Drill Vs Screw Gun: The Definitive Best Choice

For most DIYers and homeowners, a versatile drill/driver is the definitive best choice. It can both drill holes and drive screws, making it perfect for a wide range of projects. A screw gun is a specialized tool designed for repetitive, high-speed screw driving, like installing drywall, and isn’t necessary for general tasks.

Hello, fellow makers! Md Meraj here, your friendly guide in the workshop. I’ve seen it happen many times. You’re standing in the tool aisle, looking at a wall of power tools. You see a drill, then something that looks like a drill, but is called a screw gun. What’s the difference? Which one do you actually need for your weekend project? It can be confusing, but don’t worry.

This is one of the most common questions I get. Together, we’re going to clear it all up, so you can walk away with confidence, knowing you have the right tool for the job. Let’s dive in and make sense of it all.

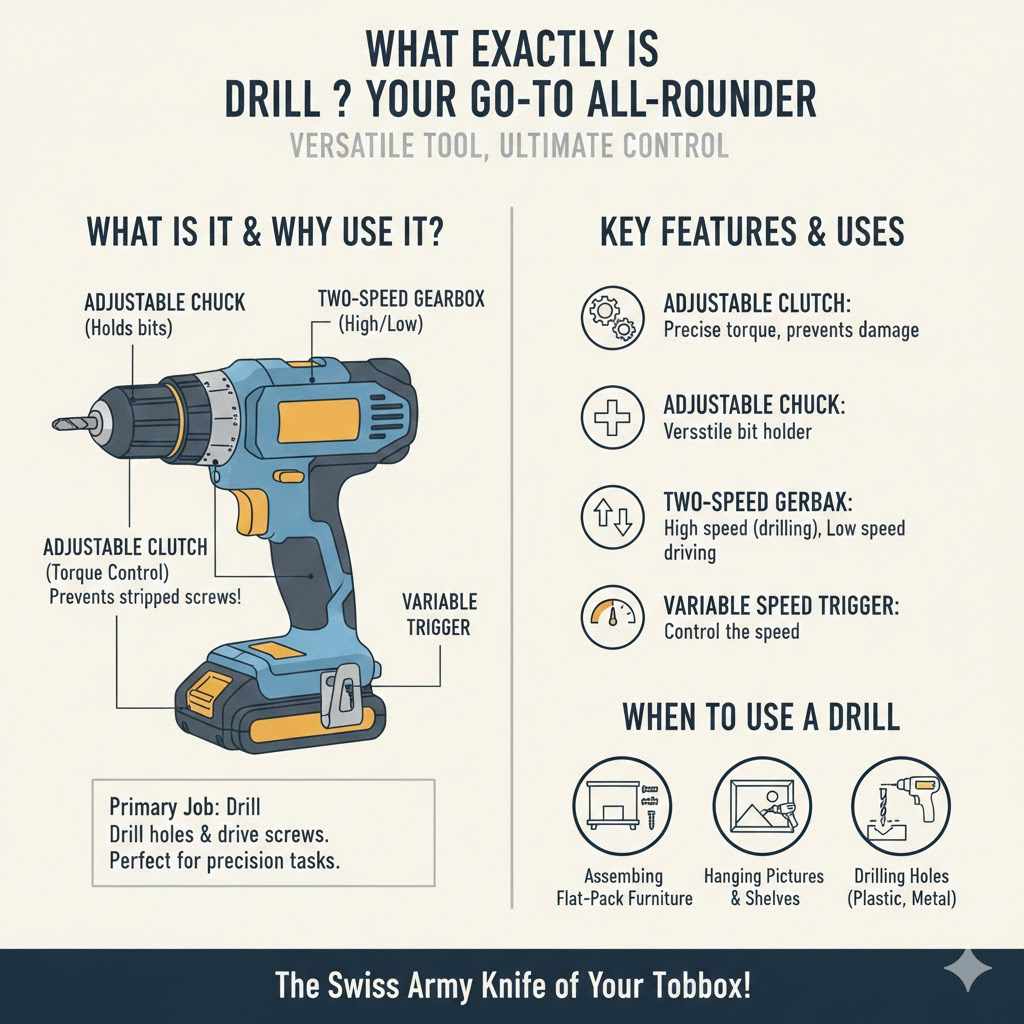

What Exactly Is a Drill? Your Go-To All-Rounder

Think of a drill as the Swiss Army knife of your power tool collection. Its main job is to create holes. Whether you’re drilling into wood, metal, plastic, or even brick (with the right bit), a drill is the tool you’ll reach for. It spins a drill bit at high speeds to carve out material, creating a clean opening for screws, bolts, or wires.

But that’s not all. Modern drills, often called “drill/drivers,” are incredibly versatile. They have an adjustable clutch and a variable speed trigger, which means you can also use them to drive screws. By swapping out the drill bit for a driver bit, you can build furniture, hang shelves, and tackle hundreds of other common household tasks.

Key Features of a Drill:

- Adjustable Chuck: The front part of the drill, called the chuck, can be tightened or loosened to hold a huge variety of different-sized drill bits and driver bits.

- Variable Speed Trigger: The harder you press the trigger, the faster it spins. This gives you amazing control, allowing you to start screws slowly or drill at full power.

- Torque Clutch: This is the numbered collar right behind the chuck. It lets you set how much twisting force (torque) the drill applies. Once it reaches that force, the clutch slips with a clicking sound. This is a fantastic feature that helps prevent you from driving a screw too deep or stripping the screw head.

- Two-Speed Gearbox: Most drills have a switch for high speed (for drilling) and low speed (for driving screws, which requires more torque).

