Can Sheet Metal Screws Be Used In Wood? Essential Guide

Yes, sheet metal screws can generally be used in wood, but with important considerations. For best results and durability, specially designed wood screws are often preferred. Understanding the differences and when to use which will ensure your projects are strong and lasting.

Woodworking can sometimes feel like a puzzle, and one of the pieces that often causes confusion for beginners is choosing the right fastener. You’re working on a project, and you have a box of screws handy. They look sturdy, they’re readily available, and you wonder, “Can sheet metal screws really work in wood?” It’s a common question, and it’s totally understandable to want to use what you have. This guide is here to demystify this very topic. We’ll walk through the ins and outs, helping you make confident choices for your woodworking adventures. By the end, you’ll know exactly when and how to use sheet metal screws in wood, and when it’s better to reach for a different type of screw.

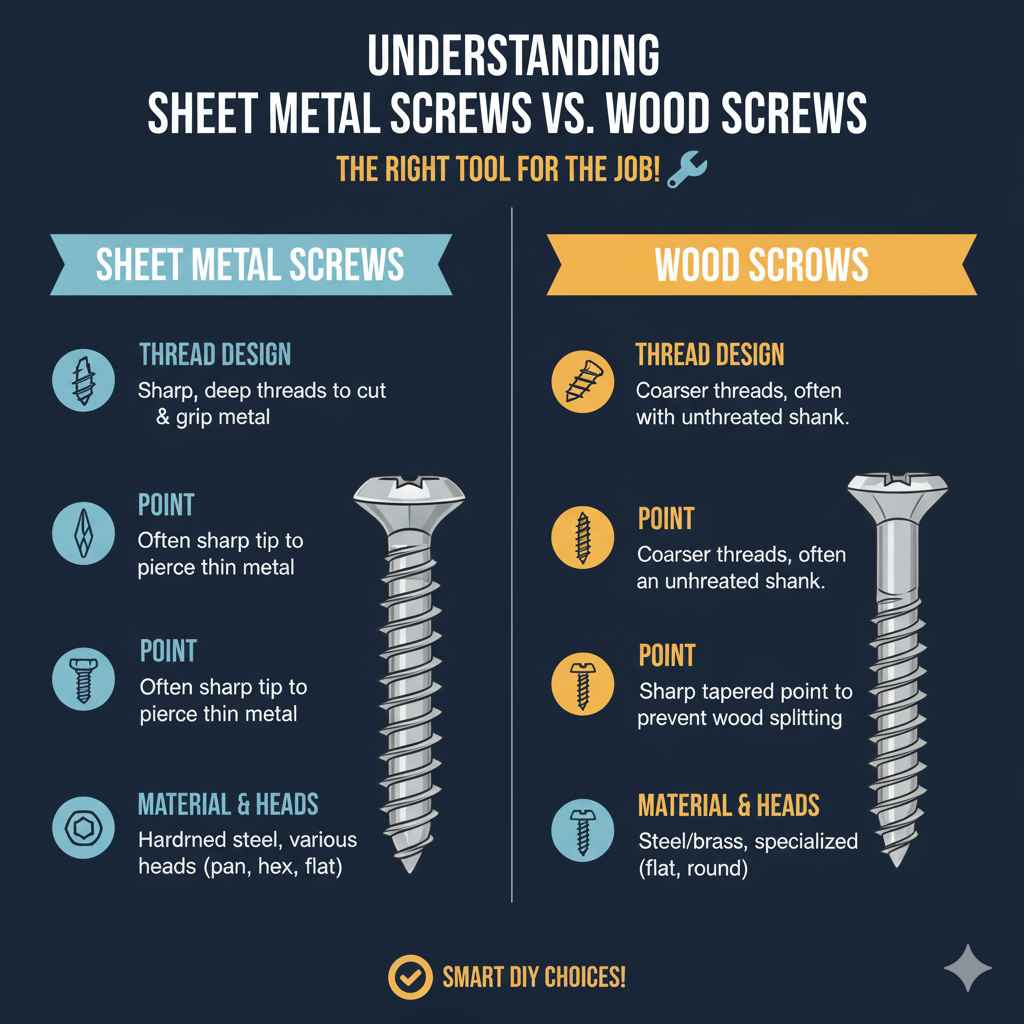

Understanding Sheet Metal Screws vs. Wood Screws

Before we dive into using sheet metal screws in wood, it’s helpful to know what makes them different from screws designed specifically for wood. Think of it like using the right tool for the job – each screw has its purpose!

