Your Ultimate Guide to DeWalt Circular Saw and Multi-Tool: Power, Precision, and Versatility for Woodworking

Hey there, fellow woodworking enthusiast! If you’re like me, you’ve probably spent hours in your workshop, dreaming up projects and searching for tools that make your work easier, faster, and more precise. That’s why I’m excited to dive into the world of DeWalt circular saws and multi-tools with you today. These tools are game-changers for anyone who loves woodworking, whether you’re building furniture, tackling home renovations, or crafting intricate designs. I’ve been using DeWalt tools for years, and I can tell you firsthand how their circular saws and multi-tools bring power, durability, and versatility to every project.

In this guide, I’ll walk you through everything you need to know about these tools, from their standout features to practical tips for getting the most out of them. So, grab a cup of coffee, settle in, and let’s explore why DeWalt’s circular saws and multi-tools are must-haves for your workshop!

Why DeWalt Stands Out in the Woodworking World

Let me start by saying that DeWalt is a name I trust. When I first started woodworking, I tried tools from various brands, but DeWalt quickly became my go-to. Why? Because their tools are built to last, designed with the user in mind, and packed with features that make tough jobs feel effortless. Whether you’re a beginner cutting your first piece of plywood or a seasoned pro crafting custom cabinetry, DeWalt’s circular saws and multi-tools deliver the performance you need.

Their cordless designs, powerful motors, and innovative technology make them perfect for both small DIY projects and heavy-duty tasks. Plus, their bright yellow and black design just screams reliability, don’t you think? Let’s break down these tools one by one and see what makes them so special.

DeWalt Circular Saws: Power and Precision in Every Cut

When I think about cutting through thick oak or ripping plywood sheets, my DeWalt circular saw is the first tool I reach for. These saws are built to handle a wide range of materials with ease, and they’ve never let me down. Let’s talk about what makes DeWalt circular saws so impressive.

The Heart of the Tool: Powerful Motors

One thing I love about DeWalt circular saws is their powerful motors. For example, the DeWalt 20V MAX XR 7-1/4 in. Circular Saw with POWER DETECT technology has a motor that spins the blade at up to 5,500 RPM. That’s more than enough power to slice through hardwoods, softwoods, and even some metals. I’ve used this saw to cut through 2-inch oak boards, and it glides through like a hot knife through butter. The motor’s brushless design means less maintenance and longer runtime, which is a huge plus when I’m working on big projects.

Cordless Freedom with FLEXVOLT and POWER DETECT

If you’ve ever tripped over a cord in the middle of a cut, you’ll appreciate DeWalt’s cordless circular saws. Their 20V MAX and 60V MAX FLEXVOLT batteries are a game-changer. The FLEXVOLT system is especially cool because it automatically switches voltage depending on the tool. For example, I can use the same battery on my 20V circular saw for lighter tasks and then pop it into a 60V MAX tool for heavy-duty cuts. The POWER DETECT technology takes it up a notch by adjusting the saw’s output based on the battery’s power, giving me up to 54% more power when I use a higher-capacity battery. This means I can keep cutting without worrying about the battery dying halfway through a project.

Blade Options for Every Job

DeWalt circular saws come with carbide-tipped blades, typically ranging from 6-1/2 inches to 7-1/4 inches. I’ve found that the 6-1/2-inch blade is perfect for lighter tasks like trimming plywood, while the 7-1/4-inch blade is my go-to for thicker materials. The blades are designed for clean cuts, but here’s a tip: always check the number of teeth on the blade.

A blade with more teeth (like 24 or more) gives smoother cuts for finish work, while fewer teeth (around 18) are better for rough cuts. I keep a few different blades in my workshop so I’m ready for any job.

