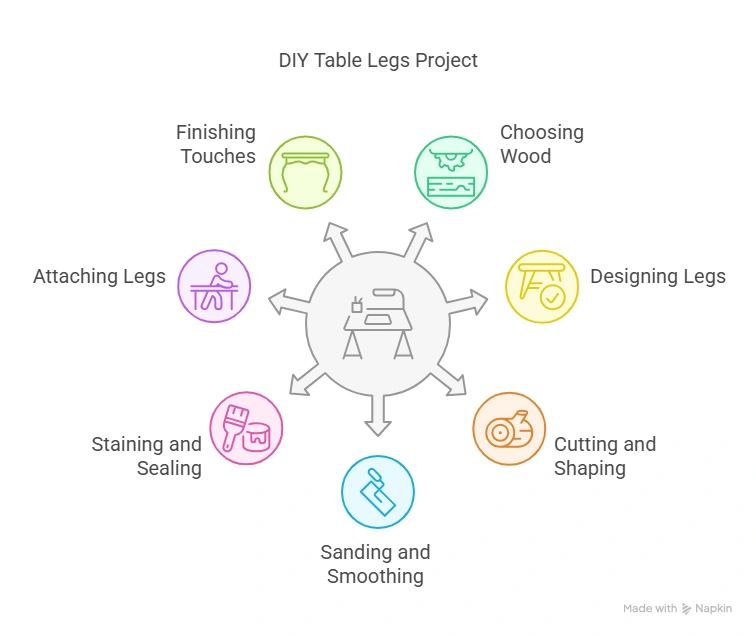

DIY Table Legs Wood: Craft Stunning Furniture on a Budget

Creating your own wooden table legs can be a fun project. It’s a great way to add a personal touch to your furniture.

Wooden table legs come in various styles and shapes. They can transform a simple table into a stunning piece. Making your own table legs might seem daunting. But with the right guidance, it’s easier than you think. This blog will help you understand the basics.

From choosing the right wood to the tools you’ll need, we’ll cover it all. Whether you’re a beginner or a seasoned DIY enthusiast, you’ll find useful tips here. Let’s dive into the world of DIY wooden table legs and get creative!

Credit: www.thehairpinlegcompany.co.uk

Introduction To Diy Table Legs

Building your own table legs can be fun. It adds a personal touch. Customizing the height and design is easy. Saving money is another perk. You can choose better materials. Learning new skills is rewarding. It’s a great way to spend your weekend. Friends and family will admire your work. Unique designs make your table stand out. You can create a table to fit your space. No more searching for the perfect table.

Gather these items: wood, screws, a saw, and a drill. Sandpaper smooths the wood. Use a tape measure for accuracy. Wood glue holds pieces together. Safety gear like goggles and gloves is important. Clamps help keep wood in place. Paint or stain for finishing touches.

Credit: flowyline.com

Choosing The Right Wood

Different types of wood have unique features. Hardwood like oak and maple are very strong. They last for a long time. Softwood like pine is easier to work with. It is also cheaper. Reclaimed wood is an eco-friendly choice. It gives a rustic look.

Think about strength and durability. Hardwoods are best for heavy tables. Appearance matters too. Some woods have beautiful grain patterns. Cost is another factor. Hardwood is more expensive than softwood. Ease of use is important. Softwoods are easier to cut and shape.

Designing Your Table Legs

Different styles and shapes of table legs give your table a unique look. Straight legs are simple and classic. Tapered legs are wider at the top and thinner at the bottom. Turned legs have round designs and look fancy. Hairpin legs are thin and modern. Choose the shape that fits your table and room.

Measure the height of your table. Decide the width and length of the legs. Plan the number of legs you need. Sketch your design on paper. This helps you see how the table will look. Check the wood for quality. Good wood makes strong legs. Cut the wood carefully. Measurements must be exact.

Cutting And Shaping The Wood

Wear safety goggles to protect your eyes. Always use ear protection to shield your ears from loud noises. Keep your work area clean and free of clutter. Use gloves to protect your hands from splinters. Ensure your saw blade is sharp to avoid accidents. Never rush the cutting process. Always secure the wood before cutting. Keep children and pets away from the work area. Make sure your saw is in good condition. Follow all manufacturer instructions for your tools. Have a first aid kit nearby in case of injuries.

