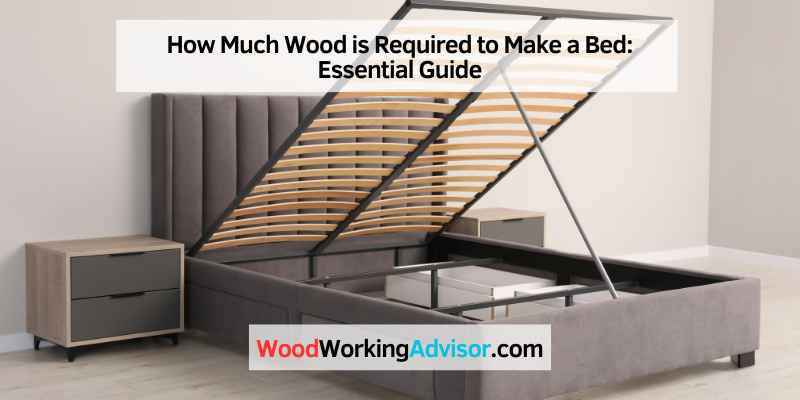

How Much Wood is Required to Make a Bed: Essential Guide

To make a bed, approximately 30-40 board feet of wood is required. Wood type and bed size influence the exact amount needed.

Crafting a bed involves precision in wood selection and measurements to ensure durability and aesthetics. A sturdy bed frame provides essential support for a good night’s sleep. The choice of wood can impact the bed’s overall appearance and longevity. Whether opting for a classic oak frame or a sleek walnut design, the quality and quantity of wood are crucial in creating a comfortable and stylish bed.

By understanding the wood requirements for bed making, one can embark on a woodworking project that promises both functionality and beauty.

The Importance Of Wood In Bed Crafting

When it comes to crafting a bed, the choice of wood plays a crucial role in determining its sustainability, quality, and overall aesthetic appeal. From the durability and strength to the unique characteristics of different wood types, understanding the importance of wood is essential for creating a bed that not only provides comfort but also stands the test of time. In this article, we will explore two key aspects of wood selection in bed crafting: sustainability and quality, as well as the different types of wood and their characteristics.

Sustainability And Quality

Choosing sustainable wood for bed crafting is not only environmentally responsible but also ensures the longevity of the bed. Sustainable wood is sourced from well-managed forests where new trees are planted to replace the ones that are harvested. This ensures the preservation of natural resources and helps combat deforestation.

Additionally, using high-quality wood in bed crafting ensures that the bed is sturdy and durable. Quality wood is less likely to warp, crack, or break over time, providing a long-lasting and reliable piece of furniture.

Wood Types And Their Characteristics

There are various types of wood commonly used in bed crafting, each with its own unique characteristics. Here are some popular wood types and their notable features:

| Wood Type | Characteristics |

|---|---|

| Oak | Durable, strong, and resistant to wear and tear |

| Maple | Hardwood with a smooth grain and natural beauty |

| Cherry | Rich, warm color that darkens over time, adding character |

| Walnut | Distinctive grain pattern and deep, rich color |

| Pine | Lightweight, affordable, and often used for rustic designs |

These are just a few examples of the many wood types available for bed crafting. Each wood type brings its own unique beauty and characteristics, allowing for a wide range of design possibilities.

By considering both sustainability and quality when choosing the wood for bed crafting, you can create a bed that not only enhances your sleep experience but also contributes to a healthier environment. Whether you prefer the durability of oak or the natural beauty of maple, the right wood choice will bring both aesthetic appeal and long-lasting functionality to your bed.

Standard Bed Dimensions

Single

A standard single bed measures 90cm by 190cm.

Double

A double bed typically measures 135cm by 190cm.

King Sizes

A king-size bed usually measures 150cm by 200cm.

Custom Beds And Special Sizes

For custom beds and special sizes, the wood required varies based on the specific dimensions and design.

Calculating Wood Quantity For Different Bed Sizes

Calculating wood quantity for different bed sizes is essential when planning a bed construction project. The amount of wood required varies depending on the bed size and design, and accurate calculations are crucial for efficient planning and cost estimation.

