How Hard Is Maple: A Proven, Essential Guide

Hard maple is one of the hardest domestic woods, with a Janka rating of 1,450 lbf, making it extremely durable but challenging for beginners to work with hand tools. Soft maple is more manageable, with a rating between 700 and 950 lbf, offering a great balance of durability and workability for most DIY projects.

Hello there, fellow maker! It’s Md Meraj, and today we’re tackling a question I hear all the time in the workshop: just how hard is maple wood? If you’ve ever admired a beautiful bowling alley, a sturdy butcher block, or a classic piece of furniture, you’ve probably seen maple in action. It’s a popular choice for so many reasons, but its hardness can feel a bit intimidating when you’re just starting out.

Don’t you worry. Maple’s reputation for being tough is well-earned, but it’s absolutely a wood you can learn to work with and love. We’re going to break it all down in simple, easy-to-understand terms. Together, we’ll look at what “wood hardness” really means, compare different types of maple, and give you practical tips for cutting, shaping, and finishing it successfully. Let’s get started!

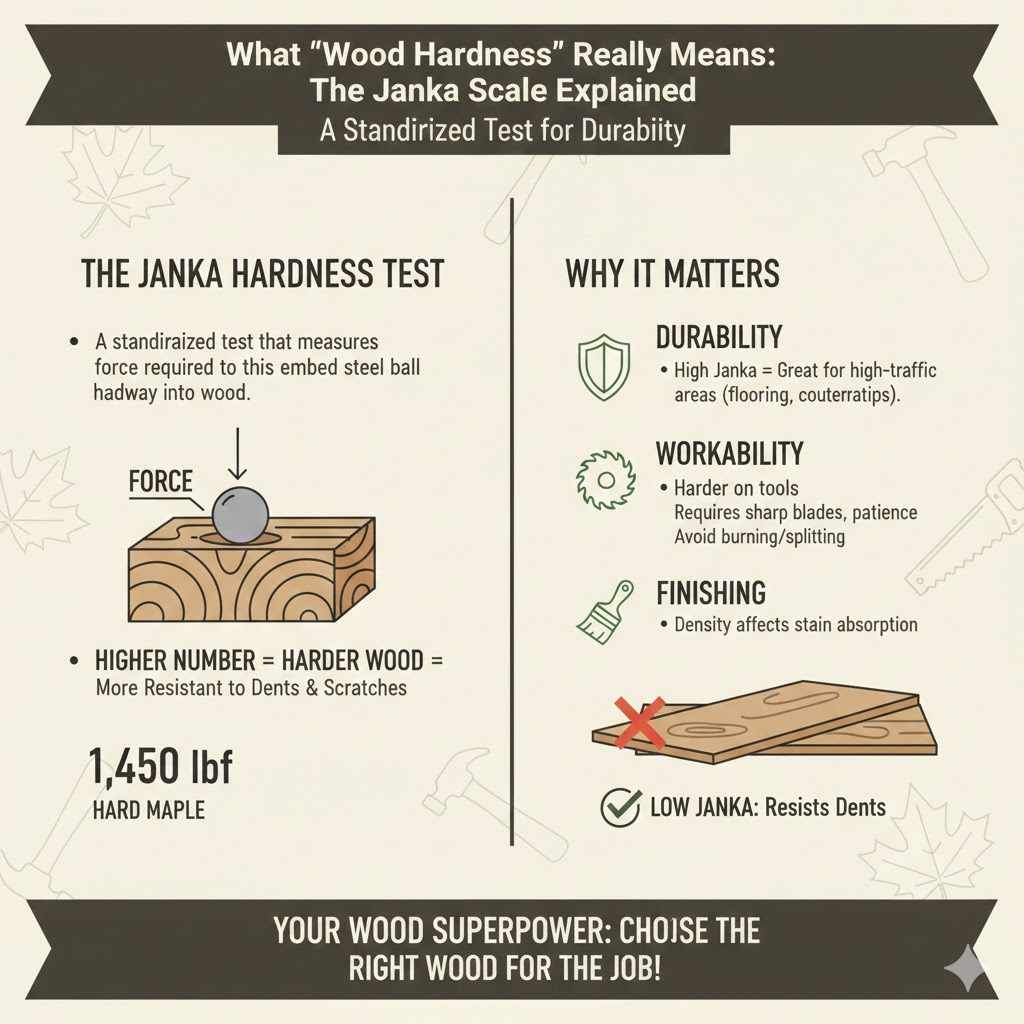

What “Wood Hardness” Really Means: The Janka Scale Explained

Before we dive into maple specifically, let’s clear up what we mean by “hard.” In the woodworking world, we don’t just guess. We use a standardized test called the Janka Hardness Test. It might sound technical, but the idea is actually very simple.

