HDF Vs MDF: Ultimate Guide to Choosing the Right Material

HDF (High-Density Fiberboard) is denser and stronger than MDF (Medium-Density Fiberboard). MDF is more cost-effective and easier to shape.

HDF and MDF are engineered wood products used in furniture and cabinetry. HDF offers higher density and strength, making it suitable for high-traffic areas. MDF, on the other hand, is less dense but easier to work with and shape, making it ideal for detailed designs and smooth finishes.

Both materials have their unique advantages depending on the specific requirements of the project. HDF is typically more durable and resistant to damage, while MDF provides a more affordable and versatile option for various applications. Understanding the differences helps in selecting the right material for your needs.

Introduction To HDF And MDF

Choosing the right material is crucial in woodworking and furniture making. HDF (High-Density Fiberboard) and MDF (Medium-Density Fiberboard) are popular choices. Each has unique properties and uses. Understanding these materials helps in making an informed decision. Let’s dive into the basics of each.

The Basics Of HDF

HDF stands for High-Density Fiberboard. It is made from wood fibers compressed under high pressure. This process creates a dense and strong board.

Key Features of HDF:

- Very dense and strong

- Smooth surface ideal for painting

- Resistant to warping and splitting

HDF is perfect for applications that need durability and strength. It is often used in high-traffic areas.

The Basics Of MDF

MDF stands for Medium-Density Fiberboard. It is also made from wood fibers, but it is less dense than HDF. MDF is created by breaking down hardwood or softwood residuals into fibers, combining it with wax and resin, and forming panels by applying high temperature and pressure.

Key Features of MDF:

- Smooth surface that is easy to paint

- Uniform texture without knots or grain

- Cheaper than HDF

MDF is a popular choice for many indoor projects. It is versatile and cost-effective, making it ideal for various applications.

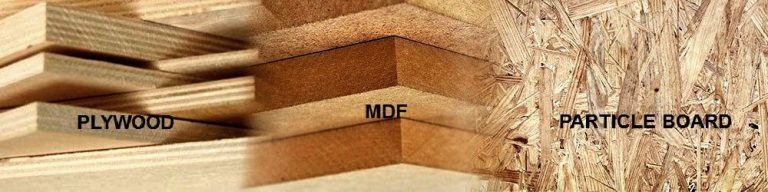

Materials And Composition

Understanding the materials and composition of HDF and MDF is crucial. These factors determine their properties, uses, and performance. Let’s delve into what makes up HDF and MDF.

What HDF Is Made Of

High-Density Fiberboard (HDF) is made from wood fibers. These wood fibers come from hardwood. The fibers are compressed using heat and pressure.

HDF has a higher density than MDF. This makes it stronger and more durable. The composition includes:

- Wood fibers

- Resin binder

- Wax

The result is a dense and sturdy board. HDF is ideal for high-traffic areas. It is also resistant to water.

What MDF Is Made Of

Medium-Density Fiberboard (MDF) is similar to HDF but less dense. It is made from both hardwood and softwood fibers. The fibers are also compressed with heat and pressure.

MDF’s composition includes:

- Wood fibers (hardwood and softwood)

- Resin binder

- Wax

MDF is easier to shape and cut. It is used in furniture and cabinetry. MDF is also more affordable than HDF.

| Material | Wood Fiber Source | Density | Uses |

|---|---|---|---|

| HDF | Hardwood | High | Flooring, high-traffic areas |

| MDF | Hardwood and Softwood | Medium | Furniture, cabinetry |

Physical Properties

Understanding the physical properties of HDF (High-Density Fiberboard) and MDF (Medium-Density Fiberboard) is crucial. These properties determine their suitability for different applications in home and office settings.

Density And Strength

Density and strength are key factors in choosing between HDF and MDF. HDF is denser than MDF. HDF has a density of 800 to 1040 kg/m³. MDF has a lower density, ranging from 600 to 800 kg/m³. This higher density makes HDF stronger and more durable. HDF can handle more weight and pressure. MDF is less strong but still suitable for many uses like furniture and cabinets.

