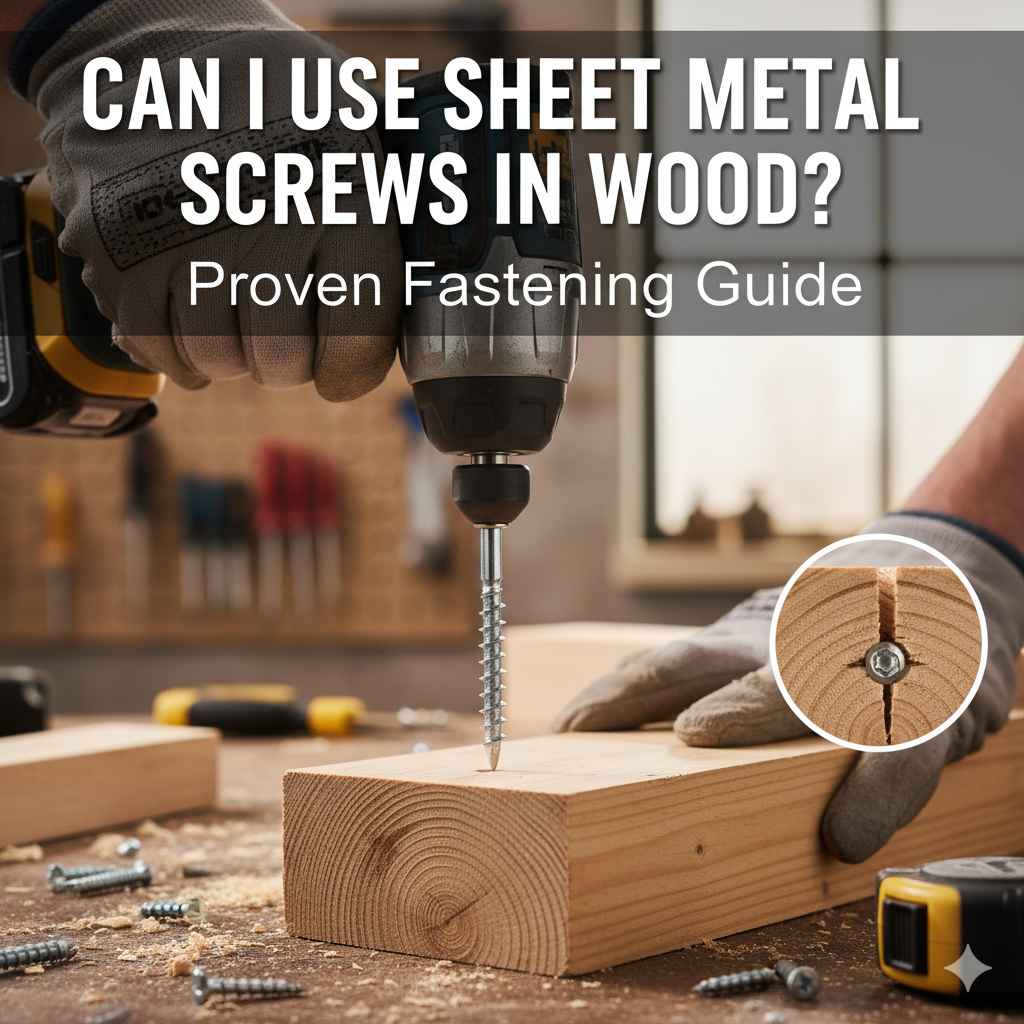

Can I Use Sheet Metal Screws In Wood? Proven Fastening

Yes, you can use sheet metal screws in wood, but with important considerations! While they can work in a pinch, they aren’t ideal for most woodworking projects. Understanding their design and limitations will help you choose the right fastener for a strong, lasting hold. We’ll guide you through when it’s okay, when to avoid them, and how to use them effectively if you must.