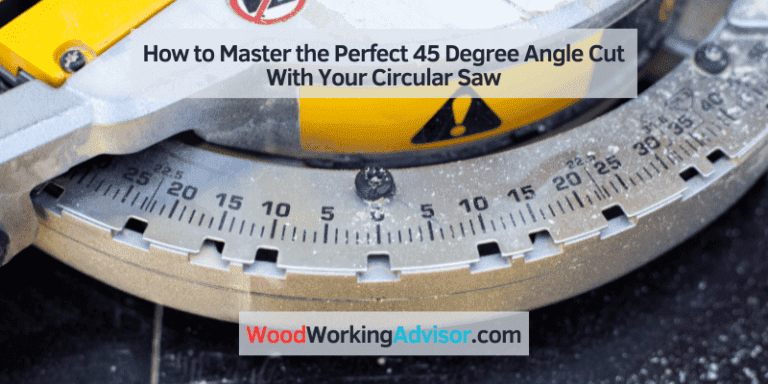

Ergdepart:Bevel Cutting and Laser Guides

Bevel cuts are a breeze with DeWalt circular saws. Most models, like the 20V MAX 6-1/2 in. Circular Saw, offer a bevel capacity of 0 to 50 degrees. This means I can make angled cuts for projects like roof framing or furniture with slanted edges. Some models even come with a laser guide, which is a lifesaver for keeping cuts straight. The first time I used the laser guide, I was amazed at how much easier it made lining up my cuts, especially on long rips. It’s like having an extra set of eyes to keep you on track.

Ergonomics and Safety Features

DeWalt circular saws are designed with comfort in mind. At around 7.5 to 8 pounds, they’re lightweight enough for me to use for hours without fatigue. The rubberized grips and ergonomic handle make them easy to control, even during tricky cuts. Safety is also a priority. The electronic blade brake stops the blade almost instantly when I release the trigger, which gives me peace of mind. Plus, the built-in LED light on some models illuminates the cut line, so I can work in dim lighting without missing a beat.

Maintenance Tips for Longevity

To keep my DeWalt circular saw in top shape, I make it a habit to clean it after every use. Sawdust can build up in the blade guard, so I wipe it down with a dry cloth. I also check the blade for dullness or damage—dull blades make cutting harder and can burn the wood. Replacing a blade is simple: just lock the spindle, loosen the bolt, and swap it out. I store my batteries in a cool, dry place to prevent corrosion, and I always follow the manual’s guidelines for lubricating moving parts. These small steps keep my saw running smoothly for years.

DeWalt Multi-Tools: The Swiss Army Knife of Woodworking

Now, let’s talk about DeWalt’s multi-tools, or oscillating tools, as they’re sometimes called. These tools are like the Swiss Army knife of my workshop. Whether I need to sand, cut, or scrape, my DeWalt multi-tool gets the job done. Here’s why I can’t imagine woodworking without one.

Versatility for Every Task

The first time I used a DeWalt multi-tool, I was blown away by its versatility. It’s perfect for tasks like cutting drywall, trimming baseboards, or sanding tight corners. I’ve even used it to cut through oak cabinet frames with a sharp blade, and it handled the job beautifully. The oscillating motion—moving back and forth rapidly—lets me make precise cuts without the bulk of a larger tool. It’s my go-to for jobs where a circular saw would be too big or unwieldy.

Cordless Convenience

Like DeWalt’s circular saws, their multi-tools come in cordless models, like the 20V MAX XR Oscillating Multi-Tool. The cordless design is a lifesaver when I’m working in tight spaces or outside. I can swap the same 20V battery between my circular saw and multi-tool, which saves me from juggling multiple chargers. The variable speed trigger lets me adjust the oscillations (up to 20,000 per minute!) for different materials, giving me total control.

A Range of Attachments

DeWalt multi-tools come with a variety of attachments, from cutting blades to sanding pads. I’ve used the plunge-cut blade for precise cuts in wood and drywall, the semi-circle blade for wider cuts, and the sanding pad for smoothing rough edges. Changing attachments is quick and tool-free on most models, which means I can switch from cutting to sanding in seconds. Pro tip: invest in high-quality blades. Cheaper ones dull quickly and make your work harder.

Precision in Tight Spaces

One of my favorite things about the DeWalt multi-tool is how it shines in tight spaces. The blade’s position lets me see exactly where I’m cutting, and there’s no guard to get in the way. I’ve used it to trim baseboards flush against a wall and to cut out old caulk in corners—jobs that would’ve been a nightmare with other tools. The compact size makes it easy to maneuver, even in awkward spots.

Durability and Maintenance

DeWalt multi-tools are built to take a beating, but I still take care of mine to keep it performing well. After each use, I clean off dust and debris, especially around the attachment point. I check the blades for wear and replace them when they start to dull. Storing the tool and its battery properly ensures it’s ready for action whenever I need it. With a little care, my multi-tool has been a reliable partner for years.