Imagine pushing a small steel ball into a piece of wood. The Janka test measures the amount of force (in pounds-force, or lbf) it takes to press that ball halfway into the wood. A higher number means the wood is harder and more resistant to dents and scratches. A lower number means it’s softer.

Why does this matter to you?

- Durability: A high Janka rating means the wood is great for high-traffic areas like flooring or surfaces that take a beating, like countertops.

- Workability: Harder woods can be tougher on your tools. They require sharp blades, more effort with hand tools, and careful techniques to avoid burning or splitting.

- Finishing: The density of hard woods can also affect how they absorb stains and finishes.

This simple number gives us a reliable way to compare different woods. You can find official Janka ratings for hundreds of wood species from resources like the U.S. Forest Service Forest Products Laboratory, which is a fantastic source for reliable data.

The Two Faces of Maple: Hard Maple vs. Soft Maple

Here’s the first thing every beginner needs to know: “maple” isn’t just one type of wood. When people talk about maple, they are usually referring to one of two main categories: Hard Maple or Soft Maple. And yes, the difference in hardness is significant!

Hard Maple (The Champion of Durability)

When you hear about maple being incredibly tough, people are talking about hard maple. The most common species is Sugar Maple (Acer saccharum), the same tree that gives us delicious maple syrup! It’s also sometimes called Rock Maple.

Janka Hardness Rating: 1,450 lbf

To put that number in perspective, it’s significantly harder than popular woods like Cherry (950 lbf) and Walnut (1,010 lbf). This exceptional hardness is why hard maple is the go-to choice for:

- Hardwood flooring in gyms and homes

- Bowling alley lanes

- Butcher blocks and cutting boards

- High-end cabinets and furniture

- Workbenches that need to withstand abuse

- Baseball bats

Working with hard maple requires patience and sharp tools. It resists denting wonderfully, but it also resists your saw blade and drill bit. Driving a screw directly into it without a pilot hole is a recipe for a snapped screw or split wood.

Soft Maple (The Friendly All-Rounder)

Now, the term “soft maple” is a little misleading. It is not a soft wood like pine or cedar. It’s simply softer relative to hard maple. Soft maple is still a very durable hardwood, perfectly suitable for many projects. The most common species are Red Maple (Acer rubrum) and Silver Maple (Acer saccharinum).

Janka Hardness Rating: 700 lbf (Silver Maple) to 950 lbf (Red Maple)

As you can see, there’s a range, but even on the higher end, it’s about 35% softer than hard maple. This makes it much more forgiving for a beginner woodworker. It’s easier to cut, drill, and shape with both power and hand tools.

Soft maple is often used for:

- Furniture frames

- Cabinetry (especially painted cabinets)

- Wooden toys and crafts

- Moulding and trim work

- Drawer boxes

While it won’t stand up to the same level of abuse as hard maple, it is more than strong enough for everyday furniture and projects. Plus, it’s typically less expensive and easier on your tools.

Maple Hardness in Perspective: A Comparison Table

Numbers are helpful, but context is everything. Let’s see how hard and soft maple stack up against other common woods you might find at the lumberyard. This table will help you visualize where maple fits in the grand scheme of things.

| Wood Species | Janka Hardness (lbf) | Common Uses |

|---|---|---|

| Balsa | 100 | Model airplanes, crafts |

| Eastern White Pine | 380 | Construction lumber, rustic furniture |

| Poplar | 540 | Paint-grade furniture, drawer sides |

| Soft Maple (Silver) | 700 | Cabinets, crates, some furniture |

| Cherry | 950 | Fine furniture, cabinetry |

| Soft Maple (Red) | 950 | Furniture, moulding, musical instruments |

| Walnut | 1,010 | High-end furniture, veneers |

| Red Oak | 1,290 | Flooring, cabinets, furniture |

| White Ash | 1,320 | Tool handles, baseball bats |

| Hard Maple (Sugar) | 1,450 | Flooring, workbenches, cutting boards |

| Hickory | 1,820 | Tool handles, flooring, smoked meats |

Working with Maple: Practical Tips for Beginners

So, you’ve brought home a beautiful piece of maple. Now what? Knowing its hardness helps you prepare. Here’s how to approach your project for the best results, whether you have hard or soft maple.