For any beginner, a good quality cordless drill/driver is almost always the first power tool I recommend. It’s the single most useful tool you can own for home repairs and DIY projects.

What Is a Screw Gun? The Specialist for Speed

Now, let’s look at the screw gun. While it might look similar to a drill, it’s a highly specialized tool designed to do one thing exceptionally well: drive a lot of screws, very fast, to the exact same depth every single time. Its most common use is by professionals installing drywall.

Imagine hanging hundreds of sheets of drywall. Each sheet needs dozens of screws, and every single screw must be sunk just perfectly—deep enough to hold, but not so deep that it tears the paper surface of the drywall. Doing this with a regular drill would be slow and tiring, and you’d get inconsistent results. This is where the screw gun shines.

Key Features of a Screw Gun:

- Depth-Sensing Nose Cone: This is the screw gun’s secret weapon. Instead of a torque clutch, it has an adjustable nose cone. The motor doesn’t stop turning. You push the tool, and the bit spins and drives the screw until the nose cone touches the surface of the material. At that precise moment, the clutch disengages the bit, stopping the screw at the perfect depth. It’s incredibly consistent.

- High Speed, Low Torque: Screw guns are built for speed (high RPMs). They spin much faster than a typical drill to get the job done quickly. However, they have less raw twisting power (torque) because they are designed for driving screws into relatively soft materials like drywall and wood studs.

- Specialized Bit Holder: Instead of an adjustable chuck, a screw gun has a fixed hex-collet that only accepts 1/4-inch hex shank driver bits.

- Collated Screw Option: Many professional screw guns can be fitted with an attachment that feeds strips of screws automatically, like a nail gun. This makes the process even faster.

A screw gun is a master of repetition. It’s a production tool for professionals, not a general-purpose tool for a home workshop.

Drill vs. Screw Gun: A Head-to-Head Comparison

To really understand the difference, let’s put them side-by-side. Seeing how they stack up in key areas will help you see why one is a flexible multi-tasker and the other is a focused expert.

Function and Versatility

This is the biggest and most important difference. A drill is the clear winner in versatility.

- Drill: Can drill holes of all sizes in various materials. Can also drive screws, nuts, and bolts. You can even find attachments for stirring paint or sanding small areas. It’s a true multi-tool.