Comparing DeWalt Circular Saws and Multi-Tools

To help you decide which tool is right for your project, here’s a quick comparison of DeWalt circular saws and multi-tools based on my experience:

| Feature | DeWalt Circular Saw | DeWalt Multi-Tool |

|---|---|---|

| Primary Use | Straight cuts through thick materials | Precision cuts, sanding, scraping in tight spots |

| Blade Size | 6-1/2” to 7-1/4” carbide-tipped | Various (plunge, semi-circle, sanding pads) |

| Power Source | Cordless (20V MAX, 60V FLEXVOLT) | Cordless (20V MAX) |

| Speed | Up to 5,500 RPM | Up to 20,000 oscillations per minute |

| Best For | Large-scale cuts, framing, plywood ripping | Detail work, tight spaces, versatile tasks |

| Weight | 7.5–8 lbs | ~3–4 lbs |

| Key Features | Laser guide, bevel cuts, electronic brake | Variable speed, tool-free blade changes |

Both tools are fantastic, but they serve different purposes. I use my circular saw for big, straight cuts and my multi-tool for precision and versatility. Together, they’re a powerhouse duo in my workshop.

Tips for Getting the Most Out of Your DeWalt Tools

Over the years, I’ve picked up some tricks to make my DeWalt circular saw and multi-tool work even better. Here are a few of my favorites:

- Use a Guide Rail: For super-straight cuts with your circular saw, pair it with a DeWalt guide rail. It’s like having a built-in ruler for perfect lines every time.

- Choose the Right Blade: Match your blade to the material. For example, use a fine-tooth blade for plywood to avoid splintering.

- Safety First: Always wear safety goggles, a dust mask, and earmuffs. I also stand slightly to the side to avoid kickback from the circular saw.

- Practice Makes Perfect: If you’re new to multi-tools, start with small cuts to get the hang of the oscillation. It takes a little practice to master.

- Keep Batteries Charged: I always have a spare battery charged and ready, especially for long projects. It saves so much time.

Why I Love DeWalt for Woodworking

After years of using DeWalt tools, I can honestly say they’ve made my woodworking projects more enjoyable and efficient. The circular saw’s power and precision let me tackle big jobs with confidence, while the multi-tool’s versatility handles the little details that make a project stand out. Whether I’m building a bookshelf, renovating a room, or crafting a custom piece, these tools are my trusted partners. DeWalt’s commitment to quality, from durable construction to innovative features like FLEXVOLT and laser guides, makes them worth every penny.

Wrapping It Up: Your Next Steps with DeWalt

I hope this guide has shown you why DeWalt circular saws and multi-tools are must-haves for any woodworker. They’ve transformed the way I work, making my cuts cleaner, my projects faster, and my workshop more fun. If you’re ready to take your woodworking to the next level, start with a DeWalt 20V MAX Circular Saw for power and a 20V MAX Multi-Tool for versatility. Trust me, once you try these tools, you’ll wonder how you ever worked without them. So, what are you waiting for? Head to your local hardware store or check out DeWalt’s website, grab these tools, and start creating something amazing. Happy woodworking!

Frequently Asked Questions

What’s the difference between a DeWalt circular saw and a multi-tool?

A circular saw is designed for straight, powerful cuts through thick materials like wood or plywood. It’s great for big projects. A multi-tool, on the other hand, is for precision tasks like cutting in tight spaces, sanding, or scraping. I use both depending on the job.

Can a DeWalt multi-tool cut through hardwood like oak?

Yes, it can! I’ve cut through oak with my DeWalt multi-tool using a sharp plunge-cut blade. It’s precise but slower than a circular saw, so it’s best for smaller cuts or detail work.

How do I make straight cuts with a DeWalt circular saw?

I recommend using a guide rail or a straightedge clamped to your workpiece. Line up the saw’s base plate with the guide, and use the laser guide if your model has one. It makes straight cuts a breeze.

Are DeWalt’s cordless tools worth it?

Absolutely! I love the cordless freedom of DeWalt’s 20V MAX and FLEXVOLT systems. They’re powerful, versatile, and let me work anywhere without tripping over cords.

How often should I replace blades on my DeWalt tools?

It depends on how much you use them. I check my blades after every big project. If they’re dull, chipped, or burning the wood, I swap them out. High-quality blades last longer but still need regular inspection.