What are Sheet Metal Screws?

Sheet metal screws are, as their name suggests, designed primarily for fastening sheet metal to itself or to other materials. They are known for their strength and their ability to tap their own threads.

Thread Design: Sheet metal screws typically have sharp, deep threads that run all the way up to the head. This aggressive thread design helps them grip tightly into thin materials and cut through them effectively.

Point: Many sheet metal screws have a sharp, pointed tip, allowing them to pierce through thin metal without needing a pilot hole. Some have a blunt end, but the threads are still very pronounced.

Head Types: They come in various head types, like pan heads, hex heads, and flat heads, often designed to sit flush or provide a stable bearing surface.

Material: They are usually made from hardened steel, stainless steel, or brass, offering good corrosion resistance and strength.

What are Wood Screws?

Wood screws are engineered specifically for woodworking. Their design focuses on creating a strong, reliable joint in wood.

Thread Design: Wood screws have threads that are typically coarser than sheet metal screws. Crucially, they often have a section near the head that is unthreaded (called a “shank”). This shank allows the screw to pull two pieces of wood tightly together once the threads engage in the bottom piece. The threads are also often tapered to better grip wood fibers.

Point: Wood screws usually have a sharp, tapered point designed to easily penetrate wood without splitting it, especially when used with a pilot hole.

Head Types: In addition to common types, wood screws often feature specialized heads like oval or round heads for decorative purposes or flat heads for countersinking into wood.

Material: They are commonly made from steel (often coated for corrosion resistance) or brass.

Can You Use Sheet Metal Screws in Wood? The Short Answer

The truthful answer is: Yes, you can use sheet metal screws in wood, but it’s not always the ideal choice. They can work for certain applications, especially in softer woods or for temporary fixings. However, for strong, permanent, and aesthetically pleasing wood joints, dedicated wood screws are usually superior.

When Sheet Metal Screws Might Work in Wood

Softwoods: They can perform acceptably in softer woods like pine or fir. Their aggressive threads can bite into the wood fibers.

Thin Wood: If you’re attaching a thin piece of wood (like a veneer or a thin plywood panel) to another piece, sheet metal screws might suffice.

Temporary Fixings: For projects that don’t require a lot of strength or longevity, they can be a quick option.

When No Other Option is Available: In a pinch, if it’s the only screw you have, they can sometimes get the job done.

Why Dedicated Wood Screws Are Usually Better

Stronger Hold: The shank on wood screws allows for superior clamping power, pulling the pieces together tightly.

Less Risk of Splitting: The tapered design and often slightly blunter tip of wood screws help prevent the wood from splitting, especially when a pilot hole is used.

Better Aesthetics: Wood screws often have heads designed to countersink smoothly into wood, providing a cleaner finish.

Durability: Wood screws are designed for the way wood behaves, offering a more durable and lasting connection.

Using Sheet Metal Screws in Wood: A Step-by-Step Guide

If you’ve decided to use sheet metal screws in wood, or if it’s your only option, here’s how to do it effectively and minimize potential problems.

Step 1: Choose the Right Sheet Metal Screw

Not all sheet metal screws are created equal. For wood, look for:

Coarser Threads: If possible, select sheet metal screws with threads that are a bit more spaced out, as these tend to grip wood better than very fine threads.

Appropriate Length and Diameter: Ensure the screw is long enough to penetrate both pieces of wood sufficiently (at least two-thirds of the way into the second piece) but not so long that it pokes through. The diameter should match the holding power needed.

Material: Stainless steel screws offer good corrosion resistance if your project will be exposed to moisture.

Step 2: Measure and Mark

Before you drive any screws, take the time to measure and mark precisely where you want the pieces to join. This ensures accuracy and a professional-looking result.

Use a tape measure and pencil to plot the screw locations.

If you’re joining edges, use a square to ensure your marks are at a 90-degree angle.

Step 3: Pilot Holes are Your Friend!

This is probably the MOST important step when using sheet metal screws in wood. Their aggressive threads can easily split wood, especially hardwoods or near edges. A pilot hole prevents this.