1. Cutting and Sawing Maple

Maple’s dense grain can cause your saw to work harder, which generates heat. This heat can lead to “burning,” where the wood along the cut line turns dark brown or black.

How to Avoid Burning:

- Use a Sharp Blade: This is non-negotiable. A dull blade rubs instead of cuts, creating friction and heat.

- Choose the Right Blade: For your table saw or miter saw, use a blade with a higher tooth count (60-80 teeth) for a cleaner crosscut. For ripping (cutting with the grain), a dedicated 24-tooth ripping blade is best. A good combination blade (40-50 teeth) can also work well.

- Maintain a Steady Feed Rate: Don’t force the wood through the blade, but don’t hesitate either. Pushing too slow allows heat to build up. Find a smooth, consistent pace where the blade is doing the work without bogging down.

- Keep Blades Clean: Wood resin (pitch) can build up on saw blades, increasing friction and heat. A clean blade is a happy blade!

If you get some light burning, don’t panic! It can usually be sanded off.

2. Drilling and Fastening

Because maple is so dense and brittle, it’s prone to splitting if you don’t take precautions. Trying to drive a screw or nail into maple without preparing the hole first is asking for trouble.

The Golden Rule: Always Drill a Pilot Hole!

- A pilot hole is a small hole drilled before you drive in a screw. It removes wood, giving the screw threads a clear path.

- The pilot hole for the threaded part of the screw should be about the same diameter as the screw’s shank (the solid part without threads).

- For hard maple, it’s also a great idea to use a countersink bit. This creates a small cone-shaped opening for the screw head to sit in, preventing the wood from mushrooming up around the screw and ensuring a flush finish.

3. Sanding and Finishing Maple

Maple has a tight, fine grain that allows it to be sanded to an incredibly smooth, almost glass-like finish. This is one of its best qualities! However, that same tight grain can make staining a challenge.

Sanding Tips:

- Start with a medium grit sandpaper (like 120-grit) to remove any tool marks.

- Progress smoothly through the grits (150, 180, and finally 220-grit). Don’t skip grits! Each higher grit is designed to remove the scratches from the previous one.

- After sanding, wipe the surface with a tack cloth or a rag lightly dampened with mineral spirits to remove all the fine dust.

The Challenge with Staining Maple:

Maple is notorious for absorbing stain unevenly, resulting in a “blotchy” appearance. This is because its density varies slightly across the board. The more porous areas soak up more stain and become darker, while the denser areas absorb less.

How to Get an Even Stain:

- Use a Pre-Stain Wood Conditioner: This is the most effective solution. A pre-stain conditioner is a thin, sealer-like product that you apply before staining. It partially seals the wood, forcing the stain to absorb more evenly across the entire surface. Apply it according to the manufacturer’s instructions.

- Consider Gel Stains or Dyes: Gel stains sit more on the surface of the wood rather than soaking in deeply, which can greatly reduce blotching. Wood dyes are another great option as they have smaller pigments that color the wood more uniformly.

- Embrace a Natural Finish: Honestly, one of the best ways to finish maple is with a simple clear coat like polyurethane, shellac, or lacquer. These finishes bring out the wood’s subtle, creamy beauty without the risk of blotching. An oil-based polyurethane will give it a warm, amber hue, while a water-based finish will keep it looking whiter and more natural.

4. Using Hand Tools

If you enjoy the quiet satisfaction of using hand planes, chisels, and hand saws, you’ll find soft maple to be a pleasant partner. Hard maple, on the other hand, will test your skills and the sharpness of your tools.

- Sharpness is Key: Your tools must be razor-sharp. Hard maple will quickly find any dull spot on your plane iron or chisel. You’ll need to stop and sharpen more frequently than with softer woods.

