Hevea Wood Vs Birch: Proven Essential Comparison

Hevea wood vs Birch: For beginners, Hevea (Rubberwood) burns slightly hotter and is highly eco-friendly due to sustainability initiatives linked to latex production. Birch is prized for its color consistency, excellent stability for plywood manufacturing, and tradition in fine furniture, representing a slightly stronger, denser base for durable carpentry projects requiring excellent stain capability.

Welcome, builder friend! Choosing the right wood can sometimes feel like navigating a dizzying lumber aisle. You’ve heard good things about both Hevea (Rubberwood) and Birch, and now you’re scratching your head: which one belongs in your next project? Don’t worry; this choice paralyzes even seasoned pros sometimes. I’m Md Meraj, and I’ve spent years learning the personality of every board. We will compare these two fantastic woods, side-by-side, using language that keeps things simple. Get ready to build with confidence. We dive deep into density, design, budget, and the big environmental differences next.

Unpacking the Essential Comparison: Hevea Wood vs Birch

Whether you are tackling a cutting board, building simple Shaker cabinets, or designing sturdy shelving, the wood choice matters deeply concerning how the project looks, feels, and lasts. When putting Hevea wood vs Birch against each other, it’s not about crown or shame—it’s about fit for purpose.

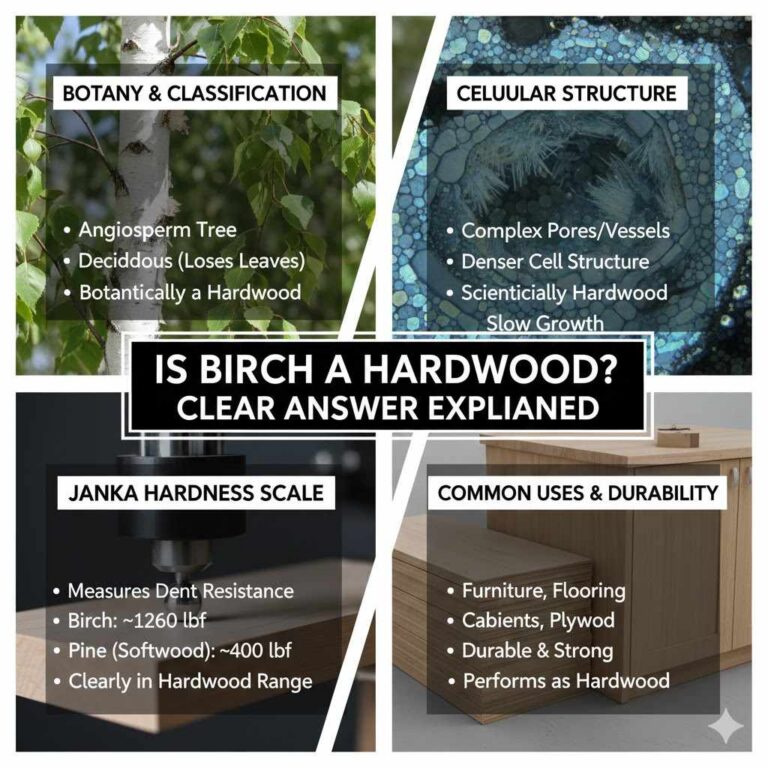

What You Need to Know About Hevea Wood (Rubberwood)

Hevea brasiliensis, commonly known as Rubberwood, is a relative newcomer to high woodworking appeal, primarily famous for something completely different: rubber tapping! Once a Hevea tree stops producing latex sustainably, after about 25-30 years, then it becomes hardwood timber. This means it often comes with a feel-good ecological bonus because it uses discarded material.

Characteristics of Hevea Wood as Beginner Lumber

Hevea is generally easy on tools and straightforward—ideal for those of us laying off the heavy-duty training weights on our machinery. It blends characteristics seen in softer hardwoods, making it useful for many indoor applications.

- Density: It’s firmly in the medium-density range. Not feather-light, but easy to handle.

- Grain Structure: Features a relatively straight, sometimes interesting, open grain. Often light tan to rosy brown.

- Best For Project Types: Excellent for indoor furniture, cutting tables (light use), laminate or molded components, and craftsman jigs.

- Budget Friendliness: High repeatability and excellent supply often keep bulk pricing lower than traditional hardwoods like Oak—great for expanding your stock inventory!