Formulae And Estimations

To calculate the wood quantity for a bed, you can use the following simple formula:

| Bed Size | Wood Quantity Formula |

|---|---|

| Single | Length (L) + 2 Width (W) + 2 Height (H) |

| Double | 2 Length (L) + 2 Width (W) + 2 Height (H) |

| Queen | 2 Length (L) + 2 Width (W) + 2 Height (H) |

| King | 2 Length (L) + 2 Width (W) + 2 Height (H) |

Considerations For Thickness And Support

- Thickness: The thickness of the wood affects the overall strength and durability of the bed. Thicker wood may be required for larger beds to provide adequate support.

- Support: Consider the type of support system, such as slats or a solid platform, when estimating the wood quantity. Additional supports may be needed for larger or heavier mattresses.

Types Of Wood And Their Uses In Bed Making

Different types of wood can be used to make beds, and the amount of wood required depends on the size and design of the bed. Hardwoods like maple and oak are popular choices due to their durability, while softer woods like pine and cedar are often used for their affordability and aesthetic appeal.

When it comes to making a bed, the type of wood used is crucial to the finished product’s quality and durability. There are several types of wood used in bed making, and each has its unique properties and uses. In this article, we will explore the various types of wood used in bed making and their characteristics.

Hardwoods Versus Softwoods

Hardwoods are denser, heavier, and more durable than softwoods. They are generally more expensive than softwoods and are used for the bed’s frame and legs. Some common hardwoods used in bed making include oak, maple, cherry, and mahogany.

Softwoods, on the other hand, are lighter and less dense than hardwoods. They are less expensive and are used for the bed’s headboard and footboard. Some common softwoods used in bed making include pine, cedar, and spruce.

Exotic Woods And Cost Implications

Exotic woods are becoming increasingly popular in bed making due to their unique patterns and colors. However, they are more expensive than domestic woods and may not be suitable for everyone’s budget. Some examples of exotic woods used in bed making include teak, ebony, and rosewood.

The cost of wood used in bed making depends on various factors such as the type of wood, size of the bed, and the bed’s design. It is essential to consider the cost implications before settling on a particular type of wood.

In conclusion, the type of wood used in bed making is crucial to the bed’s quality, durability, and overall appearance. When choosing the type of wood, consider the bed’s design, budget, and desired aesthetic.

Tools And Materials Needed Besides Wood

When making a bed, besides wood, you’ll need essential tools for woodworking and hardware and accessories.

Essential Tools For Woodworking

- Saw

- Drill

- Hammer

- Screwdriver

Hardware And Accessories

Additional items such as screws, nails, brackets, and hinges are necessary for bed construction.

Step-by-step Guide To Constructing A Wooden Bed Frame

To construct a wooden bed frame, the amount of wood required depends on the bed size. For a queen-sized bed, you’ll need approximately 20-25 board feet of lumber, while a king-sized bed may require 25-30 board feet. It’s essential to measure and plan carefully to ensure you have enough wood for the project.

Cutting And Shaping The Wood

To build a wooden bed frame, you’ll need to cut and shape the wood to the right size. The amount of wood required depends on the size of the bed you want to build. For a standard queen-sized bed, you’ll need about 50 board feet of lumber. Here’s how to cut and shape the wood:

- Measure and cut the headboard, footboard, and side rails to the right length using a circular saw.

- Use a router to shape the edges of the headboard, footboard, and side rails.

- Drill holes for the bolts that will hold the bed frame together.

- Sand all the pieces of wood until they are smooth.

Assembly And Finishing Touches

Once you’ve cut and shaped the wood, it’s time to assemble the bed frame. Here’s how to do it:

- Attach the headboard and footboard to the side rails using bolts and nuts.

- Add support slats to the bed frame.

- Stain or paint the bed frame to your desired color.

- Allow the bed frame to dry completely.

Building a wooden bed frame requires some skill and patience, but the end result is a beautiful and sturdy piece of furniture that will last for years. With this step-by-step guide, you’ll be able to construct a wooden bed frame that’s perfect for your bedroom.

Troubleshooting Common Issues In Bed Making

To make a bed, you typically need about 20-25 board feet of wood, depending on the bed size and design. Common issues in bed making may include inaccurate measurements, uneven cuts, or improper assembly. Ensuring precise measurements and using quality wood can help avoid these problems.

Dealing With Wood Imperfections

Inspect wood for cracks, knots, and warping.

Fill cracks with wood filler for smooth surface.

Remove knots carefully to prevent weak spots.