Determine Pilot Hole Size: You’ll need a drill bit that is slightly smaller than the minor diameter (the diameter at the base of the threads) of your sheet metal screw. For hardwoods, you might even go slightly larger. A good rule of thumb for softwoods is a bit that matches the screw’s core diameter (the solid rod part before threads). For harder woods, use a bit that’s slightly larger than this core diameter.

Drill the Pilot Hole: Using your chosen drill bit and a drill/driver, carefully drill a hole at each marked location.

Ensure the drill is held straight and perpendicular to the wood surface.

Drill to a depth that is slightly less than the screw’s intended penetration. This allows the screw’s threads to bite into the wood effectively.

Countersinking (Optional but Recommended): For a cleaner look, especially if you want the screw head to sit flush or below the wood surface, you can create a countersink. Use a countersink bit that matches the head of your screw to create a small recess at the pilot hole.

Step 4: Drive the Screw

Once your pilot holes are drilled and countersunk (if desired), it’s time to drive the screws.

Use the Right Bit: Make sure you have the correct driver bit (e.g., Phillips, Torx, Square) for your screw head. Using the wrong bit can strip the screw head, making it difficult to drive or remove.

Start Slowly: Begin driving the screw slowly and gently. Let the screw’s threads catch the wood.

Maintain Straightness: Keep the drill/driver as straight as possible. Driving screws at an angle can weaken the joint and potentially strip the threads in the wood.

Don’t Overtighten: As the screw tightens, you’ll feel increased resistance. Stop driving once the head is flush (or countersunk as desired) and the pieces are pulled together snugly. Overtightening can strip the threads in the wood, causing the screw to spin freely and lose its holding power.

When to Avoid Sheet Metal Screws in Wood

While we’ve covered how to use them, there are definitely situations where you should steer clear of sheet metal screws for wood projects.

Structural Components: For anything that bears significant weight or is critical for the stability of a structure (e.g., load-bearing shelves, framing, deck railings), always use screws specifically designed for structural wood applications. These have better shear and pull-out strength.

Hardwoods: While possible with pilot holes, dense hardwoods can be tough on sheet metal screws. They are more prone to stripping the wood fibers or even breaking the screw.

Fine Furniture or Visible Projects: For any project where appearance is important, a wood screw will provide a cleaner finish and better holding power. The aggressive threads of sheet metal screws can sometimes mar the wood surface.

High-Stress Joints: If the joint will experience a lot of force, vibration, or movement, the less ideal thread engagement of a sheet metal screw might lead to failure over time.

Cabinetry: Cabinet doors and drawers require strong, secure fastenings. While sheet metal screws might hold initially, they are not designed for the repeated stress.

A Quick Comparison: Sheet Metal Screws vs. Wood Screws for Wood

To summarize the key differences and help you decide, here’s a handy table:

| Feature | Sheet Metal Screws | Wood Screws |

|---|---|---|

| Primary Use | Fastening sheet metal | Fastening wood to wood |

| Thread Design | Sharp, deep, often continuous to head | Coarser, often with a smooth shank near head |

| Holding Power in Wood | Moderate (can strip easily) | Excellent (designed for wood fibers) |

| Risk of Splitting Wood | High (requires pilot hole) | Lower (especially with pilot hole) |

| Appearance in Wood | Can be less clean, aggressive threads | Designed for flush or elegant finish |

| Pilot Hole Necessity | Highly recommended for wood | Often recommended, especially in hardwoods |

| Best for | Light-duty, temporary, softwoods | Most woodworking applications, structural joints |

Pros and Cons of Using Sheet Metal Screws in Wood

Like any tool or fastener, there are advantages and disadvantages to consider.

Pros:

Availability: Often readily available in many hardware stores and workshops.

Cost-Effective: Can be cheaper than specialized wood screws in some cases.

Good for Thin Materials: Their sharp threads can pierce and hold thin materials well.

Self-Tapping Capability: Can sometimes create their own starting point, though pilot holes are still advised for wood.

Cons:

Risk of Splitting Wood: Aggressive threads increase the chance of splitting, especially near edges or in hardwoods.

Lower Holding Power: Generally provide a less secure and durable connection in wood compared to wood screws.

Stripping Threads is Easier: Both the screw head and the threads within the wood are more prone to stripping.