The Eco Factor: Why Hevea Often Makes the ‘Green Grab’

In today’s world, sustainability matters a great deal. Hevea truly shines concerning responsible sourcing because the wood is the byproduct of the flourishing natural rubber industry.

At places like commercial facilities following responsible harvesting protocols managed by various agricultural governance groups, minimizing lumber demand from slower-growing, slower-harvest forests is key ([Reference suggestion: Look toward agricultural department resource data for sourcing regions]). You won’t find too many forestry initiatives dedicated singularly to cutting down Hevea; they grow it for the sap first!

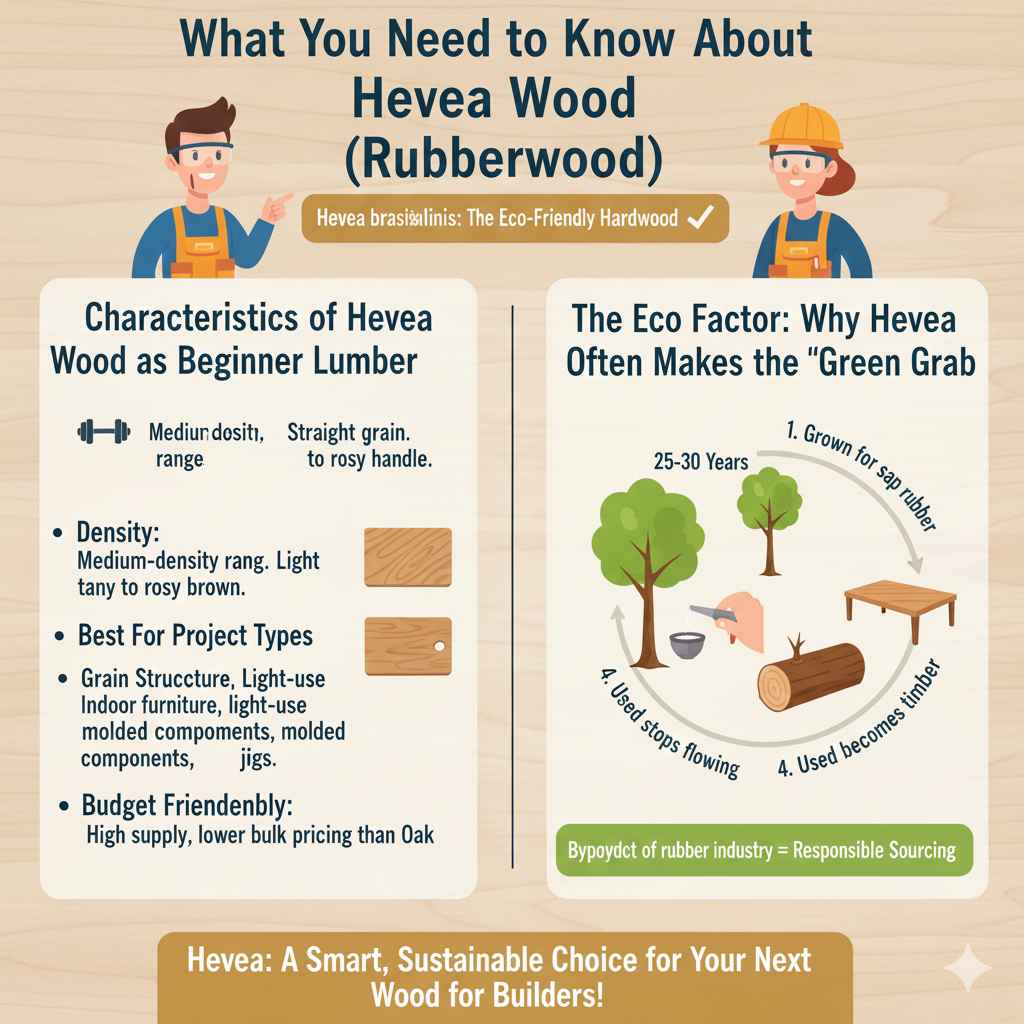

What You Need to Know About Birch Wood

Birchwood trees are classic staples found across North America and Europe. It’s a mature, dependable performer in the hardwood family. When people choose Birch, they are almost always expecting light character, excellent paint uptake, and wonderful balance regarding sheer strength versus weight.

Characteristics and Stability Requirements

Birch isn’t usually available in massive, slow-grown boards in the same way Oak is. However, it shines spectacularly laminated into veneer form (hello, high-quality plywood!) where manufacturers like The Wood Database offers verified specs on American and European species, proving its strength rating. For a beginner working with solid Birch lumber, expect tightness and uniformity.

