almost daily, the durability and power of a brushless drill will pay off.

Tougher Materials: Working with hardwoods, large lumber, or needing to drill larger holes? The extra torque and power of a brushless drill will make these tasks significantly easier and more efficient.

Long-Term Value: While the initial cost is higher, the extended lifespan and reduced maintenance needs of a brushless drill can make it a more cost-effective choice over the many years you’ll own it.

Battery Life is Key: If you often work far from power outlets or simply dislike the interruption of frequent battery changes, the superior battery efficiency of a brushless drill is a major advantage.

Future-Proofing: Investing in brushless technology now means you’re acquiring tools that align with the latest advancements in power tool performance and efficiency.

Key Features to Look for in Either Drill Type

No matter which motor type you lean towards, there are other features that make a drill a great tool for your projects:

Voltage (V): This indicates the drill’s power. Common voltages are 12V, 18V, and 20V (often marketed as 20V MAX). Higher voltage generally means more power. For most DIYers and beginners, 18V or 20V MAX is a sweet spot.

Amp-Hours (Ah): This battery rating tells you how long the battery will last on a charge. A higher Ah rating means longer runtimes. Modern drills often come with 2.0 Ah or 4.0 Ah batteries.

Chuck Size: This is the part that holds the drill bit. Most drills have a 1/4-inch or 1/2-inch chuck. A 1/2-inch chuck can accommodate larger drill bits and is generally preferred for versatility.

Torque Settings (Clutch): This allows you to adjust the drilling power. It’s crucial for preventing over-driving screws (stripping the head or damaging the material) or for drilling pilot holes properly. Look for at least 10-15 torque settings.

Variable Speed Trigger: Most modern drills have this. It lets you control the speed of the drill bit by how hard you squeeze the trigger – slow for starting screws, faster for drilling.

LED Light: A built-in light that illuminates your work area is incredibly handy.

Ergonomics and Weight: The drill should feel comfortable in your hand, especially for prolonged use. Lighter drills can reduce fatigue. Check out brushless drills; they often make up for the controller’s weight with a more compact motor.

Understanding Tool Performance Standards

When looking at drill specifications, you’ll often see references to industry standards or performance metrics. For instance, the International Organization for Standardization (ISO) develops standards that ensure quality and interoperability across industries, including tools. While specific drill motor standards are not always prominently advertised to consumers, understanding metrics like torque (measured in inch-pounds or Newton-meters) and revolutions per minute (RPM) gives you a quantifiable way to compare drill capabilities. Higher torque is better for tough jobs, while higher RPM is good for fast drilling.

Maintenance Tips for Your Drill’s Longevity

To make sure your drill, whether brushed or brushless, lasts as long as possible and performs at its best:

Keep it Clean: Dust and debris are the enemies of power tools. After each use, wipe down your drill, especially around vents, to prevent buildup. Use compressed air to blow out dust from vents, but wear safety glasses!

Store Properly: Store your drill in a dry environment, away from extreme temperatures. Many drills come with a case, which is ideal for protection. Ensure batteries are stored according to the manufacturer’s recommendations, usually at a partial charge.

Manage Batteries: For rechargeable batteries (especially Lithium-ion used in most modern drills), avoid draining them completely. Charging them when they still have some juice is fine and can actually extend their life. Store batteries indoors, not in a hot car or garage.

Inspect Regularly: Periodically check the chuck for debris and make sure it tightens and loosens smoothly. For brushed drills, keep an eye on the brushes; if your drill starts losing power or sounds “off,” worn brushes could be the culprit.

Avoid Over-Stress: Don’t force the drill to do something it’s not designed for. If a bit is binding, stop, ease up, and try again. Using the right bit for the job is also crucial. Forcing a drill, especially an older brushed model, can lead to overheating or component failure. For deeper dives into tool maintenance, resources like the Occupational Safety and Health Administration (OSHA) offer general guidance on safe tool handling and maintenance, which is always a good foundational principle.