Hey there, fellow DIYers and woodworking enthusiasts! Md Meraj here, ready to tackle a question that pops up surprisingly often in workshops and garages everywhere. You’re in the middle of a project, you reach for your screws, and you realize you’ve only got sheet metal screws on hand. That little voice in your head asks, “Can I use these on wood?” It’s a common worry, especially when you want your projects to be sturdy and look great.

Sometimes, the right tool for the job isn’t readily available, and we’re tempted to make do with what we have. This is especially true with fasteners – screws are screws, right? Well, not exactly! While a sheet metal screw can technically go into wood, it might not give you the best results. We’re going to break down exactly why that is, when it might be acceptable, and what you should do instead. Stick with me, and by the end of this guide, you’ll know exactly how to pick the perfect screw for your wooden projects, ensuring strength and longevity!

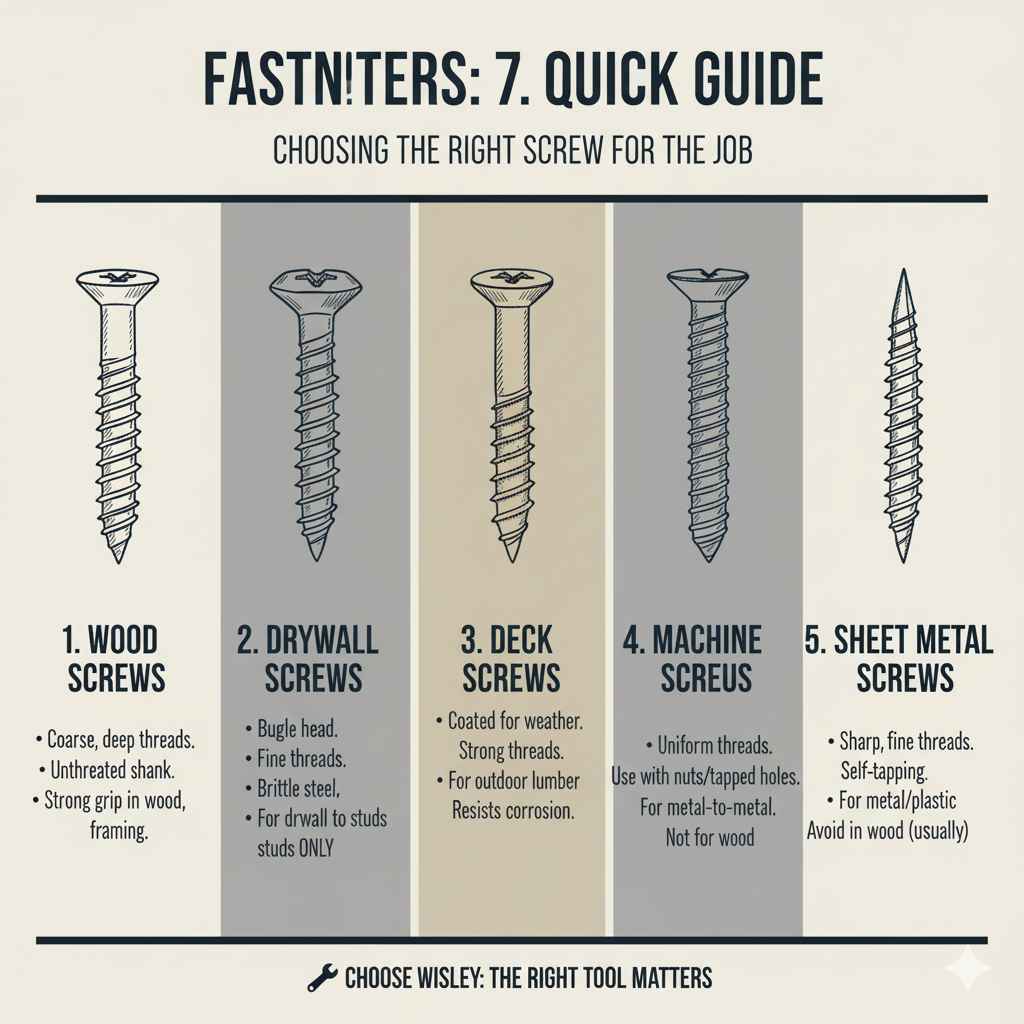

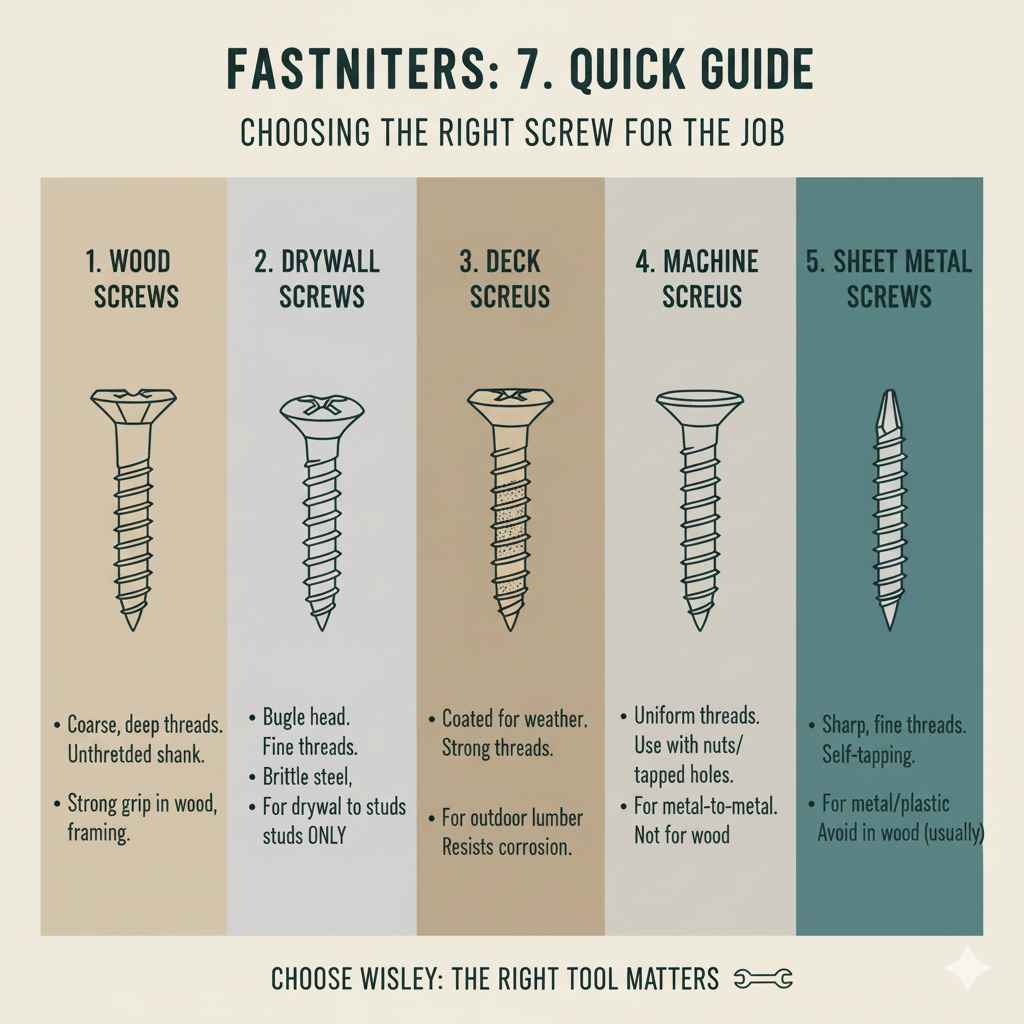

Understanding Different Types of Screws: A Quick Look

Before we dive into sheet metal screws and wood, it’s helpful to know that not all screws are created equal. They are designed with specific materials and tasks in mind. Think of it like using a hammer for nails versus a screwdriver for screws – they serve different purposes!