- Grain Structure: Mostly straight grain, very fine pore structure, creamy white, or pale yellow color. This tight finish makes it highly beautiful when clear-coated.

- Hardness (Janka): Generally falls slightly above Hevea. Sweet Birch, for instance, clocks in higher than many common Pine varieties due to its dense nature post-kiln. Beginners find it takes screws and nails well without excessive surface checking but requires careful handling during routing.

- Best For Project Types: Cabinets, modern interiors, toy manufacturing, dowels, turning stock, and premium, stability-focused boxes where paint is the target finish.

The Crucial Role of Processing in Birch Behavior

The way Birch is processed drastically influences its performance. Yellow Birch is steam bent far easier than, say, Maple. Be warned that sapwoods often bleach naturally when dried, but heartwood sections can remain slightly darker, giving character inconsistencies that impact perfect painting tasks if not stickered and dried correctly.

Head-to-Head Comparison Table: Key Differences

Let’s put these forest buddies on a match card to see where they really differ as you plan those first few builds:

| Feature | Hevea Wood (Rubberwood) | Birch Wood |

|---|---|---|

| Avg. Janka Hardness (lbf) (Approx.) | Approx. 950 – 1050 | Approx. 1260 – 1450 (Depends on species: Yellow vs. White/Paper) |

| Color Palette | Light tan to light rose gold/brown. Grain highly varied. | Creamy white to pale yellow. Tight, consistent look. |

| Resistance to Pests/Rot | Low (If not kiln dried properly) | Moderate (Generally requires sealing as it’s not rotary resistant) |

| Eco Profile | High (Byproduct of recycled rubber process) | Balanced (Sustainably or commercially forested softwood where grown) |

| Acceptance of Finishes | Accepts stain well, but blotch prone due to absorption variance. Oils are excellent. | Accepts light stains okay, excellent for light paint coverage/graining preservation. |

| Cost Status | Generally Low to Medium Market Price (Excellent Value Index) | Medium Market Price |

Crafting Confidence: Which Wood Chooses the Job?

Here is where theory meets the toolbox. Knowing the specs is perfect, but what if I’m an enthusiast who needs that pantry shelf built this weekend?

Best Scenarios for Choosing Hevea

When Durability Meets a Discount Door

If your project demands good stability indoors but you are working with a tighter budget or need large panels (like butcher block countertops designed predominantly as decorative workspaces), lean into Hevea.

- Value Buying: When you anticipate using substantial material thickness where budget impacts the final cost heavily.

- Eco Focus: For projects prioritized heavily on minimizing fresh forestry impact first and foremost.

- Finishing with Oil or Varnish: Oils do a marvelous job of evening out the inherent color variations found across different Hevea pieces because controlled wiping minimizes standing pools of stain solution.

Best Scenarios for Choosing Birch

For Appearance and Uniform Texture Inside Show Cases

Birch is the winner when your look requires pale cream/off-white base color that needs to remain light even when clear coated underneath protective polyurethane. It lends incredible stiffness, particularly in thin panel applications or in engineered products.

- Superior Painting Projects: Birch’s extremely tight grain means almost no wood fiber projects outward once that first coat hits it, leading to famously smooth painted tabletops or drawer faces. See resources for preparing wood for paint by organizations like the PCA for primer sealing tips.

- Heavy-Use Indoor Projects: For the base framework of your kitchen project chairs or heavy office furniture that needs to handle light abrasion without marking deep craters—its higher effective Janka rating offers protection.

- Fine Turning: Home lathe work thrives on Birch because it takes razor-sharp edges incredibly well and doesn’t crumble easily if dried correctly.

Working With the Wood: Beginner Tool Tips Meraj Recommends

Safety comes first ALWAYS. Regardless of the wood, know how your clamps or planes feel. But specific woods require small tweaks in approach when routing, sawing, tear-out edges, or preparing surfaces.

Handling Tips for Hevea (For Easy Sawing and Sanding)

Because Hevea can be tricky with sap retention (sometimes leading different boards to react drastically differently to finish soaking), prepping the surface slowly often saves headaches later.

- Sanding Path: For Hevea flooring or paneling, skip ultra-aggressive initial sanding (like starting at 40 grit unless absolutely flattening). Gradually step up: Start reliably at 80 grit, move to 120, then 180, and finish at 220. Going too rough first can leave sanding scars near knotholes.