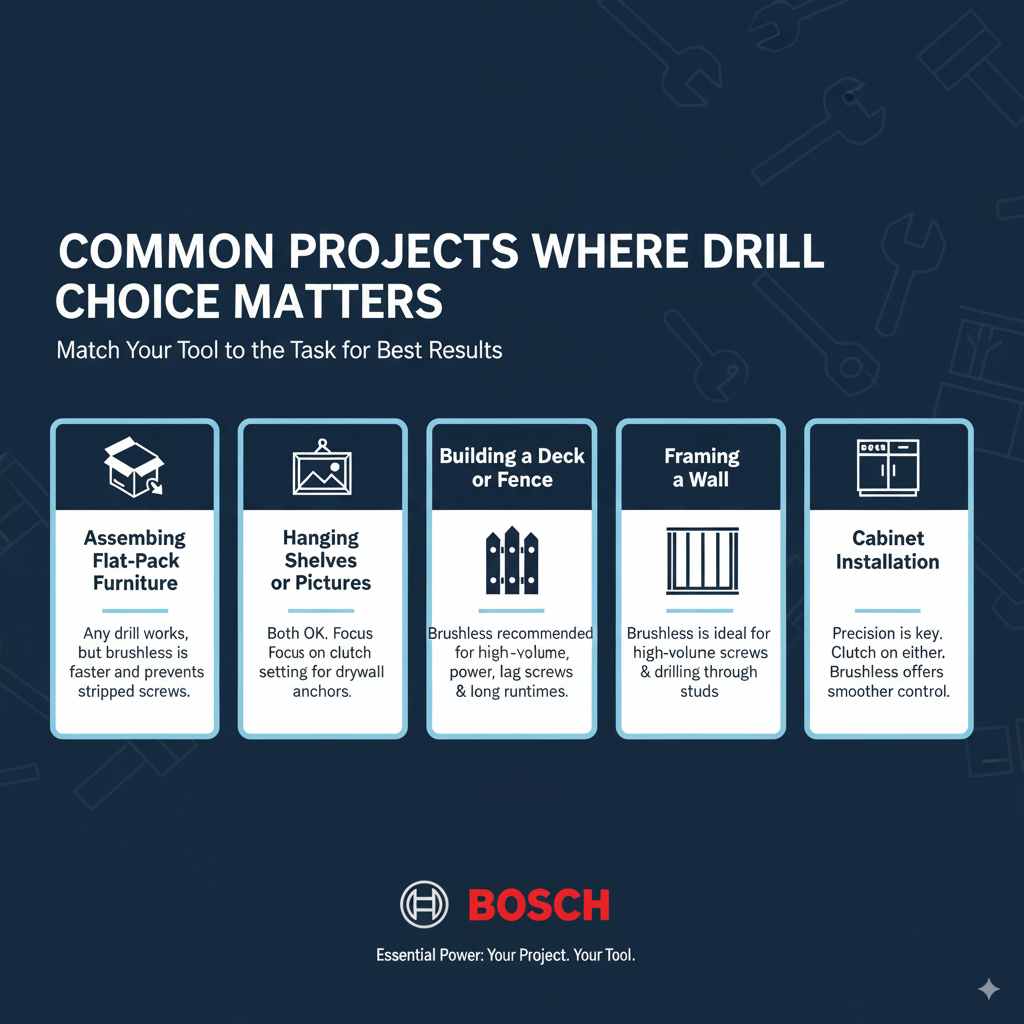

Common Projects Where Drill Choice Matters

Assembling Flat-Pack Furniture: Almost any drill will do, but a brushless drill with a good clutch setting will drive screws faster and more smoothly, preventing stripping.

Hanging Shelves or Pictures: A brushed or brushless drill is fine. Focus on getting a good clutch setting to avoid overtightening and damaging drywall anchors.

Building a Deck or Fence: This is where more power is beneficial. A brushless drill will handle the larger lag screws and longer runtimes needed for a big project much better.

Framing a Wall: You’ll be driving many screws and potentially drilling through studs. The power and stamina of a brushless drill are highly advantageous here.

Cabinet Installation: Precision is key. A good clutch setting on either drill type is essential, but the smoother operation of a brushless drill can make fine adjustments easier.

Frequently Asked Questions (FAQ) About Brush vs Brushless Drills

What is the main difference between a brushed and brushless drill?

The core difference lies in how their motors operate. Brushed drills use physical carbon brushes to transfer electricity, which wear out. Brushless drills use electronic controls instead, meaning no brushes to replace and more efficient power delivery. Are brushless drills more powerful than brushed drills?

Generally, yes. Brushless motors can deliver more torque and power more efficiently, making them better suited for demanding tasks. They also tend to have longer runtimes on a battery charge. Which type of drill is better for a beginner?

For a beginner on a budget or for light, occasional use, a brushed drill is a great starting point. If you plan on frequent DIY projects or tackling tougher jobs, investing in a brushless drill is often worth the extra cost for its performance and longevity. Do I need to replace brushes on a brushless drill?

No, that’s the beauty of brushless! Brushless drills do not have carbon brushes that wear out, so they require less maintenance in that regard and the motor typically lasts longer. How long do the batteries last in brushless drills compared to brushed?

Brushless drills are more energy-efficient. This means they can typically get more work done on a single battery charge compared to a brushed drill of similar voltage and battery capacity. Are brushless drills significantly more expensive?

Yes, brushless drills usually have a higher upfront cost due to the more advanced electronic components and motor technology. However, this can be offset by their longer lifespan and improved performance over time. Can I use the same batteries for brushed and brushless drills?

Typically, yes, if they are from the same brand and series. For example, if you have an 18V Bosch brushed drill and an 18V Bosch brushless drill, their batteries will likely be interchangeable. Always check the manufacturer’s specifications to be sure.

Conclusion: Powering Your Projects with Confidence

Well, there you have it! We’ve journeyed from the classic comfort of brushed drills to the innovative power of brushless technology. For us DIY enthusiasts and woodworking hobbyists, understanding this distinction is like knowing which saw to grab for a specific cut.

A brushed drill is a loyal, affordable companion for simpler tasks and budgets. It’s the workhorse that gets many of us started on our creative journeys. But for those moments when you need that extra bit of oomph, that longer stretch of power, or the assurance of a tool built to last through countless projects, a brushless drill is an investment that truly pays off.

Whichever you choose, remember that the most important tool is the one in your hands, used with care and a willingness to learn. Keep practicing, keep building, and most importantly, keep creating those amazing projects! Happy building, everyone!