Moisture Resistance

Moisture resistance is another important property. HDF is more resistant to moisture than MDF. This makes HDF better for areas with high humidity. MDF can swell or warp when exposed to water. Specially treated MDF can resist moisture better. But it still doesn’t match HDF’s resistance. Below is a table summarizing the moisture resistance of HDF and MDF:

| Material | Moisture Resistance |

|---|---|

| HDF | High |

| MDF | Low to Moderate |

Knowing the physical properties of HDF and MDF helps in making the right choice. This ensures the best performance and longevity for your projects.

Manufacturing Process

Understanding the manufacturing process of HDF and MDF is crucial. It helps you choose the right material for your project. Let’s dive into how these materials are created.

How HDF Is Created

High-Density Fiberboard (HDF) is made from wood fibers. The process begins with breaking down wood into fibers. These fibers are then combined with resin and other additives.

The mixture is formed into panels using high pressure and heat. The result is a dense, strong board. HDF is more durable than MDF due to its higher density.

Key Points:

- Wood fibers are used.

- Resin and additives are added.

- High pressure and heat form the panels.

- HDF is denser and stronger.

How MDF Is Created

Medium-Density Fiberboard (MDF) also starts with wood fibers. The fibers are combined with wax and resin.

The mixture is then heated and pressed into panels. MDF is less dense than HDF. It is easier to cut and shape.

Key Points:

- Wood fibers are used.

- Wax and resin are added.

- Panels are formed using heat and pressure.

- MDF is less dense and easier to shape.

Here’s a quick comparison in table form:

| Aspect | HDF | MDF |

|---|---|---|

| Materials | Wood fibers, resin, additives | Wood fibers, wax, resin |

| Process | High pressure and heat | Heat and pressure |

| Density | High | Medium |

| Strength | Strong | Moderate |

| Ease of shaping | Less easy | Easy |

Applications In Design And Construction

In the world of design and construction, materials like High-Density Fiberboard (HDF) and Medium-Density Fiberboard (MDF) play crucial roles. They are versatile, durable, and cost-effective. Understanding where to use HDF and MDF can significantly impact the quality and functionality of your projects. This section delves into the specific applications of HDF and MDF in design and construction.

Where To Use HDF

High-Density Fiberboard (HDF) is known for its strength and durability. These attributes make HDF ideal for high-traffic areas and heavy-duty applications.

- Flooring: HDF is often used in laminate flooring due to its high density and strength. It withstands wear and tear better than MDF.

- Doors: HDF is perfect for making solid and durable doors. It provides better sound insulation compared to MDF.

- Wall Panels: HDF wall panels are preferred for their durability and resistance to damage. They are used in commercial buildings and homes.

- Furniture: HDF is excellent for making furniture that needs to support a lot of weight. It ensures longevity and durability.

Where To Use MDF

Medium-Density Fiberboard (MDF) is versatile and cost-effective. It is suitable for a variety of applications, especially where intricate designs are required.

- Cabinetry: MDF is widely used in kitchen and bathroom cabinets. It is easy to work with and provides a smooth finish.

- Interior Trim: MDF is ideal for baseboards, crown molding, and window sills. It can be easily shaped and painted.

- Furniture: MDF is used for making various types of furniture. It allows for detailed designs and is budget-friendly.

- Partitions: MDF partitions are common in offices. They are lightweight and easy to install.

| Application | HDF | MDF |

|---|---|---|

| Flooring | ✔️ | ❌ |

| Doors | ✔️ | ❌ |

| Wall Panels | ✔️ | ❌ |

| Cabinetry | ❌ | ✔️ |

| Interior Trim | ❌ | ✔️ |

| Partitions | ❌ | ✔️ |

Cost Comparison

When choosing between HDF and MDF, understanding their costs is crucial. This section explores the pricing differences between High-Density Fiberboard (HDF) and Medium-Density Fiberboard (MDF).

Pricing Of HDF

High-Density Fiberboard (HDF) is known for its durability. This makes it more expensive than MDF. HDF is often used in high-traffic areas. Its cost is justified by its high strength and longevity.

The price of HDF can vary depending on the manufacturer and location. On average, expect to pay between $50 to $70 per sheet. Custom sizes or thicknesses may increase the cost.