- Gluing Note: Ensure your Hevea is fully kiln-dried and equalize its environment in your shop for three to five days before gluing up panels—it has a history of shifting if moved rapidly from shipping environment to working humidity settings.

- Power Use Safety: Maintain good dust extraction. When using powerful belt or drum sanders on denser Hevea patches, always feed the material slowly to avoid burning marks typical with softer tropical medium woods.

Handling Tips for Birch (Mastering the Grain)

The density here works with you for carving profiles but beware of tear-out on challenging grain alignment points.

- Routing Setup: Aim for an aggressive down-spiral (or ‘banding the cutter’) on your router bits when forming softer profiles on Birch. This pulls up, rather than pushes out, the cut line tear-out potential found along flat grain sections.

- Pre-Sealing is Your Lifesaver for Paint/Light Stain: Seal light-colored Birch before staining using a specialized stainable wood sealer or sanding sealer applied very thinly. This locks the pigment’s footprint in place, making that uneven absorption between sapwood and heartwood areas much less noticeable. Most reputable sealants can reduce blotching by significant degrees according to tests done by housing associations.

- Joinery Integrity: Precision cut your joinery (dovetails or pocket holes). Because Birch is marginally harder, slightly undersized tenons pressed incorrectly can cause fine end-grain splitting, so measure twice! (Especially crucial here since its density doesn’t “allow” for forgiveness like very short-grained composites.)

Environmental Footprint of Hevea vs. Birch Forests Regulations

As responsible builders entering the world of lumber consumption, knowing where the wood comes from sets things right before you even plane the material.

The Hevea Story of Sustainability

True conservation wins aren’t always achieved by stopping chopping, but sometimes about making harvest sensible over timeframes.

- Harvest Cycle Advantage: Hevea becomes commercially viable only after giving industry excellent service life as a rubber producer. This lifespan model stands in sharp contrast to trees solely managed for timber in some rapid monoculture grows somewhere in the world using questionable short-cycle land reclamation practices utilized prior to logging policies focusing on sustained yield benchmarks required by governing bodies here and abroad. (General reference pointing to global sustainable logging research outlines the benefits of by-product utilization).

- Transportation Weight Effect: Often processed closer to the coastal processing ports in Asia before bulk shipment, its processing footprint might be more geographically concentrated than long-distance domestic hauling paths.

The Birch Source Reality

Birch requires active management through forestry programs governed by rigorous licensing. In North America, responsible logging operators follow state or provincial laws managed by agencies focused on health and maximum land usability for the future crop.

Certified Supply Chains: Look for Birch stocks carrying SCS Global Services or Forestry Stewardship Council (FSC) certifications in specialty hardwood distributors if old-growth integrity matters deeply to your region’s standard concerns.

Density of Ownership: Birch frequently comes more readily from smaller, community-based harvesting permits across many states vs. the vast, large-tract tropical plantations common for Hevea suppliers.

Affordability Snapshot: Budgeting Your Project Choices

Let’s talk ‘wood money.’ For most beginner workshops, a $10-$50 price swing per board simplifies into something tangible: are the shelves fancy enough or sturdy enough?

Hevea: The Price Play

Hevea usually competes with good quality Hemlock or sometimes Maple (depending on your port fees in North America, where land-shipped Birch tends to originate often). It is consistently priced favorably against hardwoods imported via longer pathways relative to the dense availability near Eastern processing mills, offering great board footage per dollar spent.

Birch: Consistency Trades Price

Birch consistency commands a premium. Because manufacturing specifications within Baltic Birch Plywood or highly sorted Yellow Birch strips must be tighter for its end users (especially in high-security packaging or construction frames), acquiring it can mean consistently choosing Tier A material costing slightly more per linear foot than a good utility crate run of Hevea.

Your Guide to Maintenance and Long-Term Finish Safety (Hevea vs Birch)

Finishing both woods well ensures they look great and defend furniture construction from moisture absorption. Beginners often focus too much on sanding steps before clear coat time, accidentally leaving themselves vulnerable to moisture long term.

Protecting Your Hevea Projects

Hevea performs best when its pores are deeply saturated with protective oil first. Think cutting boards: you can use this approach here as well.

- Apply penetrating mineral oil mixtures often during assembly for furniture pieces, particularly legs that might meet tile or concrete flooring. Soak the end grain for an extra layer of defense. A good initial treatment here is non-negotiable consistency with the first few cleanings.