Less Aesthetic Appeal: The thread design isn’t optimized for clean integration into wood surfaces.

Potential for Wood Damage: May tear wood fibers more than a dedicated wood screw.

Alternatives and When to Use Them

Knowing the alternatives can save you a lot of trouble and result in better projects.

Wood Screws (Standard)

These are the go-to for most woodworking. They come in various lengths, diameters, and head types to suit almost any task. Their design, especially the unthreaded shank, allows for superior pull-down power.

Deck Screws

Designed for outdoor use, deck screws are incredibly strong and corrosion-resistant. They have aggressive threads and often a sharp point. They are excellent for wood-to-wood connections in demanding environments, though their appearance might be a bit industrial for fine furniture. For more information on choosing the right fasteners for outdoor projects, check out resources from organizations like the North Carolina State University Extension which offers great insights into wood construction and fasteners.

Cabinet Screws

These are specialized wood screws designed for joining cabinet components. They often have a wide, flat head with a washer-like bearing surface to prevent pull-through in particleboard or MDF, and a specific thread pattern for these materials.

Lag Screws (Lag Bolts)

For very heavy-duty applications (like attaching beams or large structural elements), lag screws are the answer. They are essentially large wood screws with a hex head, requiring a wrench or socket to drive.

Drywall Screws

Important Note: While they look somewhat similar and are readily available, drywall screws are brittle and not suitable for structural woodworking. They are designed to hold drywall to studs and can snap under lateral stress. Avoid using them for anything other than their intended purpose.

Tips for Success

Always Pre-Drill: I can’t stress this enough! For sheet metal screws in wood, a pilot hole is not optional; it’s essential.

Go Slow: When driving any screw, a controlled speed ensures better engagement and less chance of error.

Test on Scrap Wood: If you’re unsure about how a screw will perform in a specific type of wood, practice on a scrap piece first.

Consider the Wood Type: Hardwoods require more careful pilot hole sizing than softwoods. The WoodworkingTools.ie guide to wood types offers a good overview of their properties.

Safety First: Always wear safety glasses when drilling or driving screws to protect your eyes from flying debris.

Frequently Asked Questions (FAQ)

Q1: Will using sheet metal screws in wood make my project weak?

It can, depending on the application. For light-duty tasks, they might be fine. However, for structural integrity or joints that will experience stress, dedicated wood screws are much stronger and more reliable.

Q2: How deep should a pilot hole be for a sheet metal screw in wood?

The pilot hole should be slightly smaller than the screw’s core diameter and about two-thirds to three-quarters of the length the screw will penetrate into the second piece of wood. This allows the threads to grip effectively.

Q3: Can I use sheet metal screws for outdoor wood projects?

You can, especially if they are stainless steel. However, dedicated exterior wood screws or deck screws are usually better as they are designed for the forces and moisture exposure often found outdoors.

Q4: What’s the biggest risk of using sheet metal screws in wood?

The biggest risk is splitting the wood, especially if you don’t pre-drill a pilot hole or if you’re working close to the edge of the wood. They can also strip out of the wood more easily than wood screws.

Q5: Are sheet metal screws harder to drive into wood than wood screws?

Once you have a pilot hole, sheet metal screws can be relatively easy to drive due to their sharp threads. However, without a pilot hole, they are much more likely to split the wood or get stuck.

Q6: Can I use sheet metal screws to attach metal to wood?

Absolutely! This is one of their primary uses. The sharp, self-tapping threads excel at biting into wood while also securely fastening metal components.

Conclusion

So, after all this, can sheet metal screws be used in wood? The answer is a nuanced yes. They can be a functional fastener in many scenarios, especially when simplicity and cost are key, or for lighter applications. Just remember that their aggressive thread design, optimized for metal, can be a double-edged sword in wood, increasing the risk of splitting and potentially offering less long-term holding power than screws specifically engineered for wood.

For beginners, the key takeaway is this: if your project demands strength, durability, and a clean finish, reach for dedicated wood screws. They are designed to interact with wood fibers in the best possible way, ensuring your hard work stands the test of time. However, if you find yourself in a pinch, or if the application is simple and low-impact, using sheet metal screws with a proper pilot hole can certainly get the job done without disaster. Always weigh the needs of your project, consider the type of wood you’re using, and prioritize the longevity and safety of your creation. Happy building!