Here’s a quick overview of HDF pricing:

| Standard Size | Price Range |

|---|---|

| 4×8 feet | $50 – $70 |

| 5×10 feet | $80 – $100 |

Pricing Of MDF

Medium-Density Fiberboard (MDF) is less expensive than HDF. MDF is a cost-effective choice for many projects. It is popular for furniture and cabinetry.

The cost of MDF is lower due to its lighter weight and easier manufacturing process. On average, expect to pay between $30 to $50 per sheet. Larger sizes or special finishes can affect the price.

Here’s a quick overview of MDF pricing:

| Standard Size | Price Range |

|---|---|

| 4×8 feet | $30 – $50 |

| 5×10 feet | $55 – $75 |

In summary, HDF is more expensive due to its superior strength. MDF offers a budget-friendly alternative. Choose based on your project needs and budget.

Working With HDF And MDF

High-Density Fiberboard (HDF) and Medium-Density Fiberboard (MDF) are popular choices for woodworking projects. Both materials have unique properties that affect how they are cut, shaped, and finished. Understanding the differences can help you decide which is best for your project.

Cutting And Shaping

HDF is denser than MDF, making it harder to cut. It requires sharp, high-quality blades to achieve clean cuts. MDF is softer and easier to cut, making it a preferred choice for intricate shapes.

Using the right tools is crucial for both materials. Here’s a comparison:

| Tool | HDF | MDF |

|---|---|---|

| Circular Saw | Yes, with carbide-tipped blades | Yes, standard blades work |

| Jigsaw | Yes, with high-speed blades | Yes, fine-toothed blades preferred |

| Router | Yes, slower speed for control | Yes, versatile for detailing |

Finishing Techniques

Both HDF and MDF have smooth surfaces, making them ideal for painting. HDF has a denser structure, providing a better finish. MDF is more porous and requires sealing before painting.

Here are some tips for finishing each material:

- Sanding: Use fine-grit sandpaper for both HDF and MDF.

- Priming: HDF needs a single coat, while MDF may require two.

- Painting: Both materials accept paint well, but HDF offers a smoother finish.

Sealing the edges of MDF is essential to prevent moisture absorption. Edge banding can also be used for a professional look.

Environmental Impact And Sustainability

Understanding the environmental impact and sustainability of building materials is crucial. Both HDF (High-Density Fiberboard) and MDF (Medium-Density Fiberboard) are popular choices. Their production processes and environmental effects differ. This section explores their eco-friendliness.

Eco-friendliness Of HDF

HDF is known for its high density. It uses more wood fibers, resulting in a denser product. This density means HDF has greater durability. The production process involves using wood waste. This helps in reducing deforestation.

During manufacturing, HDF often uses low or no added formaldehyde resins. This makes it a safer choice for indoor air quality. Additionally, HDF can be recycled, contributing to a circular economy.

Here are some key points about HDF’s eco-friendliness:

- Uses wood waste, reducing deforestation

- Low or no added formaldehyde resins

- Recyclable and durable

Eco-friendliness Of MDF

MDF is less dense than HDF. It also uses wood fibers but in smaller quantities. The production process of MDF can involve higher formaldehyde emissions. This can impact indoor air quality.

Despite this, MDF production often uses recycled wood fibers. This helps in minimizing waste. MDF is also recyclable, but its lower density means it may not last as long as HDF.

Here are some key points about MDF’s eco-friendliness:

- Uses recycled wood fibers

- Potential for higher formaldehyde emissions

- Recyclable but less durable than HDF

| Feature | HDF | MDF |

|---|---|---|

| Wood Usage | High | Moderate |

| Formaldehyde Emissions | Low/None | Potentially High |

| Durability | High | Moderate |

| Recyclability | Yes | Yes |

Pros And Cons

Choosing the right material for your project can be tricky. High-Density Fiberboard (HDF) and Medium-Density Fiberboard (MDF) are popular choices. Each has its own set of advantages and limitations. Let’s explore the pros and cons of both to help you decide.

Advantages Of HDF

- Durability: HDF is denser and stronger than MDF, making it more durable.

- Moisture Resistance: HDF resists moisture better, suitable for humid environments.

- Fine Finish: It offers a smoother surface, perfect for detailed finishes.