Ensuring Structural Integrity

Use proper measurements for bed frame stability.

Secure joints with screws or nails for durability.

Check alignment to avoid wobbling or uneven weight distribution.

Finishing And Maintenance Of Wooden Beds

Wooden beds bring warmth and elegance to any bedroom, but proper finishing and maintenance are essential for longevity.

Choosing The Right Finish

Select a finish based on the wood type and desired aesthetic – oil-based finishes for a natural look or lacquer for a glossy finish.

Consider water-based finishes for eco-friendliness and easy application with low VOC content.

Long-term Care For Durability

- Regularly dust and wipe the bed frame with a soft cloth to prevent dust accumulation.

- Apply furniture polish or beeswax to maintain the wood’s luster and protect it from scratches.

- Avoid placing wooden beds in direct sunlight or near sources of heat to prevent warping.

Economic Considerations And Budgeting

To determine the amount of wood needed to make a bed, several economic considerations and budgeting factors come into play. Careful planning is required to assess the dimensions of the bed frame, the type of wood, and any additional materials needed for construction.

By considering these factors, one can accurately estimate the quantity of wood required for the project, ensuring efficient budgeting and cost-effectiveness.

Cost-effective Wood Choices

When it comes to building a bed, choosing the right type of wood can significantly impact the cost of the project. Pine is one of the most cost-effective wood choices for constructing a bed frame. It is readily available, lightweight, and easy to work with. Pine is also a softwood, which makes it less durable than hardwoods. However, it can still make a sturdy bed frame if designed and assembled correctly.

Another cost-effective wood choice is plywood. It is a composite material made up of thin layers of wood veneer glued together. Plywood is an excellent option for bed frames as it is strong, durable, and less expensive than solid wood. It is also available in various thicknesses, which makes it a versatile material for constructing bed frames.

Balancing Quality And Expense

When considering economic considerations and budgeting for building a bed frame, it is essential to balance quality and expense. Opting for low-cost materials may save money upfront, but it can lead to poor quality and a shorter lifespan of the bed frame. On the other hand, investing in high-quality materials may cost more initially, but it can result in a more durable and long-lasting bed frame.

One way to balance quality and expense is to consider the purpose of the bed. If it is a temporary bed for a guest room, then using cost-effective materials may suffice. However, if it is a permanent bed for everyday use, investing in high-quality materials may be a better option.

In conclusion, economic considerations and budgeting play a vital role in determining the type of wood to use when building a bed frame. Choosing cost-effective wood choices like pine and plywood can help save money, but it is crucial to balance quality and expense to ensure a durable and long-lasting bed frame.

Environmental Impact And Sustainable Practices

When it comes to creating a bed, it’s crucial to consider the environmental impact and sustainable practices. Let’s delve into how wood sourcing and recycling play a vital role in promoting eco-friendliness.

Eco-friendly Wood Sourcing

Eco-friendly wood sourcing involves using sustainably harvested timber from responsibly managed forests. This practice helps preserve natural habitats and reduce deforestation.

Recycling And Upcycling Options

Recycling and upcycling wood offer environmentally friendly alternatives. By repurposing old wood, we minimize waste and contribute to a circular economy.

Frequently Asked Questions

How Much Wood Is Needed To Make A Bed?

To make a standard double bed, you would need approximately 30-40 board feet of wood. This includes the frame, headboard, and footboard. The exact amount can vary depending on the bed design and the type of wood used.

What Type Of Wood Is Best For Making A Bed?

Hardwoods like oak, maple, cherry, and walnut are popular choices for bed construction due to their durability and strength. They provide long-lasting support and a beautiful finish. Softwoods like pine are also used for a more affordable option, but may require more maintenance.

Can I Use Reclaimed Wood To Build A Bed?

Yes, using reclaimed wood for a bed is a sustainable and eco-friendly choice. It adds character and history to the piece, and with proper treatment, it can be just as sturdy and reliable as new wood. Ensure the wood is properly cleaned and treated before use.

Conclusion

To sum up, determining the amount of wood required to make a bed depends on various factors such as the bed frame design, size, and material thickness. By understanding these factors and carefully planning the woodcutting process, you can ensure an efficient and cost-effective project.

Remember to consider any additional features or embellishments that may require extra wood. By following these guidelines, you can confidently embark on your bed-making journey. Happy woodworking!