Here’s a basic rundown of common screw types you might encounter:

Wood Screws: These are the champions for woodworking. They typically have a coarser thread that’s designed to grip wood fibers effectively. They often have an unthreaded shank section just below the head, which helps pull the pieces of wood together tightly without stripping.

Drywall Screws: Easily recognizable by their bugle-shaped head (which countersinks without tearing the paper of drywall) and sharp point. They are brittle and designed for holding drywall to studs, not for the stresses of woodworking.

Deck Screws: Similar to wood screws but usually coated for corrosion resistance, making them perfect for outdoor projects like decks. They have strong threads for holding power in treated lumber.

Machine Screws: These have a uniform thread size along their entire length and are meant to be used with nuts or tapped holes in metal. Definitely not for wood!

Sheet Metal Screws (Self-Tapping Screws): Ah, the star of our show! These screws have sharp threads that run all the way up the shank and are designed to cut their own threads into metal or plastic. More on these in a bit!

Understanding these differences helps us appreciate why choosing the right screw matters for a durable and beautiful project.

What Exactly Are Sheet Metal Screws?

Sheet metal screws, also commonly called self-tapping screws, are engineered for a specific purpose: fastening thin materials like metal sheets, plastics, or even sometimes fiberglass. The key characteristics that define them are:

Sharp Threads: They have aggressive, sharp threads that are designed to cut into the material they are being driven into. This allows them to create their own mating threads, hence “self-tapping.”

Tapered Tip: Many sheet metal screws have a tapered tip. This helps them easily pierce the material and start the threading process without the need for a pre-drilled pilot hole in some cases (though pre-drilling is often recommended for better control and thread engagement).)

Uniform Threading: Unlike many wood screws, the threads on a sheet metal screw typically run all the way up to the head. This means there’s no smooth shank to pull material together.

Hardened Steel: They are usually made from hardened steel to withstand the forces required to cut threads into metal.

Their design makes them excellent for joining thin metal pieces. However, these very features can present challenges when trying to use them in wood.

Can You Use Sheet Metal Screws in Wood? The Short Answer and Why It Matters

So, to get straight to the point: Yes, you can use sheet metal screws in wood, but it’s generally not the best practice for strong, long-lasting wooden structures.

Why the caution? It all comes down to how these screws interact with wood fibers compared to how they interact with metal.

Wood is a softer, more fibrous material than metal. When you drive a screw into wood, you want it to anchor securely into those fibers. The aggressive, sharp threads of a sheet metal screw can sometimes chew up the wood fibers rather than cutting clean threads and providing a strong grip. This can lead to a weaker connection.

Furthermore, the continuous threads on sheet metal screws mean they don’t have that unthreaded shank that allows a wood screw to pull two pieces of wood together snugly. Instead, the threads catch on both pieces of wood, which can leave a small gap between them.

Think of it this way: a wood screw is like a specialized key designed to fit perfectly into a wooden lock. A sheet metal screw is more like a general-purpose tool that can force its way in but might not offer the most secure or elegant fit.

When It Might Be Okay to Use Sheet Metal Screws in Wood

While not ideal, there are a few specific situations where using sheet metal screws in wood might be acceptable, especially for temporary fixes or very light-duty applications.

Temporary Fastening: If you need to temporarily hold two pieces of wood together for gluing, clamping, or to test a fit before disassembling, a sheet metal screw can do the job. The hold won’t be permanent or super strong, but it will keep things in place.

Very Light-Duty Applications: For projects where the screw is not bearing any significant weight or stress – think attaching a thin decorative trim piece that’s also glued, or securing a small, lightweight bracket where structural integrity isn’t a concern.

Soft Woods (with caution): In very soft woods like pine, the sharp threads might do a slightly better job of biting without completely destroying the wood fibers. However, the issues with the continuous thread and lack of a pull-down shank still apply.

No Other Option Available: In an emergency or a situation where you absolutely cannot get to a store to buy proper wood screws, and the project demands a fastener, a sheet metal screw can be used. Just be aware of its limitations.