- Screw Gun: Is designed only for driving screws. It cannot drill holes because it lacks a chuck to hold drill bits and the power needed for serious drilling.

Speed vs. Power (RPM vs. Torque)

Power tools talk in terms of speed (RPM, or revolutions per minute) and torque (twisting force). Here’s how they compare:

- Drill: Offers a balance. It has a lower maximum RPM (usually around 2,000 RPM) but much higher torque. The high torque is essential for boring large holes or driving long screws into dense hardwood. You can control this power with the variable speed trigger and two-speed gearbox.

- Screw Gun: Built for pure speed. They can spin at over 4,000 RPM, double that of a drill. This allows for rapid-fire screw installation. However, their torque is much lower, which makes them unsuitable for tough jobs that a drill can handle easily.

Control and Precision

This is where the screw gun’s specialization comes into play. The way each tool controls the screw-driving process is fundamentally different.

- Drill (Torque Clutch): A drill’s clutch controls how hard it twists. You set the clutch to a number (say, 5 out of 20). The drill will drive the screw with increasing force until it meets the resistance level you set, then it will start to click and slip. This is great for preventing a screw from snapping or stripping its head. However, it does not guarantee a consistent depth, especially in materials of varying density.

- Screw Gun (Depth Clutch): A screw gun’s clutch controls how deep the screw goes. You set the depth on the nose cone. The motor will drive the screw at full speed until the head is perfectly flush (or slightly recessed, as you set it) and then instantly disengages. Every screw is set to the same, perfect depth. This level of precision is vital for drywall, where a screw that is too deep or too shallow ruins the finish.

Quick Comparison Chart

Sometimes a simple table makes everything clear. Here’s a quick summary of the main differences.

| Feature | Drill / Driver | Screw Gun |

|---|---|---|

| Primary Use | Drilling holes, driving screws (multi-purpose) | Driving many screws rapidly to a consistent depth |

| Versatility | Very high. Can use many bit types. | Very low. Only for driving screws. |

| Clutch Type | Adjustable torque clutch (stops by force) | Adjustable depth clutch (stops by depth) |

| Speed (RPM) | Lower (around 0 – 2,000 RPM) | Very high (often 4,000+ RPM) |

| Torque (Power) | High | Low |

| Best For… | General DIY, home repair, furniture building, hanging items | Installing drywall, subflooring, decking (production work) |

| For Beginners? | Yes, essential first tool. | No, specialized professional tool. |

When Should You Use Each Tool?

Theory is great, but let’s talk about real-world projects. Which tool should you grab for the job at hand? Here are some common scenarios to help you decide.

| Project or Task | Best Tool Choice | Why? |

|---|---|---|

| Assembling a Flat-Pack Bookcase | Drill / Driver | You need to drive a moderate number of screws, and the adjustable torque clutch on a drill is perfect for preventing damage to the soft particleboard. |

| Hanging a Picture Frame or Curtain Rod | Drill / Driver | You’ll need to drill a pilot hole for the wall anchor first, then drive the screw. A drill/driver does both jobs perfectly. A screw gun cannot drill the hole. |

| Building a Backyard Deck | Drill / Driver or Impact Driver | Decking requires driving long, thick screws into pressure-treated lumber. This requires high torque, which is a drill’s strength. A screw gun doesn’t have enough power. |

| Finishing a Basement (Installing Drywall) | Screw Gun | This is the screw gun’s ideal job. You will be driving thousands of screws, and the speed and perfect depth setting will save you hours of work and give a professional finish. |

| General Home Repairs | Drill / Driver | From tightening a loose cabinet hinge to fixing a fence board, the versatility of a drill/driver is unmatched for the unpredictable nature of home repairs. |

A Note on Impact Drivers

Just to make things a little more interesting, you’ll often see a third tool next to drills and screw guns: the impact driver. An impact driver is also a screw-driving specialist, but it works differently. It combines rotation with short, powerful concussive bursts (impacts) to drive long screws and loosen stubborn bolts with immense torque.