- For top coat protection, traditional oil-based polyurethane coats work beautifully over properly sealed Hevea components, offering good general lifespan outdoors provided UV is not constantly hammering the surface into its most delicate elements.

Protecting Birch Projects for the Long Haul

Birch, especially lighter grades, likes uniform surfaces, which aids heavily finished items where spill resistance is necessary (like the shop workbench top over Hevea which might be stained but accepts spill damage far worse than laminated top Birch panels).

- Water Resistance: Birch needs robust water-sealant coverage if used where steam or humidity plays a large part—Bath vanity bases must be flooded using an epoxy or heavy water-based, acrylic seal coat or a moisture resistant shellac derivative that rejects standing water pooling across the surfaces exposed near the sink area or over the workshop floor surfaces requiring intense wiping.

- Light Fading: Pay attention in sunny spots where highly attractive light/pale coloration appears often, bleaching slightly unevenly compared to Maple counterparts unless specialized finishing waxes meant specifically for the fine pores found there are used consistently over time at yearly scheduled events, to protect aesthetic appeal during long daylight hours.

Frequently Asked Questions (Hevea vs Birch for Home Builds)

Q: Does Hevea wood mold or mildew easily if I’m building something moderately humid environment?

A: In highly humid environments without proper wood drying/kiln treatment, Hevea can be susceptible, just like many other tropical woods. Always ensure materials reach equilibrium moisture content relative to your construction atmosphere and use antifungal primer before topcoats if humidity near 70%+. High performance insulation within attic spaces really protects wood!

Q: Which wood is easier for a complete beginner just setting up hand tools for the first time?

A: Birch wood is technically easier for consistent hand tool seasoning and planing due to its uniform hardness and lack of drastically different porosity regions in a single small board. Hevea requires more careful feel testing your plane depth.

Q: Can I use high heat settings when ironing veneer on using Hevea or Birch wood as my base stock?

A: Both absorb moisture and burn unevenly if overheated! Because the inherent glue-line systems found within the fibers are different, generally, use medium electronic transfer heat settings (about 285°F if using an accurate electric iron surface calibrator/thermometer tool) and avoid soaking wet brown wrapping paper as a barrier against drying heat loss transference when dealing underneath metal tools.

Q: If I want dark walnut stain on budget furniture for visual depth, between these two, what results should I anticipate?

A: Hevea typically stains darker initially but remains blotchy despite repeated wiping techniques necessary to evening pigment spread during initial stages. Aim for high-quality pre-stain conditioner on Birch if staining past its light natural color profile upwards toward that deep hue you prefer because Birch accepts conditioner adherence best.

Q: Birch prices seem high based on where I live. Is Rubberwood/Hevea really a proper substitute for sturdy workshop tables?

A: Yes. Hevea boasts a favorable strength-to–weight ratio and lower acquisition overhead in trade, pairing affordability against good dimensional stabilization when solid stock is used for workshop surfaces used normally indoors by DIY enthusiasts in general household repair contexts for most carpentry needs concerning light machine usage.

Q: Do I require special non-ferrous router bits for these species specifically as I learn my joinery techniques?

A: When machining Hevea’s denser sections or if running standard bits through brittle, older Birch heartwood, upgrading your carbide or adding quality lubricant minimizes excessive bit friction wear you see near edges! Always focus upon fresh, manufacturer-rated carpentry cutters optimized for harder materials even when tackling midlings species, ensuring superior chip evacuation methods.

Deciding between Hevea wood vs Birch truly boils down to your twin desires: budget and specified final appearance pressure against extreme use coefficient factors for that project duration. If you need economical value, excellent medium density for panelization experiments, and enjoy wood that takes oil finishes beautifully, Hevea is a fantastic launching partner from our workshop guide selection platform.

If structural reliability needs to prioritize the ultimate light-color palette or needs maximum strength potential achievable without heading over to much pricier American Maple selection protocols for decorative trim purposes near windows or doorway access control points, then Birch definitely brings the necessary density to the final look.

Both woods are stepping stones to better woodworking. Don’t fear the choice; examine the specs against tomorrow’s finish line and pick the one that fills that necessary segment of structural integrity now. You’ve got this wood prepared and sanded. Now go get those joints cut! Keep making wonderful, sturdy things, friend, and trust your hands and good measurement setup during marking final material preparations today!