Measure the wood with a tape measure. Mark the cut lines with a pencil. Double-check your measurements. Set up your saw on a stable surface. Use clamps to hold the wood in place. Start the saw and make a slow, steady cut. Follow the pencil marks closely. Cut all pieces to the same length. Sand the edges to remove rough spots. Check all pieces for accuracy. Assemble the legs by following your design plan.

Sanding And Smoothing

Start with coarse sandpaper. A 60-grit is good for rough wood. It removes large splinters and uneven parts. Next, use medium grit sandpaper. 120-grit works well. This smooths out the surface. Finally, finish with fine sandpaper. 220-grit makes the wood very smooth. Each step is important. Skipping one can cause problems later.

Always sand in the direction of the wood grain. This avoids scratches. Use a sanding block for flat surfaces. It keeps the sandpaper even. For edges and curves, use a folded piece of sandpaper. Check your progress often. Feel the wood with your hand. It should be smooth to touch. If not, keep sanding. Take your time. Rushing can lead to mistakes.

Credit: www.youtube.com

Staining And Sealing

Stains and finishes give wood a new look. There are oil-based stains, which provide a deep color. Water-based stains dry fast and have less odor. Gel stains are thick and easy to apply. Finishes protect the wood from damage. You can choose from polyurethane, varnish, or shellac. Polyurethane is durable and water-resistant. Varnish gives a glossy finish. Shellac gives a natural look but can be damaged by water.

Applying stain needs some care. First, sand the wood to make it smooth. Use a clean cloth to apply the stain. Wipe off extra stain with another cloth. Let it dry before adding more coats. For finishes, use a brush or sponge. Apply thin layers and let each layer dry. Sand lightly between coats for a smooth finish.

Attaching The Legs To The Table

Attach the legs to the table by aligning them with the pre-drilled holes. Secure them using screws and a screwdriver. Ensure the legs are even and stable for a sturdy finish.

Hardware Options

Several hardware options are available for attaching table legs. Screws and bolts are common choices. Brackets and corner plates provide extra support. Use screws for quick and easy attachment. Bolts offer a more secure connection.

Ensuring Stability

Stability is crucial for a sturdy table. Ensure legs are evenly spaced. Use a level to check the balance. Tighten all hardware properly. Cross-bracing can add extra support. This prevents wobbling. Check the table’s stability before use.

Finishing Touches

Enhance your furniture project with DIY table legs wood for a rustic charm. Easy to install and cost-effective. Add a personal touch to your home decor.

Decorative Elements

Adding decorative elements to your table legs can make them stand out. You can use wood carvings or paint designs on them. Some people like to add metal accents for a modern touch. Small details make a big difference.

Maintenance Tips

Keep your table legs clean and polished. Wipe them with a soft cloth regularly. Avoid using harsh chemicals that might damage the wood. Check for loose screws and tighten them if needed. This ensures your table stays strong and looks great.

Frequently Asked Questions

What Is The Best Wood To Make Table Legs Out Of?

Hardwoods like oak, maple, and walnut are best for table legs. They offer strength, durability, and a beautiful finish.

Can I Use 2×4 For Table Legs?

Yes, you can use 2x4s for table legs. They are sturdy and provide good support for most tables.

How Do You Make Wooden Table Legs?

To make wooden table legs, cut wood to desired length, shape with a lathe or saw, sand smooth, and finish.

What Can You Use Instead Of Table Legs?

Use hairpin legs, wooden crates, cinder blocks, or metal pipes instead of traditional table legs. These alternatives offer unique styles.

Conclusion

Crafting your own table legs from wood can be fulfilling and fun. It’s a chance to create something unique and personal. Plus, you save money. You also learn new skills. Remember, measure carefully and choose quality wood. Follow safety tips to avoid injuries.

With practice, your projects will improve. Soon, you’ll have furniture to be proud of. Happy crafting!