It’s much more powerful than a drill for driving screws but is noisy and can easily overdrive small screws. It’s a great companion to a drill, but not a replacement, and it is not the same as a screw gun.

Safety Always Comes First

No matter which tool you choose, safety is your most important job in the workshop. These tools are powerful and deserve respect. For guidance on power tool safety, you can always refer to trusted resources like the Occupational Safety and Health Administration (OSHA Hand and Power Tools guide). Here are my essential rules:

- Wear Safety Glasses: This is non-negotiable. Sawdust, metal filings, or a snapping screw can cause serious eye injury.

- Secure Your Work: Use clamps to hold your workpiece firmly in place. Don’t try to hold a small piece of wood with one hand while drilling with the other.

- Use the Right Bit for the Job: A dull bit or the wrong type of bit can slip, damage your project, and cause injury. Keep your bits sharp and organized.

- Keep Your Fingers Clear: Be aware of where the bit or screw will exit the material. Keep your hands and fingers away from the path of the tool.

- Disconnect Power: When changing bits or making adjustments, always remove the battery from a cordless tool or unplug a corded one.

- Start Slow: When driving a screw or starting a hole, squeeze the trigger gently to get it started accurately before increasing speed.

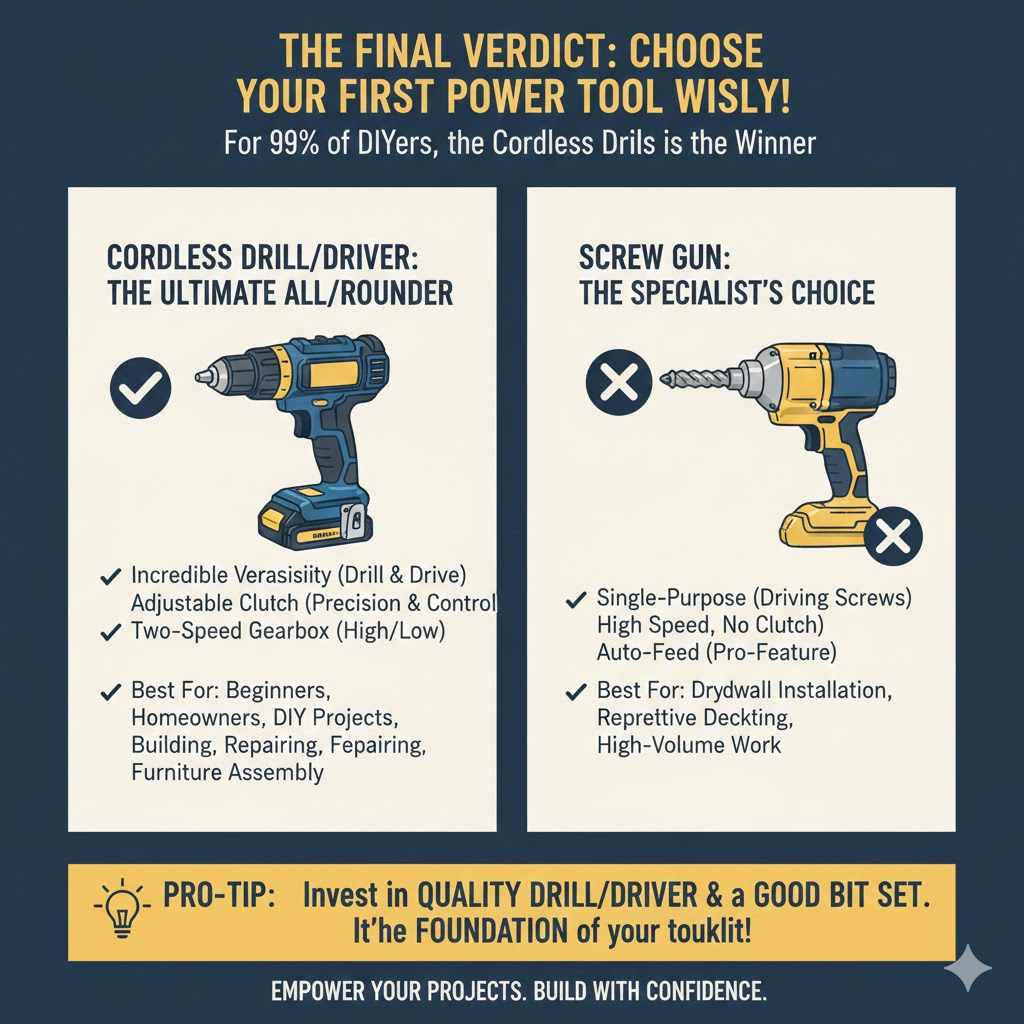

So, What’s the Final Verdict?

For over 99% of people reading this—beginners, homeowners, and DIY hobbyists—the definitive best choice is a good quality cordless drill/driver.

Its incredible versatility is unmatched. You can build, repair, and create an amazing number of things with just this one tool. It is the foundation of any tool kit. You will use it for everything from putting up shelves to building your first woodworking project. It provides the right balance of power, control, and flexibility that you’ll need for years to come.

A screw gun is a fantastic tool, but it’s a pro-level luxury designed for a specific, repetitive job. Unless you plan on starting a drywall installation business or undertaking a massive renovation project, you simply don’t need one. Your money is much better spent on a reliable drill/driver and a good set of drill and driver bits.

Invest in a good drill. Learn its features—the clutch, the speed settings, the chuck. Practice on some scrap wood. As you build your skills and your confidence, that one tool will open up a whole new world of projects you can proudly say you built yourself.

Frequently Asked Questions (FAQ)

1. Can I just use my drill as a screw gun?