Advantages Of MDF

- Cost-Effective: MDF is generally cheaper than HDF, making it budget-friendly.

- Workability: MDF is easier to cut and shape, ideal for intricate designs.

- Uniformity: It has no grain, ensuring a consistent look.

Limitations And Considerations

| Material | Limitations | Considerations |

|---|---|---|

| HDF | Heavier and harder to handle | Requires special tools for cutting |

| MDF | Less durable and prone to damage | Not suitable for high-moisture areas |

Expert Tips For Selection

Choosing between High-Density Fiberboard (HDF) and Medium-Density Fiberboard (MDF) can be challenging. Each material has unique characteristics that suit different projects. Here are expert tips to help you make the right choice for your needs.

Choosing The Right Material For Your Project

Understanding your project’s requirements is crucial. HDF is denser and stronger than MDF. It is ideal for high-traffic areas and heavy-duty use.

MDF is less dense and easier to cut. It is perfect for decorative elements and intricate designs. Consider your project’s demands before selecting the material.

| Feature | HDF | MDF |

|---|---|---|

| Density | Higher | Lower |

| Strength | Stronger | Weaker |

| Workability | Harder to cut | Easier to cut |

| Cost | More expensive | Less expensive |

Maintenance And Care

Proper maintenance is essential for both HDF and MDF. It prolongs the lifespan of your project.

- Keep the surface clean using a soft, damp cloth.

- Avoid using harsh chemicals that can damage the material.

- Regularly inspect for scratches or dents.

HDF is more resistant to moisture and wear. It requires less frequent maintenance than MDF.

MDF, being softer, is prone to damage. It needs more careful handling and regular upkeep.

Future Trends In Engineered Wood

Engineered wood products like HDF and MDF are evolving. These materials are becoming more advanced and sustainable. The future holds many exciting trends for these engineered wood products.

Innovations In HDF

High-Density Fiberboard (HDF) is seeing remarkable innovations. These changes aim to improve durability and performance.

One key trend is the use of eco-friendly adhesives. These adhesives reduce harmful emissions. This makes HDF a more sustainable choice.

Another trend is the enhancement of moisture resistance. Improved coatings are now available. These coatings protect HDF from water damage.

Manufacturers are also focusing on increasing strength. Advanced compaction techniques are being used. This results in a denser and stronger board.

Innovations In MDF

Medium-Density Fiberboard (MDF) is also experiencing significant advancements. These innovations aim to make MDF more versatile and eco-friendly.

One major trend is the use of recycled wood fibers. This reduces waste and promotes sustainability. It also lowers the cost of production.

Another exciting development is the introduction of fire-resistant MDF. Special treatments make the board less flammable. This is crucial for safety in various applications.

Manufacturers are also working on improving surface finishes. New techniques offer smoother and more attractive surfaces. This makes MDF ideal for high-end furniture.

| Feature | HDF | MDF |

|---|---|---|

| Adhesives | Eco-friendly | Standard |

| Moisture Resistance | High | Moderate |

| Strength | Very High | High |

| Recycled Content | Low | High |

| Fire Resistance | Standard | High |

| Surface Finish | Standard | Enhanced |

The future of engineered wood looks promising. Both HDF and MDF are becoming more sustainable and efficient. These innovations will shape the industry for years to come.

Frequently Asked Questions

Is HDF Better Than MDF?

HDF is denser and stronger than MDF. It offers better durability and resistance. MDF is cheaper and easier to work with. Choose based on your project needs.

What Are The Disadvantages Of HDF?

HDF is less moisture-resistant than plywood. It can swell or warp when exposed to water. It’s also heavier and harder to cut.

Is HDF Good For Kitchen Cabinets?

Yes, HDF is good for kitchen cabinets. It offers durability, smooth finish, and resistance to moisture. Ideal for high-traffic areas.

How Long Will HDF Cabinets Last?

HDF cabinets typically last 15-20 years with proper care and maintenance. Their durability depends on usage and environment.

Conclusion

Choosing between HDF and MDF depends on your specific needs. HDF offers higher density and strength, ideal for flooring. MDF, being cost-effective and versatile, suits furniture and cabinetry. Both have unique advantages. Understanding their differences helps in making an informed decision for your projects.