- Mind the Grain: Maple, especially varieties with figured grain like curly or bird’s-eye maple, can be prone to tear-out when planing. Take shallow passes and read the grain direction carefully.

- Take Your Time: Don’t try to hog off large amounts of material at once. Patience and light, steady cuts will yield the best results.

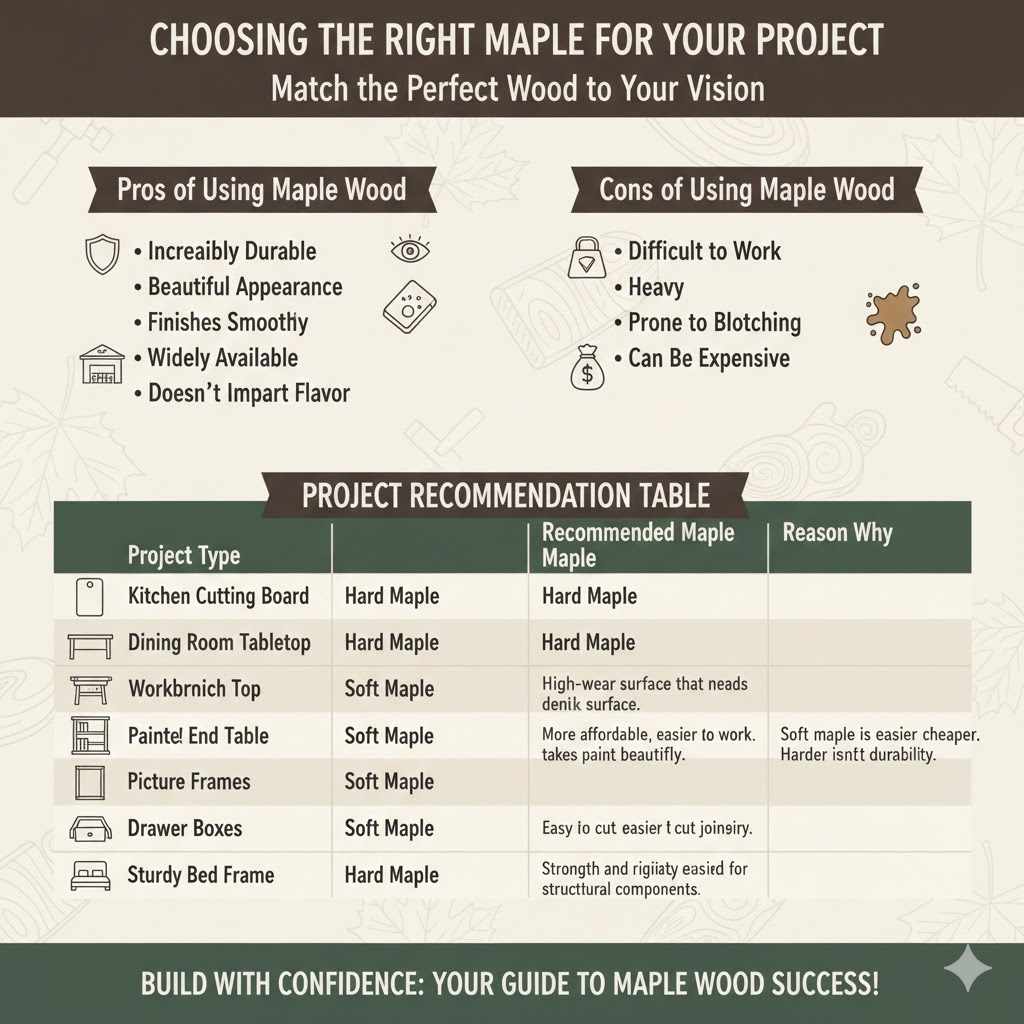

Choosing the Right Maple for Your Project

Is maple the right wood for what you’re building? Let’s weigh the pros and cons and look at a handy project suggestion table.

Pros of Using Maple Wood

- Incredibly Durable: It resists scratches, dents, and wear better than most other woods.

- Beautiful Appearance: Its light, creamy color and subtle grain pattern offer a clean, modern look.

- Finishes Smoothly: It can be sanded to a very high sheen.

- Widely Available: Both hard and soft maple are readily available at most lumber suppliers.

- Doesn’t Impart Flavor: Its closed-grain structure makes it an excellent and safe choice for cutting boards and other kitchen items.