Even in these cases, it’s wise to proceed with caution and consider the potential downsides.

When You Should Absolutely Avoid Using Sheet Metal Screws in Wood

For the vast majority of your woodworking projects, you should steer clear of sheet metal screws. Using them in these scenarios can lead to weak joints, project failure, and frustration.

Structural Components: Any part of your project that needs to bear weight or withstand force – cabinet frames, table legs, deck railings, shelves that will hold heavy items, or wall-mounted shelves. A weak connection here can be dangerous.

Drawer Slides or Moving Parts: The continuous thread can bind or strip the wood easily, preventing smooth operation.

Joinery Requiring Tightness: If you need to pull two pieces of wood together flush, the continuous thread of a sheet metal screw will work against you.

Hardwoods: Driving sheet metal screws into hardwoods like oak or maple is almost guaranteed to strip the wood before they get a good grip, leading to a very weak hold.

Projects Requiring Fine Craftsmanship: For furniture or decorative pieces where a clean finish and strong, invisible joints are desired, sheet metal screws are a poor choice.

Outdoor Projects (without proper coating): Standard sheet metal screws are often not galvanized or coated for rust prevention. They will quickly corrode when exposed to moisture, weakening the screw and staining the wood.

In essence, if the joint needs to be strong, durable, and reliable, reach for the right tool – a wood screw!

How to Use Sheet Metal Screws in Wood (If You Must)

If you find yourself in a situation where using sheet metal screws in wood is your only option, here are some tips to maximize your chances of success and minimize potential damage. This is about making the best of a less-than-ideal situation!

1. Choose the Right Size:

Select a sheet metal screw that is appropriately sized for the thickness of the wood. A screw that is too long can poke through the other side, and one that is too short won’t have enough thread engagement.

2. Pilot Holes are Crucial:

This is probably the most important step! Unlike in sheet metal where they can often tap their own threads, wood absolutely benefits from a pilot hole.

- Drill a pilot hole that is slightly smaller than the screw’s minor diameter (the diameter at the root of the threads). This is often a bit tricky to determine for beginners. A good rule of thumb is to use a drill bit that is about 50-70% of the screw’s shank diameter.

- For harder woods, make the pilot hole slightly larger to accommodate the threads without splitting the wood or stripping out.

- Ensure the pilot hole is drilled straight and deep enough for the screw length you are using.

Referencing resources like Popular Mechanics’ guide on pilot hole sizes can be very helpful.

3. Drive Slowly and Carefully:

Use a drill or a screwdriver at a slow speed. Start by hand to ensure the screw is going in straight. As you drive the screw, pay attention to the resistance. If you feel the screw start to spin freely without tightening, you’ve likely stripped the wood, and the connection will be weak.

4. Avoid Overtightening:

Sheet metal screws, especially their threads, can easily strip wood fibers. Once the screw is snug, stop. Overtightening will just damage the hole and weaken the connection. Since they don’t have a smooth shank to pull pieces together, over-tightening can also pull the pieces apart slightly.

5. Pre-drill for the Head (Optional but Recommended):

If you want the screw head to sit flush or slightly below the surface (countersunk), you’ll need to pre-drill a clearance hole for the screw head. This hole should be slightly larger than the screw head diameter and only go as deep as you want the head to sit.

6. Consider Reinforcement:

If you’re using sheet metal screws for something where strength is even remotely important, consider reinforcing the joint with wood glue or other mechanical fasteners (like L-brackets) if aesthetics allow.

The Ideal Fastener: Wood Screws

Now that we’ve discussed sheet metal screws in wood, let’s talk about what you should be using for most of your woodworking projects: wood screws. They are specifically designed for this purpose and will give you the best results.

Here’s why wood screws are superior for woodworking:

Thread Design: Wood screws have coarser, deeper threads that are angled to grip wood fibers more effectively, creating a much stronger hold. They are less likely to strip the wood than sheet metal screws.