Yes, absolutely! For most tasks, a drill/driver works perfectly well as a screw gun. That’s what the “driver” part of its name means. Use the adjustable torque clutch and the low-speed setting to carefully drive screws without damaging them or your project. It won’t be as fast as a dedicated screw gun for drywall, but for general use, it’s the perfect tool.

2. Do I really need a screw gun for simple home projects?

No, you do not. A screw gun is overkill for simple home projects like hanging pictures, assembling furniture, or fixing a squeaky door. A standard drill/driver is more than capable and far more versatile for these everyday tasks.

3. What does a “collated” screw gun do?

A collated screw gun has a special attachment that holds a long strip of screws (they look like a plastic belt of ammunition). It automatically feeds the next screw into place after you drive one. This saves a tremendous amount of time because you don’t have to handle individual screws, making it a favorite for professionals on large jobs.

4. Is an impact driver the same as a screw gun?

No, they are different tools. A screw gun is designed for speed and depth-sensitive applications like drywall. An impact driver is designed for high-torque applications, using powerful impacts to drive large screws or lag bolts into tough materials. An impact driver has far more power but less finesse than a screw gun.

5. Which tool is better for building wood furniture?

A drill/driver is the better choice for building furniture. You will need to drill precise pilot holes and potentially use countersink bits, which a screw gun cannot do. Furthermore, the drill’s adjustable torque clutch is crucial for gently setting screws into wood without over-tightening and splitting it.

6. Why does my drill keep stripping the heads of my screws?

This is a common issue for beginners! It’s usually caused by a few things: using the wrong size or type of driver bit for the screw head, applying too much speed too quickly, or not putting enough downward pressure on the drill. Make sure the bit fits snugly in the screw head, start slowly, press firmly, and use the drill’s clutch setting to prevent overpowering the screw.

7. Is a corded or cordless drill better for a beginner?

For a beginner, a cordless drill is almost always the better choice. The freedom from a cord is incredibly convenient for all types of home projects. Modern battery technology provides plenty of power and runtime for most DIY tasks. Corded drills are typically more powerful and lighter (no heavy battery), but are better suited for heavy-duty, stationary workshop use.