Cons of Using Maple Wood

- Difficult to Work: Hard maple especially can be tough on tools and requires more effort.

- Heavy: It is a dense, heavy wood, which can be a factor in large furniture pieces.

- Prone to Blotching: Achieving an even stain requires extra steps and care.

- Can Be Expensive: High-quality hard maple often costs more than other domestic hardwoods like oak or poplar.

Project Recommendation Table: Hard Maple vs. Soft Maple

Use this table as a quick guide to decide which type of maple is best for your next project.

| Project Type | Recommended Maple | Reason Why |

|---|---|---|

| Kitchen Cutting Board | Hard Maple | Needs maximum durability and scratch resistance. Food-safe. |

| Dining Room Tabletop | Hard Maple | High-wear surface that needs to resist dents from plates and utensils. |

| Workbench Top | Hard Maple | The ultimate choice for a durable work surface that will last a lifetime. |

| Painted Bookshelf | Soft Maple | More affordable, easier to work, and takes paint beautifully. Hardness isn’t critical. |

| Small End Table | Soft Maple or Hard Maple | Soft maple is easier and cheaper. Hard maple offers more durability if it will see heavy use. |

| Picture Frames | Soft Maple | Easy to cut and join. Doesn’t require extreme hardness. |

| Drawer Boxes | Soft Maple | Strong enough for the job but much easier to cut joinery (like dovetails) in. |

| Sturdy Bed Frame | Hard Maple | Its strength and rigidity are perfect for structural furniture components. |

Frequently Asked Questions (FAQ)

Is maple harder than oak?

It depends! Hard maple (1,450 lbf) is significantly harder than Red Oak (1,290 lbf), a very common hardwood. However, some species of White Oak can be very close in hardness. Soft maple (700-950 lbf) is much softer than both Red and White Oak.

Can you use a hand saw on maple?

Absolutely! You can use a hand saw on both soft and hard maple. Just make sure your saw is sharp. You will notice it takes more effort to cut hard maple compared to a softer wood like pine, so be patient and let the saw do the work.

Why did my maple stain look blotchy and uneven?

This is a very common issue. Maple has a dense, tight grain that absorbs stain unevenly. The best way to prevent blotching is to apply a pre-stain wood conditioner before you apply the stain. This helps the wood absorb the stain more uniformly for a much cleaner result.

Is hard maple expensive?

Hard maple is generally considered a mid-to-high-priced domestic hardwood. It is typically more expensive than oak or poplar but less expensive than walnut or cherry. Prices vary by region and board quality, but it provides excellent value for its durability.

What is the easiest way to tell the difference between hard and soft maple?

It can be tough for a beginner, as they can look very similar. Hard maple often has a creamier, more uniform color, while soft maple can have more gray or reddish streaks. Hard maple is also noticeably heavier. If you press a fingernail firmly into a corner of the board, it will leave a mark much more easily on soft maple than on hard maple.

Is maple a good choice for outdoor furniture?

No, maple is not recommended for outdoor projects. It has very little natural resistance to rot, decay, and insects. When exposed to moisture, it will break down quickly. For outdoor furniture, it’s better to choose naturally resistant woods like Cedar, Teak, or White Oak.

Does maple wood get darker over time?

Yes, but very subtly. Over many years, maple will slowly develop a light, yellowish-amber patina, especially when exposed to sunlight. This is a natural aging process that many people find beautiful. It is much less dramatic than the darkening seen in woods like Cherry.

Conclusion: You Can Conquer Maple!

So, how hard is maple? As we’ve seen, the answer is: it depends! Hard maple is a true champion of strength and durability, perfect for projects that need to last a lifetime and withstand daily abuse. Soft maple offers much of that classic maple look and feel in a much friendlier, more forgiving package that’s perfect for beginners.

Don’t let maple’s tough reputation scare you away. By understanding its properties and using the right techniques—sharp tools, steady feed rates, pilot holes, and a careful finishing process—you can absolutely achieve beautiful results. Start with a project using soft maple to build your confidence, and before you know it, you’ll be ready to tackle that hard maple workbench or cutting board you’ve been dreaming of.

Woodworking is a journey of learning, and every new material teaches us something. Embrace the challenge, respect the wood, and have fun building. Happy crafting!