Unthreaded Shank: Many wood screws have an unthreaded portion below the head. When you drive them, this smooth shank pulls the piece of wood with the drilled hole down tightly against the piece receiving the screw tip. This is crucial for creating strong, flush joints.

Variety for Applications: Wood screws come in a huge variety of types, head styles (flat, round, pan, washer), and materials (steel, stainless steel, brass) to suit countless woodworking needs. You can find specialized screws for everything from fine furniture to robust outdoor structures.

Ease of Use: While pilot holes are still often recommended, wood screws generally perform much better and are more forgiving in wood than sheet metal screws.

A quick look at resources from organizations like the Woodworking Network highlights the importance of choosing the correct fastener.

Sheet Metal Screws vs. Wood Screws: A Comparison Table

To summarize the core differences and help you make informed decisions, here’s a table comparing sheet metal screws and wood screws when used in wood:

| Feature | Sheet Metal Screw (in Wood) | Wood Screw (in Wood) |

|---|---|---|

| Primary Design Purpose | Fastening sheet metal, plastic, thin materials. Acts as a self-tapping screw. | Fastening wood to wood. Designed for grip and holding power in wood fibers. |

| Thread Type | Sharp, aggressive, often fine threads that run the full length of the screw. | Coarser, deeper threads designed to bite into wood. Often has an unthreaded shank. |

| Holding Power in Wood | Generally weaker. Sharp threads can strip wood fibers. Continuous thread can lead to gaps. | Much stronger. Coarser threads grip wood fibers effectively. Unthreaded shank allows for tight pull-down. |

| Best For | Temporary fixes, very light-duty applications where strength isn’t critical. | Most woodworking projects, structural joints, furniture, cabinetry, outdoor projects. |

| Pilot Hole Necessity | Highly recommended to prevent splitting and aid thread cutting. Needs to be sized carefully. | Often recommended for hardwoods and to ensure straight driving, but their design is more forgiving. |

| Risk of Stripping Wood | High, especially if not using the correct pilot hole or if overtightened. | Lower, especially when using appropriate pilot holes for the wood type. |

| Cost | Often less expensive per screw. | Can be slightly more expensive, but often better value for performance. |

As you can see from the table, wood screws are the clear winner for most woodworking tasks. Investing a little extra in the correct fasteners will save you time, frustration, and ensure the longevity and integrity of your projects.

Choosing Drill Bits for Wood Screws

For optimal performance with wood screws, proper pilot hole drilling is key. Here’s a general guide:

- Pilot Hole for the Shank: This is the main hole that the screw threads will bite into. The diameter of this hole should be about 50-70% of the major diameter of the screw (the widest part of the threads). For hardwoods, you might go slightly larger (closer to 70%) to prevent splitting.

- Clearance Hole for the Shank (Optional): If you’re using a screw with an unthreaded shank and want to pull two pieces of wood together tightly, you’ll drill a clearance hole in the top piece of wood. This hole should be the same diameter as the screw’s unthreaded shank. This allows the shank to pass through freely so the threads can grab the bottom piece and pull it tight.

- Countersink Hole (Optional): If you want the screw head to sit flush with the surface of the wood (like with flat-head screws), you’ll drill a shallow hole the diameter of the screw head. This can be done with a larger drill bit, a specialized countersink bit, or even a spade bit used carefully.

A handy resource for understanding pilot hole sizes is often found on manufacturer websites or DIY sites that cater to woodworkers. For example, sites like Rockler.com offer excellent guides and tool recommendations.

Conclusion: Prioritize the Right Screw for Stronger Wood Projects

So, there you have it! While you can* use sheet metal screws in wood in a pinch for very light-duty or temporary applications, they are far from ideal for most woodworking projects. Their design, optimized for metal, can lead to weaker joints, stripped wood, and gaps when used incorrectly in wood.

For sturdy, reliable, and beautiful results every time, always opt for wood screws.